What Does MDF Stand For in Wood: Your Essential Guide

MDF stands for Medium-Density Fibreboard, a popular engineered wood product. It’s made from wood fibers compressed with resin, offering a smooth surface ideal for painting and furniture making, and is a cost-effective alternative to solid wood for many projects.

Have you ever browsed lumber aisles or looked at furniture descriptions and seen the term “MDF” and wondered what it actually means? You’re not alone! It’s a common material in today’s homes, from cabinets to bookshelves, but its name can sound a bit technical. Many beginners find themselves unsure if it’s the right choice for their DIY project. This can be frustrating when you’re excited to start building something great. Don’t worry, though! I’m here as your woodworking mentor to break it all down. We’ll go through exactly what MDF is, how it’s made, and where it shines. Get ready to understand this versatile material and feel confident choosing it for your next creation.

What Does MDF Stand For in Wood? The Simple Answer

So, let’s get straight to it. “MDF” is an acronym that stands for Medium-Density Fibreboard. Think of it as a type of engineered wood panel. It’s made by breaking down hardwood and softwood trees into tiny wood fibers, then mixing these fibers with wax and a resin binder. This mixture is then heated and pressed into uniform thin mats under high pressure. The result is a strong, stable panel that’s incredibly smooth on both sides.

Unlike plywood, which is made by layering thin sheets of wood veneer glued together with the grain of each layer at right angles, MDF is made from individual wood fibers. This fiber-based construction is key to its unique properties. Because there’s no grain pattern like you’d find in solid wood, MDF behaves very consistently. This means it doesn’t warp, twist, or crack easily, making it a predictable material to work with for many applications. It’s become a staple in the furniture industry and for DIY projects because of its affordability and smooth finish.

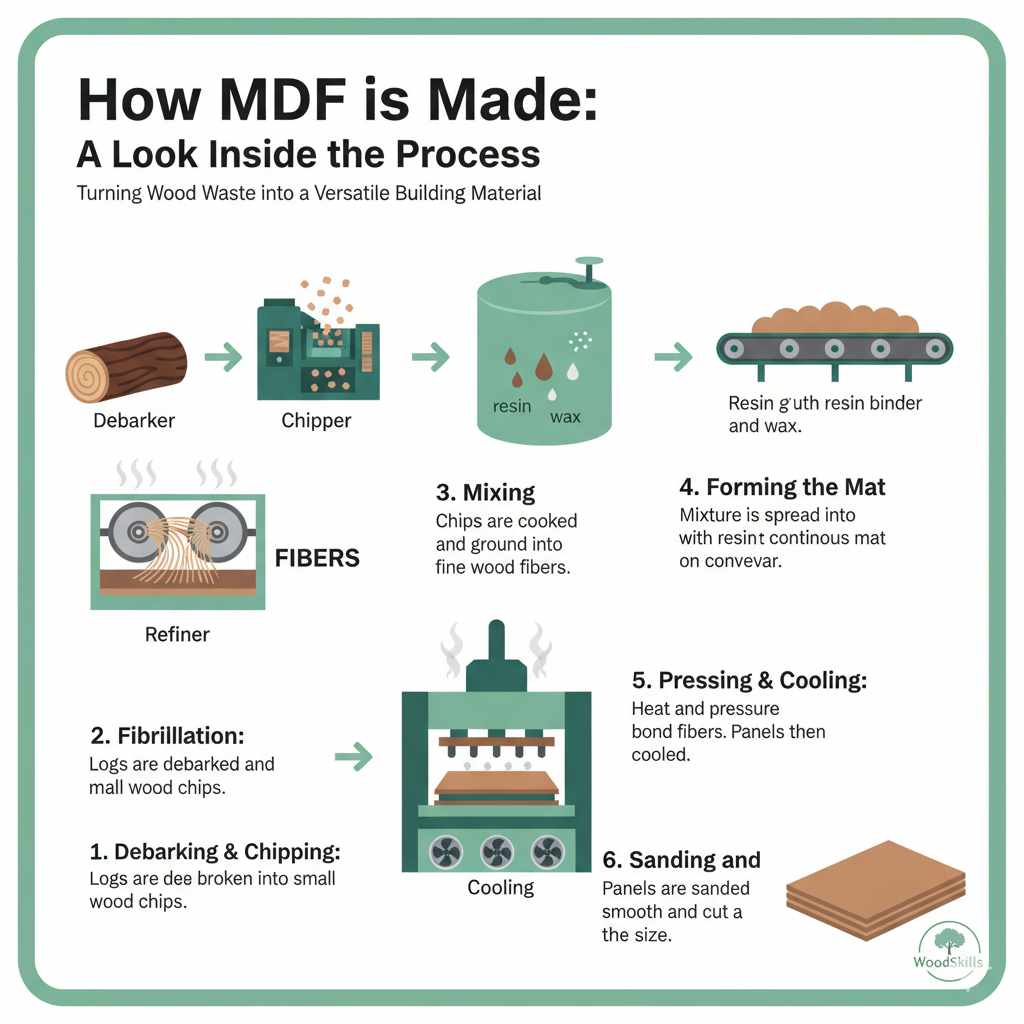

How is MDF Made? A Look Inside the Process

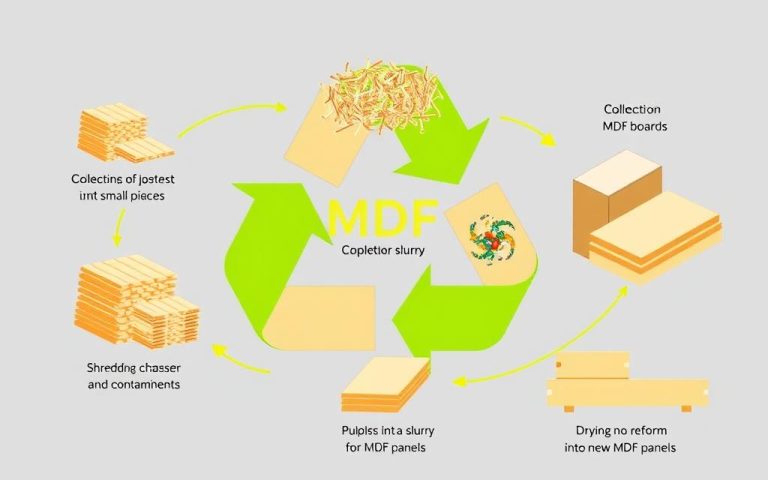

Understanding how MDF is made can help you appreciate its strengths and potential limitations. The process is quite clever and efficient, turning wood waste and smaller trees into a useful building material. Here’s a simplified breakdown:

- Debarking and Chipping: Logs, which can include waste wood or smaller trees that aren’t suitable for lumber, are first debarked. Then, they are fed into chippers that break them down into small wood chips.

- Fibrillation: These wood chips are then cooked and sent through a refiner. This machine, often essentially two metal discs spinning against each other, grinds the chips into fine wood fibers. This is the “fibreboard” part of its name – it’s made of fibers!

- Mixing: The wood fibers are then mixed with a special type of resin binder and wax. These binders are crucial for holding the fibers together when they are pressed and heated, giving MDF its strength and stability.

- Forming the Mat: The mixture of fibers, resin, and wax is spread evenly onto a large conveyor belt to form a continuous mat. The thickness of this mat determines the final thickness of the MDF panel.

- Pressing and Cooling: This mat then goes into a hot press. Under high pressure and heat, the resin cures, bonding the fibers together and compressing the mat into a dense, uniform panel. After pressing, the panels are cooled and conditioned.

- Sanding and Cutting: Finally, the panels are trimmed to standard sizes and sanded smooth. This sanding process is what gives MDF its signature smooth surface, ready for finishing or further processing.

This manufacturing process, often explained by organizations like the WoodSkills organization, results in a panel that is remarkably flat and uniform. The absence of natural wood grain means that cuts and edges reveal the same texture throughout, which is a big advantage for certain types of projects.

MDF vs. Solid Wood vs. Plywood: Key Differences

When you’re starting a project, choosing the right material is key. MDF, solid wood, and plywood are three common options, and they each have their own set of pros and cons. Knowing the difference will help you make the best decision for your needs.

Solid Wood

Solid wood comes directly from trees. It has a natural grain pattern and can be very beautiful. Each piece is unique.

- Pros: Strong, durable, can be repaired (e.g., sanding out scratches), looks natural and premium, can hold screws well (especially in denser woods), can be stained or painted beautifully.

- Cons: More expensive, can warp or crack with changes in humidity and temperature, can be heavy, grain patterns aren’t always uniform, requires more skill to work with to avoid issues like tear-out.

Plywood

Plywood is made by layering thin sheets of wood veneer. The grain of each layer runs in a different direction, which makes it strong and stable.

- Pros: Strong and stable (resists warping better than solid wood), available in many grades and types (hardwood plywood for visible surfaces, utility grades for structures), can be stained or painted, good screw-holding power along the surface.

- Cons: Edges can be unsightly (showing the layers) and require edge banding or treatment, can be prone to delaminating (layers separating) if exposed to moisture, cost varies widely depending on grade and wood type, can be heavy.

MDF (Medium-Density Fibreboard)

As we’ve discussed, MDF is made from wood fibers pressed together with resin.

- Pros: Very smooth and consistent surface (ideal for painting), no wood grain means no tear-out when cutting, dimensionally stable (doesn’t warp or twist easily), affordable, easy to machine (cuts cleanly), good for intricate designs and detailed edges.

- Cons: Heavy, weak in tension (can snap if not supported properly), edges can crumble if not handled carefully, screw-holding power is decent but not as strong as solid wood (especially for repeated screwing/unscrewing), can swell and disintegrate if exposed to moisture (unless it’s a special moisture-resistant type), dust created during cutting and sanding can be very fine and potentially irritating, requiring good dust collection and respiratory protection.

Here’s a quick reference table to help visualize these differences:

| Material | Construction | Surface | Strength | Moisture Resistance | Cost | Best For |

|---|---|---|---|---|---|---|

| Solid Wood | Natural timber from trees | Natural grain, can be rough | High, variable by species | Poor (unless treated) | High | Structural elements, fine furniture, visible wood grain projects |

| Plywood | Layered wood veneers | Varying quality, can have visible plies | High, good in multiple directions | Moderate (better than MDF/solid wood) | Medium to High | Cabinet boxes, shelving, subflooring, structural panels |

| MDF | Compressed wood fibers and resin | Extremely smooth, uniform | Moderate, good in compression | Very Poor (unless treated) | Low to Medium | Painted furniture, cabinet doors, decorative panels, speaker enclosures |

Where Does MDF Shine?: Common Uses for MDF

MDF’s unique characteristics make it an excellent choice for specific applications. Its smooth, uniform surface is its biggest selling point, especially when you want a flawless finish.

Painting and Finishing Projects

This is where MDF truly excels. Because it’s free of grain, knots, and imperfections, MDF provides an incredibly smooth and consistent surface that is perfect for painting. Unlike solid wood, you won’t see grain showing through your paint, and you won’t have to worry about “grain raising” after applying a primer. This makes it ideal for:

- Cabinet doors: Leading to a sleek, modern look.

- Paneling and wainscoting: Creating a beautifully painted wall finish.

- Picture frames and decorative molding: Where a smooth, paintable surface is desired.

- Custom furniture pieces: Especially those designed to be painted rather than stained.

Furniture Construction

Many commercially produced furniture pieces use MDF, particularly for components that don’t require the structural integrity or aesthetic of solid wood. It’s often used for:

- Drawer fronts and sides

- Wardrobe panels

- Bookshelves and casework

- Back panels for cabinets and dressers

Its stability means that it won’t warp or twist as temperature and humidity fluctuate, which is great for maintaining the shape of furniture over time. For applications needing high strength, it’s often combined with plywood or solid wood.

Speaker Boxes and Enclosures

The density and non-resonant nature of MDF make it an excellent material for building high-quality speaker enclosures. It doesn’t vibrate or “sing” like some other wood products, which allows the speaker drivers to produce a cleaner, more accurate sound. Manufacturers of audio equipment often rely on the consistent density of MDF for predictable acoustic performance.

Crafts and Hobby Projects

For crafters and hobbyists, MDF offers an affordable and easy-to-work-with material. It can be easily cut with laser cutters, routers, or even hand saws, making it versatile for:

- DIY home decor items

- Model building

- Custom signage

- Stencils

Underlayment and Substrates

While not its most glamorous use, MDF can serve as an underlayment for certain flooring applications or as a substrate for laminates and veneers. Its flatness ensures a smooth base for whatever is placed on top.

Working with MDF: Tips for Beginners

MDF is generally forgiving and easy to work with, which is why it’s a favorite for beginners. However, there are a few things to keep in mind to get the best results and stay safe.

Cutting and Machining

MDF cuts very cleanly. However, the fine dust it produces is a significant consideration. Always use a dust mask or respirator (like an N95 or better) and eye protection when cutting or sanding. Investing in a good dust collection system for your saw is highly recommended.

- Tools: Fine-tooth saw blades designed for MDF or coated blades will give the cleanest cuts and last longer. A circular saw, table saw, or jigsaw can all be used. A router is excellent for creating decorative edges.

- Clean Cuts: To prevent chipping on the exit side when cutting, place a piece of scrap wood underneath your cut line or score the cut line with a utility knife. For very precise cuts, consider using a track saw.

- Dust Management: This is crucial! MDF dust is extremely fine and can be very irritating to your lungs and eyes. Always work in a well-ventilated area and use appropriate personal protective equipment (PPE).

For more on workshop safety and dust control, resources from organizations like the Occupational Safety and Health Administration (OSHA) provide valuable guidance on managing wood dust hazards.

Screws and Fasteners

MDF holds screws reasonably well, especially into the face of the panel. However, it doesn’t have the holding power of solid wood, particularly if you need to remove and reinsert screws multiple times.

- Pilot Holes: Always drill pilot holes before inserting screws to prevent the MDF from splitting, especially near the edges.

- Screw Length: Use screws that are long enough to get good grip but not so long that they poke through the other side. Standard wood screws work well.

- Edge Strength: Screws driven into the edges of MDF panels are not very strong. If you need to join edges, consider using wood glue along with screws, or reinforce the joint with corner braces or biscuits.

- Hardware Installation: For hinges and drawer slides, pre-drilling is essential. Using inserts or larger washers can sometimes improve the holding power.

Moisture Sensitivity

Standard MDF is highly susceptible to moisture. If it gets wet, it will swell, warp, and can even disintegrate. If your project might encounter humidity or occasional splashes, consider using:

- Moisture-Resistant MDF (MR MDF): This type is treated with special binders and resins to resist swelling and disintegration in damp environments. It’s often colored green.

- Sealing: Always seal MDF edges and surfaces thoroughly with primer or a sealant before painting, especially in areas prone to moisture, like kitchens and bathrooms. Even moisture-resistant MDF benefits from proper sealing.

Joining MDF

MDF can be joined using standard woodworking glues like PVA (white or yellow wood glue). Again, the edges are more fragile than solid wood.

- Glue Applications: Apply glue to the surfaces. For edge joints, clamp securely until the glue dries.

- Joint Reinforcement: Consider using dowels, biscuits, or pocket screws for stronger joints, especially on structural pieces.

- Filling Gaps: If you have minor imperfections or gaps, these can often be filled with wood filler or an MDF-specific filler before sanding and finishing.

Advantages and Disadvantages of MDF

Like any material, MDF has its pros and cons. Weighing these against your project needs will help you decide if it’s the right fit.

Advantages

- Smooth, Paintable Surface: Unrivaled for a paint finish without visible grain.

- Cost-Effective: Generally cheaper than plywood and significantly cheaper than solid wood.

- Stability: Resists warping, twisting, and cracking with changes in temperature and humidity.

- Machinability: Easy to cut, shape, and route, allowing for intricate designs and clean edges.

- Uniformity: Consistent density and thickness throughout the panel.

- No Grain Patterns: Eliminates issues like tear-out and ensures consistent look for painted projects.

Disadvantages

- Moisture Sensitivity: Standard MDF swells and degrades when wet.

- Heavy: MDF panels are quite dense and can be heavy to handle.

- Lower Screw-Holding Power: Not as strong as solid wood or plywood, especially on edges.

- Dust: Produces very fine dust that can be an irritant and requires good dust control.

- Weak in Tension: Can snap if subjected to significant bending forces without proper support.

- Difficult to Stain: While it can be done with specialized techniques, MDF doesn’t take stain like solid wood, as it lacks natural grain patterns.

Understanding these points is essential for successful woodworking. For instance, if you’re building a workbench that will get wet, MDF probably isn’t your best bet. But for a beautiful, painted bookshelf, it’s often an excellent choice.

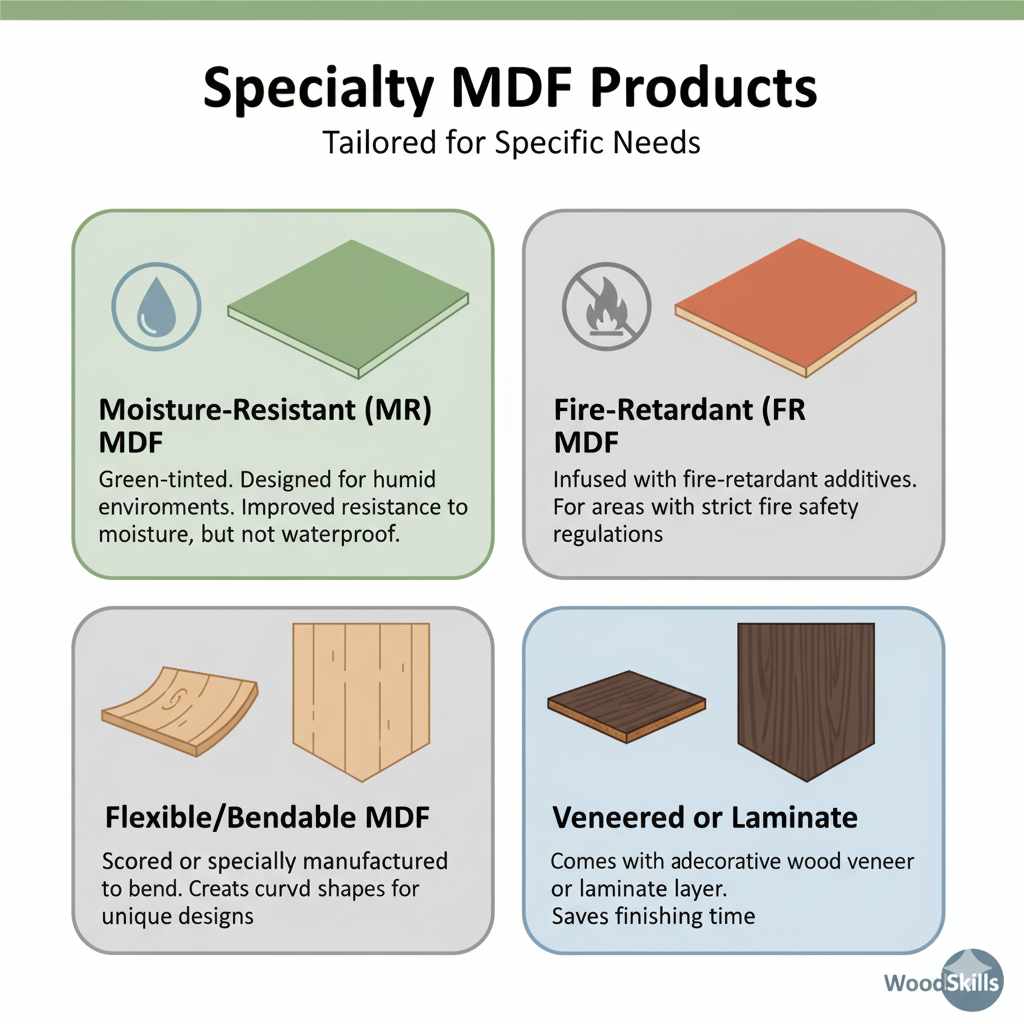

Specialty MDF Products

Beyond the standard MDF, there are specialty versions designed for specific needs:

- Moisture-Resistant (MR) MDF: As mentioned, this green-tinted MDF is designed for use in humid environments or areas prone to occasional splashing. It’s not waterproof but offers a significant improvement over standard MDF.

- Fire-Retardant (FR) MDF: This type is infused with fire-retardant additives, making it suitable for construction projects where fire safety regulations are strict, such as in public buildings or commercial spaces.

- Flexible/Bendable MDF: A version that has been scored or specially manufactured to allow it to be bent into curved shapes.

- Veneered or Laminate MDF: MDF panels that come with a decorative veneer or laminate already applied to one or both sides, saving a finishing step.

These specialized boards offer solutions for projects that standard MDF can’t handle. Always check the manufacturer’s specifications for the intended use of these products.

FAQ: Your MDF Questions Answered

Here are some common questions beginners have about MDF.

Is MDF a type of wood?

Yes, MDF is considered an engineered wood product. It’s made from reclaimed wood fibers, resins, and wax, all pressed together. So, while not solid timber, it originates from wood.

Can you paint MDF?

Absolutely! MDF is one of the best materials for painting due to its perfectly smooth and grain-free surface. Just be sure to seal the edges and use a good primer for the best results.