OSB Plywood 1/2 Price at Lowe’s: Updated Cost Guide

Finding good deals on building supplies can feel tricky. You might see an amazing sale like OSB Plywood 1/2 Price at Lowe’s: Updated Cost Guide and wonder if it’s really that good or how to make sure you’re getting the best value. It’s easy for beginners to get confused by different sizes and types.

This guide makes it simple. We will walk through everything step by step so you know exactly what to look for and how much you can save. Get ready to discover how to get the most for your money.

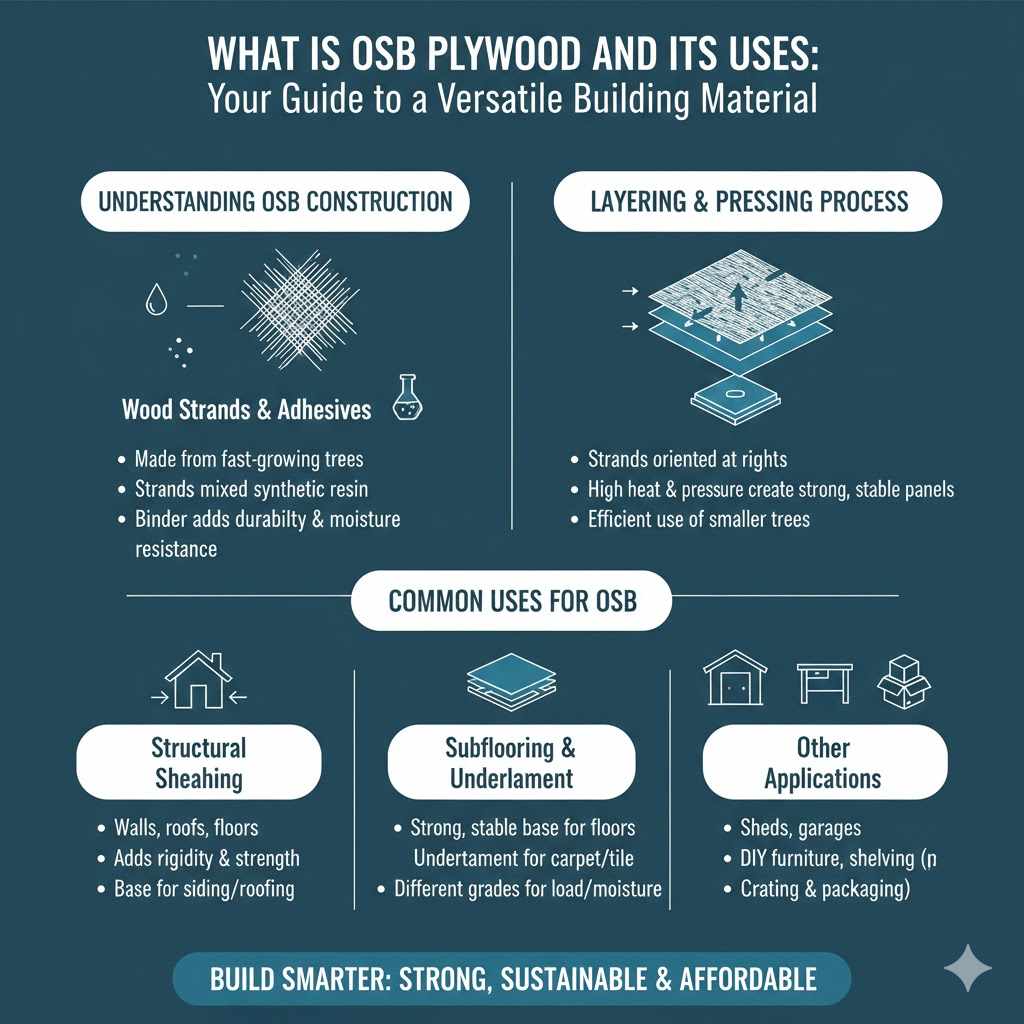

What Is OSB Plywood and Its Uses

OSB, or Oriented Strand Board, is a popular building material made from wood strands pressed together with adhesives. It’s known for its strength and affordability, making it a go-to choice for many construction projects. Unlike traditional plywood, OSB is made from smaller wood pieces arranged in layers, which gives it a unique look and consistent performance.

This makes it a practical option for walls, floors, and roofs in both residential and commercial buildings.

Understanding OSB Construction

OSB is made by layering thin strands of wood, called wafers or flakes, at right angles to each other. These strands are mixed with a binder, like synthetic resin. Then, the mixture is pressed under high heat and pressure.

This process creates a strong, stable panel. The direction of the wood strands in each layer gives OSB its directional strength, similar to plywood but achieved differently.

This manufacturing method uses smaller trees and wood waste efficiently. It reduces the need for larger, prime timber often used in plywood. This makes OSB a more sustainable option for many builders.

The wood strands are chosen for their strength and flexibility. Their orientation in cross-hatched layers provides excellent structural integrity.

Wood Strands and Adhesives

The wood strands used in OSB are typically made from fast-growing trees like aspen, poplar, or pine. These strands are cut to specific sizes and shapes, then dried and screened for quality. The binder, usually a phenol or urea-formaldehyde resin, is mixed with the strands to hold them together.

This adhesive is critical for the board’s durability and resistance to moisture and heat.

The amount and type of adhesive used depend on the intended use of the OSB panel. For outdoor or high-moisture applications, more robust adhesives and moisture-resistant treatments are incorporated. The binder ensures the strands bond securely during the pressing process, creating a solid, uniform board.

Layering and Pressing Process

The OSB manufacturing process involves several key steps. First, wood logs are debarked and fed into a flaker machine that produces uniform strands. These strands are then dried and screened to remove fines and oversized pieces.

Next, they are sprayed with resin and wax.

The treated strands are then spread onto a forming line. The surface layers have strands oriented lengthwise, while the inner layers have strands oriented crosswise. This cross-orientation is what gives OSB its strength and stability.

The mat of strands is then fed into a large, heated press that cures the resin and compresses the mat into a rigid panel.

Common Uses for OSB Plywood

OSB is a versatile material used in many areas of construction. Its strength and cost-effectiveness make it ideal for structural sheathing, subflooring, and roof decking. It is also used for furniture, shelving, and even decorative purposes.

Builders often choose OSB for its consistent thickness and smooth surface. This makes it easy to work with and reduces waste. The panels are also available in various thicknesses to suit different load-bearing requirements.

From framing a house to building a simple workbench, OSB is a reliable choice.

Structural Sheathing

One of the most common uses for OSB is as structural sheathing for walls and roofs. It is attached to the studs or rafters to provide rigidity to the building frame. This sheathing adds shear strength, helping the structure resist forces like wind and earthquakes.

It also provides a solid surface for applying siding and roofing materials.

When used for walls, OSB provides a solid base for house wrap, insulation, and the final exterior finish. For roofs, it supports shingles or other roofing materials and protects the attic space. The panels are typically applied in a staggered pattern to avoid weak joints.

Subflooring and Underlayment

OSB is widely used as subflooring, providing a strong and stable base for finished flooring like carpet, tile, or hardwood. It is installed over floor joists and provides a smooth, level surface for the final floor covering. Its durability ensures the floor can withstand heavy use.

As underlayment, OSB can add an extra layer of support and sound dampening. It is particularly useful under thinner flooring materials where a smooth, solid surface is essential. Different grades of OSB are available for subflooring, depending on the expected load and moisture exposure.

Other Applications

Beyond structural uses, OSB finds its way into many other applications. It is often used for temporary shelters, sheds, and garages due to its low cost and ease of use. Some DIY enthusiasts use OSB for building furniture, cabinets, and shelving.

Its uniform surface can be sanded and painted or stained for a finished look.

In some commercial settings, OSB is used for display fixtures and temporary partitions. Its ability to be cut and shaped easily makes it adaptable for various custom projects. Even in less visible applications like crating and packaging, OSB offers a cost-effective solution.

Why OSB Plywood Sales Are Important

Sales on building materials like OSB are crucial for anyone undertaking construction or renovation projects. They allow individuals and businesses to save significant amounts of money, especially on larger projects where material costs can add up quickly. These discounts make building and DIY projects more accessible and affordable.

When you see a sale like OSB Plywood 1/2 Price at Lowe’s, it’s an opportunity to significantly reduce your budget. This is particularly important for contractors who need to manage costs for multiple clients, and for homeowners tackling a DIY renovation on a tight budget. Taking advantage of these sales means more money can be allocated to other aspects of the project or simply saved.

The Impact of Discounts on Project Budgets

Building a house or even renovating a single room involves many materials, and OSB is often a significant component. When OSB is offered at half price, the savings can be substantial. For a large project, this could mean saving thousands of dollars.

For example, a typical home might require 200-300 sheets of OSB for walls, floors, and roof. If a sheet costs $20, the total would be $4,000-$6,000. If you could get it for half price, that’s a saving of $2,000-$3,000.

This directly impacts the overall project budget, making it feasible for more people to undertake their desired projects.

Cost Savings for Homeowners

For homeowners planning a DIY project, these sales are a game-changer. A deck, a shed, or a room addition can become much more affordable. The money saved on OSB can be used for other finishing touches, better quality tools, or simply kept in the bank.

Imagine building a backyard shed. You might need 20 sheets of OSB. If each sheet is normally $20 and you find a 50% off sale, you save $200.

This $200 could buy you new paint, better fasteners, or even a small power tool to help with the build.

Savings for Contractors and Builders

Professional contractors and builders also benefit greatly from these deep discounts. They can pass some savings onto their clients or increase their profit margins. For businesses that buy materials in bulk, even small percentage savings per sheet add up to very large amounts.

A contractor working on multiple homes simultaneously can significantly reduce their overhead by stocking up on materials during sale periods. This competitive advantage allows them to offer more attractive pricing to their customers, potentially securing more jobs.

Understanding OSB pricing involves looking at various factors. The price of OSB can fluctuate based on demand, lumber prices, and seasonal sales. Knowing when and where to buy can lead to substantial savings.

Keeping an eye on major retailers like Lowe’s for their advertised deals is a smart strategy.

The term OSB Plywood 1/2 Price at Lowe’s: Updated Cost Guide is appealing because it directly addresses a significant price reduction. However, it’s important to understand what you’re buying and if the sale truly meets your needs.

Factors Influencing OSB Prices

Several factors influence the price of OSB. The cost of raw materials, primarily trees, is a major driver. Lumber market trends, demand from the construction industry, and regional economic conditions also play a role.

Energy costs for manufacturing and transportation also contribute to the final price.

Seasonal demand can also affect pricing. During peak building seasons, demand for OSB increases, potentially leading to higher prices. Conversely, in slower periods, prices might drop to move inventory.

Retailer-specific sales, like the advertised 50% off, are often strategic efforts to boost sales volume during specific periods.

Understanding Different Grades and Sizes

OSB is available in different grades, typically indicated by numbers like OSB/2, OSB/3, and OSB/4. Higher numbers generally signify greater strength and moisture resistance. Different thicknesses are also available, ranging from 7/16 inch to 1 inch or more, each suited for specific applications.

Common panel sizes are 4 feet by 8 feet. When looking at a sale, it’s important to confirm the grade and thickness being offered to ensure it meets your project’s requirements. A very cheap OSB might be a lower grade not suitable for structural support, even if it’s a great deal.

OSB Plywood 1/2 Price at Lowe’s: Updated Cost Guide Details

When a major retailer like Lowe’s announces a significant discount, like OSB Plywood 1/2 Price, it’s worth investigating. This kind of sale can dramatically lower the cost of materials for your project. Understanding the specifics of the sale, including the exact product, duration, and any limitations, is key to making the most of it.

This section will break down what a 50% off sale on OSB at Lowe’s typically entails. We will look at the potential savings, what products are usually included, and how to verify the information. This updated cost guide will help you plan your purchase effectively.

What to Expect from a 50% Off Sale

A 50% off sale on OSB at Lowe’s means you can buy the product for half its regular price. This is a substantial discount. Such sales are often part of seasonal promotions or special events.

They are designed to attract a large number of customers and boost sales significantly.

You should expect to see specific types and sizes of OSB included in the promotion. It’s rare for every single OSB product to be discounted this heavily. Retailers usually highlight the best deals and may limit quantities per customer.

Typical Products Included

When Lowe’s offers a 50% discount, it commonly applies to their most popular or standard OSB panels. This often includes common sizes like 4×8 feet in standard thicknesses such as 7/16 inch or 1/2 inch. These are the workhorse products used in many general construction tasks.

It’s less likely that premium or specialized OSB products, like those with enhanced moisture resistance or specific structural ratings for high-stress applications, will be part of such a broad half-price sale. Always check the product details carefully.

Sale Duration and Limitations

Sales like this are usually time-limited. They might run for a weekend, a week, or as part of a larger holiday promotion. It’s important to check the sale dates and plan your shopping accordingly.

Also, be aware of potential purchase limits, such as “limit 10 sheets per customer.”

These limitations are in place to ensure fair distribution of the discounted items and prevent bulk buying by a few individuals or businesses who might resell them at a higher price. If you need a large quantity for a big project, you might need to coordinate with others or make multiple trips.

How to Verify the Best Prices

To make sure you’re getting the advertised price and the best deal, always verify the information. Check the Lowe’s website, their weekly ad, or ask an associate in the building materials department. Comparing prices with other retailers can also confirm if it’s a genuinely good offer.

The OSB Plywood 1/2 Price at Lowe’s: Updated Cost Guide is most useful when you actively confirm the details. Don’t rely solely on a headline; dig into the specifics.

Checking Lowe’s Website and Ads

Lowe’s prominently displays their sales on their website and in their weekly print or digital flyers. You can usually find the details of any current promotions, including specific products, prices, and dates, by visiting their promotions page or checking their weekly ad online. Product pages themselves will often show the sale price.

Sometimes, online-only deals are available, or in-store specials. It’s wise to check both channels. Look for clear indications of the original price versus the sale price to understand the full discount.

Comparing Prices and Quality

While a 50% off sale is attractive, it’s wise to compare. See what other stores are charging for similar OSB products. Sometimes, a “sale” price might be close to the everyday price at a competitor.

Also, ensure the OSB quality is comparable. A slightly higher price for a better grade might be worth it.

A quick online search or a visit to a local lumber yard can provide valuable comparison data. Remember that the cheapest option isn’t always the best if it compromises on the quality needed for your project.

Understanding OSB Grades and Their Costs

The cost of OSB varies significantly based on its grade. Higher grades offer better performance and, therefore, come at a higher price point. Understanding these grades helps you know if a sale price is truly a good deal for the quality you are getting.

For example, OSB/3 and OSB/4 are designed for structural use in humid conditions and cost more than OSB/2, which is suitable for dry interior conditions.

Grades Explained

OSB grades are standardized by organizations like the APA (The Engineered Wood Association). Here’s a general breakdown:

- OSB/1: For general use in dry interior conditions. Least durable and cheapest.

- OSB/2: For load-bearing applications in dry interior conditions. More strength than OSB/1.

- OSB/3: For load-bearing applications in humid conditions. Better moisture resistance.

- OSB/4: For heavy-duty load-bearing applications, even in humid conditions. Most durable and expensive.

Cost Differences Between Grades

The price difference between an OSB/2 and an OSB/4 panel can be substantial, often ranging from 20% to 50% more for the higher grade. A 50% off sale on OSB/4 would represent a much larger dollar saving than the same percentage off on OSB/2.

When Lowe’s advertises OSB Plywood 1/2 Price at Lowe’s: Updated Cost Guide, it’s crucial to know which grade the sale applies to. If it’s a lower grade, the saving might be less impactful for structural applications.

Tips for Maximizing Savings on OSB

To truly benefit from OSB sales, you need a strategy. Beyond just finding a discount, there are several ways to ensure you are getting the best possible deal and value for your money. Planning ahead and being aware of related costs are key.

Maximizing savings involves more than just the initial purchase price. It also includes considering delivery, handling, and ensuring you buy exactly what you need to avoid waste.

Planning Your Purchase

Before a sale even starts, have a clear plan. Know the exact dimensions and quantities of OSB you require for your project. This prevents impulse buys of incorrect or unnecessary materials.

Measure your project space accurately. If you’re building a wall, calculate the number of 4×8 sheets needed, accounting for waste from cuts. Online calculators can help with this.

Calculating Required Quantities

Let’s say you need to sheath a wall that is 8 feet high and 32 feet long. The area is 8 x 32 = 256 square feet. Since each OSB sheet is 4×8 feet, it covers 32 square feet.

To cover 256 square feet, you would need 256 / 32 = 8 sheets.

However, you must account for cuts and waste. A good rule of thumb is to add 10-15% for waste. So, 8 sheets + 10% = 8.8 sheets.

You would likely round this up to 9 or 10 sheets to be safe. Always buy a little extra to account for mistakes or unforeseen needs.

Considering Delivery Costs

If you are buying a large quantity of OSB, delivery can be a significant cost. Lowe’s offers delivery services, but there’s a fee. If you are able to pick up the materials yourself with a suitable vehicle, you can save this cost.

For very large orders, sometimes delivery fees are waived or reduced. Check with Lowe’s about their delivery policies and any potential volume discounts on shipping.

Buying in Bulk and Storage

If you have the storage space and anticipate future needs, buying OSB in bulk during a 50% off sale can be very economical. This strategy is especially useful for contractors or DIYers who have multiple projects planned.

Proper storage is essential to keep OSB in good condition until it’s needed. This includes keeping it dry and protected from the elements.

Storage Requirements

OSB panels should be stored flat on a level surface to prevent warping. If stored outdoors, they must be covered completely with a waterproof tarp. Avoid storing OSB in direct sunlight or in very humid environments, as this can damage the board.

A dry garage, shed, or basement is ideal for storing OSB. Elevating the stack off the ground slightly with strips of wood can help prevent moisture absorption from the floor.

When Bulk Buying Makes Sense

Buying in bulk makes sense if you have a consistent need for OSB over time. For example, a contractor building several homes a year will benefit from stocking up when prices are low. Similarly, a homeowner planning a major renovation project that will span several months might find it advantageous.

The key is to ensure you have the space to store the materials properly and that you will realistically use them before they deteriorate. Buying too much and having it go bad is not a saving at all.

Looking for Bundled Deals or Rebates

Sometimes, sales are presented as bundled deals where OSB might be sold with other related materials at a discounted package price. Also, keep an eye out for manufacturer rebates, which can offer additional savings on top of store discounts.

These extra offers can sometimes yield even greater savings than a straightforward percentage off sale.

Bundled Offers

Retailers might offer deals like “buy X amount of OSB, get Y amount of screws or nails free” or at a reduced price. These promotions are designed to encourage larger purchases.

Always calculate the total cost of the bundle versus buying items separately to confirm it’s a genuine saving.

Rebate Opportunities

Manufacturer rebates are common in the building materials industry. After purchasing the OSB, you might be able to submit a form to the manufacturer to receive a cash rebate. These can range from a few dollars per sheet to a larger percentage of the purchase price.

Read the rebate terms and conditions carefully and submit your claim promptly to ensure you receive your money back.

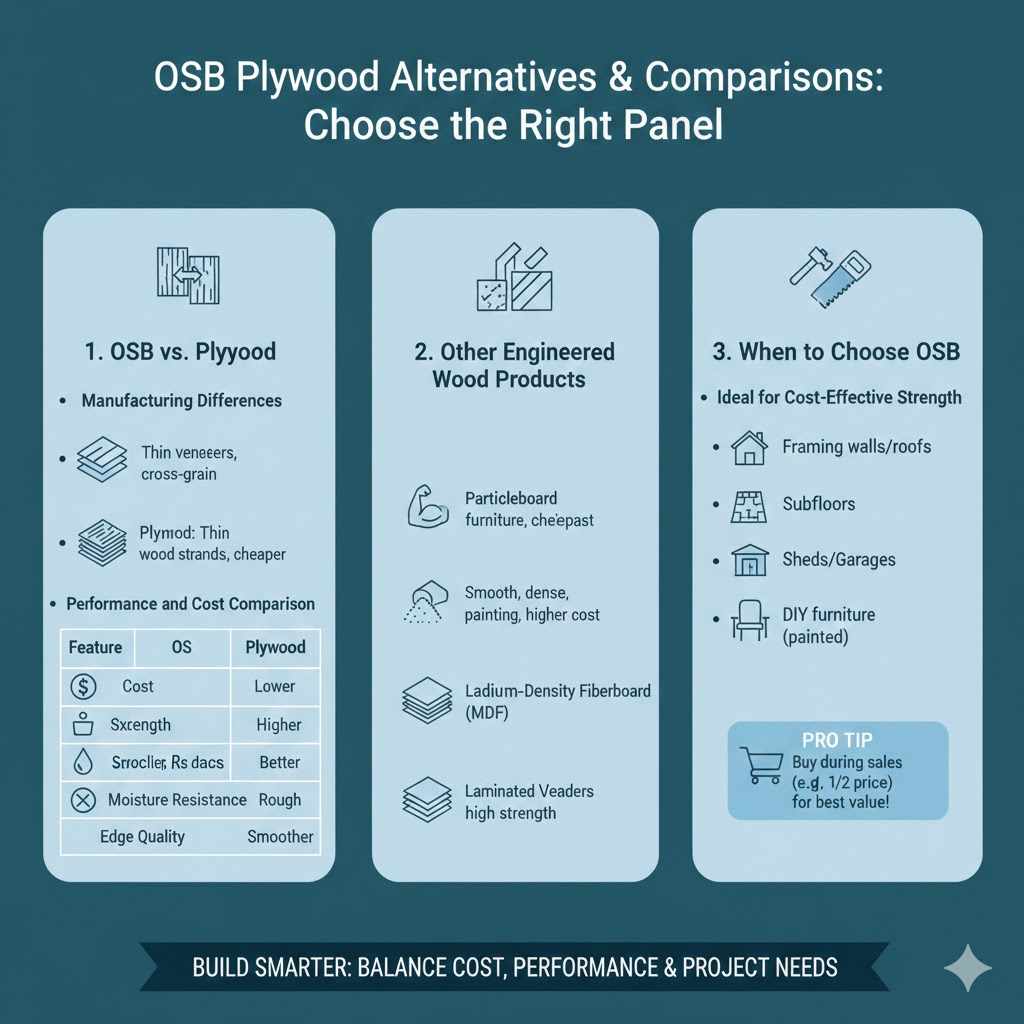

Alternatives and Comparisons

While OSB is a popular choice, other similar panel products exist. Understanding these alternatives and how they compare to OSB in terms of cost, performance, and application can help you make the best choice for your project, even during a sale.

Comparing OSB to plywood, for instance, is a common decision point for many builders and DIYers.

OSB vs. Plywood

OSB and plywood are both wood panel products used in construction, but they are made differently and have distinct characteristics.

Manufacturing Differences

Plywood is made from thin veneers of wood that are glued together with the grain running in alternating directions. This cross-graining makes plywood very strong and stable. OSB, as discussed earlier, is made from compressed wood strands.

The manufacturing process for plywood is more labor-intensive as it requires peeling large logs into thin sheets. OSB uses smaller trees and waste wood more efficiently, which often makes it a more affordable option.

Performance and Cost Comparison

| Feature | OSB | Plywood |

|---|---|---|

| Cost | Generally lower | Generally higher |

| Strength | Good, consistent | Excellent, anisotropic (varies by direction) |

| Moisture Resistance | Moderate (can swell) | Better (depending on grade and glue) |

| Edge Quality | Can be rough | Smoother, more uniform |

| Weight | Slightly heavier for same thickness | Slightly lighter for same thickness |

For many common applications like subflooring and wall sheathing, OSB performs adequately and offers significant cost savings, especially when on sale. Plywood may be preferred for applications requiring maximum strength, stability, or a smoother finish, but it comes at a higher price.

Other Engineered Wood Products

Beyond OSB and plywood, other engineered wood products are used in construction. These include particleboard, medium-density fiberboard (MDF), and laminated veneer lumber (LVL).

Particleboard

Particleboard is made from wood particles bonded together with resin. It is generally weaker and less moisture-resistant than OSB or plywood. It is typically used for furniture, shelving, and underlayment where structural strength is not a primary concern.

Its cost is usually lower than OSB, but its performance is also significantly less. It can crumble easily when wet.

Medium-Density Fiberboard (MDF)

MDF is made from wood fibers that are broken down and then reformed with wax and resin. It has a very smooth and uniform surface, making it excellent for painting and furniture making. MDF is denser and heavier than OSB and particleboard.

However, MDF can be susceptible to moisture damage and is not typically used for structural applications like sheathing or subflooring. Its cost is usually higher than OSB.

When to Choose OSB Over Alternatives

OSB is often the best choice when you need a cost-effective, strong, and stable panel product for structural applications. Its consistent manufacturing makes it predictable in terms of performance.

When a sale like OSB Plywood 1/2 Price at Lowe’s: Updated Cost Guide is available, it makes OSB an even more compelling option for projects like:

- Framing walls and roofs

- Creating subfloors

- Building sheds and garages

- DIY furniture or shelving where a painted finish is acceptable

If your project requires exceptional strength, moisture resistance, or a premium finish, you might consider plywood or other engineered woods. However, for general-purpose building, OSB often hits the sweet spot of performance and price, especially during significant sales.

Frequently Asked Questions

Question: What is the difference between OSB and plywood?

Answer: OSB is made from wood strands layered and pressed together, while plywood is made from thin wood veneers glued in alternating directions. OSB is generally more affordable and uses wood waste efficiently, while plywood offers superior strength and stability.

Question: Is OSB good for subflooring?

Answer: Yes, OSB is a very common and effective material for subflooring. It provides a strong, stable base for finished flooring like carpet, tile, or hardwood, and is generally more economical than plywood.

Question: Can OSB be used outdoors?

Answer: Some grades of OSB are designed for use in humid conditions, and when properly protected, it can be used in exterior applications. However, it is not as inherently moisture-resistant as some types of plywood and must be shielded from direct water exposure.

Question: How much weight can OSB hold?

Answer: The weight-bearing capacity of OSB depends on its grade and thickness. For example, 1/2 inch OSB typically supports around 40-50 pounds per square foot when used as subflooring over joists spaced 16 inches apart. Higher grades and thicker panels can support more.

Question: Is OSB cheaper than plywood at Lowe’s?

Answer: Typically, OSB is cheaper than plywood at Lowe’s and other retailers. However, during specific sales, like a 50% off OSB promotion, the price difference can become even more dramatic, making OSB a significantly better value.

Wrap Up

Taking advantage of sales like OSB Plywood 1/2 Price at Lowe’s: Updated Cost Guide can lead to significant savings. Know your project needs, verify sale details, and compare quality to ensure you get the best value. With this information, you’re ready to build smarter.