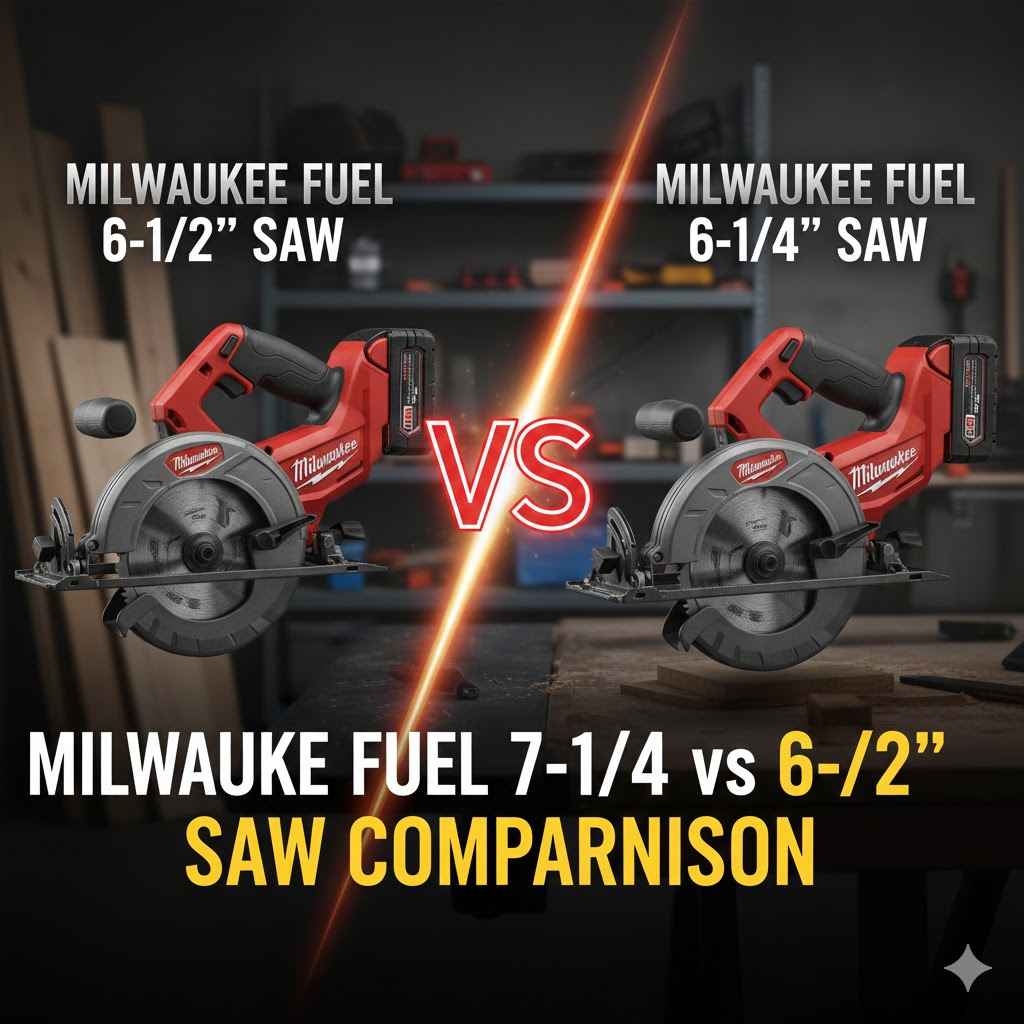

Milwaukee Fuel 7-1/4 vs 6-1/2 Saw Comparison

Choosing the right circular saw can feel a bit confusing, especially when looking at different sizes. For example, the Milwaukee Fuel 7-1/4 vs 6-1/2 Circular Saw choice comes up a lot. Beginners might wonder which one is better for their projects.

It’s not as tricky as it seems. We’ll break it down simply so you know exactly what you need. Let’s look at what makes each saw great and when you might pick one over the other.

Milwaukee Fuel Circular Saw Size Matters

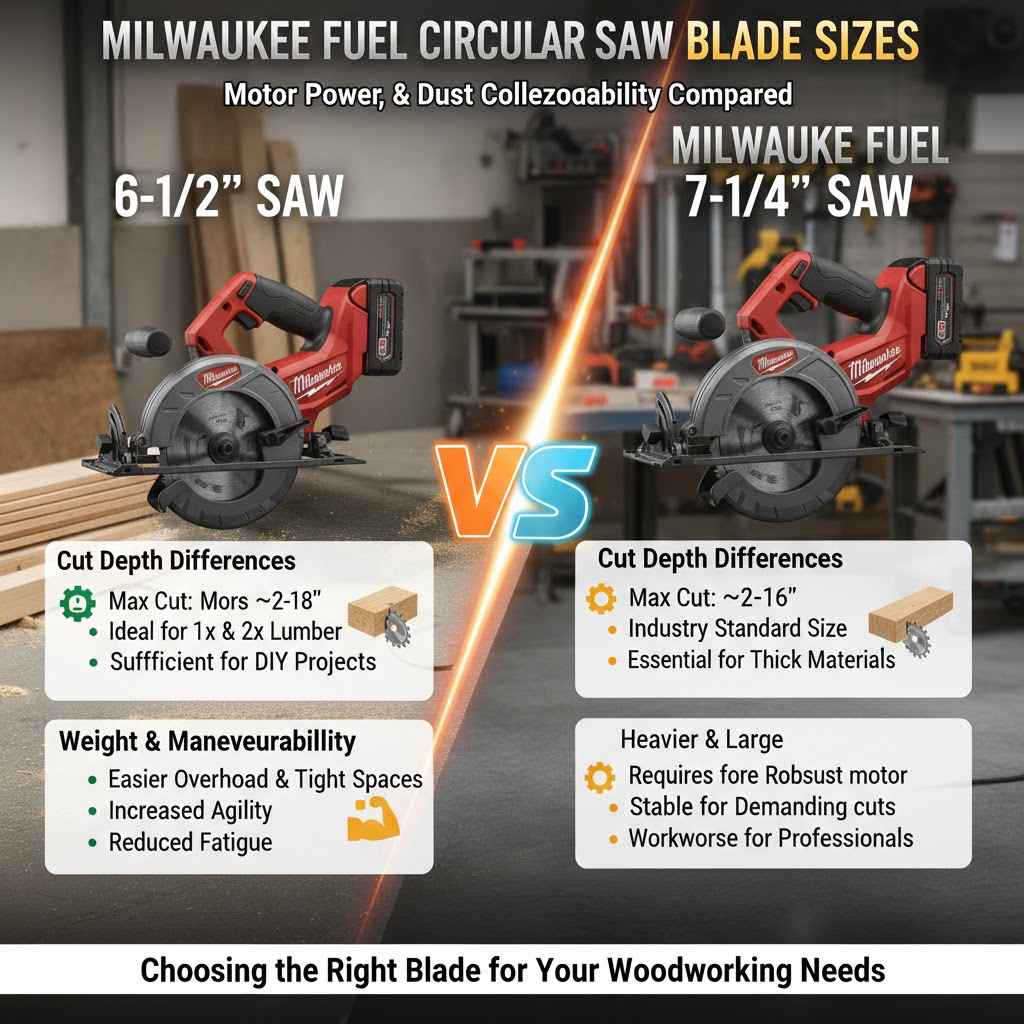

Understanding Milwaukee Fuel Circular Saw Blade Sizes

Blade size is a big deal when picking a circular saw. The size of the blade directly affects how deep you can cut and also influences the overall size and weight of the saw. A larger blade generally means a deeper cut, which is great for thicker materials.

However, it also means the saw itself will be bigger, heavier, and might require more power to spin effectively. For woodworking and general construction, different blade sizes offer distinct advantages. For instance, a 7-1/4 inch blade is a very common standard size in North America.

It’s versatile for many tasks.

A 6-1/2 inch blade is a bit smaller. This makes the saw lighter and often more maneuverable. It’s a good choice if you’ll be doing a lot of cuts overhead or in tight spaces.

Smaller blades can also be quicker to get up to speed. They are often found on more compact saws. The difference in depth of cut isn’t always huge, but it can be important for specific jobs.

For example, some thicker dimensional lumber might need that extra quarter-inch or so that a 7-1/4 inch blade can provide. On the other hand, for many DIY projects, the cut depth from a 6-1/2 inch blade is more than enough.

Cut Depth Differences Explained

The main physical difference between a 7-1/4 inch saw and a 6-1/2 inch saw is the blade diameter. This directly translates to the maximum depth of cut each saw can achieve. A standard 7-1/4 inch circular saw, when set to its maximum depth, can typically cut through about 2-9/16 inches of material.

This is usually enough to handle most common lumber sizes, including 2x lumber, which is often found in framing and construction. This ability to power through thicker wood makes it a go-to for many professionals.

A 6-1/2 inch circular saw, on the other hand, will have a maximum cut depth of around 2-1/8 inches. While this is less than the 7-1/4 inch saw, it’s still sufficient for many tasks. For example, cutting standard 1-inch thick boards or even most 2x lumber is well within its capabilities.

If your work primarily involves sheet goods, smaller lumber, or you value a lighter tool, the 6-1/2 inch saw might be perfect. The difference of about 3/8 inch in cut depth is important to consider based on your typical project needs.

Weight and Maneuverability

When you pick up a circular saw, the first thing you might notice is its weight. A saw with a 7-1/4 inch blade is generally heavier than one with a 6-1/2 inch blade. This is because the larger blade itself is heavier, and the saw’s motor and housing often need to be more robust to power it.

For long workdays or tasks that require a lot of overhead cutting, this extra weight can lead to fatigue. A lighter saw is easier to control and maneuver, especially in awkward positions.

The 6-1/2 inch saws are designed with portability and ease of use in mind. They often feel more balanced and less cumbersome. This can be a huge advantage if you’re a DIYer working on smaller projects or if you need to make many cuts in a single session.

If you’re building cabinets, making trim work, or cutting sheet materials like plywood, the increased maneuverability of a 6-1/2 inch saw can make the job go smoother and faster. It’s about finding a tool that feels comfortable and manageable for the type of work you do most often.

Benefits of Smaller Blades

- Ease of Handling A smaller blade often means a lighter saw. This makes it easier to lift, carry, and control for extended periods.

- Increased Agility With a more compact design, smaller saws can be more agile. They are easier to position and cut accurately in tight spaces or on angled cuts.

- Faster Spin-Up Smaller, lighter blades can often reach their optimal cutting speed more quickly. This can feel more responsive during use.

- Reduced User Fatigue The overall lighter weight and better balance of a saw with a smaller blade contribute to less fatigue during long work sessions.

Using a saw with a smaller blade, like the 6-1/2 inch option, brings several practical advantages. One of the most significant is its ease of handling. These saws tend to be lighter overall.

This is great for people who might not have a lot of upper body strength or for tasks that require you to hold the saw above shoulder height for a while. The reduced weight means you can work longer without feeling as tired.

Agility is another key benefit. Because the saw is smaller and lighter, it’s often more nimble. You can get into tighter spots to make your cuts.

This is super helpful when you’re working with intricate designs or in confined areas where a larger saw would be clumsy. The saw also spins up to full speed very quickly. This makes it feel responsive when you start a cut, which can lead to more precise work.

Less fatigue also means you can concentrate better on making accurate cuts, improving the quality of your finished projects.

Benefits of Larger Blades

- Greater Cut Depth The most obvious advantage is the ability to cut through thicker materials. This is essential for framing and heavy-duty applications.

- Stability and Power Larger blades often come on more substantial saws, which can offer more power and stability during demanding cuts.

- Versatility for Framing For general construction and framing jobs, the 7-1/4 inch blade is the industry standard and can handle most common lumber sizes with ease.

- Reduced Sawing Passes For very thick materials, a larger blade might achieve the cut in fewer passes than a smaller blade.

The primary benefit of a 7-1/4 inch circular saw is its superior cut depth. This allows you to easily cut through thicker lumber, such as 2×6 or 2×8 boards, in a single pass. This capability is critical for framing walls, building decks, or any construction project that involves substantial timber.

The saw’s larger size often means it has a more powerful motor, providing consistent performance even when pushing through tough materials. This robustness makes it a workhorse for professional contractors.

For framing, this saw is often considered the standard. It handles the common dimensions of lumber used in building very well. You don’t have to worry about not being able to make a full cut.

This saves time and effort on job sites. Also, for very thick materials, a larger blade can sometimes finish the job in fewer passes compared to a smaller blade. This means less effort for the user and a cleaner cut because the blade doesn’t have to work as hard over a longer duration.

It’s built for these heavy-duty tasks.

Milwaukee Fuel 7-1/4 vs 6-1/2 Circular Saw Performance Comparison

When we talk about performance, we’re looking at how well the saw cuts, how powerful it is, and how efficiently it uses its battery if it’s a cordless model. The Milwaukee M18 FUEL line is known for its high performance. Both the 7-1/4 inch and 6-1/2 inch versions are designed to deliver.

The key differences in performance often come down to the specific motor, battery system, and how the saw is balanced for its intended use. Understanding these aspects helps you choose the right tool for your needs.

For instance, the torque a saw can deliver is important for cutting through denser woods or making repetitive cuts. Battery life is also a significant factor for cordless tools. A bigger blade might draw more power, potentially affecting how long you can work on a single charge.

However, Milwaukee’s FUEL technology aims to optimize this. The design of the saw, including its gearing and blade speed, plays a crucial role in its overall cutting power and efficiency. We will explore these details to give you a clearer picture of how they stack up against each other.

Motor Power and Torque

The motor is the heart of any circular saw, and Milwaukee’s FUEL line is renowned for its brushless motors. These motors are highly efficient and provide more power and longer runtimes compared to brushed motors. For the 7-1/4 inch saw, the motor is typically designed to handle the demands of a larger blade and deeper cuts.

This means it needs to generate substantial torque to maintain blade speed when cutting through tough materials or making plunge cuts. The power output is often measured in watts out, and higher numbers indicate a more capable motor.

With a 6-1/2 inch saw, while still using a FUEL brushless motor, the motor may be tuned differently. It might prioritize higher RPMs for faster cutting in less demanding applications, or it could be optimized for battery efficiency in a lighter tool. Torque is still important, but the overall demand might be less than for a 7-1/4 inch saw cutting through thick hardwood.

Both saws benefit from Milwaukee’s advanced motor technology, ensuring they deliver consistent power and performance without bogging down.

One common measure of motor power is amperage or wattage. For example, a high-performance 7-1/4 inch cordless saw might draw around 15-18 amps from the battery to deliver its peak performance. This is comparable to many corded saws.

A 6-1/2 inch saw might draw slightly less, perhaps 12-15 amps, depending on its specific motor design and the cutting load. However, it’s not just about peak draw; sustained power delivery is what matters most. Milwaukee’s FUEL technology excels at providing this sustained power.

Battery Life and Runtime

Battery life is a critical consideration for cordless tools like the Milwaukee FUEL saws. The capacity of the battery, measured in Amp-hours (Ah), directly impacts how long the saw can run on a single charge. A larger battery pack, like Milwaukee’s 5.0 Ah or 6.0 Ah batteries, will provide significantly longer runtime than a smaller 2.0 Ah or 3.0 Ah pack.

For heavy-duty tasks that involve a lot of cutting, using larger capacity batteries is essential to minimize downtime.

When comparing the 7-1/4 inch and 6-1/2 inch models, the larger blade on the 7-1/4 inch saw generally requires more power to spin. This means that, all other factors being equal, the 7-1/4 inch saw might consume battery power slightly faster than the 6-1/2 inch model. However, Milwaukee’s FUEL system is highly efficient.

The brushless motors and optimized power management systems work to maximize runtime. So, the actual difference in runtime can be less pronounced than one might expect, especially if the 6-1/2 inch saw is used for tasks that push its limits.

For example, a typical 7-1/4 inch cordless saw with a 5.0 Ah battery might get you through about 70-100 linear feet of 2×10 lumber cuts. A 6-1/2 inch saw with the same battery might achieve 80-120 linear feet of cuts on similar material, or even more if the material is thinner. The exact figures can vary greatly depending on the wood density, blade sharpness, and cutting technique used.

Milwaukee offers a range of battery sizes, allowing users to choose the best balance between weight and runtime for their specific job.

Cutting Speed and Efficiency

Cutting speed refers to how quickly the saw can make a cut. This is influenced by factors such as the saw’s RPM (revolutions per minute), motor power, and the sharpness of the blade. A higher RPM generally leads to a faster cut.

The Milwaukee FUEL saws are designed to achieve high RPMs, allowing for efficient cutting. The brushless motors maintain their speed even under load, which means the saw won’t slow down significantly when it encounters resistance in the wood.

Efficiency also relates to how cleanly the saw cuts and how much material it removes with each pass. A sharp blade and a powerful, well-balanced saw will result in smoother, more accurate cuts with less splintering. For the Milwaukee Fuel 7-1/4 vs 6-1/2 Circular Saw comparison, both saws are engineered for high efficiency within their respective size classes.

The 7-1/4 inch saw is built to power through thicker materials quickly, while the 6-1/2 inch saw is optimized for fast, precise cuts in less demanding situations. The FUEL technology ensures that both models deliver consistent, high-speed performance.

Cutting a 2×10 Board

- Preparation Ensure the 2×10 board is securely clamped to a stable surface. Mark your cut line clearly.

- Blade Selection Use a sharp 24-tooth or 40-tooth carbide-tipped blade suitable for dimensional lumber.

- Saw Setup For a 7-1/4 inch saw, set the cut depth to just slightly more than the 3-1/2 inch actual thickness of the 2×10.

- Starting the Cut Place the saw on the board with the blade guard retracted. Ensure the shoe is flat on the wood.

- Executing the Cut Start the saw and let it reach full speed before engaging the wood. Push the saw forward smoothly and steadily along the cut line. Let the saw do the work without forcing it.

- Finishing Once the cut is complete, allow the blade to stop spinning before lifting the saw.

Cutting a 2×10 board is a good test for any circular saw. A 2×10 is actually about 9-1/4 inches wide and 1-1/2 inches thick. A 7-1/4 inch blade can easily cut through this in one go because its maximum cut depth is around 2-9/16 inches.

You would set the depth to just a bit over 1-1/2 inches. The saw’s powerful motor would maintain speed throughout the cut, providing a clean finish. This is a typical framing task where the 7-1/4 inch saw shines.

A 6-1/2 inch saw can also cut a 2×10, but it requires a slight adjustment in technique. Its maximum cut depth is about 2-1/8 inches. So, you would still set the depth to just over 1-1/2 inches.

The cut would be made similarly, but if the 2×10 were slightly thicker or warped, a 6-1/2 inch saw might require a bit more attention to maintain speed, especially if the blade isn’t perfectly sharp. However, for standard dimensional lumber, both saws can perform this task effectively, with the 7-1/4 inch often feeling more effortless.

Cutting Plywood Sheets

- Material Support Lay the plywood sheet flat on sawhorses or a sturdy workbench. Ensure it is well-supported to prevent sagging.

- Marking Line Measure and mark your desired cut line clearly with a pencil or chalk line.

- Blade Depth Setting Set the cut depth of your saw to slightly more than the thickness of the plywood (e.g., 1/2 inch for 3/4 inch plywood).

- Blade Choice Use a blade designed for cutting sheet goods or a general-purpose blade with at least 40 teeth for a cleaner edge.

- Starting and Cutting Place the saw’s shoe firmly on the plywood. Start the saw and slowly push it along the marked line.

- Maintaining Control Keep the saw moving at a steady pace, allowing the blade to cut through the material without forcing it.

- Finishing the Cut Once the cut is complete, lift the saw carefully after the blade has stopped spinning.

Cutting plywood sheets is a common task for both 7-1/4 inch and 6-1/2 inch saws. Plywood typically comes in 4×8 sheets and in various thicknesses, such as 1/2 inch, 3/4 inch, or even thicker. For a 3/4 inch plywood sheet, both saws can make the cut easily.

The 7-1/4 inch saw has ample depth capacity, and the 6-1/2 inch saw also easily exceeds the 3/4 inch thickness needed. A key consideration here is the finish. Using a sharp, high-tooth-count blade will help minimize tear-out, especially on the top surface of the plywood.

The maneuverability of the 6-1/2 inch saw can be an advantage when cutting large sheets of plywood, especially if you are cutting them down from a full 4×8 sheet into smaller pieces. It’s lighter and easier to control when making long, straight cuts or when you need to turn corners. While the 7-1/4 inch saw is also very capable, its slightly larger size and weight might make it a bit more cumbersome for extended sheet good cutting sessions.

However, for accuracy and a clean finish, both saws with the right blade and technique perform admirably.

Comparing Milwaukee Fuel 7-1/4 vs 6-1/2 Circular Saw Features

Beyond blade size, Milwaukee packs a lot of technology into its FUEL circular saws. Features like LED lights, electric brakes, and dust collection ports enhance the user experience and safety. When comparing the 7-1/4 inch and 6-1/2 inch models, you’ll find many of these premium features are available on both, reflecting Milwaukee’s commitment to quality across its product lines.

However, there might be slight variations or specific optimizations based on the intended use of each saw size.

For example, both saws will likely come with an electric brake that stops the blade quickly after you release the trigger, a significant safety improvement. The LED lights are also standard, illuminating your cut line for better visibility. Dust collection is another feature to consider.

While a dust port is usually present, its effectiveness can vary based on the saw’s design and the amount of dust generated. Let’s look at some of these common features and how they might apply to both sizes.

Safety Features

Safety is paramount when using any power tool, and Milwaukee designs its FUEL saws with user protection in mind. One of the most important safety features is the electric brake. When you let go of the trigger, this system quickly spins down the blade, bringing it to a complete stop in just a few seconds.

This dramatically reduces the risk of accidental cuts after the saw has finished its work.

Another crucial safety aspect is the blade guard. Both the 7-1/4 inch and 6-1/2 inch saws have spring-loaded lower blade guards that automatically retract as you push the saw through the material and snap back into place when you lift it. This keeps the sharp blade covered when not actively cutting, preventing accidental contact.

Milwaukee saws also typically feature a spindle lock for easy blade changes and a sturdy shoe that provides a stable base on your workpiece.

Electric Brake Functionality

The electric brake is a standout safety feature found on most modern Milwaukee FUEL circular saws. Its primary function is to rapidly stop the blade’s rotation once the trigger is released. This is a significant improvement over older saws where the blade would continue to spin for some time, increasing the risk of injury if the saw is accidentally set down or if there’s a kickback.

The brake works by applying a counter-current to the motor, which quickly slows and stops the blade.

In a practical sense, this means you can place the saw down immediately after completing a cut, knowing the blade will stop spinning almost instantly. This not only enhances safety but also speeds up your workflow, as you don’t have to wait for the blade to stop on its own. For both the 7-1/4 inch and 6-1/2 inch models, this feature is standard and provides peace of mind during operation.

Blade Guard Design

The blade guard on a circular saw is designed to protect the user from the spinning blade. Milwaukee’s guards are typically made of durable metal or heavy-duty plastic and are engineered to retract smoothly as you begin cutting and snap back into place as you finish. This mechanism is crucial for preventing accidental contact with the blade while it’s spinning.

The guard’s design also helps manage sawdust and chips, directing them away from the user.

Both the 7-1/4 inch and 6-1/2 inch FUEL saws feature well-designed, reliable blade guards. They are spring-loaded to ensure they always return to their protective position. The smooth retraction allows for easy engagement with the material, and the guard’s ability to snap back quickly adds a layer of safety when you lift the saw off the workpiece.

This attention to guard design is a consistent aspect of Milwaukee’s commitment to user safety across their saw lines.

LED Lighting and Visibility

Good visibility of the cut line is essential for accuracy and safety. Milwaukee understands this and equips its FUEL circular saws with integrated LED lights. These lights are typically positioned to illuminate the area directly in front of the blade, casting a bright beam onto the workpiece.

This feature is incredibly useful when working in dimly lit conditions, such as basements, garages, or outdoor areas as dusk approaches. The LED light remains on as long as the trigger is depressed, providing continuous illumination.

Whether you choose the 7-1/4 inch or the 6-1/2 inch model, you can expect this helpful visibility feature. It eliminates the need for an external work light or relying on ambient light. For precise cuts, especially when following a faint pencil line, the LED light makes a significant difference.

It helps you stay on track and ensures cleaner, more accurate results, contributing to a better overall woodworking or construction experience.

Dust Collection

Dust collection is an important consideration, especially when working indoors or with materials that produce a lot of fine dust, like MDF or certain types of wood. Milwaukee FUEL circular saws often include a dust port. This port can be connected to a shop vacuum or a dust collection system to capture sawdust as you cut.

By reducing the amount of airborne dust, dust collection helps keep your workspace cleaner and improves air quality.

The effectiveness of dust collection can vary between saw models. While both the 7-1/4 inch and 6-1/2 inch saws typically have a dust port, some designs might be more efficient than others at capturing fine particles. For best results, a powerful vacuum attached to the port is recommended.

This feature is particularly beneficial for professionals who spend long hours cutting and for DIYers who want to maintain a cleaner home workshop. It’s a thoughtful addition that contributes to a more pleasant and healthier working environment.

Ergonomics and Comfort

Ergonomics refers to how comfortable and easy a tool is to use. Milwaukee pays close attention to the design of its tools to ensure they are comfortable to hold and operate, even for extended periods. This includes the shape and texture of the handle grips, the balance of the saw, and the placement of controls.

A well-designed saw will feel like an extension of your hand, reducing strain and improving control.

For the Milwaukee Fuel 7-1/4 vs 6-1/2 Circular Saw, both models are designed with user comfort in mind. The 6-1/2 inch saw, being lighter, will naturally feel more comfortable for users who prioritize less weight and easier maneuverability. However, the 7-1/4 inch saw, despite its larger size, often has a well-balanced design that makes it feel less heavy than its dimensions might suggest.

Contoured grips and vibration-dampening features further enhance the comfortable feel of both saws.

Milwaukee Fuel 7-1/4 vs 6-1/2 Circular Saw Which is Right for You

Deciding between the Milwaukee Fuel 7-1/4 inch and 6-1/2 inch circular saw ultimately depends on your specific needs and the types of projects you tackle most often. Both are high-quality tools from a reputable brand, offering excellent performance and durability. There isn’t a universally “better” saw; rather, there’s a saw that is better suited for particular tasks and user preferences.

Consider what you’ll be cutting, how often you’ll be using the saw, and what aspects of tool handling are most important to you.

Think about the materials you work with. Are you cutting through thick beams and framing lumber frequently, or are your projects more focused on sheet goods and smaller dimensional lumber? Your comfort with the tool’s weight and size is also a key factor.

By carefully considering these points, you can confidently choose the Milwaukee FUEL circular saw that will best serve your DIY or professional needs. Let’s break down some scenarios to help you make the best choice.

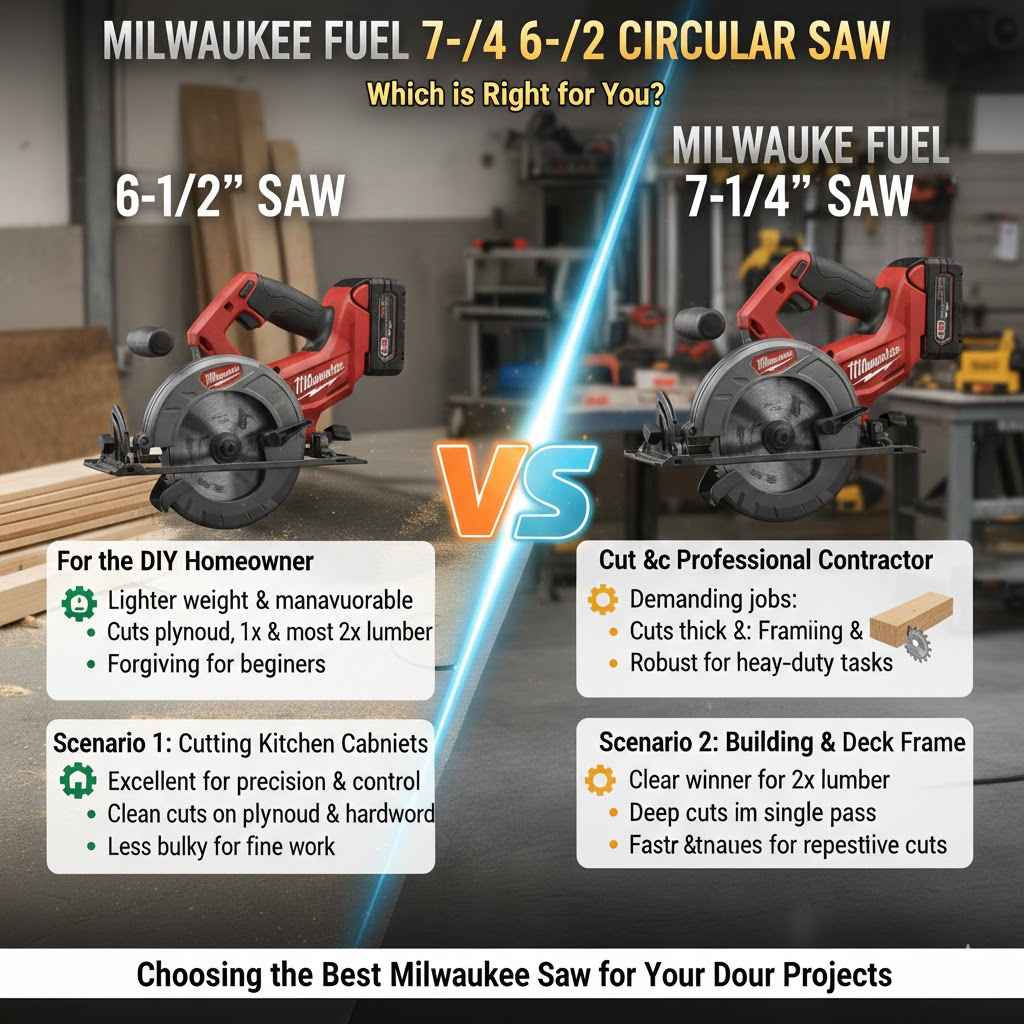

For the DIY Homeowner

If you’re a DIY homeowner who tackles various projects around the house, from building shelves and small decks to cutting lumber for repairs, the choice between the two sizes becomes clearer. For many general home projects, the 6-1/2 inch saw might be the more practical choice. Its lighter weight and increased maneuverability make it easier to handle for a wide range of tasks.

You can cut plywood, 1x lumber, and even most 2x lumber with it, which covers a lot of common DIY needs.

The 6-1/2 inch saw is generally more forgiving for beginners. Its lighter weight means less fatigue, allowing for more focus on accurate cuts. If you’re not frequently cutting through very thick beams or performing heavy-duty framing, the 6-1/2 inch saw will likely meet all your requirements.

It offers a great balance of power and user-friendliness, making it a versatile tool for any homeowner’s toolbox.

For the Professional Contractor

Professional contractors often face demanding job requirements where efficiency, power, and the ability to cut through thicker materials quickly are paramount. In this context, the 7-1/4 inch Milwaukee Fuel circular saw is frequently the preferred choice. Its larger blade provides the necessary depth of cut for framing lumber, structural beams, and other heavy-duty applications common in construction.

The saw’s robust motor is designed to maintain power and speed even under significant load.

While the 7-1/4 inch saw is heavier, its power and cutting capacity often outweigh this drawback for professionals. The ability to make deep, clean cuts in a single pass saves valuable time on the job. For framing, deck building, and general carpentry work, the 7-1/4 inch saw is the industry standard and a reliable workhorse that professionals rely on for its performance and durability.

Scenario 1 Cutting Kitchen Cabinets

Imagine you’re building custom kitchen cabinets. This involves cutting sheet goods like plywood and particle board, as well as ripping smaller pieces of hardwood or laminate for frames and accents. The precision and control needed for cabinet making are high.

A 6-1/2 inch saw would be an excellent choice here. Its lighter weight and greater maneuverability allow for precise cuts on large sheets of plywood, minimizing tear-out and ensuring accurate dimensions. The ability to make quick, controlled cuts on smaller pieces of hardwood is also advantageous.

The 7-1/4 inch saw could also do this, but it might feel a bit bulky for the finer work involved in cabinet construction.

Scenario 2 Building a Deck Frame

Now consider building a deck frame. This typically involves cutting large quantities of 2x lumber, such as 2x6s and 2x8s, for joists and beams. The primary requirement is the ability to cut through these thick pieces of wood quickly and efficiently.

In this scenario, the 7-1/4 inch Milwaukee Fuel circular saw is the clear winner. Its larger blade has the depth to easily cut through 2x lumber in a single pass. The saw’s power ensures it maintains speed, making repetitive cuts faster and less strenuous.

While a 6-1/2 inch saw could technically make the cuts, it would likely be slower and require more effort, potentially impacting the project timeline.

Frequently Asked Questions

Question: Which Milwaukee Fuel saw is better for beginners?

Answer: For most beginners, a 6-1/2 inch Milwaukee Fuel circular saw is often recommended. It’s lighter and easier to handle, which makes it less intimidating and helps build confidence. The reduced weight also contributes to better control, leading to more accurate cuts as you learn.

Question: Can a 6-1/2 inch saw cut through 2x4s?

Answer: Yes, a 6-1/2 inch Milwaukee Fuel saw can easily cut through 2×4 lumber. A standard 2×4 is actually 1-1/2 inches thick, and a 6-1/2 inch saw can cut up to about 2-1/8 inches deep, so it has plenty of capacity.

Question: Does Milwaukee make a corded 7-1/4 inch Fuel saw?

Answer: Milwaukee’s FUEL line is primarily their premium cordless battery-powered tools. While they offer corded saws, the FUEL designation specifically refers to their advanced brushless motor technology in battery-powered tools.

Question: How often should I change the blade on my Milwaukee Fuel saw?

Answer: The frequency of blade changes depends on how much you use the saw and the materials you cut. A dull blade makes cutting harder and can lead to rougher cuts. Generally, change the blade when you notice a decrease in cutting performance or increased splintering.

For frequent use, consider replacing it every few months or sooner if performance degrades.

Question: Is the Milwaukee Fuel 7-1/4 inch saw too heavy for home DIY?

Answer: The 7-1/4 inch Milwaukee Fuel saw is heavier than the 6-1/2 inch model, but its weight is well-balanced. For many DIY tasks like cutting lumber for projects or sheet goods, it’s manageable. If you anticipate mostly lighter tasks or have less upper body strength, the 6-1/2 inch might be a more comfortable choice.

Conclusion

Choosing between the Milwaukee Fuel 7-1/4 inch and 6-1/2 inch circular saw comes down to your specific projects. The 7-1/4 inch is ideal for heavy-duty tasks like framing, offering maximum cut depth and power. The 6-1/2 inch is lighter, more maneuverable, and excellent for general DIY, sheet goods, and finer woodworking where ease of handling is key.

Both deliver exceptional performance thanks to Milwaukee’s FUEL technology. Select the size that best matches your most common cutting needs for a satisfying and efficient experience.