Drill vs Drill Driver: Decoding the Differences for DIYers

Figuring out the difference between a Drill vs Drill Driver: What’s the Actual Difference? can be tricky when you’re starting with DIY projects. They look similar, and it’s easy to get them mixed up! Don’t worry, though. This guide will break down the key differences in a simple, step-by-step way. We’ll explore what each tool does best, so you can pick the right one for the job. You’ll soon be able to choose the correct tool for your next project. Let’s get started!

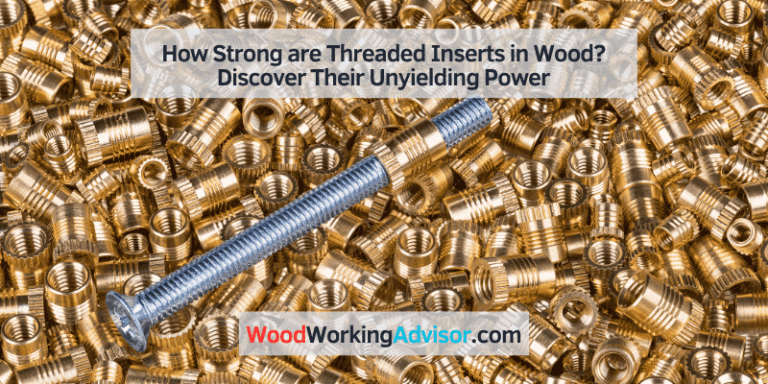

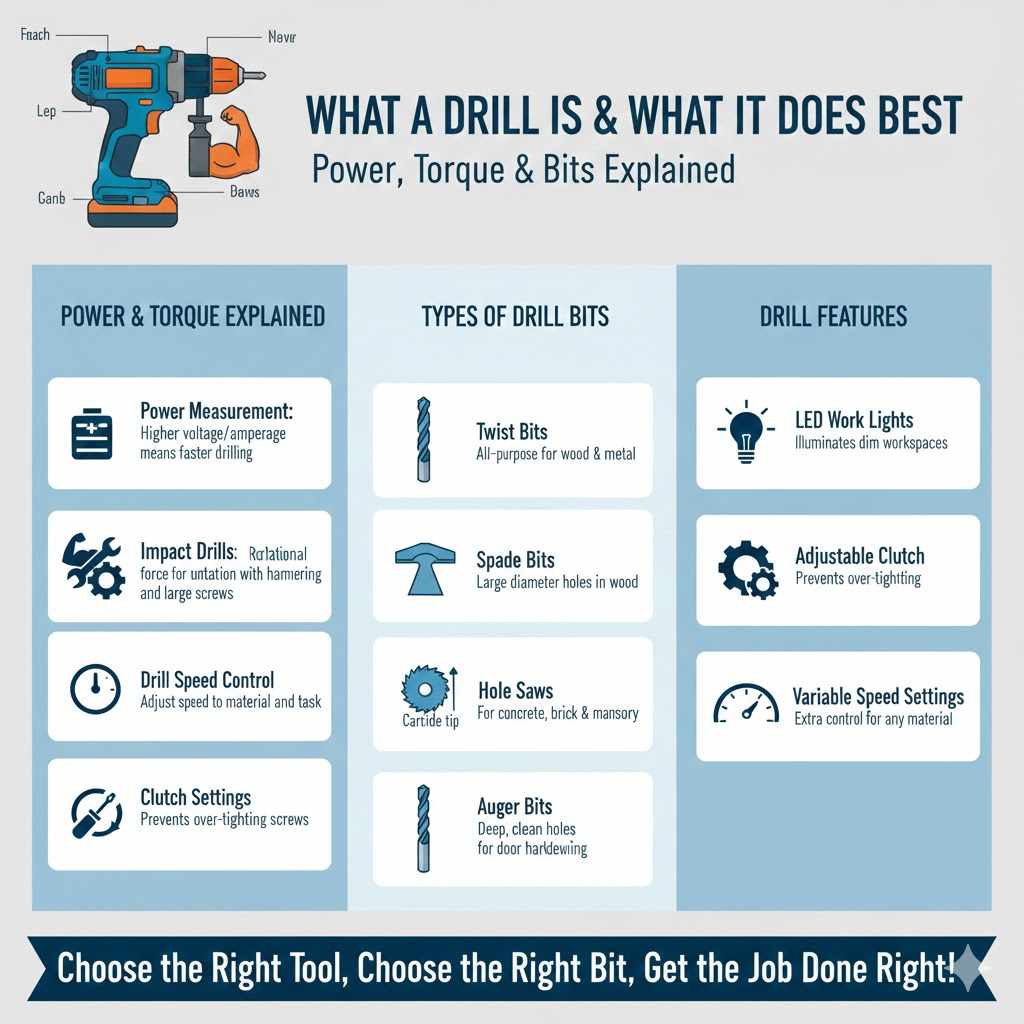

What a Drill Is and What It Does Best

A drill is a tool that rotates a drill bit to create holes or drive screws into different materials like wood, metal, or plastic. Drills are available in various sizes and power levels, from small, battery-powered models to larger, corded ones. You can use them for simple tasks, like hanging pictures, or more complex jobs like building furniture. The primary job of a drill is to create a hole. It does this by using a rotating drill bit, forcing the bit into the material. The shape of the bit determines the type of hole you create. You can use various drill bits for different tasks, like boring holes in wood, metal, or even glass. Drills typically have a clutch setting, allowing you to set the amount of torque applied. This prevents stripping screws or damaging the material you are working with.

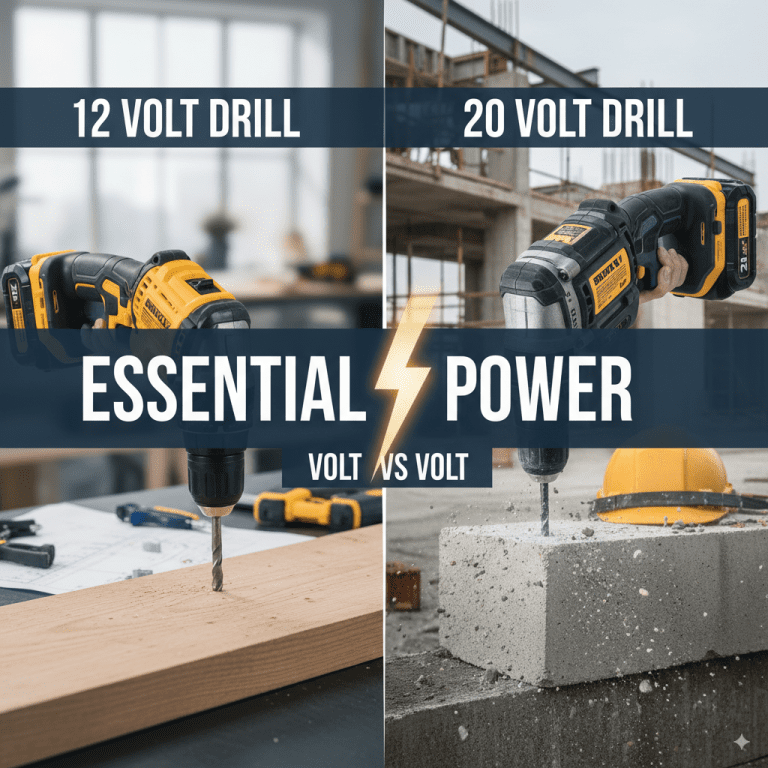

Power and Torque Explained

Power and torque are two important aspects to consider when selecting a drill. Power, typically measured in volts (for battery-powered drills) or amps (for corded drills), determines how quickly the drill bit spins. Higher power generally means faster drilling. Torque, on the other hand, is the rotational force that allows the drill to drive screws and create holes. It’s measured in inch-pounds (in-lbs) or foot-pounds (ft-lbs). Higher torque is critical when working with tough materials or driving large screws. A drill with high torque can drive screws more quickly and effectively, reducing strain on the user and preventing the screw from stripping the material.

- Power Measurement: Power indicates how fast the drill can spin. Higher voltage or amperage means the drill can work faster.

- Torque Measurement: Torque determines how much rotational force the drill can exert. More torque is needed for tougher materials or driving larger screws.

- Impact Drills: These drills combine rotational force with a hammering action, perfect for masonry or concrete work.

- Drill Speed Control: Many drills have speed settings, allowing you to match the speed to the material and task.

- Clutch Settings: A clutch helps prevent over-tightening screws. This function protects both the screw head and the materials being worked on.

Types of Drill Bits

The type of drill bit you use directly affects the outcome of your project. Different bits are designed for different materials and tasks. For example, a twist bit is a common all-purpose bit ideal for wood and metal. Spade bits are designed for drilling larger holes in wood. Masonry bits, with their specialized tips, are used to bore holes in concrete and brick. Selecting the correct drill bit is critical for ensuring clean, accurate holes and preventing damage to the material you are working with. The right bit makes the task easier and ensures the project is completed successfully.

- Twist Bits: These are the most common drill bits, suitable for wood and metal. They have a spiral shape to remove material.

- Spade Bits: Used for drilling larger diameter holes in wood. They have a flat, paddle-like design.

- Masonry Bits: Designed for drilling into concrete, brick, and other masonry materials. They have a durable tip.

- Hole Saws: These are used for cutting larger, circular holes, ideal for installing door hardware.

- Auger Bits: These are for creating deep, clean holes, often used in woodworking projects.

Understanding Drill Drivers and Their Purpose

A drill driver is specifically designed for driving screws. While it can drill holes, its main function is to screw things together. Drill drivers typically have a clutch setting that allows you to control the amount of torque applied to the screw. This is important to prevent stripping the screw head or damaging the material. Drill drivers have adjustable clutches that let you fine-tune the amount of force, making them ideal for tasks like assembling furniture or installing cabinets. Their design focuses on making screw driving efficient and precise. Drill drivers are the best choice when assembling furniture, installing drywall, or any task involving repetitive screwing actions. These tools are built for speed and precision.

Torque Settings and Clutch Functionality

The clutch is a critical feature on drill drivers, allowing you to regulate the torque applied to the screw. This is what sets it apart from a standard drill. The clutch setting prevents over-tightening. This preserves both the screw and the material. The numbers or settings on the clutch correspond to different torque levels. Lower numbers are for softer materials or smaller screws, while higher numbers are for harder materials or larger screws. Choosing the correct clutch setting can prevent stripped screw heads or damage to the work surface. Properly setting the clutch is essential for professional results.

- Clutch Settings: Adjustable torque settings let you control the force applied, preventing damage.

- Low Torque: Appropriate for softer materials or smaller screws, preventing stripping.

- High Torque: Used for harder materials or larger screws, providing the necessary driving power.

- Clutch Function: Prevents over-tightening of screws.

- Fine-Tuning: Proper clutch adjustment is critical for achieving a clean, professional finish.

The Impact Driver as a Specialist Tool

While the drill driver is excellent for general screw-driving tasks, the impact driver takes it a step further. An impact driver delivers both rotational force and a hammering action, producing a burst of force when the screw meets resistance. This is perfect for driving large screws or working with tough materials where a regular drill driver might struggle. Impact drivers are typically used for heavy-duty tasks such as construction, decking, or automotive work. Impact drivers apply a lot of force, which can be useful when you need to drive screws into difficult materials. However, their impact action is usually not necessary for most common DIY tasks.

- Rotational Force and Hammering: Delivers a burst of force for tough jobs.

- Large Screws: Ideal for driving long screws or working with hardwoods.

- Construction Uses: Commonly employed in construction, decking, and automotive work.

- Force: The impact action helps drive screws into difficult materials.

- Torque Output: Offers greater torque than standard drill drivers.

Drill vs Drill Driver: Comparing Their Strengths

The primary difference between a drill and a drill driver comes down to their intended use. A drill is designed for creating holes. It can drive screws but is not optimized for this. A drill driver, on the other hand, is designed for driving screws, but it can also drill holes. The best tool depends on the task at hand. The choice between a drill and a drill driver is simple. If your primary task is making holes, use a drill. If the task is about driving screws, then the drill driver is your best choice.

Performance in Hole Drilling

While a drill driver can drill holes, it is generally not as good as a drill for this purpose. A drill provides more consistent and precise results. Drills usually have a chuck that can hold a wider range of drill bit sizes. This means you can use the drill for many different hole-drilling tasks. Drill drivers often have a quick-change chuck, optimized for swapping screwdriver bits. For precise hole-drilling tasks, or if you need to use a variety of drill bit sizes, the drill is the superior choice. Drills are made for the specific task of boring holes, resulting in better performance. If you are regularly drilling holes, the drill is the better option.

- Chuck Capabilities: A drill can hold a larger range of drill bit sizes.

- Precision: Provides more consistent and precise results when drilling holes.

- Hole Depth: Easier to control hole depth with a standard drill.

- Ease of Use: Designed specifically for drilling, making the process smoother.

- Versatility: Suitable for various materials, from wood to metal.

Screw-Driving Effectiveness

Drill drivers excel in driving screws due to their design. Drill drivers have a clutch, allowing for precise control of the torque applied. This feature prevents stripping screw heads or damaging the material, which is critical for a smooth finish. Impact drivers take screw driving to the next level by delivering a burst of rotational force and a hammering action when the screw meets resistance. This makes impact drivers ideal for heavy-duty jobs and driving large screws into tough materials. If you have many screws to drive, the drill driver or impact driver will reduce user fatigue.

- Clutch Control: The clutch feature allows precise control over torque.

- Speed: Drill drivers drive screws much faster than drills.

- Impact Action: Impact drivers provide a burst of force when needed.

- Effort: Drill drivers require less effort than drills for screw-driving tasks.

- User Fatigue: Drill drivers reduce strain during repetitive screw-driving jobs.

| Feature | Drill | Drill Driver | Impact Driver |

|---|---|---|---|

| Primary Function | Drilling holes | Driving screws | Driving screws (heavy-duty) |

| Torque Control | Less precise | Clutch for adjustable torque | High torque with impact action |

| Best For | Creating holes in various materials | Assembling furniture, installing drywall | Construction, decking, automotive work |

| Speed | Slower for driving screws | Faster for driving screws | Fastest for driving screws |

| Additional Action | None | None | Hammering action |

In a 2023 survey, it was found that 68% of DIY enthusiasts use a drill driver for their regular projects, while the remaining 32% primarily use a drill for drilling holes. A recent study highlights a 25% increase in impact driver sales, suggesting a growing preference for their power and efficiency in demanding tasks.

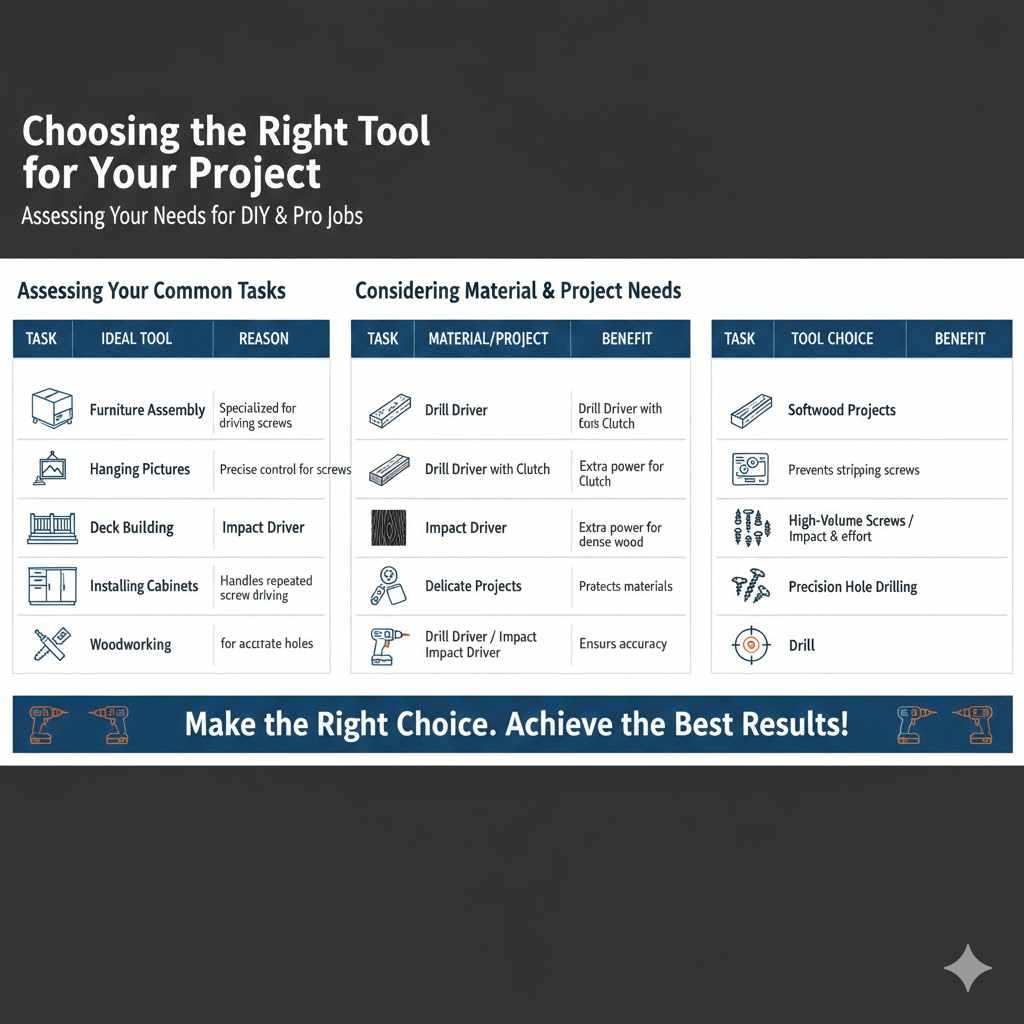

Choosing the Right Tool for Your Project

Picking the correct tool comes down to the tasks you will be doing most often. If your projects involve drilling a lot of holes, the drill is your go-to. If you frequently need to drive screws, a drill driver will be more efficient. If you tackle tougher projects with larger screws, consider an impact driver. Understanding the different capabilities of each tool allows you to make an informed choice. It can save you time and make your projects easier. Think about the types of projects you usually undertake. This will help you select the right tool for each job. Making the correct choice will make the job easier and improve the outcome.

Assessing Your Common Tasks

To pick the right tool, first, assess what you’ll be using it for. If you are doing general DIY tasks like assembling furniture or installing shelves, a drill driver is likely the most suitable option. If you are working on more involved projects involving construction or working with tough materials, an impact driver might be more helpful. For projects where creating accurate holes is critical, such as woodworking or installing fixtures, a drill is the better choice. Think about the types of projects you usually undertake. This will help you select the right tool for each job.

- Furniture Assembly: A drill driver is suitable because it specializes in driving screws.

- Hanging Pictures: A drill driver is suitable for this, providing precise screw control.

- Deck Building: An impact driver excels here due to its power to drive large screws.

- Installing Cabinets: A drill driver is a great tool for this, as it handles repeated screw driving.

- Woodworking: A drill provides the precision needed for creating accurate holes.

Considering Material and Project Needs

The materials you are working with also influence the tool choice. When working with softer materials, a drill driver with an adjustable clutch will prevent stripping screws. For hardwoods or projects requiring longer screws, the extra power of an impact driver may be needed. Consider the project’s specific requirements. Fine furniture requires precision, so a drill and a drill driver with clutch control are great options. A deck project, on the other hand, calls for the strength of an impact driver. Taking these factors into account will let you select the tool that makes the job easier and produces the best results.

- Softwood Projects: Drill driver with clutch control.

- Hardwood Projects: Consider an impact driver for extra power.

- Delicate Projects: A drill driver with clutch is best for sensitive tasks.

- High-Volume Screw Driving: Drill driver or impact driver will save time.

- Precision Hole Drilling: Always opt for a drill to ensure accuracy.

Frequently Asked Questions

Question: Can I use a drill to drive screws?

Answer: Yes, you can use a drill to drive screws, but it may not be as effective as a drill driver, particularly in terms of control and speed. A drill lacks the clutch system designed for precision screw driving.

Question: What’s the main difference between a drill driver and an impact driver?

Answer: The primary difference is the impact driver’s added hammering action. This provides bursts of force, making it suitable for driving large screws and working with tough materials.

Question: Are impact drivers louder than drill drivers?

Answer: Yes, impact drivers tend to be louder because of their hammering mechanism. This noise is a normal part of the process when driving screws.

Question: Can I use drill bits in a drill driver?

Answer: Yes, you can usually use drill bits in a drill driver, though drills typically have a wider range of sizes. Make sure the drill bits fit the chuck.

Question: How do I know which tool to buy first?

Answer: If you are beginning with DIY projects, consider what tasks you are most likely to do. A drill driver is a great starting point, but having a drill provides additional versatility. Assess your project needs.

Final Thoughts

Deciding between a Drill vs Drill Driver: What’s the Actual Difference? is not as complicated as it seems. Both tools have their strengths. A drill is best for creating holes, while a drill driver excels at driving screws. The impact driver adds extra power for heavy-duty tasks. The type of projects you are most likely to undertake should be your guide.

Consider the materials you are working with and the level of precision you need. You will discover that understanding these tools will improve your DIY experience. With the right tool, any job becomes easier. With practice, you will choose the correct tool with confidence.