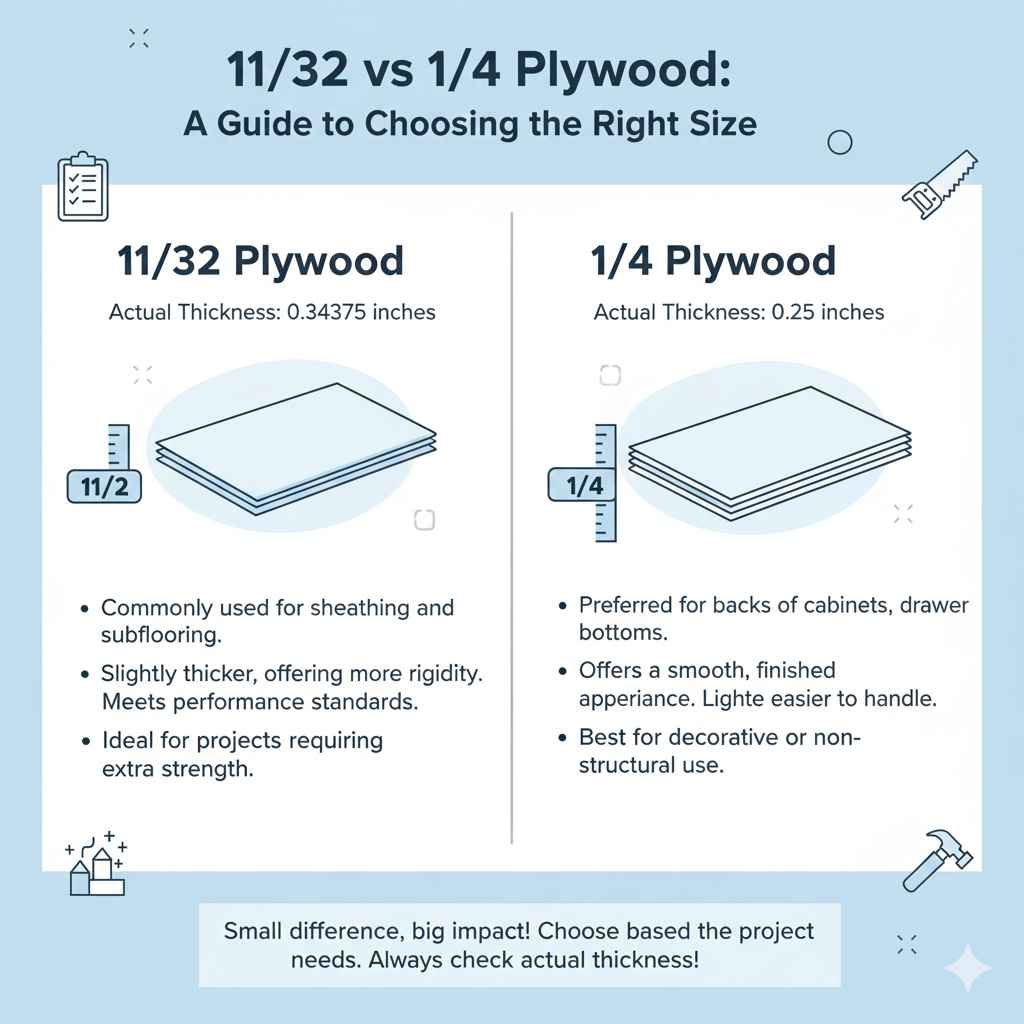

11/32 vs 1/4 Plywood: A Guide to Choosing the Right Size

Choosing the right plywood thickness, like the difference between 11/32 vs 1/4 plywood: Which Should You Use?, can be tricky for anyone starting a woodworking project. It might seem like a small detail, but it can significantly impact your project’s strength, stability, and overall appearance. Don’t worry, though! This guide breaks down the key differences and helps you select the perfect plywood for your needs, step by step. We’ll explore everything from measurement to application, making sure you feel confident in your choices. Let’s get started!

What Exactly Is Plywood and Why Does Thickness Matter?

Plywood is a fantastic material used in building and woodworking. It’s made by gluing thin layers of wood, called veneers, together. These layers are placed so the grain of each layer is at a right angle to the ones above and below it. This cross-graining construction gives plywood its strength and resistance to warping or cracking, making it a great choice for many projects. The thickness of plywood, such as the debate surrounding 11/32 vs 1/4 plywood, directly influences its strength, stiffness, and cost. It’s like choosing the right size for a puzzle piece; the wrong fit can mess up the entire picture.

Choosing the correct thickness ensures your project is both sturdy and attractive, built to last. It is important to know the difference between common types like exterior plywood, marine plywood, and furniture-grade plywood to select the correct choice for the task at hand.

The Basics of Plywood Construction

Plywood’s strength comes from its unique structure. The alternating grain direction of each layer makes it incredibly strong. This also helps plywood resist changes in temperature and humidity, meaning it’s less likely to warp or crack compared to solid wood. The number of layers (or plies) in plywood can vary, impacting the overall thickness and strength. Thicker plywood usually has more plies. The type of wood used for the veneers also plays a part; some woods are naturally stronger than others. You’ll often find hardwoods like oak or maple used for their durability and appearance, while softwoods like pine or fir are common for their affordability. The glues used to bond the veneers are usually waterproof, which is important for many projects.

- Veneers: These are the thin sheets of wood that make up each layer of plywood. The quality and type of veneer affect the plywood’s overall appearance and performance. High-quality veneers offer a smoother surface, fewer imperfections, and greater strength.

The choice of veneer directly impacts the final product. - Core: The core is the center of the plywood, sometimes made of the same veneer as the face and back, or it can be composed of a thicker, less expensive wood. The core’s construction impacts the plywood’s rigidity and weight. A strong core is vital for projects that need to bear weight or withstand stress.

- Glue: The glue holds everything together! The adhesive used is very important. Quality glue that is waterproof or water-resistant ensures plywood’s longevity, especially when exposed to moisture.

Plywood Thickness and Its Influence

The thickness of plywood is typically described in fractions of an inch, such as 1/4″, 1/2″, or 3/4″. When discussing 11/32 vs 1/4 plywood: Which Should You Use?, the thickness greatly impacts how the plywood behaves. Thicker plywood is stronger and less likely to bend under pressure. It also often costs more. Think of it like a building’s walls – thicker walls provide more stability. The thickness of the plywood also affects how the material looks. It influences the visual weight and how easily it can be cut, shaped, and finished. The right thickness ensures the project looks balanced. The choice of thickness impacts factors like strength, stiffness, and the project’s overall cost and look.

- Strength: Thicker plywood can withstand more weight and stress without breaking or bending. This is important for projects like shelving, flooring, or anything that needs to hold up heavy objects. For example, a shelf made from 3/4-inch plywood can bear far more weight than one made from 1/4-inch.

- Stiffness: Stiffer plywood resists bending or sagging. This is key for maintaining the shape of your project, especially over long spans. Think of a table – you want it to be rigid so it doesn’t wobble or flex when someone leans on it.

- Cost: Generally, thicker plywood costs more than thinner plywood. The increased materials and manufacturing processes contribute to the higher price. Always keep your budget in mind when choosing a plywood thickness.

Understanding Plywood Measurement

Plywood measurements can be a bit tricky because they are given in fractions of an inch. Commonly used thicknesses include 1/4″ (0.25 inches), 1/2″ (0.5 inches), and 3/4″ (0.75 inches), but there are also less standard thicknesses, such as the focus of this article, 11/32 vs 1/4 plywood: Which Should You Use?. These measurements represent the actual thickness of the plywood sheet. Always double-check your measurements against the project plans, and remember to account for the thickness when cutting and assembling your project. Plywood sheets come in standard sizes, typically 4 feet by 8 feet. Knowing these dimensions helps in project planning to minimize waste and ensure you buy the correct amount of material. Understanding these measurements helps in cutting, planning, and buying the appropriate plywood to fit the specifications of a project.

- Fractional vs. Decimal: Plywood thicknesses are typically listed as fractions (like 1/4″) but it’s helpful to know their decimal equivalents (0.25 inches). This makes calculations easier, especially when using a calculator or working with digital plans.

- Tolerance: Keep in mind that there might be slight variations in thickness (a small tolerance). The actual measurement may vary slightly from the nominal measurement. Always confirm your measurements.

- Units: Always pay attention to the units (inches or millimeters) in your project plans.

Accurate measurements are very important for success.

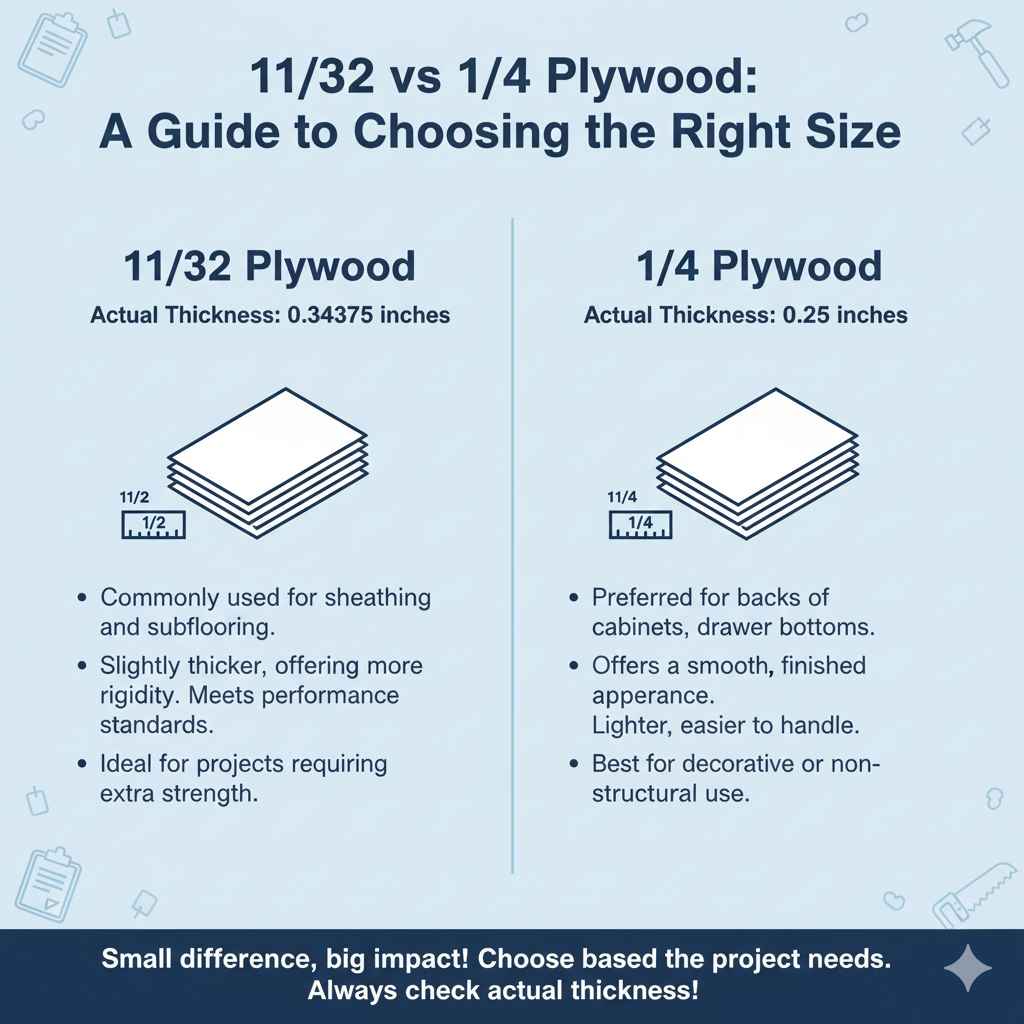

Comparing 1/4 Plywood and 11/32 Plywood

When selecting plywood, you’ll often encounter different thicknesses, and the choice between 11/32 vs 1/4 plywood: Which Should You Use? can be important for the project’s success. 1/4-inch plywood is a popular choice for light-duty projects where flexibility and cost are important. 11/32-inch plywood is slightly thicker, offering increased strength and rigidity, making it suitable for projects that require greater durability. Understanding the key differences, including their performance characteristics and the scenarios where they perform best, ensures you choose the most appropriate material. You need to consider all the different project factors, like strength, cost, and weight, for the best choice.

1/4 Plywood: Characteristics and Uses

1/4-inch plywood (0.25 inches) is a versatile option known for its lightness and affordability. It’s often used where flexibility is needed or when a lighter weight is required. This plywood is commonly used for backing, drawer bottoms, and projects that don’t need to bear a lot of weight. It’s relatively easy to cut and shape, making it user-friendly for beginners. However, it’s less resistant to bending or warping than thicker options. It’s best suited for projects where strength is not the primary requirement. This type of plywood is a cost-effective solution for a range of smaller projects, like crafting, where a strong load-bearing capacity isn’t required.

- Flexibility: 1/4-inch plywood is more flexible than thicker options, making it appropriate for curved surfaces or applications where some give is needed. This flexibility is a key advantage for some applications.

- Lightweight: The lightweight nature of 1/4-inch plywood makes it easier to handle and transport, making it an excellent option for crafting and smaller DIY projects where weight is a factor.

- Cost-Effectiveness: This plywood is generally the most affordable plywood thickness. This makes it an attractive choice for projects where budget is a major concern.

11/32 Plywood: Characteristics and Uses

11/32-inch plywood (approximately 0.34 inches) is a thicker option, offering increased strength and rigidity compared to 1/4-inch. This means it can withstand more weight and resist bending, making it more suitable for projects that require sturdier support. While it is more expensive than 1/4-inch plywood, the added stability often justifies the cost. When determining 11/32 vs 1/4 plywood: Which Should You Use? you can be assured this plywood is more resistant to warping and provides greater support. Because it’s thicker, it offers more structural integrity, which is essential for projects with a greater load-bearing requirement. It’s often favored in projects that call for a balance of strength and manageability.

- Durability: Because it is slightly thicker than 1/4-inch plywood, 11/32-inch plywood offers greater durability, making it ideal for projects that must endure more wear and tear. This thickness is more suited to applications like flooring or shelving.

- Strength: The added thickness translates to increased strength and load-bearing capacity. This plywood can hold more weight and is less prone to bending under stress. This can be important for projects that require it.

- Stability: 11/32-inch plywood is more resistant to warping or twisting compared to thinner options. Its increased stability ensures your projects retain their shape over time. This gives the user added confidence.

Thickness Comparison Table

The following table summarizes the key characteristics of 1/4″ and 11/32″ plywood, helping you decide which is best for your project. This data will help you, when considering 11/32 vs 1/4 plywood: Which Should You Use?.

| Feature | 1/4-inch Plywood | 11/32-inch Plywood |

|---|---|---|

| Thickness | 0.25 inches | 0.34 inches (approximately) |

| Strength | Moderate | Higher |

| Stiffness | Lower | Higher |

| Flexibility | High | Moderate |

| Cost | Lower | Higher |

| Common Uses | Drawer bottoms, backing, crafts | Shelving, cabinet sides, light flooring |

Project Applications: Where to Use Each Type of Plywood

Knowing where each plywood type performs best is important when deciding between 11/32 vs 1/4 plywood: Which Should You Use?. Selecting the correct plywood thickness can ensure your project is strong, long-lasting, and meets your needs. 1/4-inch plywood is a great fit for projects where flexibility and ease of handling are paramount. The increased strength of 11/32-inch plywood makes it the right choice for projects where stability and load-bearing capacity are crucial. Understanding these applications helps you get the best outcome for your project.

1/4 Plywood Applications

1/4-inch plywood is often used in projects where weight and cost are major factors. It’s a good choice for projects that don’t need to support much weight or resist significant stress. For example, it is useful in crafting and other similar DIY endeavors. The main benefit is the ease of working with the material. This plywood is ideal for DIYers and crafters. It’s also often used in furniture and other light-duty applications.

- Drawer Bottoms: 1/4-inch plywood is a common choice for drawer bottoms due to its lightweight nature and its ability to fit easily. It’s strong enough to support the contents of a drawer without adding extra weight.

- Backing for Cabinets and Furniture: It’s used as backing for cabinets and furniture, providing a surface to attach hardware and other components. It’s easy to cut and attach and provides a smooth surface.

- Craft Projects: 1/4-inch plywood is a great option for crafts, providing a stable, yet lightweight, surface for various art projects. It’s easy to cut and customize, making it appropriate for decorative applications.

11/32 Plywood Applications

11/32-inch plywood is favored in projects that require a bit more strength and stability. It’s more appropriate for applications where the plywood will bear more weight or experience more wear and tear. When thinking about 11/32 vs 1/4 plywood: Which Should You Use?, remember the slightly greater thickness and structural integrity of 11/32-inch plywood makes it useful for projects where greater durability is key. It’s often used in shelving, cabinet construction, and in certain light flooring applications. The extra strength helps ensure projects hold up over time.

- Shelving: 11/32-inch plywood is often the right choice for shelving, providing enough strength to support books, decorations, or other items. It resists bending, ensuring the shelves remain level over time.

- Cabinet Sides and Bottoms: The increased strength and rigidity of 11/32-inch plywood makes it suitable for cabinet sides and bottoms. This allows cabinets to withstand everyday use. The increased thickness adds to the structural integrity.

- Light Flooring: It can be used for light flooring applications, especially in areas where a thinner profile is required. It provides a stable surface that is more durable than thinner options.

Real-Life Examples

- A Craft Project: You’re building a simple toy box for your child. The sides and top are made from 1/2-inch plywood to provide support and the bottom from 1/4-inch plywood to keep the box lightweight and simple to build. This blend gives a good balance between strength and manageability.

- A Bookshelf: Building a bookshelf. You decide to use 11/32-inch plywood for the shelves and sides, since it can handle the weight of books. Using 1/4-inch plywood would make the shelves more likely to sag or bend over time.

Practical Tips for Working With Plywood

Working with plywood effectively involves understanding how to cut, fasten, and finish the material. Whether you’re using 1/4-inch or 11/32-inch plywood, having the right tools and techniques makes the job easier and improves the outcome of your project. Before you start, remember that choosing between 11/32 vs 1/4 plywood: Which Should You Use? may change how you handle the material. The thicker 11/32-inch may require more robust cutting methods. Learning about these tips is crucial to success.

Cutting Plywood: Tools and Techniques

Cutting plywood correctly is critical for getting accurate dimensions and preventing damage to the wood. You’ll need the right tools and techniques. Make sure to use sharp blades and proper support to get clean cuts, so you can achieve the best results, no matter which thickness you use. This will improve the outcome of your project. If you’re cutting a lot of plywood, a table saw is the best option because it offers the most stability. A circular saw is a great option as well. Be sure to cut the material carefully and use the proper safety equipment.

- Using a Circular Saw: A circular saw is a versatile tool for cutting plywood. When cutting plywood with a circular saw, use a fine-tooth blade specifically designed for plywood to minimize splintering. Support the plywood on a stable surface, and use a guide or straight edge to ensure the cut is straight. Use the right blade and be certain to cut with confidence.

- Using a Table Saw: A table saw is excellent for making long, straight cuts in plywood. Always use a push stick and ensure the blade is at the correct height to cut through the material safely. Also, use a fine-tooth blade for smooth cuts and a good quality fence for accurate cuts. Using a table saw offers accuracy.

- Preventing Splintering: Plywood can splinter along the cut edges. To prevent this, apply masking tape along the cut line or use a scoring knife. Another option is to cut with the good side of the plywood facing down, so any splintering occurs on the unseen side. Practice is a great way to improve your saw skills.

Fastening Plywood: Methods and Materials

Choosing the correct method and materials for fastening plywood is key to ensuring your project is strong and lasts. The method you use for fastening plywood depends on the project and the load it will need to bear. Using the proper fasteners, such as screws, nails, or wood glue, and making sure the chosen method is appropriate for the thickness of the plywood you are using, can ensure your project lasts for years. You must select the right approach for your specific project. These choices matter whether you are deciding between 11/32 vs 1/4 plywood: Which Should You Use?.

- Screws: Screws provide a strong and reliable way to fasten plywood. When using screws, pre-drill holes to prevent splitting, especially near the edges. Choose the correct screw length to match the plywood thickness and the material you’re attaching it to. Screws are a dependable choice.

- Nails: Nails are a quick and easy way to fasten plywood. Use a nail gun for efficiency, but ensure the nails are the right length and type. Nails may be less strong than screws, so consider their use based on project requirements. Nails are a quick option.

- Wood Glue: Wood glue adds strength to joints, especially when combined with screws or nails. Apply the glue evenly to the surfaces being joined, then clamp the pieces together until the glue dries. This method strengthens the joints significantly. Glue improves the overall outcome.

Finishing Plywood: Painting, Staining, and Sealing

Finishing plywood is very important to protect the material from wear and tear and enhance its appearance. The finishing process not only affects the look of the project but also protects the plywood from moisture and damage. You will have to decide how the plywood will be used when deciding between 11/32 vs 1/4 plywood: Which Should You Use? to select the best finish to match your project. The proper finish is a crucial part of the project’s longevity.

- Painting: Painting plywood is a great way to add color and protect the surface. First, sand the plywood to create a smooth surface, then apply a primer to improve paint adhesion. Use several thin coats of paint for a smooth and even finish. Painting improves the final look.

- Staining: Staining brings out the natural grain of the wood. Sand the plywood and apply a wood conditioner to ensure the stain absorbs evenly. Apply the stain in the direction of the wood grain, and wipe off the excess. Staining is a great option.

- Sealing: Sealing plywood is critical for protecting it from moisture and damage, especially in high-moisture environments. Use a clear sealant, such as polyurethane, to create a protective barrier. Apply multiple coats for enhanced protection. Sealing ensures lasting protection.

Frequently Asked Questions

Question: Can I use 1/4-inch plywood for a bookshelf?

Answer: It’s generally not recommended for a bookshelf, especially if you plan to store heavy books. 1/4-inch plywood may sag or bend under the weight. 11/32-inch or thicker plywood would be a better choice for shelving.

Question: Is 11/32-inch plywood more expensive than 1/4-inch plywood?

Answer: Yes, 11/32-inch plywood typically costs more than 1/4-inch plywood because it requires more material and often involves a more complex manufacturing process.

Question: What’s the best way to cut plywood to avoid splintering?

Answer: Using a fine-tooth blade designed for plywood is best. You can also score the cut line with a utility knife before cutting or use masking tape along the cut line. Cutting from the finished side down also helps.

Question: Can I use wood glue to strengthen joints in plywood projects?

Answer: Yes, wood glue is highly recommended, especially when used with screws or nails. Apply it evenly to the joining surfaces, then clamp them until the glue dries to create a strong bond.

Question: What’s a good finish for plywood used outdoors?

Answer: For outdoor projects, use a weather-resistant sealant or exterior-grade paint. This will protect the plywood from moisture, UV rays, and other elements, ensuring its longevity.

Final Thoughts

When selecting the right plywood for your project, you’re not just picking a material; you’re making a decision that impacts your project’s strength, stability, and lifespan. The choice between 11/32 vs 1/4 plywood: Which Should You Use? is an important one. 1/4-inch plywood is an excellent choice for projects where flexibility and cost are key. 11/32-inch plywood, on the other hand, provides greater. strength and durability

By considering the project’s requirements, including its intended use and any weight it will bear, you can make the right decision. Make sure you use the right tools and techniques for cutting, fastening, and finishing to ensure the best results. Take the time to understand your project’s needs and select the appropriate plywood. You’ll be well on your way to success!