What is MDF Board: Unveiling Its Uses & Benefits

MDF board is an engineered wood product made by breaking down wood residuals into fibers, combining with wax and resin, then forming into panels under high temperature and pressure. Due to its high density and composite material, MDF is widely used in residential and commercial construction for furnishing, cabinets, decorative items, doors, flooring, and soundproofing.

While MDF is not as durable as solid wood and can absorb water quickly, it is a cost-effective option for projects that require a readily available material. Understanding the differences between MDF and solid wood can help in making an informed decision based on the specific needs of the project.

Introduction To MDF Board

MDF board, or medium-density fiberboard, is an engineered wood product made by breaking down hardwood or softwood residuals into wood fiber, combining it with wax and a resin binder, and forming it into panels with high temperature and pressure. It is denser than plywood and commonly used in furniture, cabinets, and decorative items due to its high density and composite materiality.

What Is Mdf?

Medium-density fibreboard (MDF) is a type of engineered wood product that is created by breaking down hardwood or softwood residuals into wood fibers. These fibers are then combined with wax and a resin binder, and formed into panels by applying high temperature and pressure.

Composition: Wood Fibers, Wax, And Resin

The composition of MDF board consists of wood fibers, which are the main ingredient. These fibers are mixed with wax and a resin binder to create a strong and durable material. The wax is added to the mixture to make the MDF more moisture-resistant, while the resin binder is used to hold the fibers together.

MDF is generally denser than plywood, making it a popular choice for furniture construction and other applications where strength and durability are important.

Advantages Of MDF Board

MDF board has several advantages over other types of wood products. Here are some of the advantages of MDF:

- MDF is cheaper than solid wood and plywood

- MDF is more uniform in density and thickness than natural wood

- MDF is easier to paint and finish than natural wood

- MDF has a smooth, consistent surface that is ideal for veneering or laminating

- MDF is a sustainable and eco-friendly alternative to natural wood

Disadvantages Of MDF Board

While MDF board has many advantages, it also has some disadvantages that should be considered. Here are some of the disadvantages of MDF:

- MDF is comparatively weaker than wood, and has a shorter lifespan compared to wood

- MDF can crack or split under extreme stress

- MDF absorbs water more quickly than wood, making it unsuitable for outdoor use

MDF board is a popular and versatile material that is used in a variety of applications, from furniture construction to flooring and soundproofing. While it has some disadvantages compared to natural wood, it also has many advantages that make it a popular choice for builders and designers.

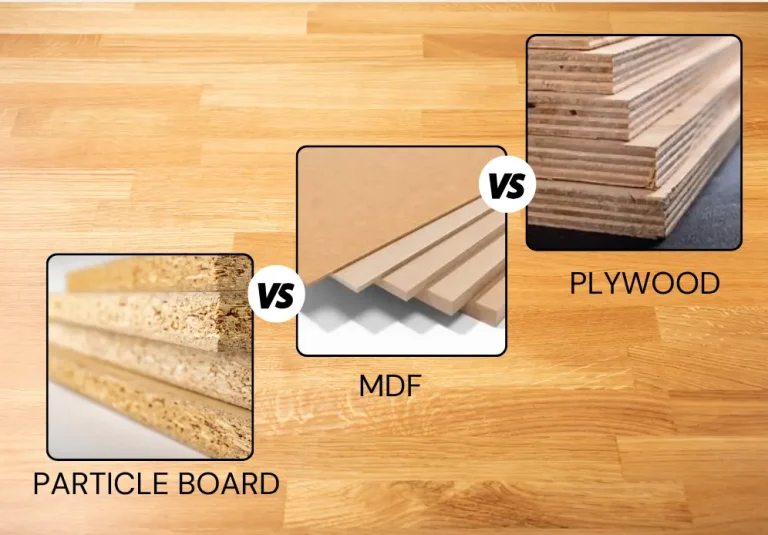

Mdf Vs. Plywood

Medium-density fiberboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fiber, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure.

MDF is generally denser than plywood and is commonly used in furnishing, cabinets, shelves, roofing materials, decorative items, doors, frames, flooring, and soundproofing due to its high density and composite materiality.

Material Comparison

When it comes to choosing the right material for your woodworking projects, two popular options are MDF (medium-density fiberboard) and plywood. While both materials have their own unique characteristics, it’s important to understand the differences between them in order to make an informed decision.

Pros And Cons

Let’s take a closer look at the pros and cons of MDF and plywood:

| MDF | Plywood |

|---|---|

|

|

It’s important to consider these factors and weigh them against your specific project requirements before making a decision. If cost and a smooth surface are your main concerns, MDF may be the better choice. However, if strength and durability are a priority, plywood might be the more suitable option.

Ultimately, the decision between MDF and plywood depends on your project’s needs, budget, and desired aesthetics. Both materials have their own advantages and disadvantages, so it’s important to carefully evaluate your options before making a final decision.

Mdf Vs. Solid Wood

Medium-density fibreboard (MDF) is an engineered wood product made from wood fibre, resin, and wax, offering a cost-effective alternative to solid wood. MDF is denser than plywood and suitable for various applications like furniture, cabinets, and decorative items.

When it comes to choosing the right type of wood for your project, two options that often come up are MDF (Medium-density fibreboard) and solid wood. While both have their advantages and disadvantages, it’s important to understand the differences between the two before making a decision.

Budget and Availability

One of the biggest advantages of MDF over solid wood is its affordability. MDF is made by breaking down hardwood or softwood residuals into wood fibre, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure. This process makes MDF a cost-effective option compared to solid wood.

Additionally, MDF is readily available at most hardware stores, making it an easy material to find for your project. On the other hand, solid wood can be more expensive and may not be as readily available depending on the type of wood you’re looking for.

Aesthetics and Durability

When it comes to aesthetics and durability, solid wood has the upper hand. Solid wood has a natural beauty that can’t be replicated by MDF. It’s also more durable and can last longer than MDF. However, it’s important to note that solid wood can be more susceptible to warping and cracking due to changes in temperature and humidity.

MDF, on the other hand, can be painted or stained to mimic the look of solid wood, but it won’t have the same natural beauty. MDF is also more susceptible to moisture damage and can break down over time if not properly maintained.

In conclusion, the decision between MDF and solid wood ultimately depends on your project’s needs and budget. While MDF is a cost-effective option that’s readily available, solid wood offers natural beauty and durability. Consider the aesthetic appeal and durability requirements of your project before making a decision.

Key Uses Of Mdf Board

Medium-density fibreboard (MDF) is a versatile material that finds various applications in construction and interior design due to its high density and composite materiality.

In Furniture

- MDF is commonly used in furniture manufacturing, such as cabinets, shelves, doors, and frames, due to its durability and smooth surface for painting.

- It provides a cost-effective alternative to solid wood for budget-friendly furniture projects.

For Decorative Items

- MDF board is popular for crafting decorative items like photo frames, wall art, and intricate designs due to its ease of shaping and painting.

- Its smooth surface allows for intricate detailing and customization for decorative purposes.

Flooring And Roofing

- MDF is used in flooring materials as an underlayment for laminate or hardwood floors to provide a smooth and stable base.

- It is also utilized in roofing applications for its structural strength and resistance to moisture.

Benefits Of Mdf

Medium Density Fiberboard (MDF) is a versatile building material that offers various benefits, making it a popular choice for many applications. Let’s explore some of the key advantages of using MDF:

Cost-effectiveness

MDF is an affordable option for projects that require a durable and uniform material. Its cost-effectiveness makes it a practical choice for budget-conscious individuals and businesses.

Workability

One of the significant benefits of MDF is its exceptional workability. It can be easily cut, drilled, and shaped, allowing for intricate designs and precise customization. This makes it a preferred choice for intricate carpentry and woodworking projects.

Uniform Finish

When it comes to achieving a smooth and uniform finish, MDF excels. Its dense composition ensures that it provides a consistent surface for painting, veneering, or laminating, resulting in a professional and polished look.

Limitations Of Mdf Board

When considering the use of Medium Density Fiberboard (MDF) in construction and furniture, it’s important to be aware of its limitations. While MDF offers various benefits, it also comes with certain drawbacks that need to be taken into account for a successful and durable end product.

Moisture Sensitivity

MDF is highly susceptible to moisture and can swell or deform when exposed to water or high humidity. This makes it unsuitable for use in areas prone to dampness or moisture, such as bathrooms or outdoor applications. It’s crucial to protect MDF from moisture to prevent deterioration and maintain its structural integrity.

Strength Concerns

Compared to solid wood, MDF is relatively weaker and less durable. It is prone to cracking, splitting, and damage under excessive stress or heavy loads. Therefore, it may not be suitable for applications that require high structural strength or need to withstand heavy use over time. Understanding its limitations in terms of strength is essential for using MDF appropriately in various projects.

Waterproofing Mdf

Techniques And Materials

Waterproofing MDF involves using appropriate techniques and materials to protect the board from moisture damage. The key is to create a barrier that prevents water from penetrating the MDF.

When And How To Waterproof

Knowing when and how to waterproof MDF is crucial to ensure its longevity and durability. It’s essential to apply the waterproofing treatment at the right stage of the project and with the correct methods to achieve the best results.

Mdf In Construction And Design

MDF, or medium-density fiberboard, is a versatile material that has found widespread use in both construction and design. Its unique properties make it a popular choice for modern construction and innovative design applications, offering a cost-effective and durable solution for various projects.

Modern Construction Uses

Modern construction projects often rely on MDF for its versatility and strength. From interior fittings to structural components, MDF is utilized in a wide range of applications. Its consistent density and smooth surface make it ideal for creating furniture, cabinetry, and decorative moldings. Additionally, MDF is frequently used for wall paneling, flooring underlayment, and interior trim due to its uniform composition and ease of shaping.

Innovative Design Applications

When it comes to innovative design, MDF offers endless possibilities. Its ability to be machined, painted, and laminated makes it a popular choice for creating intricate designs and custom elements. From intricate carvings to sleek, modern furniture, MDF provides designers with a versatile medium for bringing their visions to life. Furthermore, its stability and resistance to warping make it suitable for creating large-scale installations, such as exhibition displays and architectural features.

Frequently Asked Questions

What Are The Disadvantages Of Mdf Board?

MDF board has some disadvantages such as being weaker and having a shorter lifespan compared to wood. It can also crack or split under extreme stress and absorb water more quickly. MDF is not waterproof and is not as strong or beautiful as solid wood.

What Is Mdf Board Good For?

MDF board is good for various purposes due to its high density and composite material. It is commonly used for furnishing residential and commercial construction, cabinets and shelves, roofing materials, decorative items, doors and frames, flooring, and soundproofing. However, it is not waterproof and has a shorter lifespan compared to solid wood.

Is Mdf Board Better Than Wood?

MDF board is an engineered wood product made by breaking down hardwood or softwood residuals into wood fiber, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure.

It is denser than plywood but has a shorter lifespan compared to solid wood. The decision between MDF vs. solid wood depends on your project’s needs.

Are Mdf Boards Waterproof?

No, MDF boards are not waterproof. They are made of wood fiber, resin, and wax, which makes them moisture resistant but not completely waterproof. MDF can absorb water if exposed for a short period, causing it to swell and become unusable.

Conclusion

Medium-Density Fiberboard (MDF) is a versatile engineered wood product with various applications. While MDF may not be as durable as solid wood, it offers affordability and adaptability for different projects. Understanding the advantages and disadvantages of MDF can help you make informed decisions for your woodworking needs.