118° vs 135° Drill Bits: Unraveling the Angle Difference

Choosing the right drill bit angle can feel tricky when you’re starting out. The question of 118° vs 135° Drill Bits: Which Cuts Better? often pops up for those new to drilling. It seems simple, but getting it right means cleaner holes and less frustration. Don’t worry, though; it doesn’t have to be hard! We’ll break down the differences step by step, so you can pick the perfect bit for your next project. First, we’ll look at the basics.

Drill Bit Angle Essentials

The angle of a drill bit is a super important detail that impacts how it cuts into materials. This angle refers to the point of the drill bit, or the angle formed by the two cutting edges. A wider angle means a more blunt point, while a narrower angle has a sharper point. The two main angles we’re looking at are 118 degrees and 135 degrees. These angles affect the bit’s performance, how easy it is to start a hole, and what materials it’s best for. Think of it like a knife – a sharper knife is good for slicing soft things, but a more blunt one might be better for tougher materials.

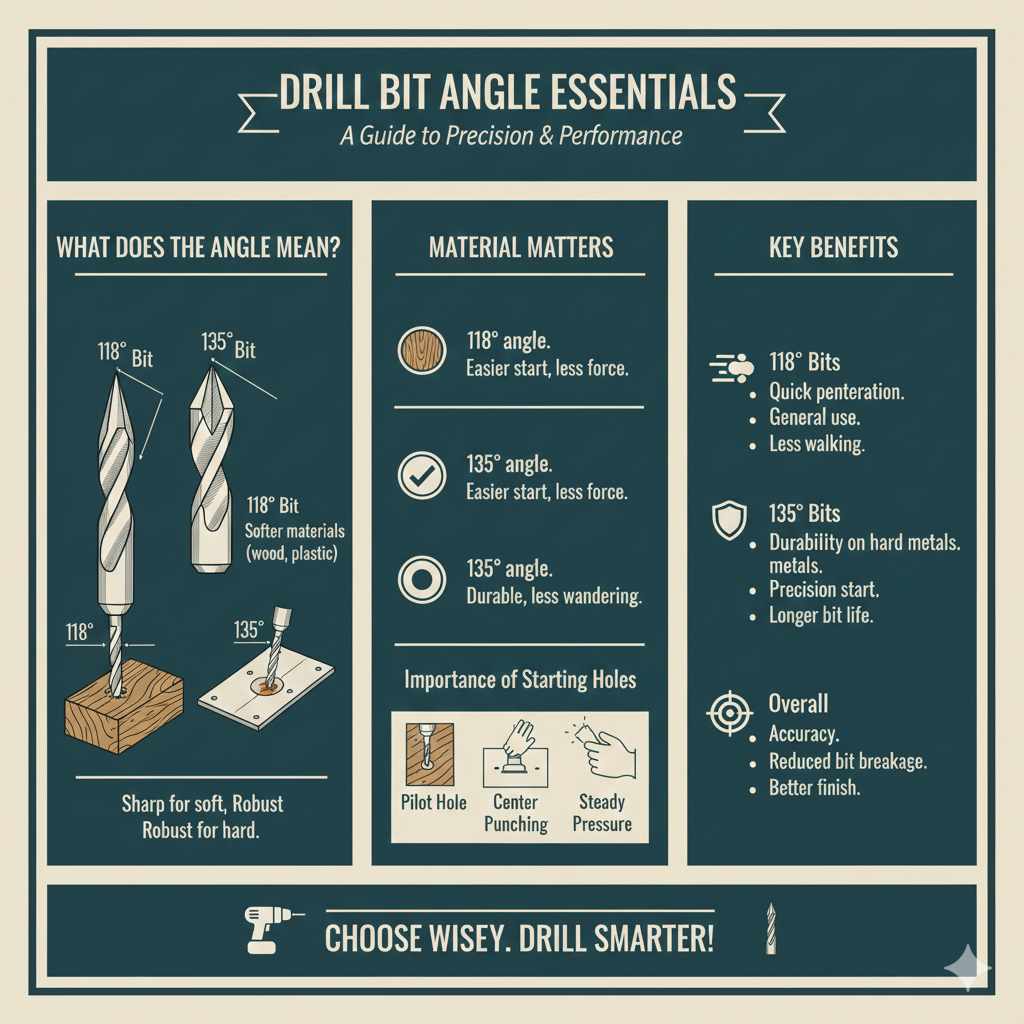

What Does the Angle Mean?

The angle of your drill bit influences how the bit interacts with the material. A smaller angle (like the 118°) is generally sharper. It digs in more easily and is great for softer materials. A larger angle (135°) has a more robust tip. This is good for harder materials because it can take more pressure. The angle decides how quickly the bit penetrates the surface, how the chips are removed, and how much force you need to apply.

118-degree Drill Bits: These bits have a sharper point. This angle is great for softer materials like wood, plastic, and thin metals. They’re easier to start and require less force.

A 118-degree bit is ideal when you need to quickly make a hole and the material isn’t super tough. Because the tip is sharper, it’s easier to center and keep on track. Consider these bits your go-to for general household jobs or lighter projects. The more acute angle helps in self-centering, giving you more control in starting the hole. This also results in less walking, meaning the bit doesn’t wander off target.

135-degree Drill Bits: These bits have a more blunt point. They’re perfect for harder materials such as stainless steel or tougher alloys. They require more force to start, but their shape makes them more durable and less likely to break or wander.

The 135-degree angle is a workhorse for tougher jobs. They handle greater pressure and last longer on difficult materials. These bits will last longer when you are drilling hard metals. Their tip is less prone to damage when going through thick or dense substances. A 135-degree bit’s design reduces the chances of it “walking” or slipping during the start of the hole. This helps with precision.

Material Matters: The type of material decides the angle you choose. Soft materials benefit from sharper angles, while hard ones require a more robust, blunt approach.

Choosing the correct angle based on the material will save you lots of time and make the job easier. For softer substances, a 118-degree bit is great for quick and clean holes. For tougher materials, the 135-degree bit’s design gives strength and helps you get through without wearing down or causing the bit to break. Always check the material’s hardness before selecting the drill bit angle.

The Importance of Starting Holes

Getting your hole started right is very important. That is when the drill bit first touches the material. If the bit slips or “walks” (moves away from your desired spot), it can make an inaccurate hole or damage the material. Choosing the correct angle helps keep the bit in place. It makes the job easier and more accurate. Think of it like this: a sharp, easy-to-grab point helps you start in the right place. A less sharp, sturdier point needs a little more help but ends up being more reliable.

Using a Pilot Hole: For hard materials, start with a pilot hole. This smaller hole guides the larger bit.

A pilot hole is like creating a path before you begin. It offers a starting point, preventing the drill bit from moving. Start with a smaller drill bit to make a pilot hole first. Then, use your main drill bit. This is especially helpful when dealing with hard materials like metal. Doing this lowers the chance of the drill bit wandering and keeps your holes accurate.

Center Punching: Mark the spot where you want the hole with a center punch. This creates a small indentation for the drill bit.

A center punch gives your drill bit a place to start. It creates a small dent on the surface. When the drill bit’s point sits in the dent, it’s less likely to move. If you are doing this on metal, a center punch is a must-have tool. The dent helps to keep the drill bit steady and on target. This leads to more precise hole placement and makes drilling easier.

Applying Steady Pressure: Use a steady pressure while drilling to keep the bit from slipping.

Applying the correct pressure is key for clean, accurate holes. You want to make sure the drill bit bites into the material without moving around. Use a moderate pressure, letting the drill do its job. When you apply too much force, the drill bit might move. If you don’t use enough, the bit will slip. Consistent pressure helps the bit cut smoothly, giving you better results.

118° vs 135° Drill Bits in Action

Knowing the angles is one thing; seeing them in action is another. When comparing 118° vs 135° Drill Bits: Which Cuts Better? it comes down to what you are doing. Let’s look at some examples of jobs where each bit shines. We will check how they perform in real-world scenarios, so you can understand when to use each one.

Case Study 1: Drilling Through Soft Wood

Imagine you’re building a bookshelf. You will use soft pine wood. Using a 118-degree drill bit here is best. Because the wood is easy to cut. The sharp angle of the 118-degree bit makes it simple to start the hole and drill through quickly. You’ll get clean holes without tearing the wood. The bit will dig in fast. This makes the job easier and faster. This angle’s design works perfectly for soft woods. This allows it to remove material efficiently.

The Process: Choose a 118-degree drill bit for wood. Place the drill bit where you need the hole. Start drilling slowly. Increase speed as needed.

Starting slowly will allow the bit to grab the material easily and accurately. Once the bit is set, you can increase the speed. Keep a steady pace as you drill through the wood. Avoid applying too much pressure. Let the bit do the work. This method will reduce the chance of splitting or damaging the wood. Your holes will be precise and clean, perfect for your bookshelf project.

The Results: Clean, quick holes with minimal splintering.

The 118-degree drill bit cuts through soft wood like a hot knife through butter. You’ll see holes that are clean and smooth, with very little splintering. This means less sanding and a better finish. The ease of use also means you finish the project sooner. This makes the 118-degree bit a good choice for woodworking projects.

Case Study 2: Drilling Through Steel

Now, let’s switch gears and work with steel. Steel is hard. You will want to use a 135-degree drill bit. The wider angle of this bit provides more strength. This is especially useful for tougher materials. It can handle the increased force and heat. The sturdy tip helps the bit stay in place. This will reduce wandering. You’ll get more accurate and cleaner holes. This choice is key for steel.

The Process: Choose a 135-degree drill bit. Use a center punch to make a small dent. Start drilling slowly. Increase speed and use cutting oil.

Starting with a center punch will give the drill bit a good starting point. Slowly ease the bit into the steel. Then gradually increase the speed to help with the cutting process. Cutting oil is very helpful when working with steel. It cools and lubricates the bit and makes the cutting smoother. The correct approach makes it easier to cut and improves the life of the drill bit. It also reduces wear and tear on the tool.

The Results: Clean, precise holes with less bit wear.

The 135-degree drill bit is tough enough to get through steel. The holes are precise and clean. The bit can cut through steel with minimal wear. Because of the cutting oil, the bit stays cool. You get clean results and a longer bit life. It is the best choice for dealing with steel and other hard metals. Using the 135-degree bit gives you the best results.

Scenario Examples

Building a Wooden Deck: You’re putting together a deck. You are using softwoods like cedar. Using a 118-degree drill bit.

For deck building, a 118-degree bit gives you clean and quick holes. The wood isn’t too hard, so this bit will start easily. Because you’ll be drilling many holes for screws and bolts, it’s very helpful to pick the right bit. You’ll save time and effort. Using the 118-degree drill bit is perfect for this job. It is ideal for this kind of woodworking. This will lead to a successful outcome.

Fixing a Metal Gate: You’re repairing a metal gate. You need to drill into the steel to attach hinges. A 135-degree drill bit is best for this task.

When you are working with metal, you need a stronger bit. The 135-degree drill bit is made for metal. Its strong tip prevents wandering. This makes sure that your hinges are securely fastened. Using the correct bit here is very important. You’ll have a stable and safe gate. It will also help with the project’s overall look. It is the perfect choice for metal jobs.

Technical Details of Drill Bit Angles

Let’s check the technical aspects of the two drill bit angles. This will help you understand how they work. Understanding these details can help you pick the right tool.

Geometry and Design

The geometry of a drill bit includes more than just the angle. The flute design, the relief angle, and the point shape all play a role. These features work together to cut and remove material efficiently. These details affect how well the drill bit cuts, its durability, and the quality of the hole it makes. The angles are at the tip. They are key parts of the bit’s design.

Flute Design: The flutes are the spiral grooves. They remove chips and help with cooling.

The flute design of a drill bit is its most important feature. These spiral grooves remove the chips as the bit cuts. This helps the bit remain cool and prevents it from getting stuck. The width, shape, and depth of the flutes can affect the drilling speed and the type of material best suited. The design is key. It affects how efficiently the drill bit cuts and lasts.

Relief Angle: This angle is behind the cutting edge. It lessens friction and helps with cutting.

The relief angle on a drill bit helps with its cutting ability. It creates space for the cutting edge to work without rubbing against the material. This lessens friction and heat. It makes the cutting more efficient and extends the life of the bit. It’s a very important detail. It impacts the bit’s performance and the quality of the hole made.

Point Shape: The point shape affects how the bit enters the material and how well it centers.

The point shape is crucial. It directly affects the starting of the hole and the tool’s performance. The shape of the point has a strong impact. This can either aid or hinder the cutting ability. For example, a split point bit is very good at centering and reduces the chance of walking. Knowing these points allows you to choose the best drill bit for your specific tasks.

Material Considerations

The type of material you are drilling has a major influence. The material’s hardness, density, and how easily it can be cut all come into play. Softer materials, like wood, need a sharper angle. Harder materials, like steel, need more force. Choosing the correct bit angle for the material saves time and gets better results.

| Material Type | Best Angle | Why |

|---|---|---|

| Soft Wood | 118 degrees | Sharp point, easy start, less splintering. |

| Hard Wood | 118 or 135 degrees | Can handle more resistance, less prone to breaking. |

| Soft Metals (Aluminum) | 118 degrees | Cuts quickly, prevents binding. |

| Hard Metals (Steel) | 135 degrees | More durable, handles heat and force. |

| Plastic | 118 or 135 degrees | Prevents cracking, clean holes. |

This table gives you a simple way to find the right drill bit angle based on the material. Remember that this is just a general guide. Consider the material’s specific properties and the project’s requirements.

Choosing the Right Drill Bit

Picking the correct drill bit means getting better results. It starts with knowing the materials you will be working with and understanding the advantages of the different angles. This will help make the work easier and safer. You can choose the right drill bit with care.

Assessing Your Project Needs

Before you get to drilling, you need to understand your project’s needs. This means thinking about the type of materials, the required hole size, and the level of precision needed. Doing your homework first will help you choose the right tools and avoid problems.

Material Type: Wood, metal, plastic, or something else? Knowing this is the first step.

The material type is very important. Different materials have different properties. For example, wood is softer than steel. The material decides the best drill bit angle and the needed tool. Make a list of all of your materials and their properties. Knowing this info will help you prepare and get better results.

Hole Size and Depth: Consider the hole size and how deep it needs to be.

The hole size and depth are also important for the project. These details will impact the drill bit type, the size, and the tools you need. Larger holes may require a step drill bit. Deeper holes may need bits with longer flutes to eliminate chips effectively. Knowing this helps you choose the correct tools and ensures the job is done right.

Precision Requirements: Accuracy is needed for certain jobs. Consider the need for precise hole placement.

Some projects need more accuracy than others. For example, when creating a joint for woodworking, perfect hole placement is very important. When accuracy is key, you’ll need the right tools. You could use a pilot hole. You can also use a center punch. Consider these elements early in your planning. This will make your projects turn out as you expect.

Drill Bit Features and Quality

Check the quality and features of your drill bits before you buy them. These features affect how well the drill bits perform and how long they last. Quality bits make drilling easier and give you better results.

Material of the Drill Bit: High-speed steel (HSS) is common, while cobalt bits are tougher.

The material the drill bit is made from is key to its performance. HSS drill bits are common and very good for general use. Cobalt drill bits are made to withstand very hard materials and high temperatures. If you’re going to drill tough metals, cobalt bits are a good choice. Selecting the correct material is very important. This choice affects the drilling performance and the bit’s life.

Coating and Finish: Coatings like black oxide can prevent rust.

Coatings will give the drill bits added protection and better performance. Black oxide coatings will help protect against corrosion. Titanium nitride (TiN) coatings can improve hardness and reduce friction. These coatings will improve the life and effectiveness of the drill bit. It gives you a better drilling experience.

Brand Reputation and Reviews: Check for reviews and the brand’s reputation to assess quality.

Look at the brand’s reputation and customer reviews before buying. You will learn from other users about the tool’s reliability and performance. Good brands will give you long-lasting and efficient drill bits. Reading the reviews will help you. Then you’ll have the best tools for your jobs. Choose based on positive feedback.

Frequently Asked Questions

Question: Can I use a 118-degree drill bit on steel?

Answer: Yes, but it’s not ideal. It will likely wear out faster. Use a 135-degree bit for steel for better results.

Question: What’s the main difference between the angles?

Answer: The 118-degree bit is sharper, good for soft materials. The 135-degree bit is more blunt, great for hard materials.

Question: Do I need a pilot hole every time?

Answer: Not always, but it’s highly recommended for hard materials or when precision is needed.

Question: Can I sharpen my drill bits?

Answer: Yes, you can use a drill bit sharpener or a bench grinder if you have experience.

Question: How do I know which angle to use if I’m unsure about the material?

Answer: If you’re unsure, it’s generally better to start with a 135-degree bit for its versatility. You can always switch.

Final Thoughts

Choosing between 118° vs 135° Drill Bits: Which Cuts Better? comes down to matching the right tool to the job. The 118-degree bit is a good choice for soft materials. It gives you clean holes and is easy to use. The 135-degree bit shines when you’re drilling hard materials. It offers strength and helps you get through tough tasks. Consider the material, the project’s requirements, and the needed level of accuracy. Using the right angle will make your work much easier. It’ll also give you better results. Remember to use pilot holes when necessary. Apply steady pressure and always prioritize safety. With the right tools and knowledge, you can tackle any drilling project. You will get clean, accurate results every time. Keep practicing. Soon, you will be able to pick the correct drill bit with ease!