Wood Screw Shear Strength Calculator: Maximize Your Build

To calculate wood screw shear strength, use the formula: Ultimate shear strength = [Force] / [cross-sectional area]. This measures the force a fastener can handle from the sides.

Wood screws have minimal shear strength compared to nails, which have more elasticity to bend under pressure. Understanding shear strength is essential for determining the appropriate fastener for a specific application. When selecting the right fastener for woodworking projects, it’s crucial to consider shear strength.

Wood screws may not be suitable for applications requiring high shear strength, such as heavy load-bearing structures. By calculating shear strength, you can ensure the safety and stability of your woodworking projects. It’s also important to refer to manufacturer specifications for the shear strength of specific fasteners and materials. With this knowledge, you can make informed decisions when selecting wood screws for your projects.

Introduction To Wood Screw Shear Strength

Wood screw shear strength is the amount of force a screw can handle from the sides. Unlike nails, screws have very little shear strength and do not bend easily under pressure. It’s important to consider shear strength when choosing between wood screws and nails for a project. Wood screws provide better holding power and are less likely to pull out under load compared to nails.

When it comes to fastening heavy loads or working with hardwoods, understanding the shear strength of wood screws is essential for ensuring the stability and durability of the construction. Calculating the shear strength of a wood screw involves determining the ultimate shear strength based on the force applied and the cross-sectional area of the screw. Manufacturers typically provide shear strength values for their fasteners, which can be referenced for specific applications.

Shear Strength Basics

Shear strength refers to the amount of force that a fastener, such as a wood screw, can handle from the sides. Unlike nails, screws have less elasticity, which means they have limited shear strength. When external forces are applied to the sides of a nail, it can bend slightly to accommodate the pressure. However, screws have minimal flexibility and are more prone to breaking or shearing under excessive loads.

Shear stress is the force per unit area that leads to the deformation or failure of a material when applied parallel to its surface. In the case of wood screws, shear stress occurs when the forces acting on the screw cause it to break or separate at the point of connection.

Several factors can affect the shear strength of wood screws, including:

- Thread design and pitch

- Screw material and hardness

- Diameter and length of the screw

- Type of wood and its density

- Pre-drilling or pilot hole size

Considering these factors is crucial when determining the shear strength of wood screws for specific applications or calculating load-bearing capacities.

Calculating Shear Strength

Wood screws have shear strength which is the amount of force they can handle from the sides. Unlike nails, screws have very little shear strength and cannot bend under pressure. The shear strength of a wood screw can be calculated using the formula: Ultimate shear strength = [Force] / [cross sectional area]. It’s important to look up the shear strength of a fastener on the manufacturer’s website. Additionally, the Factor of Safety can be calculated using the formula:

Factor of Safety = ultimate stress / allowable stress. To determine the shear capacity of lag screws in wood, a connection calculator can be used, which takes into account the type of fastener, dimensions, and number of shear planes. For bolt or pin in single shear stress calculations, an equation and calculator are available to input the shear force and bolt/pin diameter. Finally, a load calculator can be used to find the tensile, yield, proof, and estimated shear strengths of bolts.

Wood Screw Shear Strength Calculator

Wood screws are widely used in woodworking projects and it’s important to know their shear strength. Shear strength is the amount of force that a fastener can withstand from the sides. Unlike nails, screws have very little elasticity and can’t bend to accommodate pressure.

So, how can you calculate the shear strength of a wood screw? The ultimate shear strength can be calculated by dividing the force by the cross-sectional area of the screw. You can usually find the shear strength of a fastener on the manufacturer’s website.

To use a wood screw shear strength calculator, you need to enter the type of fastener (bolt, lag screw, or nail), its dimensions, and the number of shear planes (single or double). The calculator will then give you the maximum force the fastener can handle without breaking.

Remember to always check the shear capacity of lag screws in wood before using them in your project. You can use an online calculator or consult with a professional to ensure the safety and durability of your woodworking project.

Materials And Wood Screw Selection

Wood screws are commonly used for fastening wood materials due to their high holding power and ease of installation. When selecting the appropriate wood screws for a particular application, it is important to consider the types of wood screws available in the market. The three most common types of wood screws are:

- Flathead screws: These screws have a countersunk head that sits flush with the surface of the wood.

- Panhead screws: These screws have a rounded head that protrudes above the surface of the wood.

- Ovalhead screws: These screws have an oval-shaped head that sits flush with the surface of the wood.

Additionally, it is crucial to take into account the material properties of the wood and the screws being used. Shear strength is an essential factor to consider when dealing with wood screws. Shear strength is the amount of force a fastener can handle from the sides. As screws have very little shear strength, it is important to calculate the shear stress of a screw before installation. Calculating the shear stress is necessary to ensure that the screw can handle the required amount of force without breaking or damaging the wood material.

Factors Of Safety

Wood Screw Shear Strength Calculator is a tool used to determine the shear strength of wood screws. It calculates the amount of force a screw can handle from the sides, taking into account factors such as elasticity and shear capacity.

This calculator helps ensure the safety and stability of structures built with wood screws.

Defining Factor of Safety: The factor of safety is a ratio that compares the maximum stress that a material can handle to the expected stress that will be applied. It is important to use a factor of safety in engineering to ensure that structures and components can handle loads without failing.

Applying Factor of Safety in Calculations: In the case of wood screw shear strength, calculating the shear stress of a screw involves determining the ultimate shear strength of the screw and comparing it to the expected shear stress that will be applied. By using a factor of safety, engineers can ensure that the screw can handle the expected load without failing. The Wood Screw Shear Strength Calculator takes into account various factors such as the type and dimensions of the screw, as well as the number of shear planes, to provide accurate calculations of shear capacity.

Lag Screws And Shear Capacity

Easily determine the shear capacity of lag screws in wood with the Wood Screw Shear Strength Calculator. This tool helps calculate the amount of force a fastener can handle from the sides, providing essential information for wood fastening applications.

| Do wood screws have shear strength? |

| Shear strength is the amount of force a fastener can handle from the sides. A nail has more elasticity than a screw, which means as forces are pushed against the sides of a nail, the nail can bend slightly to accommodate these pressures. However, screws have very little shear strength. |

| Comparing Lag Screws to Wood Screws |

| Lag screws, also known as lag bolts, are larger than wood screws and have a more aggressive thread pattern. They are designed to be used in heavier applications that require more strength and durability. When comparing lag screws to wood screws, lag screws have a higher shear capacity due to their larger size and thread pattern. |

| Calculating Lag Screw Shear Strength |

| The shear strength of a lag screw can be calculated by using the formula: Shear strength = 0.6 x tensile strength. The tensile strength can be found by looking up the specifications for the specific type and size of lag screw being used. It’s important to ensure that the load being applied to the lag screw does not exceed its shear capacity to prevent failure. |

Practical Applications And Limitations

Wood screw shear strength calculators provide valuable insights into the amount of force a fastener can withstand from the sides. In real-world applications, it’s essential to consider the limitations of these calculators. For example, nails exhibit greater elasticity compared to screws, allowing them to bend under pressure. Conversely, screws have minimal shear strength, impacting their ability to withstand lateral forces.

When it comes to practical examples, lag screws in wood have specific shear capacity, which can be calculated using the ultimate shear strength formula. Additionally, it’s crucial to factor in the type of fastener, dimensions, and number of shear planes to accurately assess shear strength. Understanding these limitations and practical applications is vital for making informed decisions in various woodworking and construction projects.

Advanced Considerations

Wood screws have shear strength, which refers to the amount of force a fastener can handle from the sides. Unlike nails that have more elasticity and can bend slightly to accommodate pressure, screws have very little shear strength. This means that when forces are applied against the sides of a screw, it is more likely to break or fail compared to a nail.

When it comes to considering advanced factors in wood screw shear strength, the role of thread geometry plays a crucial part. The design and shape of the screw threads can affect its overall shear strength and performance. Additionally, environmental conditions can also impact the shear strength of wood screws. Factors such as moisture, temperature, and exposure to chemicals or corrosive agents can weaken the screw’s structural integrity.

If you need to calculate the shear stress of a screw, various equations and calculators are available. These tools take into account factors like bolt or pin diameter, plate thickness, and applied shear force to determine the shear stress. Manufacturers’ websites often provide information on the shear strength of specific fasteners, which can be helpful in calculations.

In conclusion, understanding wood screw shear strength is essential for choosing the right fasteners and ensuring the structural integrity of your woodworking projects. Consider thread geometry and environmental conditions, and utilize available calculators and resources to make informed decisions.

Ensuring Safe And Durable Builds

Wood screws possess shear strength, which is the force they can withstand from the sides. In comparison to nails, screws have minimal shear strength. Hence, it’s crucial to ensure proper installation practices. Additionally, regular maintenance and thorough inspection are essential to guarantee safe and durable builds. Proper calculation of shear stress is vital for determining the screw’s capability. This can be achieved by considering the ultimate shear strength and cross-sectional area. Moreover, it’s advisable to refer to the manufacturer’s specifications for the shear strength of a specific fastener. By adhering to these best practices, one can ensure the longevity and safety of the construction project.

Resources And Tools

| Resources and Tools |

| Recommended Calculators and Apps |

Wood Screw Shear Strength Calculator is a valuable tool for determining the amount of force a wood screw can handle from the sides. Unlike nails, which have more elasticity and can bend slightly under pressure, screws have very little shear strength. To calculate the shear stress of a screw, you can use the Ultimate Shear Load Calculations. This equation involves dividing the force applied by the cross-sectional area of the screw.

Additionally, you can find the shear capacity of lag screws in wood using the Wood Fastener Capacity Calculator provided by the American Wood Council. This calculator allows you to enter the type of fastener, its dimensions, and the number of shear planes. By inputting these values, you can determine the maximum weight a lag screw can hold. For further reading and studies, you can visit various online forums such as Reddit, r/AskEngineers, and r/woodworking, where professionals discuss topics related to shear strength calculations and wood screws.

Frequently Asked Questions

Do Wood Screws Have Shear Strength?

Yes, wood screws have shear strength, which is the force they can handle from the sides. Unlike nails, screws have minimal shear strength.

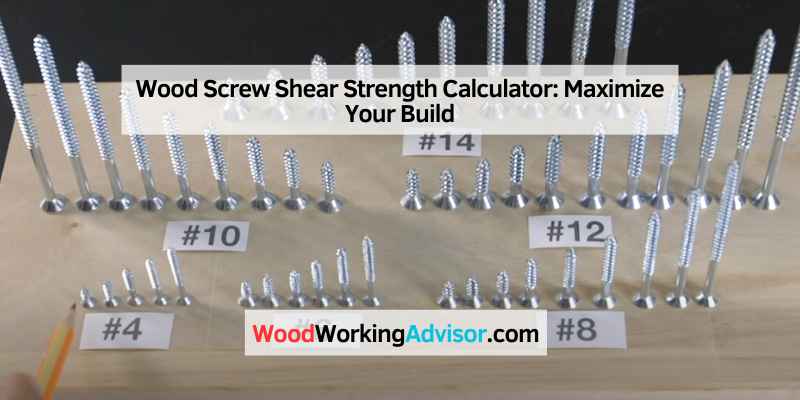

What Is The Shear Strength Of A #8 Wood Screw?

The shear strength of a #8 wood screw is relatively low compared to other fasteners like nails. Wood screws have very little shear strength because they cannot bend or flex when forces are applied from the sides. It is important to choose the right fastener for the specific application to ensure structural integrity.

How Do You Calculate The Shear Stress Of A Screw?

To calculate the shear stress of a screw, you need to determine the force applied to the screw and divide it by the cross-sectional area of the screw. The shear stress is equal to the force divided by the area.

What Is The Shear Capacity Of Lag Screws In Wood?

The shear capacity of lag screws in wood varies based on factors like wood type and screw size. It’s typically around 80-90% of the screw’s tensile capacity. Professional calculation or consulting a structural engineer is recommended for precise results.

Conclusion

Understanding the shear strength of wood screws is crucial for ensuring the stability and durability of any wooden construction project. By using a wood screw shear strength calculator, you can accurately determine the amount of force a fastener can handle from the sides.

This knowledge will help you make informed decisions about the type and size of screws to use, ensuring the structural integrity of your project. So, before embarking on any woodworking endeavor, be sure to utilize this valuable tool to ensure the safety and strength of your work.