Plywood Vs MDF Price: Essential Buying Guide

Plywood is generally more expensive than MDF due to its layered wood construction, offering superior strength and water resistance. MDF is typically cheaper but is prone to moisture damage and can be heavier for its thickness. Your project’s needs dictate the best value for your money.

Deciding between plywood and MDF for your next woodworking project can feel like a puzzle, especially when you look at the price tags. Both are fantastic sheet goods, but they have different strengths, weaknesses, and, yes, different prices. Knowing the differences helps you make the best choice for your budget and your project, ensuring you get durability and a beautiful finish without overspending. This guide will break down the plywood vs. MDF price puzzle, explore what influences their costs, and help you pick the right material for your DIY dreams. Let’s get crafting!

Understanding Plywood and MDF: The Basics

Before we dive into costs, let’s quickly understand what plywood and MDF are. This will help us see why their prices differ.

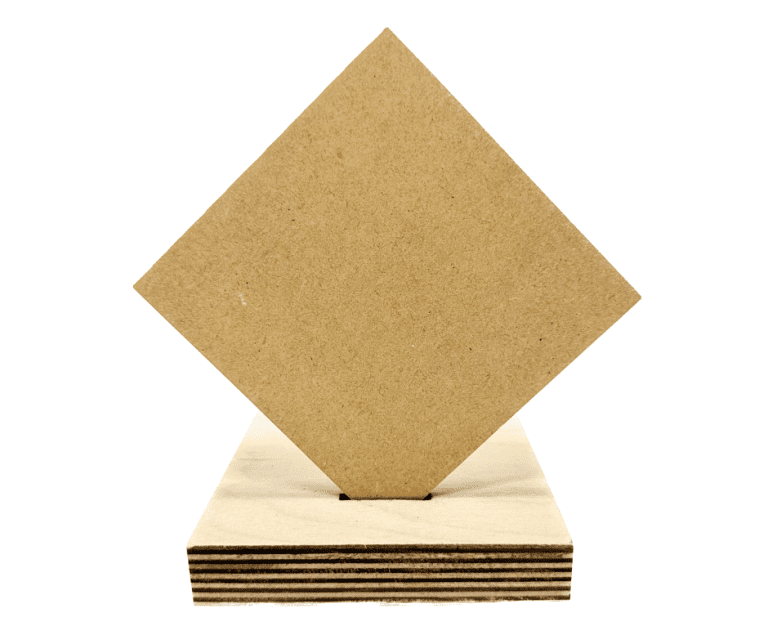

What is Plywood?

Plywood is made from thin layers of wood veneer, called plies, glued together with the grain of each layer oriented at right angles to the adjacent layer. Think of it like a strong, layered cake, but with wood! This cross-graining technique is key to its strength and stability.

Construction: Thin sheets of wood veneer are stacked and glued, with alternating grain directions for each layer.

Key Features: Strong, stable, good screw holding power, can handle moisture better than MDF if sealed properly.

Common Uses: Cabinet boxes, furniture frames, structural sheathing, subflooring, boat building, and projects where strength is paramount.

What is MDF (Medium-Density Fiberboard)?

MDF is an engineered wood product made by breaking down hardwood and softwood into wood fibers, then combining them with wax and resin binder, and applying high temperature and pressure. It forms a uniform, dense board with no grain pattern.

Construction: Wood fibers are mixed with resin and compressed into dense, flat panels.

Key Features: Smooth surface perfect for painting or veneering, uniform density, relatively inexpensive, but can be heavy and is susceptible to moisture.

Common Uses: Cabinet doors, furniture panels, shelving (in dry areas), decorative molding, cabinetry frames, and projects requiring a smooth, paintable surface.

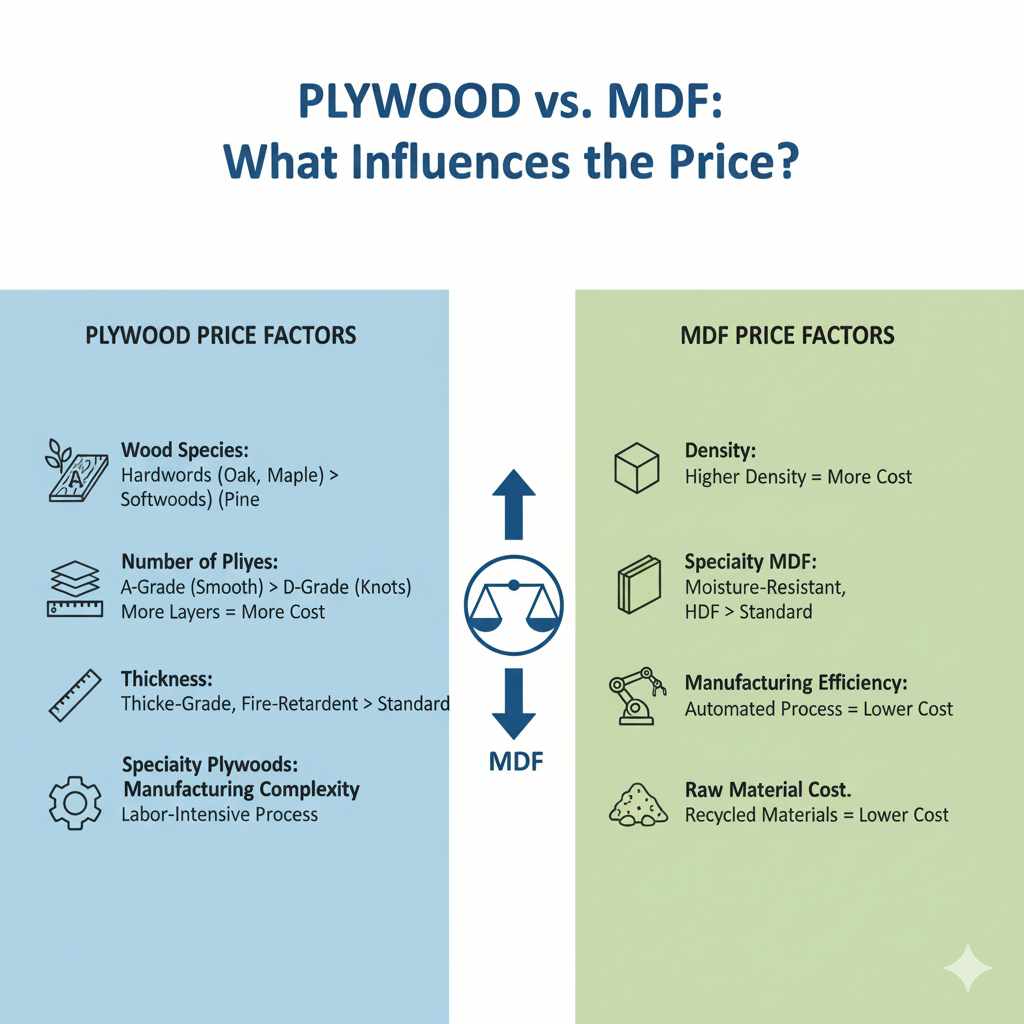

Plywood Vs. MDF Price: What Influences the Cost?

The price difference between plywood and MDF isn’t random; it’s a result of how they’re made, the materials used, and their performance characteristics.

Factors Affecting Plywood Price

Wood Species: Plywood made from hardwoods like oak, maple, or birch is generally more expensive than pine or fir plywood. Common construction grades often use softer woods.

Grade: Plywood comes in different grades (e.g., A, B, C, D). “A” grade has a smooth, sanded face, while “D” grade might have more knots and imperfections. Higher grades cost more.

Number of Plies: More plies (layers) generally mean stronger, more stable plywood, which can increase the cost.

Thickness: Thicker sheets obviously hold more wood and thus cost more. Standard thicknesses are 1/4″, 1/2″, and 3/4″.

Specialty Plywoods: Marine-grade plywood or fire-retardant treated plywood will have a significantly higher price tag due to specialized manufacturing and treatments.

Manufacturing Complexity: The process of peeling veneers, laying them up, and pressing them is more labor-intensive and requires specialized machinery compared to MDF production.

Factors Affecting MDF Price

Density: While it’s called “medium-density,” MDF can vary. Higher-density MDF might be slightly more expensive but offers better screw retention and strength.

Thickness: Similar to plywood, thicker MDF panels will cost more.

Specialty MDF: Moisture-resistant MDF (often green-colored) or industrial-grade MDF can be more expensive. High-density fiberboard (HDF) is denser and pricier than standard MDF.

Manufacturing Efficiency: MDF production is highly automated, which can lead to lower manufacturing costs compared to plywood. This efficiency often translates into lower prices for consumers.

Raw Material Cost: MDF uses wood fibers from a wider variety of wood sources, including recycled materials, which can help keep raw material costs down.

Direct Comparison: Plywood vs. MDF Price Ranges

Let’s talk numbers. Keep in mind that prices can fluctuate based on location, supplier, and current market conditions. These are general estimates for common sheet sizes (4ft x 8ft) and thicknesses (3/4 inch).

| Material Type | Typical Price Range (4×8 sheet, 3/4″) | Key Price Drivers |

|---|---|---|

| Standard Plywood | $30 – $70 | Wood species (pine vs. premium), grade (construction vs. cabinet), thickness |

| Cabinet-Grade Plywood | $50 – $110+ | Hardwood veneers (birch, oak, maple), smoother faces, fewer voids |

| MDF (Standard) | $25 – $45 | Thickness, density, supplier |

| Moisture-Resistant MDF | $40 – $60+ | Specialized resins and treatments |

| HDF (High-Density) | $50 – $80+ | Extreme density, making it stronger and heavier |

Note: These are rough estimates. Always check with your local lumberyard or home improvement store for current pricing.

One crucial factor regarding price is waste. If you’re cutting intricate shapes or many small pieces, the way a material cuts and holds its integrity can impact the overall cost of your project by minimizing waste. While MDF might be cheaper per sheet, if you have to discard many pieces due to chipping or breakage, its overall cost-effectiveness diminishes.

The Cost of Ownership: Beyond the Initial Purchase Price

The “cheaper” option isn’t always the most cost-effective in the long run. When considering plywood vs. MDF price, think about the total cost, including:

Durability and Longevity

Plywood: Generally more durable. Its layered construction provides excellent strength and resistance to warping. It holds screws and nails well, making it suitable for structural applications. If properly sealed, it can withstand some moisture.

MDF: Less durable in terms of physical impact and moisture. It can chip or dent if hit hard. Its biggest weakness is moisture, which causes it to swell significantly and lose structural integrity. It also doesn’t hold screws as well as plywood and can crumble if screwed and unscrewed too many times.

Finishing Capabilities

Plywood: Can be stained or painted. For a smooth finish, you might need to fill any veneer imperfections or wood grain. Costs can increase if you opt for high-quality veneer plywood for a visible grain finish.

MDF: Offers a superior surface for painting. Its smooth, uniform texture means no wood grain to deal with, leading to a flawless painted finish with less prep work and fewer coats of paint. This can save on finishing materials and labor.

Weight

Plywood: Lighter for its strength, especially softwood plywood, making it easier to handle.

MDF: Significantly heavier than plywood of the same thickness due to its density. This can make installation and handling more challenging and potentially increase shipping costs if buying online.

Tooling and Waste

Plywood: Can sometimes splinter or chip, especially cheaper grades. Using a sharp blade and proper cutting techniques (like scoring or using painter’s tape) minimizes this.

MDF: Cuts cleanly and smoothly, producing very little fuzz or splintering. However, its dust is extremely fine and can be a respiratory irritant, requiring good dust collection and a respirator. The fine dust can also wear out saw blades and router bits faster than wood.

When to Choose Plywood (and Why it Might Be Worth the Price)

Plywood is often the go-to choice when you need strength, stability, and some level of moisture resistance.

Projects Where Plywood Shines:

Cabinet boxes: Holds screws well, provides structural integrity, and is less prone to sagging under load.

Shelving for heavy items: Its strength prevents sagging over longer spans.

Subflooring and structural sheathing: Essential for building stability, able to withstand structural loads.

Outdoor projects (if properly sealed): With the right sealants and finishes, it can be used for certain exterior applications.

Furniture frames and components that need to be very strong: Think bed frames, workbench tops.

Veneered projects: If you want a real wood veneer look on furniture or panels, plywood is the substrate.

A great example of where plywood’s strength is essential is in building robust shelving. For instance, when building a garage storage shelf that needs to hold tools, paint cans, and other heavy items, 3/4-inch birch plywood is an excellent choice. Its ability to resist sagging is crucial. According to the Woodworking Network, advancements in plywood manufacturing continue to enhance its performance.

When to Choose MDF (and Why it Can Be a Budget-Friendly Option)

MDF is fantastic for projects where a smooth, flat surface is the priority, especially for painting.

Projects Where MDF is a Better Fit:

Cabinet doors: Its smooth surface is perfect for painting or applying veneers, giving a high-end look.

Decorative elements: Picture frames, signs, intricate laser-cut or CNC designs.

Painted furniture components: Tabletops, drawer fronts, decorative panels.

Speaker boxes: Its density and lack of resonance help create better sound acoustics.

Temporary or indoor shelving: For lighter loads in dry environments.

Moldings and trim: Can be machined into complex profiles and painted.

For incredibly smooth, professional-looking painted furniture, MDF is often the preferred material. Consider making cabinet doors. The uniform surface of MDF ensures that when you paint it, you achieve a glass-like finish without any of the grain swelling or telegraphing that can happen with wood or even plywood. The Popular Mechanics guide on working with MDF highlights its advantages for achieving a flawless painted finish. While MDF itself is cheaper, the overall cost of finishing might be reduced due to less prep work and fewer coats of primer and paint needed.

Working with Plywood and MDF: Practical Considerations

Beyond price, how easy are they to work with?

Cutting and Machining

Plywood: Cuts well with a sharp blade. Cross-cutting can sometimes cause tear-out on the surface ply, especially with cheaper grades. A scoring cut or using painter’s tape can help.

MDF: Cuts very cleanly with a sharp blade, producing minimal dust fuzz. However, the dust is extremely fine and requires excellent dust collection and personal protective equipment (PPE). MDF dust is also abrasive and can dull blades faster.

Fastening

Plywood: Holds screws and nails very well. You can countersink screws for a flush finish. Longer screws can penetrate multiple plies for a strong hold.

MDF: Can hold screws, but not as securely as plywood. If the screw is removed and reinserted, the fibers can strip. Using wood glue and fasteners in combination is often recommended. It’s best to avoid overtightening. For critical joints, consider inserts or specialized fasteners.

Edge Finishing

Plywood: The exposed plies on the edge can be attractive and can be sanded and finished. For a clean edge, you can use edge banding or a veneer strip.

MDF: Edges are plain fiber. You can sand them smooth and paint them, or cover them with edge banding or a veneer.

Moisture Sensitivity

This is a big one!

Plywood: Most common plywood is not waterproof but is water-resistant to a degree, especially hardwood plywood. With proper sealing (like a good varnish, primer, or exterior paint), it can perform well in moderately humid environments or for short exposures to moisture.

MDF: Highly susceptible to moisture. Even high humidity can cause it to swell. Spills can ruin it. For areas prone to moisture (like kitchens or bathrooms), you must use specialized moisture-resistant MDF and seal all edges and surfaces meticulously.

Weight

Plywood: Lighter for its strength. A 4×8 sheet of 3/4″ pine plywood weighs around 50-60 lbs.

MDF: Heavier. A 4×8 sheet of 3/4″ MDF weighs around 70-80 lbs. This extra weight needs to be factored in for handling, installation, and the structural support required for shelves or cabinets.

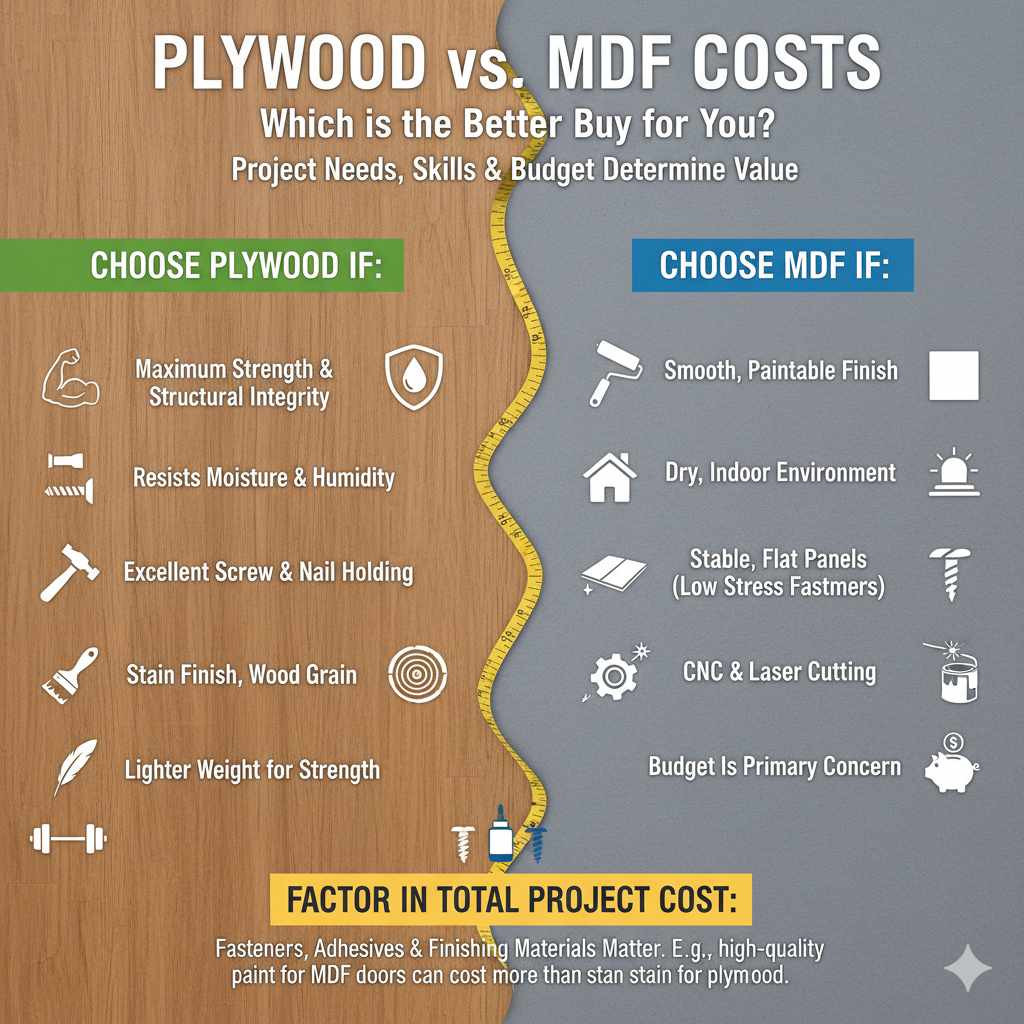

Plywood vs. MDF Costs: Which is the Better Buy for You?

The “cheaper” material isn’t always the best value. The best buy depends entirely on your project’s needs, your skills, and your budget.

Choose Plywood if:

You need maximum strength and structural integrity.

The project will be exposed to any moisture or humidity.

You need excellent screw and nail holding power.

You are finishing with a stain and want to showcase wood grain.

You need to minimize weight for its strength.

Choose MDF if:

You are painting the project and want a perfectly smooth, furniture-grade finish.

The project is for a dry, indoor environment.

You need a very stable, flat surface for applications like doors or panels and won’t be stressing the fasteners excessively.

You are working with CNC machines or laser cutters where its uniform makeup is an advantage.

Budget is a primary concern and the project’s demands align with MDF’s capabilities.

Remember that the cost of fasteners, adhesives, and finishing materials can also influence the overall project cost. For example, if using MDF for painted cabinet doors, the cost of high-quality primer and paint might be higher than finishing stained plywood, even if the raw material cost is lower.

Frequently Asked Questions (FAQ)

Q1: Is plywood always more expensive than MDF?

A1: Generally, yes. Standard construction plywood is often priced similarly to or slightly higher than standard MDF, but premium cabinet-grade plywoods with hardwood veneers can be significantly more expensive than MDF.

Q2: Which material is better for cabinet boxes, plywood or MDF?

A2: Plywood is usually preferred for cabinet boxes. It offers better structural strength, holds screws and hardware more securely, and is less prone to sagging and moisture damage than MDF.

Q3: Can I paint MDF?

A3: Yes, MDF is excellent for painting! Its smooth, grain-free surface allows for a very smooth, professional finish with less prep work compared to wood or plywood.

Q4: Which is stronger, plywood or MDF?

A4: Plywood is generally stronger and more structurally sound, especially in terms of holding fasteners and resisting bending or sagging over time. MDF is dense and rigid but can be brittle and doesn’t hold fasteners as well.

Q5: Which material is lighter, plywood or MDF?

A5: Plywood is typically lighter than MDF of the same thickness. This can make it easier to handle, install, and transport.

Q6: Is MDF safe to use in a bathroom?

A6: Standard MDF should never be used in a bathroom due to its extreme sensitivity to moisture. Special moisture-resistant MDF (often colored green) can be used, but it requires thorough sealing of all surfaces and edges, and even then, it’s still not as reliable as properly sealed plywood or specialized bathroom board.

Q7: How do I get a good edge finish on MDF?

A7: You can sand MDF edges smooth and paint them, or apply wood veneer or edge banding. For painting, ensure the edges are thoroughly sealed with primer or a dedicated edge filler before applying the topcoat.

Conclusion: Making the Smart Choice for Your Project

Navigating the world of sheet goods like plywood and MDF doesn’t have to be complicated, especially when it comes to price. Plywood, with its layered strength and better moisture resistance, often commands a higher price but offers superior durability for structural and demanding applications. MDF, on the other hand, provides a smooth, cost-effective surface ideal for painted finishes, typically at a lower per-sheet price, but with limitations regarding moisture and fastener holding.

Ultimately, the “best” value comes down to matching the material’s properties to your project’s specific needs. Weigh the upfront cost against the required performance, durability, and desired finish. By understanding the nuances of plywood vs. MDF price and performance, you can make an informed decision that saves you money and ensures your woodworking projects turn out exactly as you envision – strong, beautiful, and built to last. Happy building!