Unfinished Wood Floors vs Prefinished: Which Is Best?

Choosing between unfinished and prefinished wood floors can seem tricky, especially when you’re new to home improvement. Many people wonder which option is truly better for their home and their wallet. This choice affects how your floors look, how long they last, and how much work you have to do.

We’re here to make it simple. By the end of this, you’ll know exactly what to consider and make a confident decision for your space. Let’s explore Unfinished Wood Floors vs Prefinished: Which Is Best?

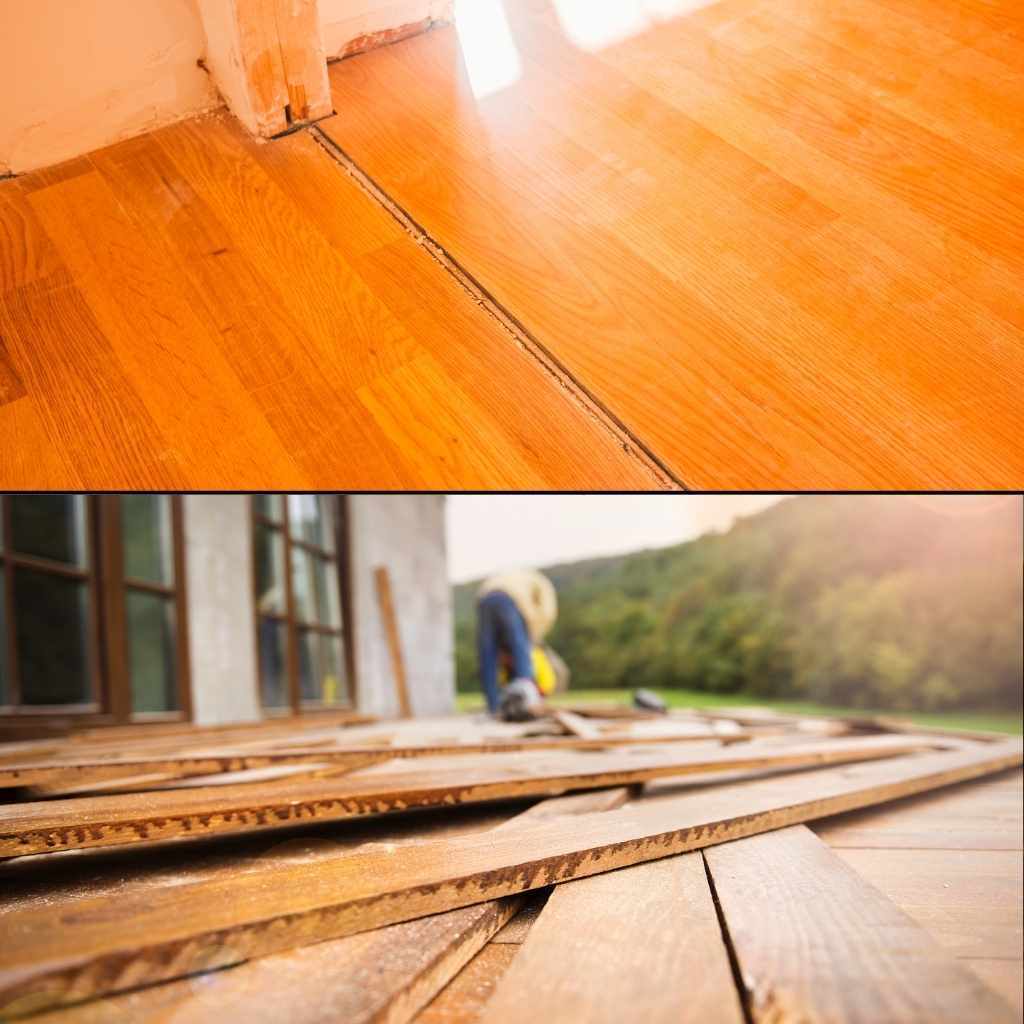

Understanding Unfinished Wood Floors

Unfinished wood floors, also known as raw wood floors, arrive at your home in their natural state. This means they haven’t been sanded, stained, or sealed at the factory. They are essentially ready to be installed and then customized right there in your house.

This offers a blank canvas for homeowners who want complete control over the final look of their flooring. It’s a more traditional approach to wood flooring installation, allowing for a truly bespoke finish.

The process for unfinished floors involves several steps after installation. First, the wood is laid down. Then, it undergoes a thorough sanding process.

This sanding smooths out any imperfections, evens out the boards, and prepares the surface for finishing. After sanding, the wood is ready for staining, if desired. You can choose from a vast range of stain colors to match your decor.

Finally, multiple coats of sealant are applied to protect the wood from wear, spills, and damage. This entire finishing process happens on-site, which means more labor and more control over the final appearance.

The Advantages of Unfinished Flooring

One of the biggest draws of unfinished wood floors is the unparalleled level of customization. You are not limited by the stain colors or finishes offered by manufacturers. This means you can achieve a truly unique look that perfectly matches your existing decor or your personal style.

Whether you want a very light, natural tone, a deep, rich espresso, or something completely custom like a gray wash or a painted finish, unfinished flooring makes it possible. This flexibility is a major selling point for many homeowners.

- Complete Color and Finish Control. You have the freedom to select any stain color imaginable, from light natural hues to dark, dramatic tones, or even custom painted finishes. This allows for a floor that is uniquely yours.

- Seamless Installation. When laid and finished on-site, unfinished floors can be sanded and finished to create a perfectly level and seamless surface. This eliminates visible lines between planks and provides a smooth, uniform appearance across the entire floor.

- Easier Repairs. If a section of unfinished wood flooring gets damaged in the future, it can often be repaired and re-finished to match the rest of the floor more seamlessly than prefinished options. This can save significant costs and effort down the line.

- Deeper Penetration of Finish. Applying the stain and sealant on-site allows these products to penetrate the wood more deeply. This can result in a more durable and long-lasting finish that is less likely to wear off quickly.

The ability to choose any color means you can adapt your floors to changing design trends or personal preferences without needing to replace the entire floor. For instance, if you decide to paint your walls a new color, you can potentially re-stain your floors to complement the new scheme. This adaptability adds significant long-term value to your home.

The Disadvantages of Unfinished Flooring

While the customization is a huge plus, it comes with significant trade-offs in terms of time and labor. Finishing unfinished floors on-site is a multi-step process that can take several days, even weeks, depending on the size of the area and drying times. This means your home will be disrupted for an extended period, with dust and fumes from sanding and finishing products.

The labor-intensive nature of finishing on-site also translates to higher costs. You’ll need to pay for skilled labor to perform the sanding, staining, and sealing. If you decide to do it yourself, it requires specialized equipment and a good deal of expertise to achieve professional results.

Mistakes during the finishing process can be costly and difficult to correct, potentially requiring the replacement of damaged boards.

- Extended Installation Time. Unlike prefinished floors which are ready to use shortly after installation, unfinished floors require days or even weeks for sanding, staining, and multiple coats of sealant to dry and cure. This means significant disruption to your daily life.

- Mess and Dust. The sanding process generates a substantial amount of fine dust. While professionals use dust containment systems, some dust is inevitable, and fumes from stains and sealants can also be a concern, requiring good ventilation.

- Higher Labor Costs. Hiring professionals for sanding and finishing is typically more expensive than installing prefinished flooring. The specialized skills and time required contribute to the overall cost.

- Potential for Inconsistent Finish. Achieving a perfectly uniform stain and finish across a large area can be challenging, especially for DIYers. Streaks, blotches, or uneven coloring can occur if not done with expertise.

Furthermore, the open-pored nature of unfinished wood before sealing can make it more susceptible to damage from spills or scuff marks during the installation and finishing process itself. Careful protection and handling are essential throughout this stage.

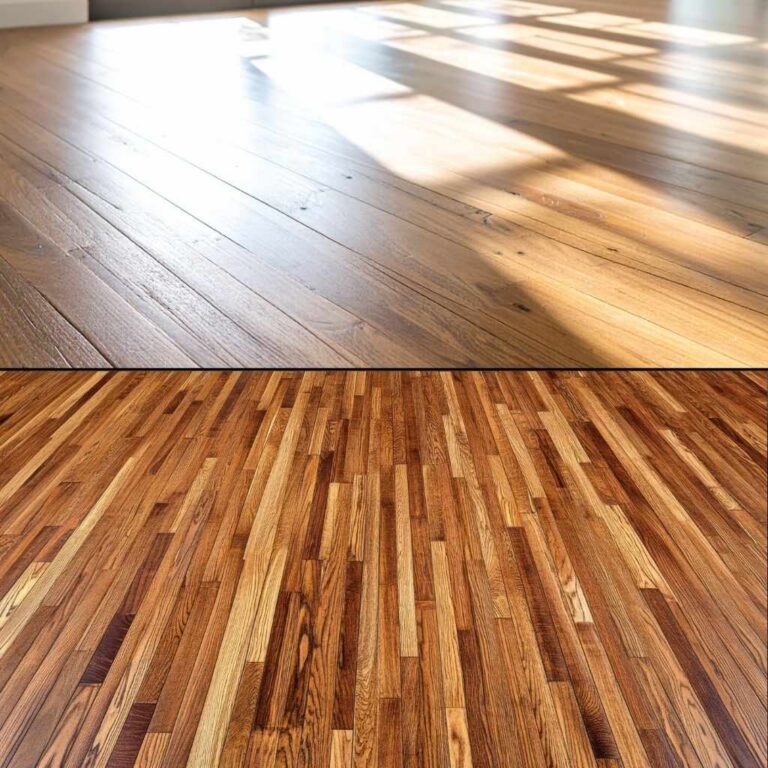

Exploring Prefinished Wood Floors

Prefinished wood floors are manufactured in a factory where they are pre-sanded, pre-stained, and pre-sealed with multiple protective coats. They arrive at your home ready to be installed and walked on almost immediately after the last board is laid. This makes them a popular choice for homeowners looking for a faster, cleaner, and often more predictable installation process.

The factory setting allows for precise control over the finishing process, ensuring a consistent and durable result.

The key advantage of prefinished flooring lies in its ready-to-use nature. Once the installers are done, you can usually start using the room without waiting for drying times. This significantly reduces the disruption to your household.

The factory finish also tends to be harder and more resistant to wear and tear than many on-site finishes because it’s often cured with UV light or other industrial methods. This makes them a practical choice for busy households.

The Advantages of Prefinished Flooring

The most significant benefit of prefinished wood floors is the speed and ease of installation. Because the finishing is done in a controlled factory environment, the floors are ready to be installed and used almost right away. This means less downtime for your home and a quicker path to enjoying your new floors.

The factory finish is also a major plus. Manufacturers use advanced techniques and high-quality sealants, often curing them under UV light, to create an exceptionally durable surface. This finish is typically harder and more resistant to scratches, scuffs, and fading than many finishes applied on-site.

This durability makes prefinished floors an excellent choice for high-traffic areas or homes with children and pets.

- Faster Installation. Prefinished floors can be installed and ready for use in a matter of days, significantly reducing the time your home is disrupted compared to unfinished floors.

- Durable Factory Finish. The factory applies multiple coats of durable finishes, often cured with UV light, creating a harder and more wear-resistant surface than most on-site applications. This protects against scratches and scuffs.

- Less Mess and Odor. Since the finishing is done off-site, there is minimal dust and no strong chemical odors during installation. This makes it a cleaner and more pleasant process for your home.

- Consistent Appearance. The factory process ensures a uniform stain color and finish across all the planks, providing a predictable and high-quality look throughout the entire floor.

This consistency means you get exactly the look you see on the sample board, with no surprises. The factory also typically applies beveled edges to the planks, which helps to mask minor gaps and imperfections that can occur during installation, further contributing to a polished appearance.

The Disadvantages of Prefinished Flooring

While prefinished floors offer many conveniences, they also have some drawbacks. The most notable is the limited customization. You are restricted to the stain colors and finishes offered by the manufacturer.

While there are many options available, you might not find the exact shade or sheen you envision, especially if you’re aiming for a very specific or unique look.

Another consideration is the beveled edge often found on prefinished planks. This slight groove between planks, while hiding installation imperfections, can trap dirt and debris over time, making it harder to clean thoroughly. It also creates a more textured look, which may not appeal to everyone who prefers a perfectly smooth, monolithic surface.

- Limited Customization Options. You are limited to the colors, sheens, and wood species offered by manufacturers. Achieving a truly unique or custom look might be difficult or impossible with prefinished options.

- Beveled Edges. Most prefinished planks have beveled edges, creating small gaps between boards. These gaps can collect dirt and dust, making cleaning more challenging and potentially affecting the smooth appearance of the floor.

- Repair Challenges. If a prefinished plank is deeply scratched or damaged, matching the exact factory finish for a repair can be very difficult. Often, the entire plank, or even a larger section, may need to be replaced.

- Potentially Less Natural Look. While high-quality, the factory finish can sometimes appear less natural or handcrafted compared to a meticulously applied on-site finish.

The cost can also be a factor. While installation is faster, the upfront material cost for prefinished flooring can sometimes be higher than raw wood due to the added manufacturing processes and quality control involved.

Key Factors to Consider for Unfinished Wood Floors vs Prefinished

When deciding between unfinished and prefinished wood floors, several factors come into play. It’s not just about the look; it’s about your lifestyle, budget, and desired outcome. Thinking through these aspects will guide you toward the best choice for your specific situation.

This involves balancing the desire for customization with the need for practicality and speed.

Your budget is often a primary driver. While unfinished wood itself can be less expensive, the total cost of installation and finishing can make it more expensive than prefinished options. Prefinished floors have a higher upfront material cost but often lower installation labor costs due to their speed and simplicity.

It’s crucial to get detailed quotes for both scenarios, including materials, labor, and any associated costs like dust containment or waste removal.

Budget and Cost Analysis

The cost of flooring can be broken down into material costs and labor costs. For unfinished wood floors, the raw wood planks are typically less expensive than their prefinished counterparts. However, this initial saving is often offset by the significant cost of professional sanding, staining, and sealing.

These services require skilled labor and specialized equipment, driving up the overall project expense. Some homeowners opt for a DIY approach to save money, but this requires considerable time, effort, and expertise to achieve satisfactory results.

Prefinished wood floors, on the other hand, have a higher material cost because of the factory finishing processes. However, their installation is generally faster and requires less specialized labor than finishing on-site. This can lead to lower overall installation labor costs.

The predictability of prefinished flooring means fewer surprises in terms of cost, as the price you’re quoted usually includes the finished product and its installation. It’s important to compare total project costs, factoring in not just the price per square foot but also the associated labor and any potential hidden fees.

| Factor | Unfinished Wood Floors | Prefinished Wood Floors |

|---|---|---|

| Initial Material Cost | Lower | Higher |

| Sanding & Finishing Labor Cost | Higher (on-site) | Lower (factory) |

| Total Installation Cost | Potentially Higher | Potentially Lower |

| DIY Cost Savings | Significant potential, but requires expertise | Limited, mostly installation labor |

A realistic budget should also account for potential contingencies. For unfinished floors, this might include costs for extra sealant or stain if more is needed, or for repairs to any boards damaged during the on-site finishing. For prefinished floors, contingencies might relate to needing a few extra planks for cuts or potential damage during transport or installation.

Installation Time and Lifestyle Impact

The timeline for installing wood floors can significantly impact your daily life. Unfinished wood floors demand a longer commitment. After installation, the sanding, staining, and sealing process can take anywhere from a few days to over a week, depending on the size of the space and the number of coats applied.

During this period, the area will be dusty and potentially have strong odors, making it unsuitable for living. This extended disruption can be challenging for families, especially those with young children or pets, or individuals who work from home.

Prefinished wood floors offer a much quicker solution. Once installed, they are typically ready for use almost immediately. This minimal downtime means your household can resume normal activities quickly, making prefinished floors a more practical choice for busy households or for renovation projects where speed is a priority.

The lack of dust and fumes during installation also contributes to a less intrusive experience.

- Scenario 1: Busy Family Renovation. Imagine a family with two young children and a dog needing to renovate their living room and kitchen. They want beautiful new hardwood floors but have limited time and can’t afford prolonged disruption. Opting for prefinished floors would allow them to have their new floors installed and be back to their regular routine within days, minimizing stress and allowing the children and pet to enjoy the new space sooner.

- Scenario 2: Custom Home Build. A couple building a custom home wants a very specific, hand-scraped look with a unique custom stain color that isn’t available prefinished. They are willing to wait for the perfect aesthetic. Choosing unfinished floors, even with the longer installation time, provides them with the exact look they envision for their dream home.

The impact on your lifestyle is a key consideration. If you have a busy schedule and need your home to be functional quickly, prefinished is often the better route. If you have more time, are building a new home, or are undertaking a renovation where extended disruption is manageable, unfinished floors offer greater creative freedom.

Durability and Maintenance Considerations

When it comes to durability, both unfinished and prefinished wood floors can be very long-lasting, but they achieve this through different means. Prefinished floors come with a factory-applied finish that is typically very hard and resistant to wear and tear. These finishes often contain aluminum oxide or similar materials, making them exceptionally durable and less prone to scratches and scuffs.

This makes them an excellent choice for high-traffic areas like hallways, living rooms, and kitchens, as well as homes with active children and pets.

Unfinished wood floors, when properly finished on-site with high-quality sealants, can also be extremely durable. The advantage here is that you can choose the exact type and number of sealant coats, allowing you to tailor the protection to your needs. For instance, you might opt for a satin finish for a more natural look or a high-gloss polyurethane for maximum protection.

The ability to apply multiple coats ensures a robust barrier against wear.

- Durability Comparison: Prefinished floors often boast superior scratch resistance right out of the box due to advanced factory curing processes. Unfinished floors can achieve similar or even greater durability if finished with multiple high-quality coats on-site, allowing for a thicker, more protective layer.

- Maintenance Ease: For everyday cleaning, both types are similar, requiring sweeping or vacuuming and occasional damp mopping. However, the beveled edges on many prefinished floors can make thorough cleaning of trapped debris more challenging than on a seamless unfinished floor.

- Repairability: This is where unfinished floors often shine. If a plank is damaged, it can be sanded and re-finished to match the surrounding floor seamlessly. Repairing a damaged prefinished plank to match the original factory finish can be very difficult, often requiring replacement of the entire plank or a larger section.

- Longevity Potential: Both types can last for decades. Unfinished floors can be re-sanded and re-finished multiple times throughout their lifespan, effectively giving them a new lease on life. Prefinished floors, while durable, cannot be re-sanded as many times because the factory finish is very thin.

Ultimately, the best choice for durability depends on the quality of the installation and the finish applied. A well-finished unfinished floor or a high-quality prefinished floor can provide beautiful and long-lasting results. Understanding how each is finished and what that means for future maintenance and repairs is key.

Aesthetic Control and Design Flexibility

The aesthetic of your floors is a major part of your home’s overall design. Unfinished wood floors offer the ultimate canvas for achieving a specific look. You are not confined by pre-set color palettes.

This allows for complete creative freedom. Whether you envision a light, airy Scandinavian feel, a rich, traditional dark wood, or a modern, distressed look, you can achieve it by selecting the stain and finish yourself or working with a professional. This level of control is invaluable for creating a truly unique home.

Prefinished floors provide a wide array of beautiful options, but you are limited to what the manufacturers offer. While this is often more than enough for most homeowners, it may not satisfy those with a very particular design vision. The consistency of prefinished floors is also a double-edged sword; while it ensures uniformity, it can sometimes result in a less “organic” or hand-crafted appearance compared to a custom-finished unfinished floor.

The beveled edges on prefinished planks also contribute to a more textured, plank-by-plank visual, which can be desirable for some but not for those seeking a perfectly smooth, flowing surface.

- Custom Staining: With unfinished floors, you can mix stains to create custom shades, or even use special techniques like cerusing or liming to achieve unique textures and looks.

- Finish Sheen: You can choose from matte, satin, semi-gloss, or high-gloss finishes on unfinished floors, directly impacting the light reflection and overall feel of the room.

- Edge Profile: Unfinished floors are typically installed and finished without beveled edges, creating a sleek, modern, or traditional seamless look.

- Wood Species and Grade: Both options allow for a choice of wood species and grades, but on unfinished floors, the grain pattern and natural characteristics of the wood are more prominently displayed after custom finishing.

For example, if you’re aiming for a specific shade of gray that isn’t available prefinished, an unfinished floor allows you to achieve it precisely. If you want the visual continuity of a floor with no visible gaps between boards, unfinished is often the way to go. However, if the vast selection of prefinished colors and textures meets your needs, the convenience and speed of installation might outweigh the need for absolute custom control.

Who Should Choose Unfinished Wood Floors

Unfinished wood floors are an excellent choice for homeowners who prioritize complete design control and are willing to invest the time and resources to achieve a truly custom look. This option is ideal for those undertaking a full home renovation or building a new home where the flooring can be a central design element. It appeals to individuals who have a very specific vision for their home’s aesthetic and want their floors to be a unique reflection of their personal style, rather than adhering to factory-set options.

If you are a DIY enthusiast with experience in woodworking and finishing, unfinished floors can offer a rewarding project. However, for most, it involves hiring skilled professionals for the on-site finishing. The extended timeline and potential for dust and fumes mean this option is best suited for situations where disruption is manageable, such as during a longer renovation or in a property that can be temporarily vacated.

The ability to re-sand and re-finish these floors multiple times over their lifespan also makes them a sound long-term investment for those who plan to stay in their home for many years and appreciate the potential for future refreshes.

- Homeowners seeking a unique, custom color or finish that isn’t available in prefinished options.

- Individuals undertaking a significant renovation or new home build where the flooring is a key design feature.

- Those who appreciate the classic, seamless look achieved by on-site finishing without beveled edges.

- People willing to invest more time and budget for a bespoke flooring solution.

- DIYers with significant experience in wood finishing who want to control every step of the process.

The ultimate decision for unfinished floors often comes down to a desire for unparalleled customization and the willingness to embrace a more involved and time-consuming installation and finishing process. The payoff is a floor that is truly one-of-a-kind, perfectly integrated into the home’s design narrative.

Who Should Choose Prefinished Wood Floors

Prefinished wood floors are an excellent choice for homeowners who value speed, convenience, and a durable finish with minimal fuss. This option is particularly well-suited for busy families, individuals undertaking quick renovations, or those who want their new floors ready for use as soon as possible. The straightforward installation process means less disruption to daily life, making it a practical choice for those who need their homes functional quickly.

If you appreciate a clean, consistent look and don’t have a highly specific or unusual color preference, prefinished floors offer a wide range of beautiful and readily available options. The factory finish provides excellent protection against everyday wear and tear, making it ideal for high-traffic areas and households with children and pets. The predictable outcome of prefinished flooring also provides peace of mind, as you know exactly what you’re getting.

- Homeowners needing a quick installation and minimal disruption to their living space.

- Families with children and pets who need a highly durable, scratch-resistant floor.

- Individuals who prefer a wide selection of attractive, ready-made color and finish options.

- Those on a tighter renovation schedule where time is a critical factor.

- People who want a clean, consistent look with minimal risk of finishing inconsistencies.

The decision for prefinished flooring often hinges on a desire for efficiency and a reliable, long-lasting finish without the complexities of on-site finishing. It’s a practical solution that delivers beautiful results in a timely manner, fitting seamlessly into modern, busy lifestyles.

Frequently Asked Questions

Question: Is unfinished wood more expensive than prefinished

Answer: Not necessarily. The raw wood for unfinished floors can be cheaper, but the cost of professional sanding, staining, and sealing adds significantly to the total project expense, often making it more expensive than prefinished flooring.

Question: Which type of wood floor is easier to clean

Answer: Both are generally easy to clean with regular sweeping or vacuuming and damp mopping. However, the beveled edges on many prefinished floors can trap more dirt than the seamless surface of a finished unfinished floor.

Question: Can I install unfinished wood floors myself

Answer: Installing the planks is manageable for DIYers with some experience. However, the sanding and finishing stages require specialized tools and skills to achieve professional results, so most people hire professionals for this part.

Question: Which floor type is better for pets

Answer: Prefinished floors often have a harder, more scratch-resistant factory finish, which can be better for homes with pets who might scratch the floor. However, both can be durable if properly finished and maintained.

Question: How long does unfinished wood flooring last

Answer: Unfinished wood floors can last for generations. They can be re-sanded and re-finished multiple times throughout their lifespan, allowing for their appearance to be renewed.

Final Thoughts

Deciding between unfinished and prefinished wood floors boils down to your priorities. If you dream of a floor with a completely custom color, a specific sheen, or a unique texture that isn’t found in standard options, unfinished floors offer that ultimate canvas. This path allows for absolute control over the final look and feel, creating a truly bespoke surface for your home.

However, it means accepting a longer installation process, potential dust and fumes, and often a higher overall cost due to the specialized labor involved in on-site finishing.

Prefinished floors, on the other hand, provide a compelling blend of convenience, speed, and durability. They arrive ready to install and use, minimizing disruption to your household and letting you enjoy your beautiful new floors much sooner. The factory-applied finishes are typically very hard-wearing, making them an excellent choice for busy homes with children and pets.

While customization is limited to available manufacturer options, the vast selection usually provides ample beautiful choices. Consider the trade-offs between creative freedom and practical efficiency, and choose the option that best aligns with your lifestyle, budget, and design aspirations for a floor you’ll love for years to come.