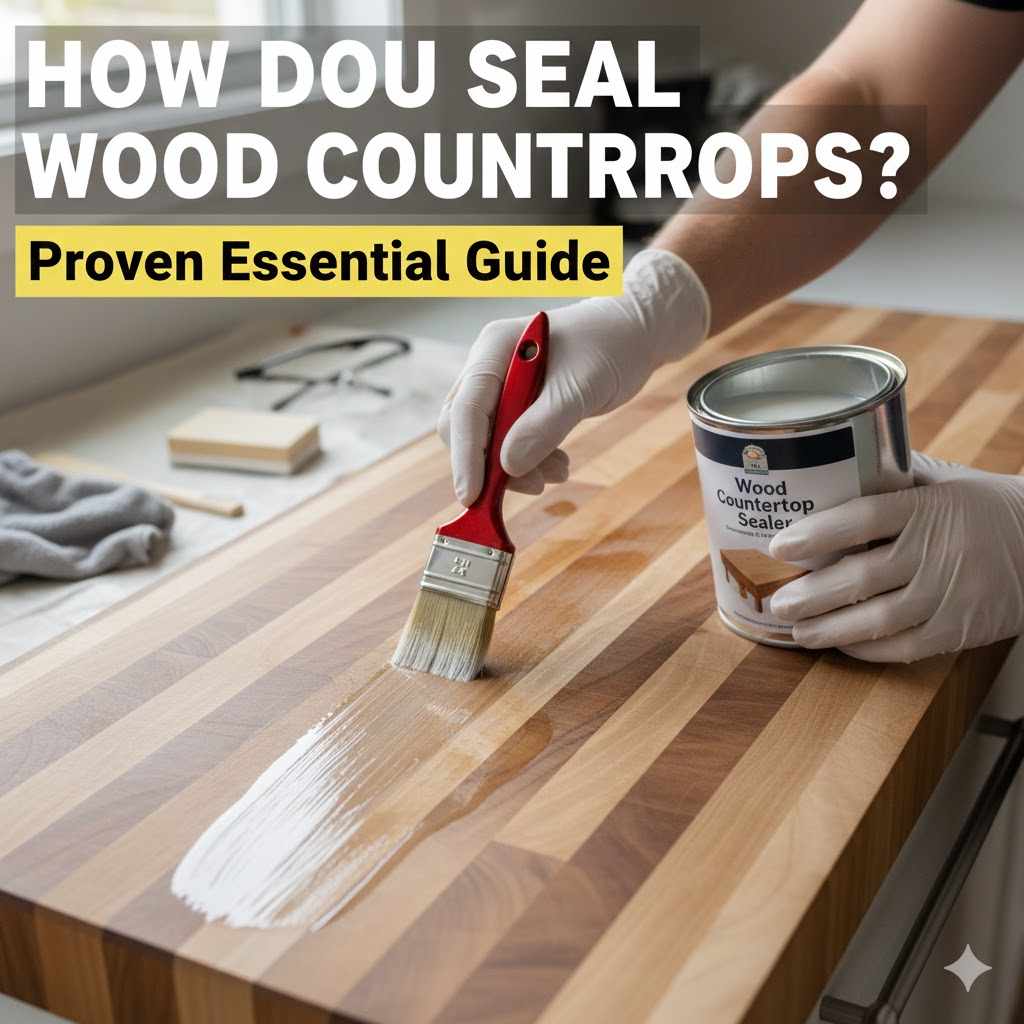

How Do You Seal Wood Countertops: Proven Essential Guide

To seal wood countertops effectively, you must first properly prepare the wood by sanding it smooth. Then, apply multiple thin coats of a durable, food-safe finish—like mineral oil, butcher block conditioner, or polyurethane—following the manufacturer’s instructions for drying and reapplication to ensure maximum protection against moisture and stains.

Welcome to the workshop! If you’ve just installed a gorgeous new wooden countertop, you know the satisfaction that comes from handmade quality. But here’s the common worry: how do you keep that beautiful wood looking amazing? Wood is porous, and without the right protection, spills can quickly turn into stubborn stains or even warped wood. It seems daunting, but I promise you, learning how do you seal wood countertops is easier than you think. It’s all about picking the right product and being patient with the coats. Stick with me, and we will walk through every step, making sure your countertop lasts for years, looking just as stunning as the day you finished it. Let’s get that wood sealed!

The Beginner’s Essential Guide to Sealing Wood Countertops

Sealing a wood countertop isn’t just about making it look good; it’s a vital step for hygiene and longevity. An unsealed surface soaks up liquids like a sponge. We want a barrier between your busy kitchen life—the spaghetti sauce, the spilled coffee, the standing water—and your beautiful wood grain. This guide will break down the intimidating process into simple, manageable tasks so you can achieve a professional, water-resistant finish with confidence.

Step 1: Choosing Your Countertop Sealer (The Most Important Decision)

Before we touch any sandpaper, we must decide what kind of protection your counter needs. The best sealant depends on how you plan to use the top. Are you preparing raw food directly on it, or just wiping it down after use?

Penetrating Oils (For Food Contact)

These finishes soak deep into the wood fibers, offering protection from the inside out. They look natural, but they require frequent reapplication. Think of them like lotion for your wood.

Pros: Completely food-safe, easy to repair (just sand a small spot and reapply), natural look.

Cons: Offers minimal resistance to standing water; needs re-oiling every few months.

Popular Oil Options:

- Food-Grade Mineral Oil: Affordable and widely available, but offers the lightest protection. Perfect for prep areas that see daily use.

- Butcher Block Conditioner: This is usually mineral oil mixed with beeswax or carnauba wax. The wax additive provides a slightly better water barrier than plain oil.

Surface Finishes (For Durability and Moisture Barrier)

These sealants cure on top of the wood, forming a hard, plastic-like shell. They are tougher against heat and spills but require more careful application to avoid streaks.

Pros: Highly durable, excellent water resistance, low long-term maintenance.

Cons: Harder to spot-repair (usually requires sanding the whole surface), less natural look depending on the sheen selected.

Popular Surface Options:

- Oil-Based Polyurethane: Extremely durable, warm amber tone. This is a heavy-duty choice popular for high-traffic areas.

- Water-Based Polyurethane: Dries clearer, less odor during application, cleans up with soap and water. It’s a great choice for beginners wanting low VOCs (Volatile Organic Compounds).

- Varnish (Tung or Danish Oil): Often considered a hybrid, they penetrate deeply but also leave a moderate surface build-up, providing decent protection.

Mentor Tip: If you slice bread or chop vegetables right on the counter daily, choose a food-safe oil. If the counter is more decorative or primarily for serving, go with polyurethane for maximum protection. For DIY confidence, water-based polyurethane is usually the easiest starting point.

| Sealer Type | Best For | Maintenance Frequency | Skill Level |

|---|---|---|---|

| Mineral Oil | High-contact food prep areas | Monthly/Bimonthly | Very Easy |

| Butcher Block Conditioner | Standard kitchen use, good balance | Every 2–3 months | Easy |

| Water-Based Polyurethane | Maximum water resistance, serving areas | Every 3–5 years | Medium |

| Oil-Based Polyurethane | Extreme durability, heavy-use areas | Every 5–7 years | Medium-Hard |

Step 2: Essential Tools and Supplies Checklist

Safety first! Always work in a well-ventilated area, especially when dealing with stains, polyurethanes, or strong solvents. Lay down drop cloths to protect your floors.

Tools Needed for Preparation:

- Electric Sander (Orbital sander is ideal for beginners)

- Sandpaper in various grits (80, 120, 180, 220)

- Tack cloth or lint-free rags

- Wood conditioner or denatured alcohol (for cleaning)

- Dust mask and safety goggles

Supplies Needed for Sealing:

- Your chosen sealant (Oil, Polyurethane, etc.)

- High-quality, clean synthetic or natural bristle brushes (if using liquid finish)

- Clean, soft, lint-free cloths (for wiping oil finishes)

- Mineral spirits or paint thinner (if using oil-based products)

Step 3: Surface Preparation (Sanding Until It’s Silky Smooth)

This is the step that separates a mediocre finish from a fantastic one. If the wood isn’t perfectly prepared, the sealer won’t adhere or look even. Don’t rush this!

- Inspect and Clean: Wipe the entire counter down with a damp cloth to remove surface dust and debris. Allow it to dry completely (at least four hours). Check for any stubborn glue spots or pencil marks.

- Start Coarse (If Needed): If your wood has deep scratches, dents, or mill marks, start with 80-grit sandpaper. This removes flaws quickly. Remember to always sand with the grain, never across it.

- Move to Medium Grit: Switch to 120-grit sandpaper. This smooths out the scratches left by the 80-grit paper. Your counter should start feeling much smoother now.

- Refine the Surface: Use 180-grit sandpaper next. This refines the texture significantly. For a surface that will see a lot of moisture, sanding up to 220-grit is a safe bet for a truly smooth, sealed look.

- The Final Dust Removal: This is crucial! Vacuum up all visible sanding dust. Then, use a tack cloth—a sticky cheesecloth—to wipe the entire surface until no fine particles remain. You can also lightly wipe with a rag dampened with mineral spirits (if using oil finish) or a designated wood prep solvent, but ensure the surface is bone dry before moving on.

Source Note: For guidelines on wood finishing standards, the US Forest Service recommends careful surface preparation to ensure longevity of the wood product finish.

Step 4: Applying Penetrating Oils (The Food-Safe Method)

If you chose mineral oil or butcher block conditioner, the process is very forgiving—which is great for beginners! This is about saturation, not forming a hard shell.

Application Steps for Oils:

- Prep the Oil: If using a conditioner, ensure it’s room temperature. If it’s too cold, it won’t penetrate as well.

- Apply Liberally: Pour a generous amount of oil directly onto the countertop surface. Don’t be shy; wood needs a lot of oil for the first coat.

- Rub It In: Use a clean, soft cloth to vigorously rub the oil into the wood grain. Work in circular motions initially to ensure good coverage, then switch to following the grain direction. Work in manageable sections (like 2ft x 2ft).

- Let it Soak (The Waiting Game): Allow the oil to soak in for at least 30 minutes, but often an hour or more is better, especially for the very first application. You should see dry patches reappear as the wood drinks the oil.

- Wipe Off Excess: After soaking, take a completely dry, clean rag and wipe off every bit of standing, excess oil. If you leave oil puddles on the surface, they will turn sticky and gummy, never truly hardening.

- Cure and Repeat: Allow the surface to cure for 12 to 24 hours (check the product label). Once dry to the touch, repeat steps 2 through 5. Most experts recommend 3 to 5 initial coats for a new counter, or until the wood stops visibly absorbing the oil quickly.

Once you have reached saturation, switch to maintaining the seal by wiping it down with a light coat once a month.

Step 5: Applying Surface Finishes (Polyurethane for Maximum Toughness)

Polyurethane creates a plastic-like barrier on top. This needs thinner, more controlled applications. Read the can carefully regarding ventilation and dry times!

Application Steps for Polyurethane:

- Stir, Don’t Shake: Open your can of polyurethane (water or oil-based). Gently stir it with a stir stick for several minutes. Shaking creates tiny air bubbles that transfer onto your counter, causing little craters in your finish.

- Cutting In: Pour a small puddle of finish onto the countertop, but not too close to the edges yet. If you have an overhang, apply a thin layer underneath first.

- Brush Technique: Dip your high-quality brush about one-third of the way into the liquid. Wipe excess off on the side of the can. Apply the finish in long, even strokes, moving with the wood grain.

- Thin Coats are Key: The number one mistake beginners make is applying a thick “wet” coat. You want coats to be thin, smooth, and almost transparent. The first coat might look streaky; that’s normal.

- The First Dry Time: Allow the first coat to dry completely. For water-based poly, this might be 2–4 hours. For oil-based, it could be 12–24 hours. The room temperature and humidity heavily influence this time.

- Light Sanding Between Coats (Crucial Step): Once the first coat is completely dry and feels slightly rough, use a very fine piece of sandpaper—ideally 320 or 400-grit—or a synthetic sanding pad (like a Scotch-Brite pad). Gently scuff the entire surface. This smooths out any tiny dust nibs or brush marks, helping the next coat stick better. Don’t sand through to the bare wood!

- Clean Up Dust: Wipe the entire surface again with a tack cloth to remove sanding dust.

- Apply Subsequent Coats: Repeat steps 2 through 5 until you reach the desired look, usually 3 to 4 coats total. The final coat is typically applied without sanding afterwards, simply allowing it to cure fully.

Curing vs. Drying Time

It is important to understand the difference when using film-building finishes like polyurethane. “Dry to the touch” means you can safely handle it or lightly sand it. “Cured” means the finish has reached maximum hardness and chemical resistance.

| Finish Stage | Water-Based Polyurethane | Oil-Based Polyurethane |

|---|---|---|

| Light Sanding Ready | 2–4 Hours | 6–12 Hours |

| Light Use Ready | 24 Hours | 48–72 Hours |

| Full Cure (Heavy Use) | 7 Days | 14–30 Days |

Note on Oil-Based Finishes: If using oil-based polyurethane or varnish, clean your rags immediately after use or soak them in water before disposal. Rags soaked in oil finishes can spontaneously combust as they dry.

Troubleshooting Common Beginner Sealing Issues

Don’t let a small issue derail your project! Almost every finish problem has a simple fix when you understand why it happened.

Problem 1: Streaks and Brush Marks

Why it happens: Usually applying the coat too thickly, or not using enough material on the brush, causing the finish to drag unevenly.

The Fix: For thin finishes like poly, ensure your brush is well-loaded but not dripping. If the finish has already dried, sand lightly (400-grit) and apply a very thin new coat, paying close attention to blending the edges as you work.

Problem 2: Sticky or Tacky Spots (Especially with Oil)

Why it happens: Excess oil was not wiped off after the soaking period, or the area is very cold/humid, slowing down the curing process.

The Fix: If it’s sticky from oil, take a clean cloth slightly dampened with mineral spirits and wipe the sticky area firmly to lift the residue. If it’s tacky polyurethane, increase the room temperature slightly if possible and allow it more time. If it remains tacky after 48 hours, very fine sanding may help remove the partially cured top layer, followed by a thin recoat.

Problem 3: “Tidelines” or Blotching (Uneven Absorption)

Why it happens: The wood was not sanded evenly, or it has been treated with something else previously (like furniture polish).

The Fix: If using a film finish (poly), a quality sanding job and 3–4 coats usually hide blotching. If using oil, the area that absorbed too much needs more oil applied, and the area that absorbed too little needs a second or third coat once the first coat is dry. Consistency is key here.

Maintenance: Keeping Your Hard Work Protected

Congratulations! You’ve sealed your countertop. Now, let’s talk about keeping it looking great long-term. The maintenance schedule depends entirely on the sealer you chose.

Caring for Oil-Sealed Counters

Oil finishes wear off with exposure to soap, water, and abrasion. You must replenish them regularly.

- Daily Cleaning: Wipe spills immediately. Clean with mild dish soap and water, and dry thoroughly. Never let water pool on the surface.

- Monthly Touch-Up: Apply a light coat of mineral oil or conditioner monthly, let it soak for 15 minutes, and wipe clean.

- Spot Repair: If you notice a permanent stain or light scratch, simply take 220-grit sandpaper, sand only that small area with the grain, and reapply the oil generously to blend it in.

Caring for Polyurethane-Sealed Counters

These tops are much easier to live with day-to-day but require more precision for repair.

- Daily Cleaning: Use a soft cloth with warm water and mild dish soap. Avoid abrasive cleaners or scouring pads, as they will dull and scratch the plastic topcoat over time.

- Avoiding Damage: Never place a hot pot directly on a polyurethane surface, as the high heat can soften or burn the plastic layer. Use trivets!

- Long-Term Refinishing: If the finish becomes dull or scratched after several years, you will need to sand the entire countertop lightly (220-grit), clean thoroughly with mineral spirits or appropriate thinner, and apply one or two fresh topcoats of your chosen sealer.

Safety Deep Dive: Working Smart with Finishes

As your woodworking mentor, I must emphasize safety. Finishing materials range from benign natural oils to strong chemical vapors. Always be prepared.

Ventilation is Non-Negotiable

When using any solvent-based finish (oil-based poly, some varnishes), the fumes are harmful to breathe.

- Open every window you have.

- Use high-powered fans to pull air out of the room or work space.

- If working indoors for an extended period, wear an organic vapor respirator, not just a simple dust mask.

Handling Flammable Materials

Oil finishes and many solvents (like mineral spirits) are flammable. Proper disposal prevents dangerous reactions:

- Soak all used rags in a metal container filled with water.

- Alternatively, lay them flat outside on concrete until completely dry and stiff before bagging for disposal. Never ball them up.

Frequently Asked Questions (FAQ) for Wood Countertop Sealing

Q1: Can I use vegetable oil (like olive oil) to seal my wood countertop?

A: No. While tempting because it’s in your kitchen, vegetable oils like olive oil or canola oil will go rancid over time. This leaves a sticky, smelly, discolored mess inside the wood pores. Stick strictly to food-grade mineral oil or dedicated butcher block conditioners.

Q2: How long do I have to wait before I can actually use the countertop after sealing?

A: This depends entirely on your sealant. For oils, you can usually wipe the surface dry and start light use within 24 hours, but wait a week for heavy scrubbing. For polyurethane, wait at least 72 hours before light use, and ideally a full 7 to 30 days (depending on the formula) before you put heavy pots or liquids on it while it fully cures.

Q3: Do I need to seal the underside of the countertop?

A: Absolutely! Sealing both the top and bottom surfaces equally helps stabilize the wood and prevents uneven moisture absorption, which reduces the risk of warping or cupping over time. Apply at least one coat to the bottom.

Q4: My countertop is already installed. Can I sand and reseal it now?

A: Yes, provided the installer sealed it with a film finish (like varnish or poly). If it was installed raw or oiled, sealing it in place is tricky because you need good airflow and space to work underneath. If it’s oiled, just sand lightly and apply a new coat of oil. If it has a hard finish, you must scuff it lightly with 220-grit paper before applying a maintenance coat of polyurethane.

Q5: Which finish looks the most natural?

A: Penetrating oils (mineral oil or pure tung oil) offer the most natural look, as they enhance the grain without leaving a visible film. Water-based polyurethanes also dry nearly clear, maintaining a very natural appearance while offering superior water resistance compared to oil.

Q6: What should I do if I get a water ring or dark stain on my sealed wood top?

A: If the sealer failed and the water penetrated, you have a few options. If it’s an oil finish, lightly sand the spot down until you remove the stain, clean it, and reapply several new coats of oil. If it’s a polyurethane finish, the damage might be too deep. You might need to sand the whole surface down to bare wood, allow it to dry completely for several days, and reapply a full finishing schedule.

Conclusion: Your Wood Countertop is Protected!

You’ve navigated the essential guide to how do you seal wood countertops, and the finish line is well within sight. Whether you opted for the natural, restorative path of mineral oil or the robust, protective barrier of polyurethane, you have given your investment the defense it deserves. Remember the golden rules we covered: proper, detailed sanding is mandatory, thin coats beat thick coats every single time, and knowing your finish’s maintenance schedule is the key to its long-term beauty.

Don’t hesitate to reach out to your finish manufacturer’s support line if you run into product-specific questions during the process. Every finish dries differently based on local conditions. Be patient, trust your sanding prep, and celebrate the beautiful, functional centerpiece you’ve created for your home. Now go enjoy your worry-free, beautifully sealed wood countertop!