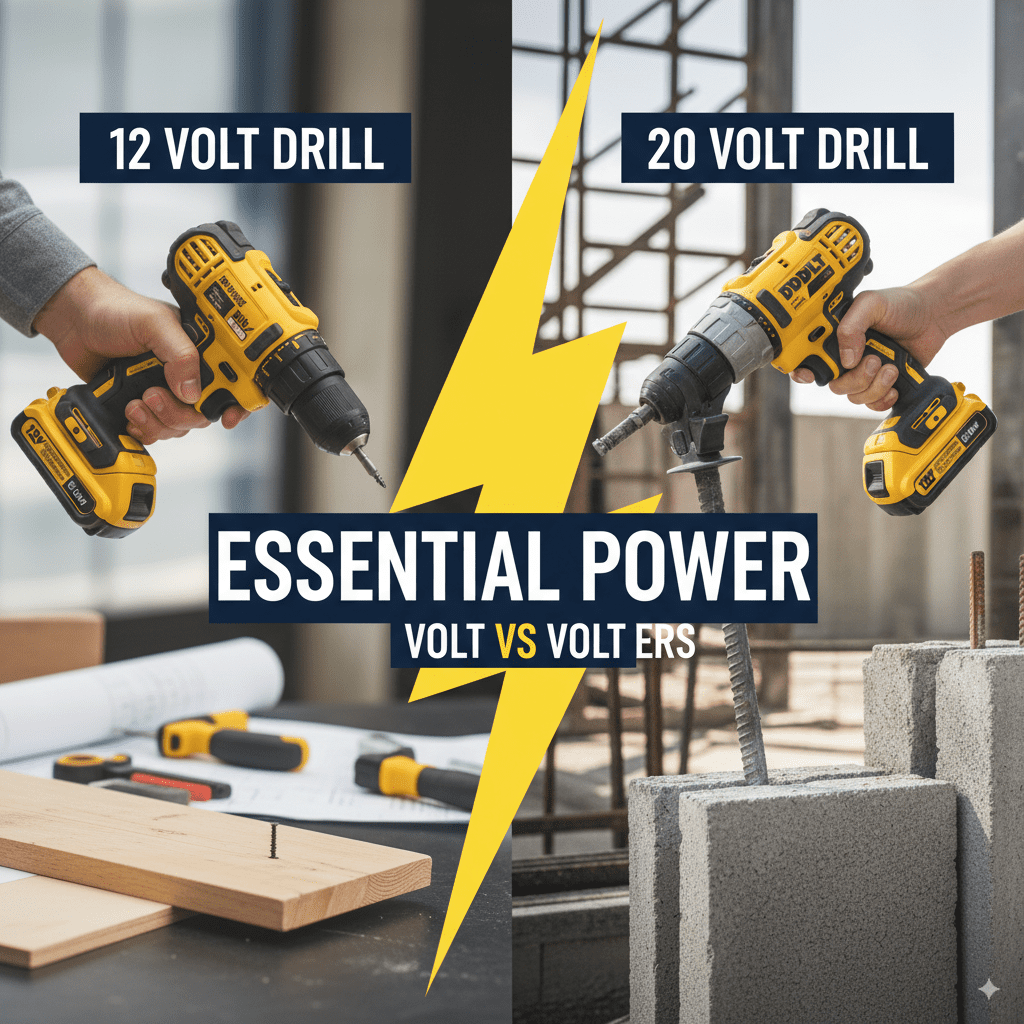

12 Volt VS 20 Volt Drill: Essential Power Comparison

Choosing between a 12V and 20V drill is key for DIYers. For light tasks and maneuverability, 12V is great. For more power, heavier jobs, and longer runtimes, 20V is the better choice. This guide simplifies the differences to help you pick the right drill for your needs.

Hey there, fellow DIYers and aspiring woodworkers! Md Meraj here, your go-to guide for all things making and building. Ever stood in the tool aisle, staring at drills, and wondered about the difference between those 12-volt and 20-volt options? It’s a common head-scratcher, and honestly, it can stop you right in your tracks before you even begin your project. But don’t worry! Picking the right power for your drill doesn’t need to be complicated. Think of it like choosing the right tool for a specific job – a small screwdriver for a tiny screw, a hammer for a nail. It’s all about matching the power to the work. This guide is crafted to break down the power differences in a way that’s easy to understand, so you can confidently choose the drill that will help you build, fix, and create with ease. Let’s uncomplicate this, shall we?

12 Volt VS 20 Volt Drill: Understanding the Power Difference

As your friendly woodworking mentor, I want to make sure you have the right tools to feel confident tackling any project. The core difference between a 12-volt and a 20-volt drill boils down to power and its implications for what you can do with it. It’s not just a number; it’s about torque, speed, battery life, and the types of tasks each drill excels at. Understanding these distinctions will make your purchase decision much clearer and ensure you’re not overspending or undershooting your needs.

What Does “Volt” Actually Mean for a Drill?

When we talk about “volts” (V) in cordless power tools like drills, we’re referring to the electrical potential, or the “oomph,” the battery supplies to the motor. Think of it like water pressure in a hose. A higher voltage means there’s more potential energy available. For a drill, this translates to more power, which often means:

- More Torque: The twisting force the drill can exert. This is crucial for driving screws into tough materials or drilling larger holes.

- Higher Speed: The drill can spin its bit faster, which can speed up drilling and driving tasks, especially in softer materials.

- Better Performance on Tougher Jobs: Higher voltage drills can handle demanding tasks with less strain.

It’s important to remember that voltage is just one piece of the puzzle. Amperage-hours (Ah) on the battery pack also play a big role in how long the drill can run, and the motor technology itself influences overall performance. But as a starting point, voltage gives you a good initial sense of the drill’s grunt.

12-Volt Drills: The Compact Powerhouses

When you pick up a 12-volt drill, the first thing you’ll likely notice is its size and weight. They are designed to be compact and lightweight, making them incredibly comfortable to hold and maneuver, especially in tight spaces or overhead. They are perfect for home renovations, light woodworking, and everyday repairs around the house.

Key Characteristics of 12-Volt Drills:

- Lightweight and Compact: Easy to handle for extended periods and in confined areas.

- Excellent Maneuverability: Great for working on ladders or beneath cabinets.

- Sufficient Power for Most Household Tasks: Ideal for hanging pictures, assembling furniture, drilling small pilot holes, and driving short screws.

- Good Battery Life for Light Use: Battery packs typically have lower amp-hours (Ah) but last for many common tasks.

- More Affordable: Generally less expensive than their 20-volt counterparts.

When a 12-Volt Drill Shines:

Imagine you’re assembling that flat-pack furniture that just arrived. You need to drive a few dozen screws, maybe drill a couple of small pilot holes for shelf pins. A 12V drill is your best friend here. It’s nimble, quick to get going, and won’t tire your arm out. It’s also a lifesaver when you’re working in a cramped closet or overhead trying to install a ceiling fan.

For beginners, a 12V drill offers a fantastic entry point into the world of cordless tools. They are less intimidating, easier to control, and forgiving if you accidentally apply a little too much pressure. You can learn the basics of drilling and driving screws without the overwhelming power that could potentially damage your workpiece if you’re not careful.

20-Volt Drills: The Heavy Hitters

Step up to a 20-volt drill, and you’re stepping up in power. These drills are built for demanding jobs. If you plan on tackling larger projects, drilling into harder materials like dense wood or even light masonry, or driving long screws, a 20V drill will make the job significantly easier and faster.

Key Characteristics of 20-Volt Drills:

- More Torque: Capable of handling tougher tasks and larger fasteners.

- Higher Speed Capabilities: Drills through materials more quickly.

- Better for Continuous Use: Often have larger batteries (higher Ah) for longer runtimes.

- Suitable for Demanding Applications: Can drill medium-sized holes and drive larger screws with ease.

- Wider Range of Applications: Can often handle tasks that might bog down a 12V drill.

When a 20-Volt Drill Shines:

Think about building a deck, framing a wall for a DIY shed, or drilling a series of larger holes for plumbing or electrical work. These are the tasks where a 20V drill really proves its worth. It has the muscle to power through resistance without stalling. If you’re working with dense hardwoods like oak or maple, the extra torque is essential to prevent the drill bit from getting stuck.

Many DIYers find that a 20V drill, while slightly heavier, offers a more robust feel and confidence-inspiring performance for a wider variety of projects. If your DIY ambitions lean towards building furniture, undertaking home improvement projects, or doing a lot of repairs, investing in a 20V system often makes more sense in the long run.

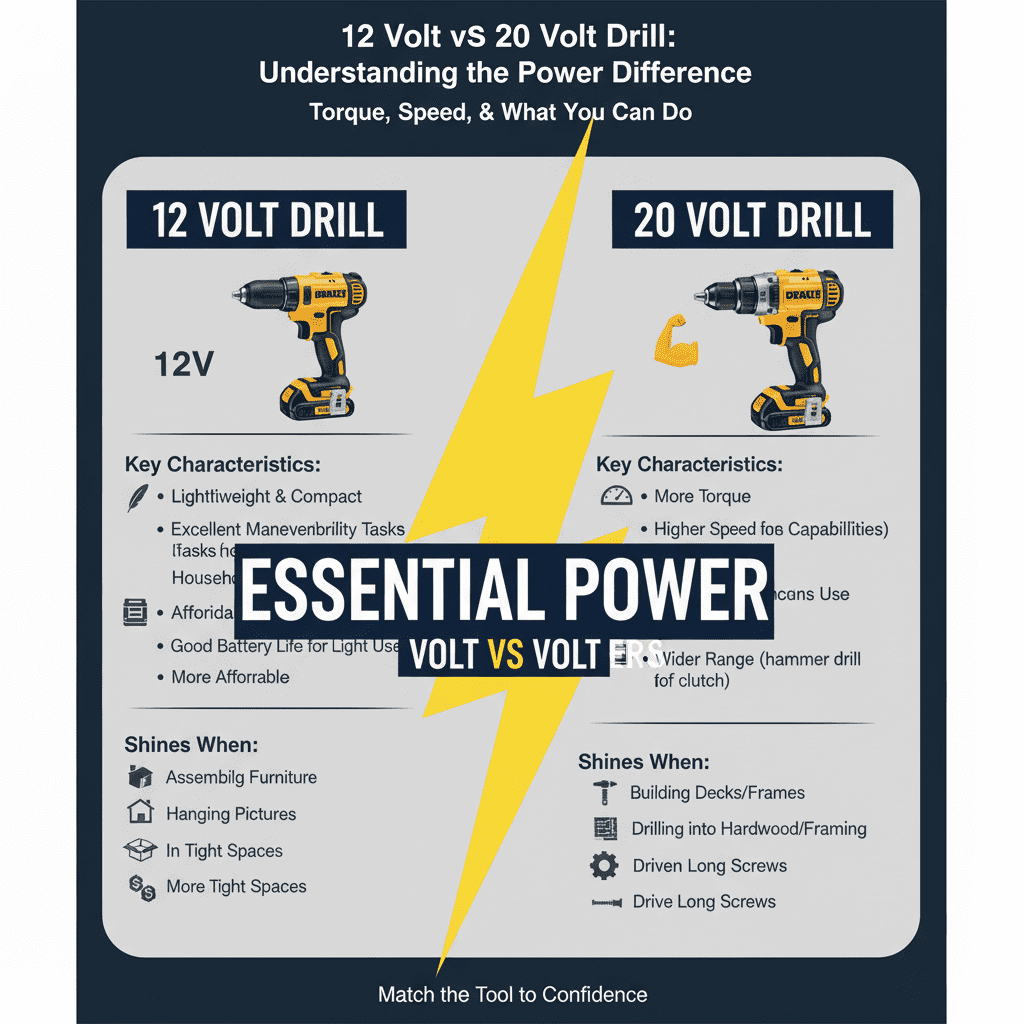

Key Differences: Power, Performance, and Purpose

Let’s break down the core distinctions in a way that’s easy to digest. When we compare 12V and 20V drills side-by-side, it’s not just about the voltage number. It’s about how that voltage impacts the drill’s capabilities and what you can expect from it on your job site, whether that’s your garage or your backyard.

Torque Comparison: The Twisting Power

Torque is the rotational force of a drill – essentially, how hard it can twist. This is arguably the most significant difference between 12V and 20V drills. Higher voltage generally means higher torque.

- 12V Drills: Typically offer between 100-300 inch-pounds (in-lbs) of torque. This is plenty for standard household screws and small pilot holes.

- 20V Drills: Can range from 300-600+ inch-pounds (in-lbs) of torque. This extra power makes them far more capable of driving larger screws into hardwoods or breaking through tough materials.

For example, driving a 3-inch screw into a piece of pine is child’s play for a 20V drill, but a 12V drill might struggle or require you to pre-drill a pilot hole. For beginners, understanding torque helps you avoid stripping screw heads or bogging down the drill, which can be frustrating.

Speed (RPM): How Fast It Spins

Revolutions Per Minute (RPM) indicates how fast the drill’s chuck can spin. While higher voltage often correlates with higher potential speeds, the gearing within the drill also plays a crucial role. However, a 20V drill generally has the power to maintain higher speeds under load.

- 12V Drills: Often have RPMs ranging from 0-400 for low speed and 0-1,400 for high speed.

- 20V Drills: Can offer RPMs from 0-500 for low speed and 0-2,000 for high speed, sometimes even more.

Higher RPMs can lead to faster drilling, especially in softer woods or plastics. For tasks like mixing paint or mud, a higher RPM is also beneficial. However, when drilling into metal or delicate materials, a slower, controlled speed is often preferred, and most high-quality drills, regardless of voltage, offer variable speed triggers to accommodate this.

Battery Life and Runtime: How Long It Lasts

Battery technology has come a long way, but voltage still influences runtime, especially when the drill is under load. Batteries are measured in amp-hours (Ah), which indicates how much current the battery can deliver over time. So, a 2.0Ah battery will last twice as long as a 1.0Ah battery at the same current draw.

- 12V Drills: Often come with batteries ranging from 1.5Ah to 2.5Ah. They are designed for lighter, intermittent use, and these batteries provide ample run time for such tasks without adding significant weight.

- 20V Drills: Typically use batteries from 2.0Ah up to 5.0Ah or even 6.0Ah. The larger batteries, combined with higher voltage, allow for significantly longer runtimes, especially under demanding conditions.

If you have a project that requires continuous drilling or driving for an extended period, a 20V drill with a higher Ah battery will likely last longer and perform more consistently than a 12V drill. Many brands also offer interchangeable battery systems within their voltage lines, meaning a 20V battery from your drill can often power other 20V tools like saws, sanders, or inflators, which is a huge advantage for expanding your toolkit.

Durability and Build Quality

While both 12V and 20V drills are built for durability, 20V models are often engineered to withstand more rigorous use. They might feature more robust gear systems, better cooling for the motor, and more impact-resistant housing. This is because they are generally intended for heavier-duty applications.

For the average homeowner or beginner DIYer, both types of drills are usually durably built enough for their intended purposes. However, if you plan on using your drill very frequently or in demanding, dusty, or damp environments, a 20V drill might offer a slight edge in terms of long-term resilience.

Choosing the Right Drill for Your DIY Projects

Now that we’ve broken down the power differences, how do you choose? The best drill for you depends entirely on the kinds of jobs you see yourself doing. Don’t buy on impulse; think about your typical weekend projects.

When to Choose a 12-Volt Drill

If your DIY to-do list involves tasks like:

- Assembling flat-pack furniture (IKEA, anyone?)

- Hanging shelves and pictures

- Performing minor repairs around the house

- Working in tight spaces or overhead

- You want a tool that’s more comfortable for extended, light-duty use.

- You are just starting out and want an easy-to-handle, less intimidating tool.

Then a 12V drill is likely your perfect match. It’s a fantastic “first drill” for many people. Its compact size and lighter weight make it far less cumbersome, and it has more than enough power for these common tasks. Plus, they are often more budget-friendly, which is always a plus for beginners.

When to Choose a 20-Volt Drill

Consider a 20V drill if your projects include:

- Building furniture from scratch

- Drilling larger holes (e.g., for drawer slides, larger bolts)

- Driving long or large screws, especially into hardwoods

- Working on home improvement projects like building shelves, decks, or fences

- You need more power for tougher materials or longer continuous use.

- You plan to expand your cordless tool collection with other 20V tools.

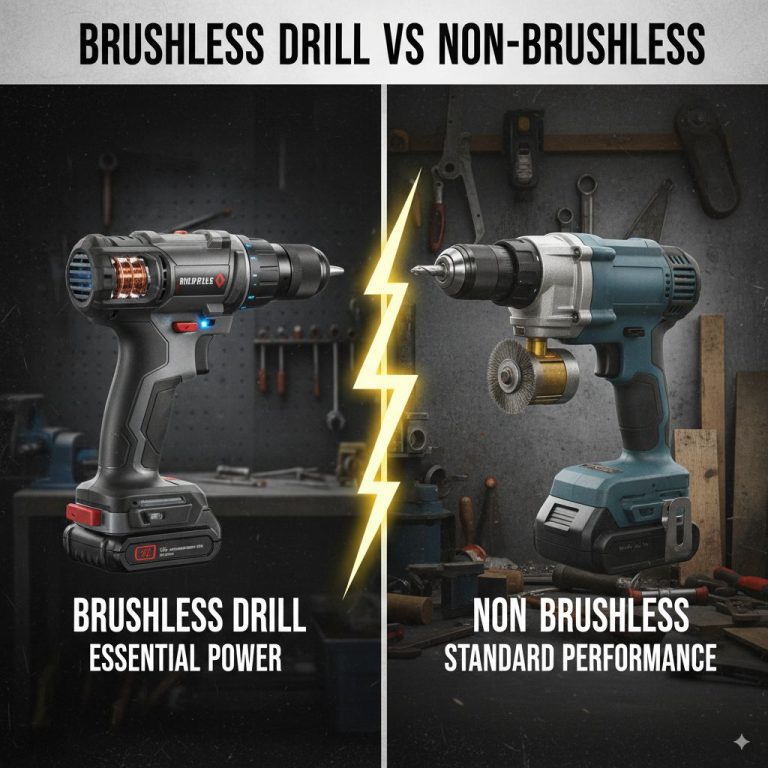

A 20V drill offers the power and endurance to handle these more demanding applications with ease. It’s a more versatile tool that can grow with your skills and project complexity. Many 20V drills also come with advanced features like brushless motors, which offer increased efficiency and longer tool life, and better clutch settings for precise screw driving. You can find excellent resources on tool specifications from organizations like the U.S. Department of Energy to understand the impact of power efficiency.

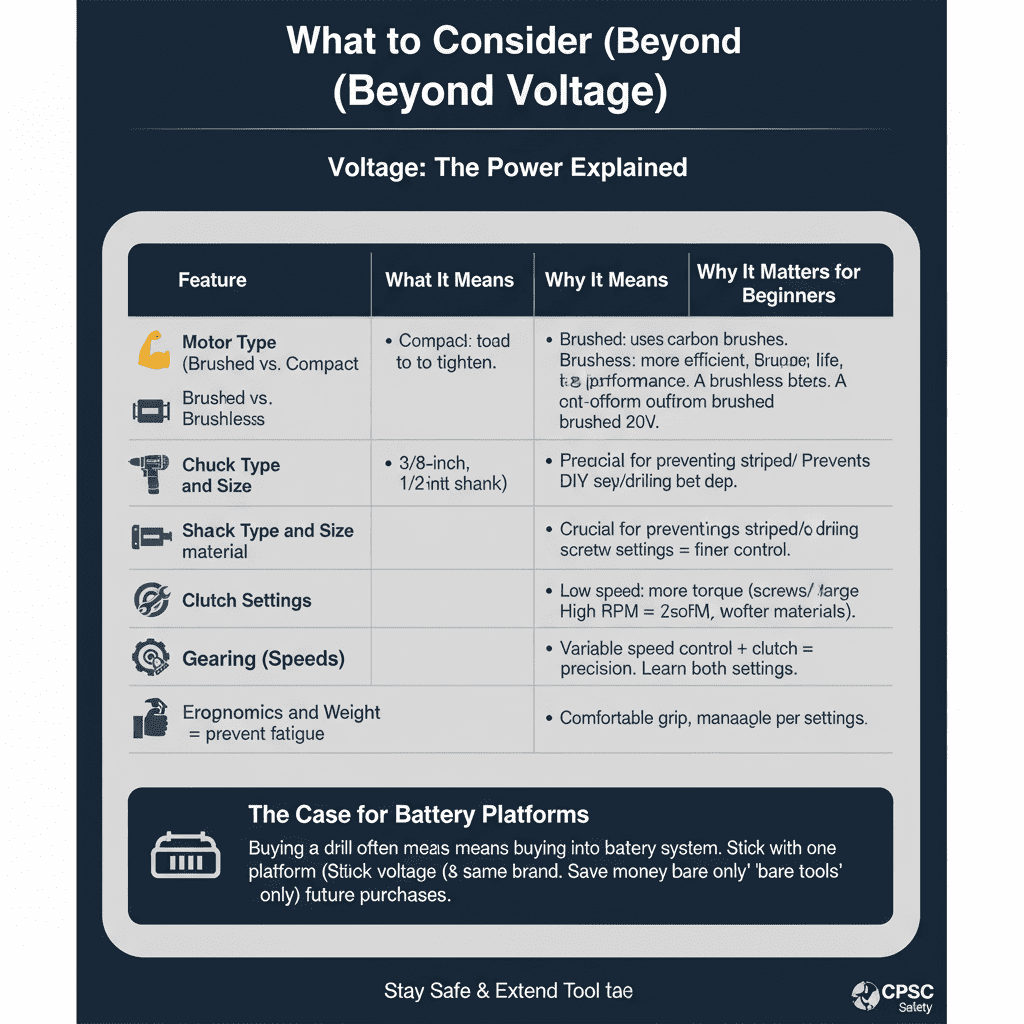

Drill Features to Consider (Beyond Voltage)

Voltage is a great starting point, but it’s not the only factor that determines a drill’s performance and suitability for your needs. As you compare models, keep these other important features in mind:

| Feature | What It Means | Why It Matters for Beginners |

|---|---|---|

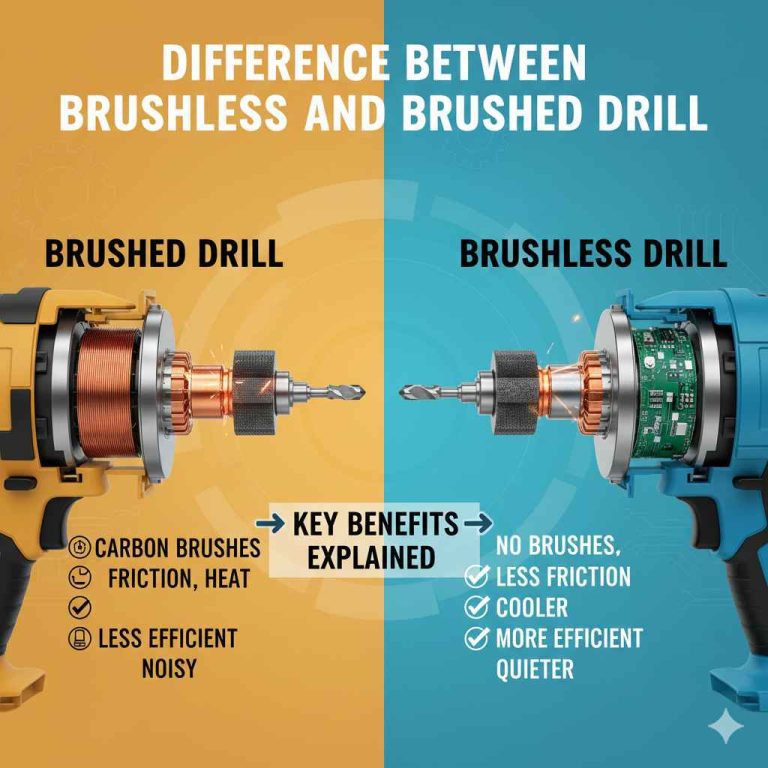

| Motor Type (Brushed vs. Brushless) | Brushed motors use carbon brushes that wear out over time. Brushless motors are more efficient, durable, and offer better power and runtime. | Brushless motors offer longer tool life and better performance, often justifying a slightly higher cost. A brushless 12V can sometimes outperform a brushed 20V. |

| Chuck Type and Size | The chuck holds the drill bits. Keyed chucks require a tool to tighten; keyless chucks tighten by hand. Size (e.g., 3/8-inch or 1/2-inch) determines the largest shank bit you can use. | Keyless chucks are faster and more convenient. For most DIY tasks, a 3/8-inch chuck is sufficient. 1/2-inch chucks are common on higher-torque 20V drills and offer wider bit compatibility. |

| Clutch Settings | This adjustable setting controls how much torque the drill applies before disengaging. It prevents over-driving screws. | Crucial for preventing stripped screw heads or drilling too deep. More settings offer finer control, which is great for beginners learning to drive screws precisely. |

| Gearing (Speeds) | Most drills have at least two speed settings. Low speed offers more torque (good for screws and large bits), high speed offers more RPM (good for drilling into softer materials). | Variable speed control, combined with a clutch, is essential for precision and avoiding damage to your workpiece. Learn to use both settings! |

| Ergonomics and Weight | How the drill feels in your hand, its balance, and its overall weight. | A comfortable grip and manageable weight are vital, especially for beginners, to maintain control and prevent fatigue during longer projects. |

The Case for Battery Platforms

When you buy a drill, you’re often buying into a battery system. If you plan on getting more cordless tools from the same brand (like a circular saw, sander, or string trimmer), it’s wise to stick with one voltage platform. For example, if you buy a 20V drill, all other 20V tools from that brand will use the same batteries.

This can save you money in the long run, as you can often buy “bare tools” (just the tool itself, without a battery and charger) for subsequent purchases. This is a great strategy for budget-conscious DIYers looking to build a comprehensive toolkit. You can learn more about battery technology and its impact on tool performance from resources like Toolskool, a reputable source for tool information.

Frequently Asked Questions (FAQ)

Q1: Can a 12V drill handle drilling into drywall?

Answer: Absolutely! Drywall is a soft material that a 12V drill can easily handle for tasks like hanging anchors or drilling small pilot holes. For driving long screws into wood studs behind the drywall, a 20V drill would be significantly more effective.

Q2: Will a 20V drill be too powerful for a beginner?

Answer: Not necessarily. While it has more power, most 20V drills come with variable speed triggers and adjustable clutches. These features allow you to control the speed and torque, making them very manageable and safe for beginners when used correctly. Learning to use the clutch setting is key!