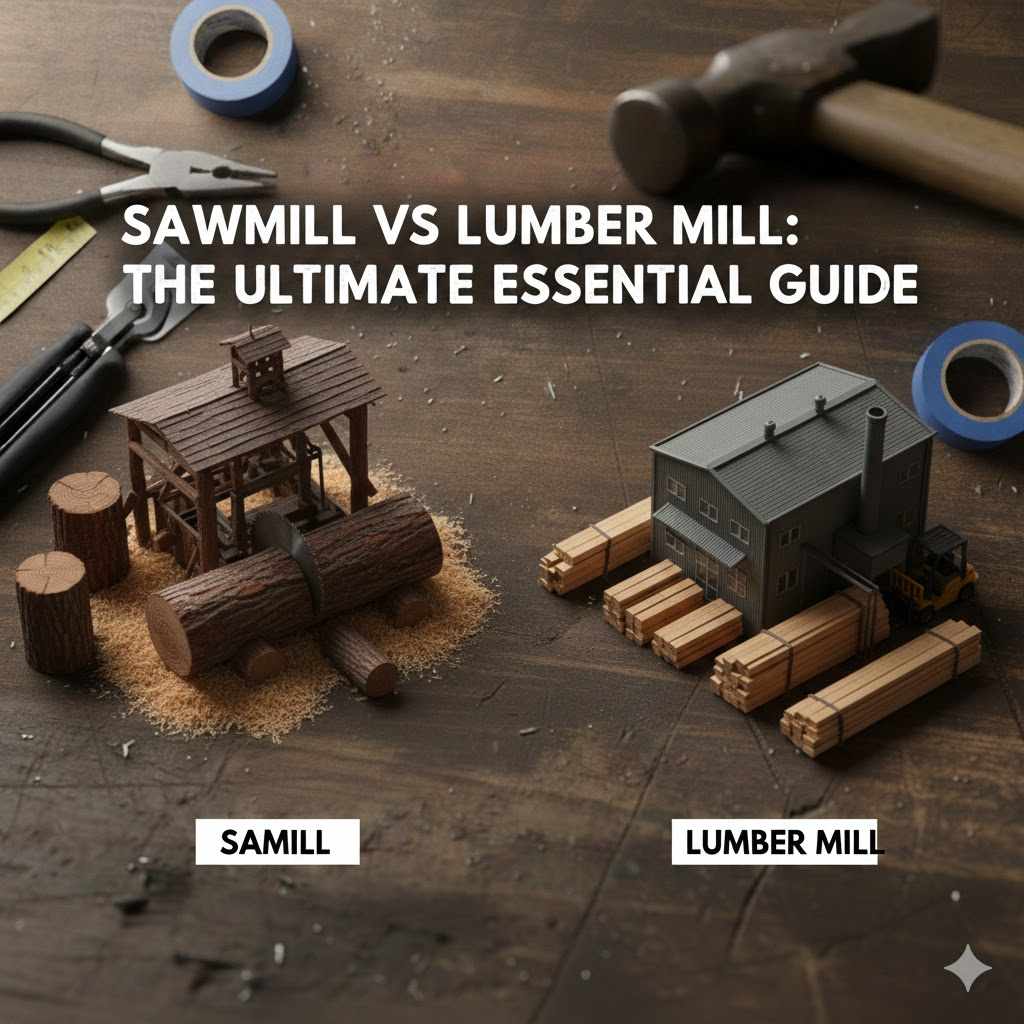

Sawmill Vs Lumber Mill: The Ultimate Essential Guide

A sawmill is where raw logs are cut into rough planks, slabs, or beams. A lumber mill is a large, industrial facility that takes this a step further—it saws, dries, planes, and grades the wood into standardized, finished products like the 2x4s you buy at a hardware store. Essentially, a sawmill makes the raw material, and a lumber mill makes the finished product.

Hello there! Md Meraj here, your friendly guide in the workshop. If you’ve ever felt a bit puzzled hearing the terms “sawmill” and “lumber mill,” you’re not alone! It’s one of those things that sounds simple, but the difference is huge for any woodworking project. It can feel frustrating when you’re just trying to figure out where to get the right wood.

But don’t you worry. We’re going to clear this up together, nice and easy. I’m here to walk you through exactly what each one is, what they do, and how to know which one is right for you. By the end of this guide, you’ll feel confident choosing the perfect wood for your next creation. Let’s get those saws of knowledge spinning!

What Exactly Is a Sawmill?

Imagine a place, big or small, where the journey from a fallen tree to usable wood begins. That’s a sawmill. At its core, a sawmill is a facility—or even just a single machine—designed to cut logs lengthwise into boards, planks, or beams. Think of it as the first major stop for a log after it leaves the forest.

The key word here is “rough.” The wood that comes out of a sawmill is called rough-sawn lumber. It’s not smooth, it’s not perfectly straight, and its dimensions can be a little inconsistent. This is wood in its most honest, rustic form.

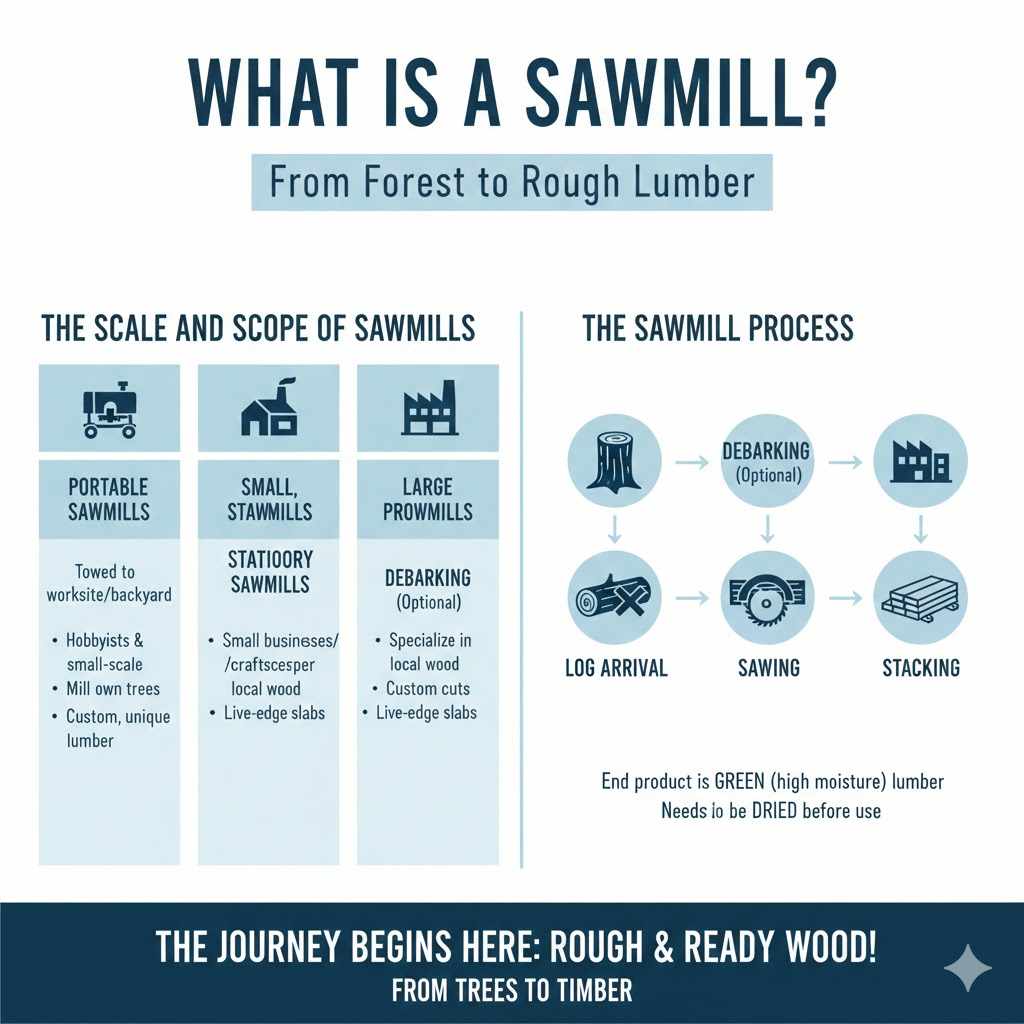

The Scale and Scope of Sawmills

One of the neatest things about sawmills is how varied they are. They come in all shapes and sizes:

- Portable Sawmills: These are amazing little machines that can be towed right to a worksite or a homeowner’s backyard. Hobbyists and small-scale woodworkers love them because they can mill their own trees or buy logs locally to create custom lumber. It’s a fantastic way to get truly unique wood.

- Small, Stationary Sawmills: These are often run by small businesses or dedicated craftspeople. They might specialize in a certain type of local wood, like beautiful black walnut or cherry. They cater to furniture makers and builders who need custom cuts or special pieces like live-edge slabs.

- Large Production Sawmills: These are bigger operations, but their main job is still the same: breaking down big logs into smaller, more manageable but still rough pieces. These larger sawmills often supply their lumber to even bigger facilities—the lumber mills.

The Sawmill Process: Simple and Direct

The process at a typical sawmill is straightforward and focuses on one primary goal: cutting logs.

- Log Arrival: A log is brought to the mill.

- Debarking (Sometimes): The bark may be removed to protect the saw blade and make cleaner cuts.

- Sawing: The log is passed through a large saw (like a bandsaw or circular saw) to cut it into slabs or boards.

- Stacking: The fresh, wet, rough-sawn lumber is stacked with spacers between each board to allow for air drying.

The end product is green (high moisture content) lumber that needs to be dried before it can be used for most projects. It’s beautiful and full of character, but it’s not ready for fine furniture just yet.

What Exactly Is a Lumber Mill?

Now, let’s step into the world of the lumber mill. If a sawmill is a rustic workshop, a lumber mill is a massive, high-tech factory. A lumber mill is an industrial facility that processes logs or rough-sawn lumber into finished, standardized building materials. When you go to a home improvement store and buy a stack of 2x4s that are all identical, you’re buying a product from a lumber mill.

The primary goal of a lumber mill is to create consistency, efficiency, and wood that is ready to be used in construction right away. It’s all about mass production of predictable, reliable lumber.

The Scale and Scope of Lumber Mills

Unlike sawmills, lumber mills are almost exclusively large-scale industrial operations. You won’t find a portable lumber mill you can tow behind your truck! These facilities are built to handle enormous volumes of wood and operate with a high degree of automation. They are the backbone of the construction industry, supplying the lumber needed to build houses, decks, and commercial buildings.

The Lumber Mill Process: A Multi-Step Transformation

The journey of wood through a lumber mill is much more complex than at a sawmill. It involves several precise stages to turn a rough board into a finished product.

- Primary Breakdown: Just like a sawmill, it starts with sawing logs into rough boards. This is often done at incredibly high speeds with advanced machinery.

- Kiln Drying: This is a critical step. The rough-sawn lumber is placed into huge ovens called kilns. These kilns carefully control temperature and humidity to dry the wood to a specific, stable moisture content (usually between 6-12%). This process prevents the wood from warping or shrinking dramatically after it’s been used in a project. According to the U.S. Forest Service, proper drying is essential for the stability and strength of the final wood product.

- Planing and Surfacing: After drying, the boards are fed through a planer. This machine has sharp cutting heads that smooth all four sides of the board (a process called S4S, or “surfaced four sides”). This is what gives dimensional lumber its smooth feel and consistent measurements.

- Grading: Trained inspectors or automated scanners examine each piece of lumber for defects like knots, splits, and grain patterns. They then stamp the board with a grade that indicates its quality and strength. This grade helps builders know if a piece of wood is suitable for structural use.

- Trimming and Bundling: Finally, the boards are trimmed to standard lengths (8 feet, 10 feet, etc.), bundled together, and shipped off to distributors and stores.

Sawmill vs. Lumber Mill: Key Differences at a Glance

Sometimes a simple chart is the best way to see how things stack up. Let’s break down the main differences between these two workhorses of the wood world.

| Feature | Sawmill | Lumber Mill |

|---|---|---|

| Scale of Operation | Can be very small (portable) to medium-sized. Often local and owner-operated. | Almost always a large, industrial, and highly automated factory. |

| Primary Process | Cuts logs into rough-sawn boards, slabs, or beams. | Cuts, dries in a kiln, planes smooth, and grades wood into a finished product. |

| End Product | Rough, unseasoned (green) lumber with natural character. Often has saw marks. | Smooth, seasoned (kiln-dried), and graded dimensional lumber (e.g., 2x4s, 1x6s). |

| Consistency | Dimensions can vary slightly. Each board is unique. | Highly consistent and standardized. A 2×4 is always the same size. |

| Moisture Content | High (green). The wood needs to be dried by the user (air-drying or kiln-drying). | Low and stable, typically between 6-12%. Ready to use immediately. |

| Best Use Case | Custom furniture, live-edge tables, rustic projects, post and beam construction. | Residential and commercial construction, framing, decking, and any project needing standard sizes. |

| Accessibility | Very accessible to hobbyists and DIYers. You can hire a portable sawmill or visit a local one. | Not accessible to the general public. You buy their products through retailers. |

Which One Should You Choose for Your Project?

Alright, this is the most important part! Now that you know the difference, how do you decide where to get your wood? It all comes down to what you are building. Let’s make this simple.

When to Head to a Sawmill (or Hire a Portable One)

Think “character” and “custom.” A sawmill is your best friend when your project calls for something special that you can’t find on a store shelf.

- For Live-Edge Projects: If you’re dreaming of a stunning live-edge dining table, a river table, or a rustic mantelpiece, a sawmill is the place to go. They specialize in cutting large slabs that preserve the natural edge of the tree.

- When You Need Custom Dimensions: Building custom bookshelves and need a board that’s 14 inches wide? Or maybe a thick, chunky beam for a timber frame? A local sawmill can cut wood to almost any dimension you need, which is impossible to find at a big-box store.

- If You Have Your Own Logs: Did a beautiful old tree fall on your property? Don’t turn it into firewood! A portable sawmill service can come to you and mill that tree into a priceless stack of lumber that you can use for years to come. It’s incredibly rewarding and sustainable.

- For Rustic Charm: If you love the look of saw marks and the natural, unrefined texture of wood, then rough-sawn lumber from a sawmill is perfect. It adds a warm, authentic feel to projects like accent walls, barn doors, and outdoor structures.

When to Buy From a Lumber Mill (via Your Local Store)

Think “structure” and “standard.” Lumber mill products are all about predictable performance and ease of use for construction.

- For Framing and Construction: If you’re building a shed, framing a wall, or constructing a deck, you need dimensional lumber from a lumber mill. These boards are graded for strength, kiln-dried for stability, and uniformly sized, making the construction process fast and reliable.

- When You Need Ready-to-Use Wood: Don’t have the time or the tools to dry and flatten rough lumber? Finished lumber from a lumber mill is ready to be cut and assembled right away. This is a huge time-saver for most DIYers.

- For Predictable Results: When you’re following a building plan that calls for standard materials (like 2x6s and 4x4s), using lumber from a lumber mill ensures that everything will fit together perfectly.

- For Convenience: Let’s be honest—it’s incredibly convenient to drive to your local hardware store and pick up exactly what you need. Lumber mills make wood accessible to everyone, everywhere.

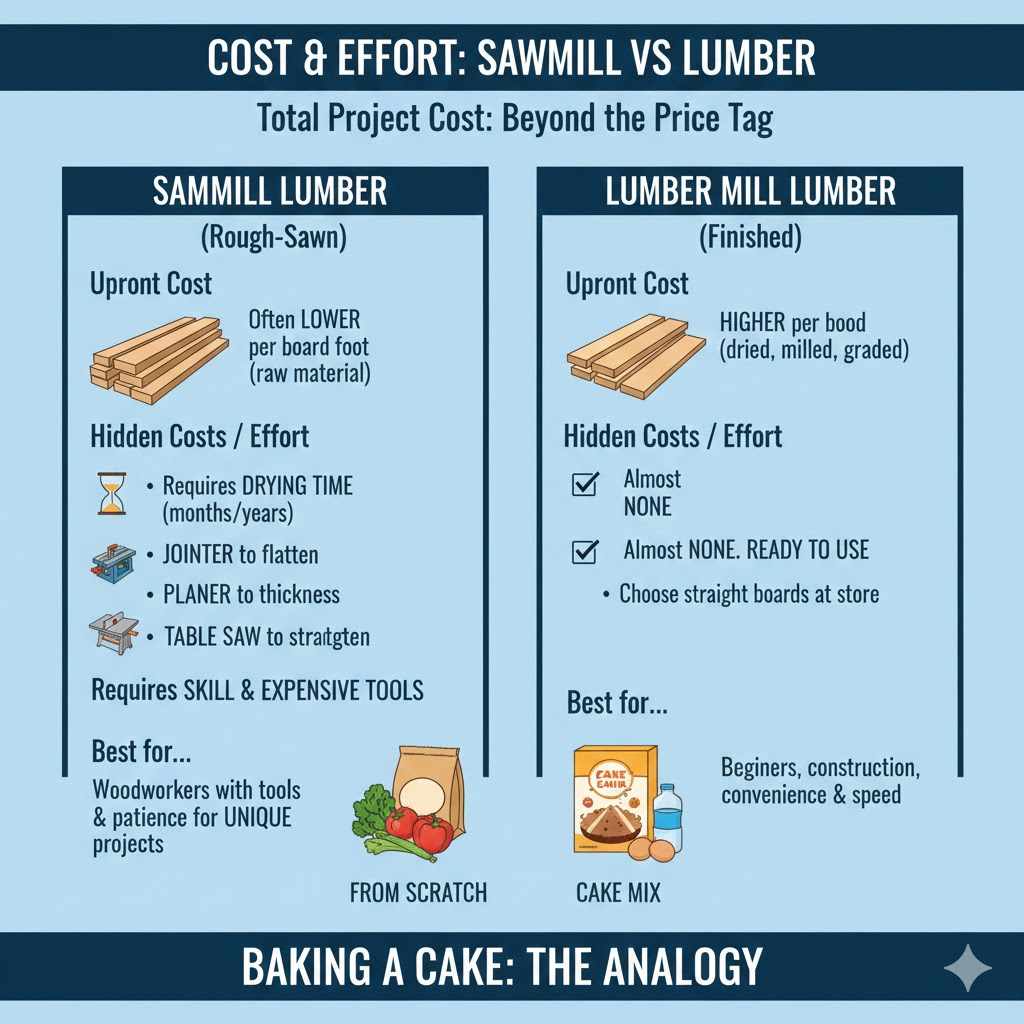

The Cost and Effort: A Quick Comparison

It’s tempting to think that rough-sawn wood from a sawmill is always cheaper, and while that’s often true per board foot, it’s not the whole story. You have to consider the “total project cost,” which includes your time and effort.

| Factor | Sawmill Lumber (Rough-Sawn) | Lumber Mill Lumber (Finished) |

|---|---|---|

| Upfront Cost | Often lower per board foot. You’re buying raw material. | Higher per board foot. You’re paying for drying, milling, and grading. |

| Hidden Costs / Effort | Requires drying time (can be months or years), a jointer to flatten one face, a planer to thickness it, and a table saw to straighten the edges. This requires skill, time, and expensive tools. | Almost none. It’s ready to use. The only “effort” is choosing good, straight boards at the store. |

| Best for… | Woodworkers with the tools and patience to process raw lumber for unique, high-quality projects. | Beginners, construction projects, and anyone who values convenience and speed. |

A good way to think about it is this: buying from a sawmill is like buying fresh vegetables and flour to bake a cake from scratch. Buying from a lumber mill is like buying a cake mix where you just need to add eggs and water. Both can result in a great cake, but the process, effort, and starting point are very different!

Frequently Asked Questions (FAQ)

1. Can I use a sawmill myself?

Yes, you can! You can purchase a personal-sized bandsaw mill for hobby use. Alternatively, you can hire a professional with a portable sawmill to come to your property and mill your logs for you. It’s a great option for turning fallen trees into usable lumber.

2. Is lumber from a sawmill better quality?

Not necessarily “better,” but often “different.” Sawmill lumber can be of exceptionally high quality, especially if you’re selecting specific logs for their grain or figure. However, it’s ungraded and unseasoned. Lumber mill wood is graded for structural quality, making it more reliable for construction. For furniture, a carefully selected piece from a sawmill might be far more beautiful.

3. Where does the wood at Home Depot or Lowe’s come from?

The wood at large home improvement stores comes from large, industrial lumber mills. These mills produce massive quantities of standardized lumber that are distributed across the country.

4. What does “dimensional lumber” mean?

Dimensional lumber is wood that has been milled to standard, finished sizes, like 2×4, 2×6, or 4×4. A confusing part for beginners is that the names are “nominal.” For example, a 2×4 is actually 1.5 inches by 3.5 inches after it has been dried and planed smooth. The name refers to its rough-sawn size. For more information on this, Penn State Extension has a great article that explains it clearly.

5. What does “kiln-dried” mean?

Kiln-dried means the wood has been put in a large, heated chamber (a kiln) to speed up the drying process and reduce its moisture content to a stable level. This is crucial because it minimizes the chances that the wood will warp, twist, or shrink after you’ve built something with it.

6. Why is rough-sawn lumber thicker than finished lumber with the same name?

A rough-sawn 2×4 from a sawmill will actually be 2 inches by 4 inches. When a lumber mill turns it into a finished board, they dry it (which causes some shrinkage) and then plane all four sides smooth. This removal of material is what reduces the final dimensions to 1.5″ x 3.5″.

7. Is it cheaper to have my own logs milled?

It can be! The cost of hiring a portable sawmill is often much less than buying the equivalent amount of lumber, especially if it’s a valuable hardwood. However, you have to factor in the cost and time of stacking, drying, and processing the rough lumber yourself before it’s usable.

Conclusion: The Right Wood for the Right Job

So there we have it! The mystery of the sawmill versus the lumber mill is solved. At the end of the day, neither one is better than the other—they simply serve two very different, but equally important, roles in the world of wood. A sawmill is your gateway to the raw, untamed character of a tree, perfect for those unique projects that tell a story. A lumber mill is your dependable partner for construction, providing the strong, stable, and standardized wood that builds our homes and our communities.

Understanding this difference is a huge step forward in your woodworking journey. It empowers you to think critically about your materials, to plan your projects more effectively, and to find the perfect piece of wood for whatever you dream up. Whether you’re grabbing a stack of 2x4s for a new workbench or visiting a local sawyer to find a majestic slab for a table, you now know the story behind that wood. Happy building!