Kreg Screws for 3/4 Plywood: The Essential Proven Pick

For standard 3/4″ plywood projects, the correct Kreg screw is the 1-1/4″ Coarse-Thread Pocket-Hole Screw (model SML-C125). This screw length ensures a strong joint without poking through the wood. The coarse threads provide excellent grip in the soft layers of plywood, preventing stripping and creating a durable, long-lasting connection for your builds.

Welcome to the workshop! If you’ve ever stood in front of a wall of Kreg screws, feeling a little overwhelmed, you’re not alone. Choosing the right screw for your project can feel like a pop quiz you didn’t study for. The good news is, it’s much simpler than it looks. One of the most common questions I get is about building with 3/4″ plywood, a go-to material for everything from cabinets to bookshelves.

Picking the wrong screw can lead to weak joints, split wood, or ugly screw tips poking through your finished piece. Nobody wants that! But don’t worry, I’m here to take the guesswork out of it. We’re going to walk through exactly which screw to use, how to set up your Kreg jig perfectly, and a few pro tips to make your projects look amazing. Let’s build something great together.

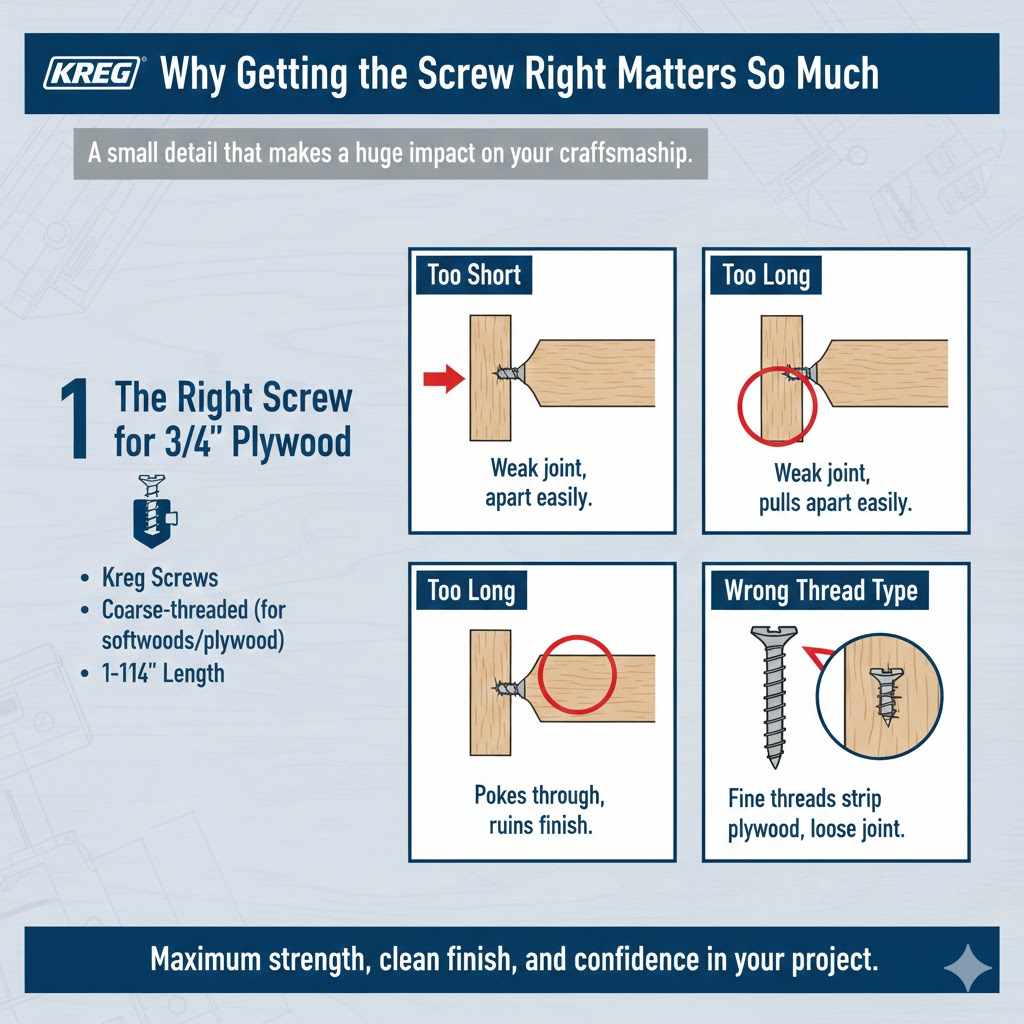

Why Getting the Screw Right Matters So Much

You might think, “a screw is a screw,” but in the world of pocket hole joinery, that couldn’t be further from the truth. Using the right Kreg screw for your 3/4″ plywood is the difference between a wobbly bookshelf that gives you anxiety and a rock-solid cabinet that will last for years. It’s all about creating a strong, secure, and clean connection.

Here’s what can go wrong when you grab the wrong screw:

- Too Short: A screw that’s too short won’t grab enough wood in the receiving piece. The joint will be weak and can easily pull apart under stress. It’s like trying to hang a heavy picture with a tiny thumbtack—it just won’t hold.

- Too Long: This is the mistake you can see. A screw that’s too long will poke right through the other side of your material, ruining the clean look of your project. It’s frustrating and often difficult to fix without leaving a visible mark.

- Wrong Thread Type: Plywood is a “softwood” in Kreg terms. Using fine-threaded screws (meant for hardwoods like oak) can cause them to strip out the wood fibers, leading to a loose joint that won’t tighten properly.

Choosing the correct screw ensures maximum strength, a clean finish, and the confidence that your project will hold together exactly as you intended. It’s a small detail that makes a huge impact on your craftsmanship.

The Winning Screw: 1-1/4″ SML-C125 Coarse-Thread Screws

Let’s cut right to the chase. The undisputed champion for joining 3/4″ plywood to 3/4″ plywood is the Kreg 1-1/4″ Coarse-Thread Pocket-Hole Screw. The model number you’ll see on the box is often SML-C125.

This is your workhorse screw. For probably 90% of the shop cabinets, shelving units, and built-ins you’ll make with standard 3/4″ plywood, this is the screw you will reach for time and time again. It’s the proven, reliable choice that woodworkers trust.

The Anatomy of the Perfect Kreg Screw

So, what makes this specific screw so special? It comes down to three key features that are perfectly designed for working with plywood.

- Length (1-1/4″): This length is precisely calculated to provide maximum thread engagement in the receiving board without any risk of poking through. It sinks deep enough to create a powerful joint but leaves just enough material at the tip for a clean, invisible finish.

- Thread Type (Coarse): Plywood is made of layers of softwood veneers. Coarse threads are like big, aggressive teeth that bite firmly into these soft wood fibers. They resist pulling out and provide a much stronger hold in materials like plywood, MDF, and pine compared to fine threads.

- Head Type (Washer Head): Most Kreg screws have a Maxi-Loc or washer head. This flat bottom on the screw head provides a wide surface area to seat firmly at the bottom of the pocket hole. This distributes the pressure evenly and prevents the screw from being driven too deep, which could crack the wood.

When these three elements come together, you get a screw that pulls your joint tight, keeps it there, and is incredibly easy to work with.

A Quick Note: When to Choose Fine-Thread Screws

While coarse-thread is king for standard plywood, there’s one important exception: hardwood plywood. If you are working with plywood that has a dense hardwood veneer like oak, maple, or cherry, you may get better results with the 1-1/4″ Fine-Thread Screw (SML-F125). Fine threads are less aggressive and are less likely to cause splitting in brittle, dense hardwoods. For most DIY projects using common pine or fir plywood from the home center, stick with coarse threads.

A Quick-Glance Kreg Screw Chart for Plywood

To make things even easier, here is a handy chart for the most common plywood thicknesses you’ll encounter. Bookmark this page so you can pull it up in the workshop!

| Plywood Thickness | Recommended Kreg Screw | Kreg Jig Setting |

|---|---|---|

| 1/2″ (12mm) | 3/4″ Coarse-Thread (SPS-C1) | 1/2″ |

| 5/8″ (15mm) | 1″ Coarse-Thread (SML-C1) | 5/8″ |

| 3/4″ (18mm) | 1-1/4″ Coarse-Thread (SML-C125) | 3/4″ |

| 1-1/2″ (38mm) | 2-1/2″ Coarse-Thread (SML-C250) | 1-1/2″ |

Setting Up Your Kreg Jig for 3/4″ Plywood: A Step-by-Step Guide

Having the right screw is only half the battle. You also need to set up your Kreg jig correctly. An incorrect setting is the #1 reason beginners get frustrated when a screw pokes through. Follow these simple steps for a perfect setup every time.

Step 1: Gather Your Tools

Before you start, make sure you have everything you need. This saves you from running around the workshop later.

- Your Kreg Pocket-Hole Jig (e.g., Kreg 720, 520, 320, or R3)

- The Kreg drill bit and stop collar that came with your jig

- Your drill/driver

- A Kreg square-drive bit

- A tape measure or calipers

- Your 3/4″ plywood workpieces

- A sturdy clamp (a face clamp is highly recommended)

Step 2: Measure Your Plywood’s Actual Thickness

This is a critical pro tip! Plywood labeled as 3/4″ is almost never exactly 3/4″ thick. It’s usually slightly thinner, often around 23/32″. This small difference matters. Grab your tape measure or a set of calipers and measure the true thickness of your board. For this guide, we’ll assume it’s close enough to 3/4″ to use that setting.

Step 3: Set the Drill Guide Block on Your Jig

Look at your Kreg jig’s main body (the blue part with the drill holes). You’ll see markings for material thickness. Slide the drill guide block so that the indicator line points directly to the 3/4″ mark. Most Kreg jigs have a spring-loaded pin or a thumbscrew to lock this in place. Make sure it’s secure.

Step 4: Set the Stop Collar on Your Drill Bit

Now, let’s set up the drill bit itself. The stop collar ensures you drill to the perfect depth. Your Kreg jig has a built-in guide for this. On newer models, you can simply drop the bit into the jig’s setup window and slide the collar down until it rests on the jig, then tighten it with the included Allen key. For older jigs, look for the diagram printed on the jig case or body. Place the bit in the groove and slide the stop collar so its edge aligns with the 3/4″ mark. Tighten the collar firmly.

Step 5: Clamp Your Jig and Drill the Pocket Holes

Position the Kreg jig on your workpiece where you want to drill your pocket holes. Make sure the end of the jig is flush with the edge of your plywood. Clamp it down securely so it can’t move. Now, connect the drill bit to your drill, set it to a high speed, and drill your pocket holes. Let the bit do the work—don’t force it. Drill until the stop collar touches the drill guide. Pull the bit out while it’s still spinning to clear out the wood chips.

Step 6: Set Your Driver Clutch and Drive the Screws

Align the two pieces of plywood you want to join. A face clamp is your best friend here; it will hold the pieces perfectly flush while you drive the screw. Set the clutch on your drill to a medium-low setting to start. This prevents you from over-driving the screw and stripping the wood. Drive your 1-1/4″ Kreg screw into the pocket hole until the joint is snug. The screw should pull the two pieces together tightly. If the drill clutch kicks in too early, increase the setting by one and try again.

Common Mistakes to Avoid (And How to Fix Them)

We all make mistakes, especially when we’re learning. Here are a few common hiccups with pocket holes in plywood and how to avoid them.

- Mistake: Screw pokes through the wood.Cause: This usually happens for one of two reasons: either your Kreg jig’s drill guide was set for a thicker material (e.g., 1-1/2″ instead of 3/4″), or the stop collar on your drill bit slipped and allowed you to drill too deep.

Fix: Double-check both your jig setting and your stop collar setting. Ensure the Allen screw on the collar is tight before you start drilling.

- Mistake: The wood splits when driving the screw.Cause: While rare in plywood, this can happen if you drill too close to the edge of the board. It can also be caused by over-tightening the screw with your drill’s clutch set too high.

Fix: Try to keep pocket holes at least 3/4″ from the edge of your workpiece. Start with a lower clutch setting on your drill and only increase it if needed.

- Mistake: The joint isn’t flush or flat.Cause: This almost always comes down to clamping. If the pieces can move even slightly while you drive the screw, the joint will end up misaligned.

Fix: Use a Kreg Face Clamp or another strong clamp to hold the two pieces firmly together and flat against your work surface. Clamp across the seam of the joint to prevent any shifting.

- Mistake: The screw spins but doesn’t tighten (strips out).Cause: This is a sign you might be using fine-thread screws in softwood plywood. The threads can’t get a good grip and strip out the wood fibers. It can also be caused by an extremely high clutch setting on your drill.

Fix: Make sure you are using coarse-thread screws. If it still happens, back the screw out and try driving it into an adjacent, fresh pocket hole. A dab of wood glue in the joint will also add significant strength.

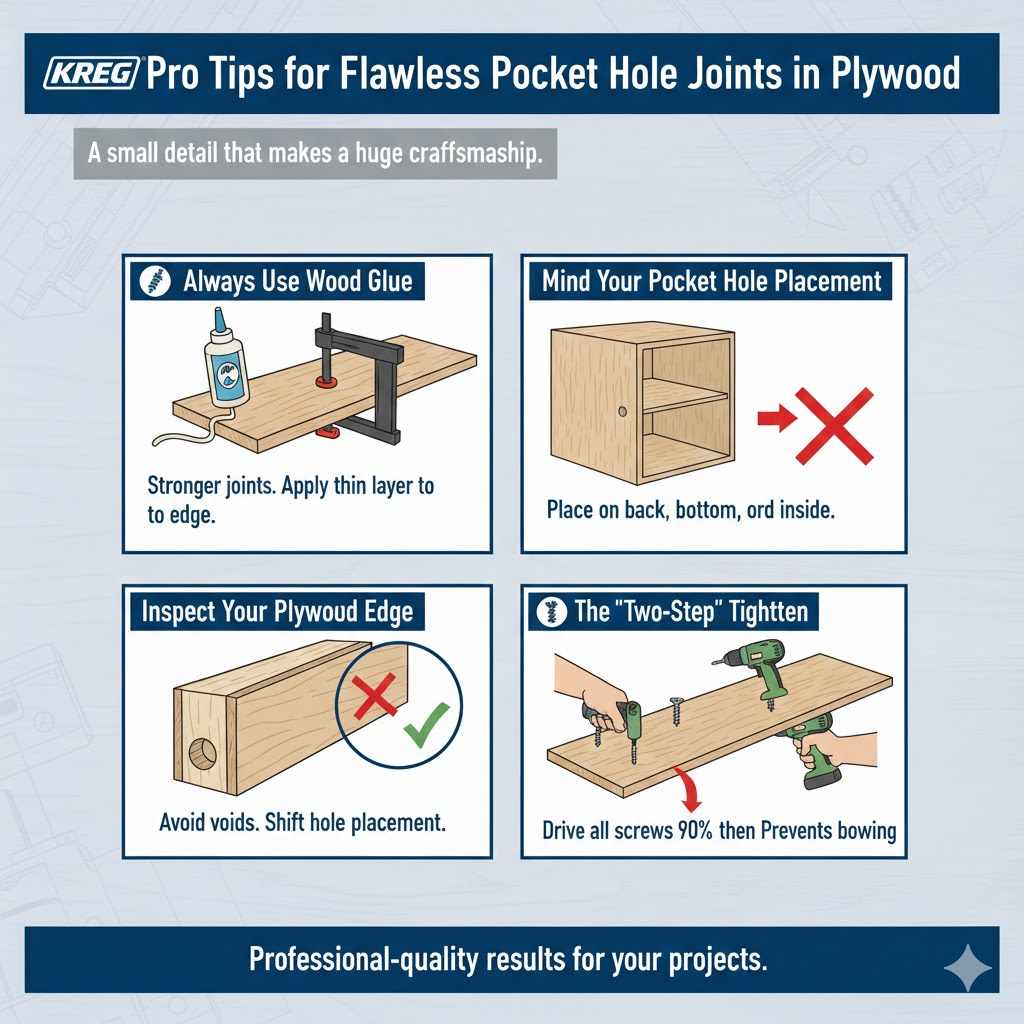

Pro Tips for Flawless Pocket Hole Joints in Plywood

Ready to take your plywood projects to the next level? Here are a few tips I’ve learned over the years for getting professional-quality results.

- Always Use Wood Glue: Kreg screws provide immense clamping pressure, which is perfect for creating a strong glue bond. Applying a thin layer of wood glue to the edge of the joint before screwing it together will make the joint significantly stronger. For more on wood adhesives, the USDA Forest Products Laboratory has comprehensive guides on their performance.

- Mind Your Pocket Hole Placement: Think about where your pocket holes will be in the final project. Will they be visible? If so, try to place them on the back, bottom, or inside of a project where they won’t be seen.

- Inspect Your Plywood Edge: Sometimes, lower-grade plywood has voids or gaps in the inner layers. Try to avoid drilling pocket holes directly into these gaps, as the screw will have nothing to grip. If you find a void, shift your hole placement over an inch or two.

- The “Two-Step” Tighten: When joining long panels, drive all the screws until they are about 90% snug. Then, go back and give each one a final quarter-turn to fully tighten them. This helps distribute the pressure evenly and can prevent the panel from bowing.

Frequently Asked Questions (FAQ)

Here are some of the most common questions I get from beginners. Hopefully, these quick answers help clear things up!

What’s the difference between coarse-thread and fine-thread screws?

Coarse-thread screws have fewer, deeper threads per inch. They are designed for softwoods like pine, plywood, and MDF because they bite aggressively without stripping the soft fibers. Fine-thread screws have more threads per inch and are for hardwoods like oak and maple, providing great holding power without splitting the dense wood.

Can I use regular drywall or wood screws in pocket holes?

It’s highly discouraged. Kreg screws are specifically designed for pocket hole joinery. They have a self-tapping tip to prevent splitting, a smooth upper shank to slide easily through the first board, and a washer head to seat perfectly in the hole. A regular tapered-head screw will try to wedge itself into the hole, often splitting the wood and creating a weak joint.

Do I always need wood glue with Kreg screws?

You don’t always need it, as the screws themselves create a very strong mechanical joint. However, wood glue makes the joint significantly stronger and more durable over the long term. For furniture, cabinets, or any project that will bear weight, adding glue is a best practice.

How many pocket holes should I drill in 3/4″ plywood?

A good rule of thumb is to space pocket holes every 6 to 8 inches apart. For joining narrow pieces, like a 1×4 (which is 3.5″ wide), two screws are usually sufficient. For wider panels, just follow the 6-8 inch spacing for a strong, stable joint.

What does “SPS” or “SML” mean on Kreg screw boxes?

“SML” stands for Screw Maxi-Loc, which is Kreg’s standard washer head screw. “SPS” stands for Screw Pan-Head, which is a smaller-headed screw used for 1/2″ thick material or repairs where a smaller profile is needed.

Can I use Kreg screws for outdoor projects with plywood?

Yes, but you must use the right type! Kreg makes Blue-Kote screws, which are specifically treated for weather and moisture resistance. You would still use a 1-1/4″ length for 3/4″ plywood, but make sure the box says “Blue-Kote” to prevent rust and corrosion.

My screw is just spinning and not tightening. What did I do wrong?

This is called “stripping out.” It most likely means your drill’s torque or clutch setting is too high, or you’ve used a fine-thread screw in a softwood like plywood. Reduce your clutch setting and make sure you’re using a coarse-thread screw. A little wood glue in the joint can help salvage it.

Conclusion: Build with Confidence

See? That wasn’t so bad! Understanding which Kreg screw to use for 3/4″ plywood is one of those fundamental skills that will serve you well on countless projects. By pairing the right hardware—the 1-1/4″ coarse-thread screw—with the correct Kreg jig settings, you are setting yourself up for success.

You’re ready to build strong, clean, and durable joints without the frustration or guesswork. Remember to take your time, double-check your settings, and always prioritize safety in the shop. Now, grab that jig, some plywood, and those screws. It’s time to stop worrying and start building. You’ve got this.