Cost of MDF vs Plywood: Essential Guide

For your DIY projects, plywood is often more durable and water-resistant than MDF, making it a better long-term investment despite a higher upfront cost. MDF is generally cheaper and offers a smoother surface for painting, but it’s less forgiving with moisture and structural stress.

Welcome to the workshop! As you start tackling new woodworking projects, you’ll quickly notice there are many material choices out there. Two of the most common are Medium-Density Fiberboard (MDF) and plywood. But which one is right for your project, and more importantly, for your budget? This can feel like a puzzle, especially when you’re just getting started. Don’t worry, I’m here to help you figure out the real cost difference between MDF and plywood, not just in dollars, but in value and suitability for your specific needs. Let’s break it down, simply and clearly, so you can make confident choices for your next DIY adventure.

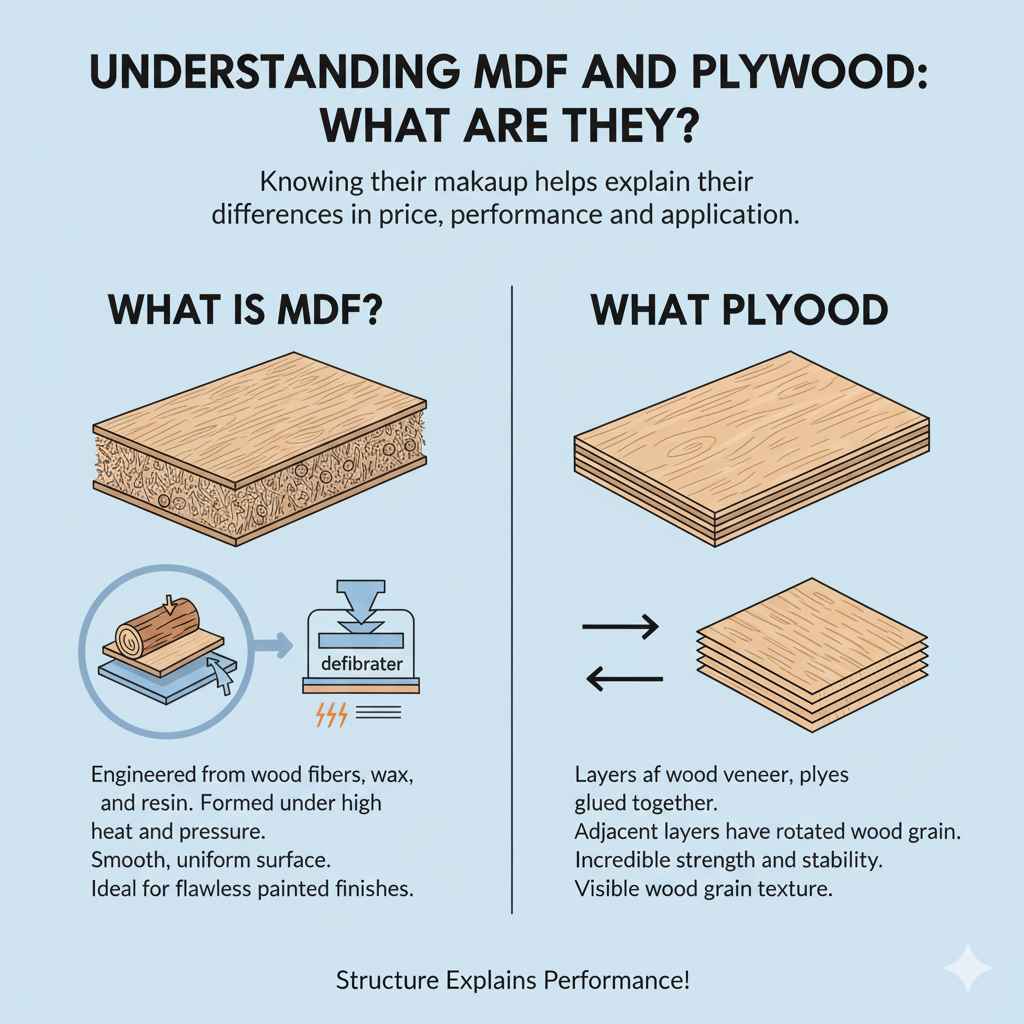

Understanding MDF and Plywood: What Are They?

Before we dive into costs, let’s get a basic understanding of what MDF and plywood are. Knowing their makeup helps explain their differences in price, performance, and application.

What is MDF?

MDF, or Medium-Density Fiberboard, is an engineered wood product. It’s made by breaking down hardwood and softwood into wood fibers, often in a “defibrator,” mixing them with wax binder and resin, and then forming panels by applying high temperature and pressure. Think of it like a very dense, smooth particleboard, but finer and stronger. Its smooth, uniform surface is a big reason why many DIYers love it for projects that need a flawless painted finish.

What is Plywood?

Plywood is also an engineered wood product, but it’s constructed differently. It’s made from thin sheets of wood veneer, also known as plies, that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. This cross-graining gives plywood incredible strength and stability. It’s like building with layers of strong paper, but much tougher! The number of plies and the type of wood used can vary, affecting its strength, appearance, and cost.

The Big Question: Cost of MDF vs Plywood

This is where many beginners get stuck! You see them side-by-side at the lumberyard, and the price tags can look quite different. Let’s look at the typical price ranges, keeping in mind that lumber prices can fluctuate based on location, demand, and the specific grade of material.

General Price Comparison

As a general rule, MDF is often more affordable than plywood for the same thickness, especially for common project grades. However, this isn’t always the case, and higher-grade plywood can certainly cost more than basic MDF.

Factors Influencing Cost

Several things influence the final price tag of both materials:

- Thickness: Thicker sheets naturally cost more. 3/4-inch sheets are generally more expensive than 1/2-inch sheets.

- Grade: Both MDF and plywood come in different grades that indicate their quality, appearance, and suitability for certain tasks. Higher grades mean higher costs.

- Wood Species (for Plywood): Plywood made from hardwoods like oak, maple, or birch is usually more expensive than plywood made from softer woods like pine or fir.

- Specialty Types: Moisture-resistant MDF, exterior-grade plywood, or flexible plywood will cost more than standard versions.

- Brand and Manufacturer: Some brands are known for higher quality, which can translate to a higher price.

- Where You Buy: Prices can vary between big box hardware stores, local lumberyards, and specialty woodworking shops.

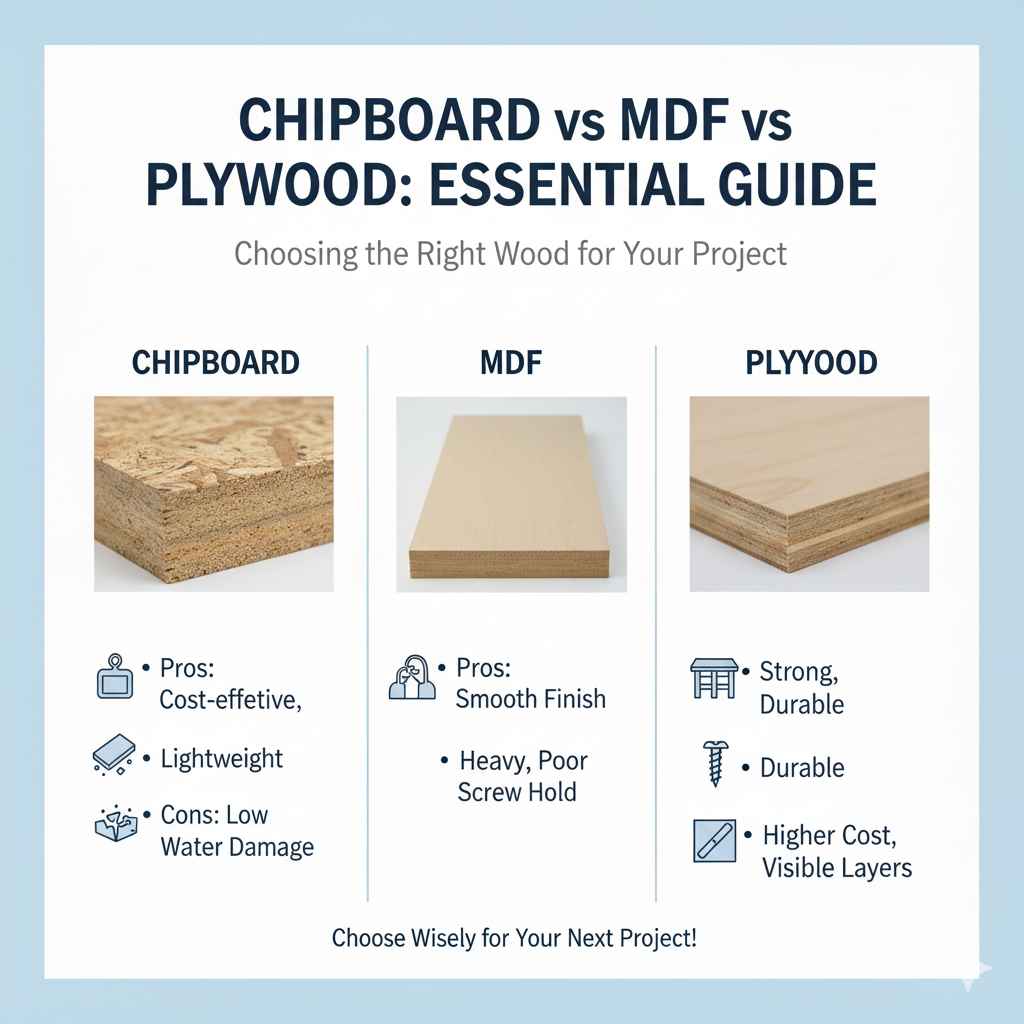

Pros and Cons: Beyond the Price Tag

The “cheaper” option isn’t always the best value. Understanding the strengths and weaknesses of each material will help you see where your money is best spent.

MDF: The Smooth Operator

MDF is fantastic for certain applications, and its lower price point is appealing. Let’s look at its advantages and disadvantages:

Pros of MDF:

- Smooth Surface: It’s incredibly smooth and uniform, making it ideal for painting. You won’t see any wood grain lines, which can be a huge plus for a flawless finish.

- Cost-Effective: Often cheaper than plywood, making it a budget-friendly choice for many projects.

- Stable: Doesn’t expand or contract with humidity changes as much as solid wood or some plywoods.

- Easy to Machine: Cuts cleanly and edges can be routed for a professional look.

- No Grain Patterns: Perfect for projects where you want a consistent, painted look, like cabinet doors or wainscoting.

Cons of MDF:

- Susceptible to Moisture: Standard MDF will swell and disintegrate if it gets wet. It’s not suitable for damp areas or outdoor projects unless treated or specially coated.

- Heavy: It’s denser and heavier than most plywoods of the same thickness.

- Poor Screw Holding: Screws can strip easily because there are no wood fibers to grip. You often need to pre-drill and use specialized techniques or glue.

- Dust: Cutting MDF creates a very fine dust that can be harmful if inhaled. Proper safety gear, especially a good dust mask and ventilation, is crucial.

- Can Sag: Under its own weight over long spans, MDF can sag more readily than plywood.

Plywood: The Strong Performer

Plywood brings strength and versatility to the table, making it a go-to for many DIYers. Here are its upsides and downsides:

Pros of Plywood:

- Strength and Durability: The cross-graining makes it very strong, resistant to cracking, shrinking, and warping. It’s excellent for structural components.

- Good Screw Holding: The layers of wood veneer provide better grip for screws and nails compared to MDF.

- Moisture Resistance (Varies): Exterior-grade plywood is designed to withstand moisture, making it suitable for outdoor or high-humidity applications. Interior grades are more susceptible but still generally better than standard MDF.

- Lighter Weight: Generally lighter than MDF, making it easier to handle and install.

- Variety of Finishes: Available with attractive wood veneers for projects where the finish is visible, like furniture or shelving.

- Stability: Less prone to bowing or warping than solid wood.

Cons of Plywood:

- Visible Grain: Wood grain patterns can be visible, especially on lower-grade plywood. This might not be ideal for a perfectly smooth painted finish without extra work.

- Edge Appearance: The layered edges can look “busy.” You might need to cover or finish them for a cleaner look.

- Cost: Can be more expensive than MDF, especially for higher grades or specific wood species.

- Splintering: Cheaper plywood can be prone to splintering, requiring careful cutting and sanding.

MDF vs Plywood: Which is Better for Specific Projects?

The “best” material depends entirely on what you’re making! Here’s a quick guide to help you choose:

Projects Best Suited for MDF:

- Cabinet Doors: The smooth, paint-ready surface is perfect for creating professional-looking cabinet fronts.

- Painted Shelving: For shelves that will be painted and not subjected to extreme weight or moisture.

- Wainscoting and Wall Paneling: Provides a smooth, consistent surface for decorative walls.

- Furniture with Painted Finishes: If you’re building a piece you intend to paint, MDF can be a great, cost-effective choice.

- Mouldings and Trim: Especially for simple, painted profiles.

Projects Best Suited for Plywood:

- Structural Shelving: Where strength and load-bearing capacity are key.

- Cabinet Boxes: The strength and stability make it ideal for the main structure of cabinets.

- Subflooring: Its strength and stability are essential for a solid subfloor.

- Outdoor Furniture or Structures: Use exterior-grade plywood for any project exposed to the elements.

- Workshop Jigs and Fixtures: Durability and stability are important here.

- Furniture with Visible Wood Grain or Natural Finishes: Birch, oak, or maple plywood can provide beautiful, finished surfaces.

- Drawers: Plywood offers the strength needed for moving parts.

Comparing Cost Sheet: A Practical Example

Let’s imagine you’re building a set of simple, painted shelves for your living room. You need to cover a wall space of 8 feet wide by 4 feet high, and you plan to have three shelves, each 8 feet long and 12 inches deep. We’ll assume a standard project requireing 3/4-inch thick material.

Scenario 1: Using MDF

- For shelves: You’ll need approximately 3 sheets of 4×8 MDF (one for each long shelf, and you’ll piece together narrower sections from others or use multiple pieces depending on design). Let’s estimate 3 sheets for ease.

- For supports/cleats (if needed): Another 1 sheet might be sufficient.

- Total MDF sheets: 4

- Estimated Cost (MDF @ $35/sheet): 4 sheets $35/sheet = $140

Scenario 2: Using Plywood

- For shelves: You’ll need material for 3 shelves, each 8 feet long. This might require cutting from larger sheets or using multiple pieces. Let’s assume you can get these out of 3 sheets of 4×8 construction-grade pine plywood.

- For supports/cleats: Another 1 sheet.

- Total Plywood sheets: 4

- Estimated Cost (Pine Plywood @ $45/sheet): 4 sheets $45/sheet = $180

In this simplified example, MDF comes out cheaper upfront. However, if your shelving project required a much more robust solution, or if you wanted a stained finish on the shelves, the cost of different plywood grades would shift the balance.

A Deeper Dive into Cost Considerations

Beyond the initial purchase price, think about the total cost of your project. This includes:

1. Tools and Supplies

Both MDF and plywood require tools for cutting, measuring, and fastening. However, MDF dust is particularly nasty, so investing in a good respirator is crucial. Plywood can sometimes require more careful edge finishing, which might mean purchasing edge banding or extra filler.

2. Finishing Materials

If you’re painting, MDF will require less prep work for a smooth finish than plywood. You might save on primer and paint by choosing MDF. If you plan to stain, plywood with a nice veneer is often the better and more cost-effective choice than trying to stain MDF (which doesn’t stain well anyway).

3. Durability and Longevity

This is where plywood often wins. If your project is something that needs to last, withstand daily use, or potentially encounter moisture, the higher initial cost of plywood can save you money in the long run by preventing costly repairs or replacements. Think of it as an investment in the lifespan of your creation.

4. Ease of Use and Waste

Sometimes, one material is easier to work with for a specific task, reducing your time and potential mistakes. If you make a mistake cutting plywood, you might be able to salvage the piece. A bad cut on MDF can be harder to fix invisibly. Efficient layout and cutting can minimize waste for both materials.

Safety First: Working with MDF and Plywood

No matter which material you choose, your safety in the workshop is paramount. I can’t stress this enough!

MDF Safety

- Dust Mask: Always wear a high-quality dust mask or respirator when cutting or sanding MDF. The fine particles can irritate your lungs and airways.

- Ventilation: Work in a well-ventilated area.

- Eye Protection: Safety glasses are a must to protect your eyes from flying debris.

- Hearing Protection: Power tools can be loud; protect your hearing.

Plywood Safety

- Sawdust: While MDF dust is finer and more irritating, all wood dust can be a health hazard. Use dust collection and a mask.

- Sharp Edges: Both materials can have sharp edges. Wear gloves if needed, and be mindful of splinters.

- Handling: Large sheets are heavy and can be unwieldy. Get help if you need to move them, and be aware of pinch points.

Frequently Asked Questions (FAQ)

Q1: Is MDF or plywood cheaper for a basic shelf?

Generally, MDF tends to be cheaper for a basic, painted shelf where moisture isn’t a concern. However, if the shelf needs to bear significant weight over a wide span, the added strength of plywood might be a better long-term value, even if it costs a bit more upfront.

Q2: Can I paint MDF or plywood?

Yes, both can be painted. MDF is often preferred for painted projects because of its perfectly smooth surface that doesn’t show wood grain. Plywood can also be painted, but you might need to fill the grain and wood knots for a perfectly smooth finish, especially on lower grades.

Q3: Which material is better for cabinet construction?

Plywood is generally the preferred material for cabinet boxes because of its superior strength, stability, and ability to hold screws well. For cabinet doors, especially if they are to be painted, MDF is a very popular choice due to its smooth surface.

Q4: Is MDF waterproof?

No, standard MDF is not waterproof. It will swell and lose its integrity when exposed to moisture. There are moisture-resistant MDF varieties available, but they are more expensive and still not entirely waterproof.

Q5: Can I use plywood outdoors?

You can use plywood outdoors if you select exterior-grade plywood, which is specifically designed to withstand moisture and weather. Standard interior plywood will delaminate and degrade quickly when exposed to the elements.

Q6: Which is stronger, MDF or plywood?

Plywood is generally stronger and more durable than MDF, especially in terms of its ability to resist bending and to hold fasteners. The cross-laminated construction of plywood gives it excellent structural integrity.

Q7: Does MDF or plywood hold screws better?

Plywood typically holds screws better than MDF. The wood fibers in plywood provide a stronger grip for screws and nails. With MDF, screws can easily strip out, and it’s often recommended to use adhesives or specialized techniques like inserting wood dowels for better screw retention.

Conclusion: Making the Smart Choice for Your Project

Deciding between MDF and plywood isn’t just about the price tag at the lumberyard; it’s about choosing the right tool for the job. While MDF often wins the battle for the lowest initial cost and provides a dream surface for painting, plywood shines when it comes to strength, durability, and resistance to moisture. Think about the demands you’ll place on your project, the finish you desire, and how long you want it to last.

For many DIY beginners, starting with MDF for painted projects like simple shelves or cabinet doors can be a budget-friendly way to achieve professional-looking results. On the other hand, if you’re building anything that needs to hold significant weight, withstand outdoor conditions, or be glued and screwed for maximum strength (like drawers or cabinet frames), investing in plywood will likely serve you much better in the long run. By understanding these differences, you’re now well-equipped to make informed decisions, save money on your projects, and build with confidence. Happy building!