Are Cobalt Drill Bits Good: Proven Value

Yes, cobalt drill bits are excellent for drilling hard metals like stainless steel and cast iron. Their added cobalt significantly increases hardness and heat resistance, making them durable and capable of sustained, high-performance drilling where standard bits fail. For tough materials, their value is undeniable.

Hey there, fellow DIYers and home project enthusiasts! Ever found yourself wrestling with a drill bit that just can’t seem to chew through that stubborn piece of metal? It’s a common frustration when you’re trying to build something awesome for your home or tackle a repair, only to have your bit give up the ghost. Don’t worry, we’ve all been there. The good news is, the right drill bit can make all the difference. Today, we’re going to explore a tool that’s a real game-changer for working with tough materials: cobalt drill bits. We’ll break down what makes them special and why they might be exactly what you need for your next project.

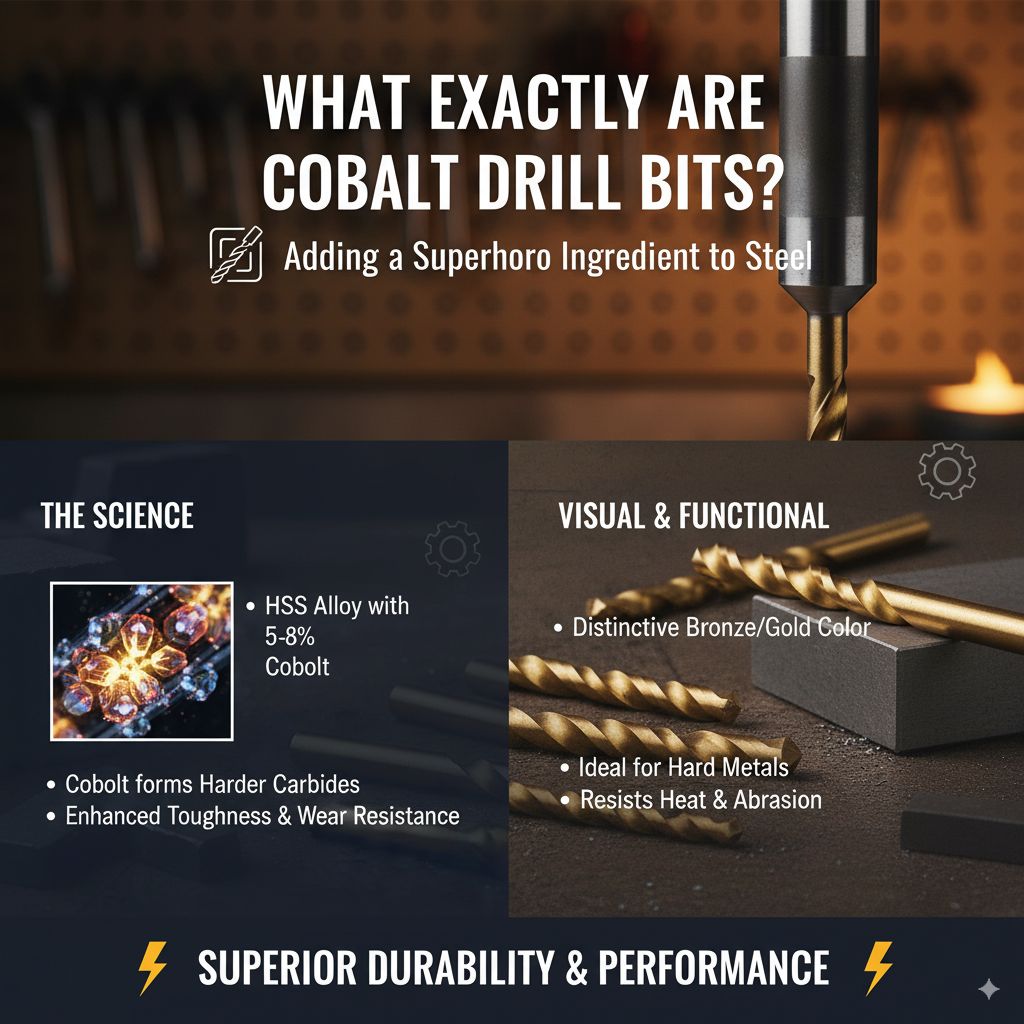

What Exactly Are Cobalt Drill Bits?

When we talk about “cobalt drill bits,” we’re usually referring to bits made from a special type of high-speed steel (HSS) alloy that has a percentage of cobalt added to it. Think of it like adding a superhero ingredient to an already strong material. This cobalt infusion isn’t just a little bit; it’s typically around 5% to 8% of the total alloy. This might not sound like much, but it dramatically changes the properties of the steel, making the drill bits far superior for specific tasks. These bits are often seen in distinctive bronze or gold colors, which is a neat way to spot them in your toolbox.

The science behind it is pretty cool: cobalt, when blended with steel, forms harder carbides within the metal’s structure. These carbides are incredibly tough and resist wear and tear much better than standard steel. This increased hardness is the key to their ability to cut through materials that would quickly dull or even melt regular drill bits. It’s this enhanced durability that solidifies their reputation in workshops everywhere.

Why the Extra Cobalt Makes a Difference

The addition of cobalt isn’t just for show; it brings some serious, practical benefits to the table, especially when you’re drilling through challenging materials. Let’s break down the main advantages:

- Extreme Hardness: Cobalt alloys are significantly harder than standard high-speed steel. This means they can cut through very tough materials like stainless steel, cast iron, titanium, and other hardened metals without losing their sharp edge.

- Superior Heat Resistance: Drilling creates friction, and friction creates heat. A lot of heat. Cobalt allows the drill bit to maintain its hardness even at higher temperatures that would normally make regular steel bits soft and prone to breaking or deforming. This is crucial for deep holes or drilling into dense materials where heat build-up is inevitable. A bit that stays hard at high temps will drill more efficiently and last longer.

- Extended Bit Life: Because cobalt bits are harder and more heat-resistant, they simply last much longer than standard HSS bits when used for their intended purpose. This means fewer trips to the store for replacements and less downtime on your project. For anyone who drills metal frequently, this longevity translates directly into cost savings and fewer interruptions.

- Improved Performance in Hard Materials: This is the big one. If you’re working with materials that are too hard for a regular drill bit, a cobalt bit is often your best bet. They can power through these tough jobs with less effort, reducing the chance of the bit skidding or binding.

- Precision Drilling: The ability of cobalt bits to maintain their shape and sharpness allows for more precise holes. This is important for applications where accuracy is key, such as in automotive repair, machinery, or any situation requiring tight tolerances.

When Should You Use Cobalt Drill Bits?

Knowing when to reach for your cobalt bits is just as important as knowing what they are. While they are fantastic for tough jobs, they aren’t always the best choice for every drilling task. Here’s a guide:

Best For:

- Hard Metals: This is their prime territory. Think stainless steel appliances, cast iron pipes, hardened steel bolts, tool steel, and even some types of hard plastics that might melt standard bits. If you’re drilling into anything labeled “hardened steel” or working with strong alloys, cobalt is often your go-to.

- High Volume Drilling: If you have many holes to drill in hard materials, the extended life of cobalt bits makes them a more economical choice in the long run, despite a higher initial cost.

- Professional and Industrial Applications: Machinists and professionals who regularly work with tough metals rely on cobalt bits for their consistency and durability.

- Deep Hole Drilling: The heat resistance is a lifesaver when drilling deep into metal, as it prevents the bit from overheating and losing its temper.

When to Consider Other Options:

Cobalt bits are harder, and this can sometimes make them more brittle than standard HSS bits (though advancements in metallurgy have reduced this concern considerably). This means they might not be the first choice for:

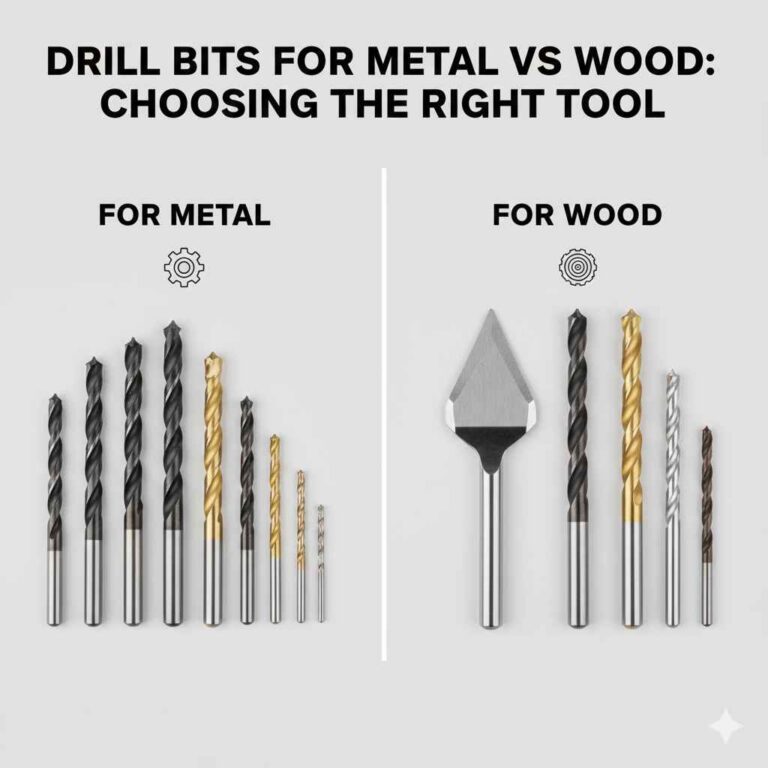

- Soft Metals: For materials like aluminum, brass, copper, or mild steel, standard or even TiN-coated HSS bits are usually sufficient and more cost-effective.

- Wood and Plastics (Generally): While a cobalt bit can drill wood or plastic, it’s usually overkill. Standard HSS bits are perfectly adequate and won’t produce as much heat, which can sometimes melt softer plastics. For wood, specialized wood bits are designed for cleaner cuts.

- Applications Requiring Extreme Flexibility: In rare cases where a bit needs to endure significant bending or flexing, the increased hardness of cobalt might make it more susceptible to snapping if stressed beyond its limits.

Types of Cobalt Drill Bits

When you start looking for cobalt drill bits, you’ll notice a few different types and coatings. While the cobalt content is the primary feature, these variations can further enhance performance:

- 135-Degree Split Point Cobalt Bits: These are the workhorses for most metalworkers. The 135-degree angle is ideal for drilling hard metals, and the split point helps prevent the bit from “walking” or wandering when you start the hole. This means easier starting and more accurate hole placement.

- Cobalt Nitride (Co-N) Coated Bits: These bits have a coating of cobalt nitride applied over the HSS-cobalt alloy. This coating adds another layer of hardness and lubricity, further improving performance and extending bit life, especially in very demanding applications.

- Black Oxide Coated Cobalt Bits: Black oxide coatings provide some added corrosion resistance and lubricity, which can help reduce friction and heat. While not as hard as nitride coatings, they offer a good balance of performance and value for general metal drilling.

- Solid Cobalt Bits: These are made entirely from a cobalt alloy. They offer the maximum hardness and heat resistance but can be more expensive and potentially more brittle than other types if mishandled.

How to Use Cobalt Drill Bits for Maximum Effectiveness

Using cobalt drill bits correctly is key to unlocking their full potential and ensuring they last. It’s not just about having the right bit, but using it wisely.

Preparation is Key:

- Secure Your Workpiece: ALWAYS clamp your material firmly. This prevents it from spinning or moving, which is dangerous and can damage the bit and your workpiece. Use clamps or a vise whenever drilling metal.

- Mark Your Spot: Use a center punch (or a strong nail if you don’t have a punch) to create a small indentation where you want to drill. This gives the drill bit a place to start and prevents it from sliding.

- Choose the Right Speed: This is CRUCIAL for metal. Harder materials and tougher bits benefit from slower drill speeds. Too fast, and you’ll generate excessive heat, dulling the bit and potentially damaging your workpiece. Start slow and test. Generally, the harder the metal, the slower the speed. A good rule of thumb is to aim for a peripheral speed of around 50-100 surface feet per minute (sfm) for HSS, and even slower for cobalt in very hard materials. For reference, drilling 1/4-inch steel might be around 700-1000 RPM, while drilling 1/2-inch steel would be much slower, perhaps 300-500 RPM. Your drill’s manual or online charts can help you find optimal speeds based on bit diameter and material.

During Drilling:

- Apply Steady, Firm Pressure: Let the drill bit do the work. Apply consistent downward pressure. Don’t force it, but don’t be timid either. The split point on 135-degree bits helps with starting, so you shouldn’t need excessive force.

- Use Cutting Fluid or Lubricant: This is non-negotiable when drilling hard metals. Cutting fluid (or even a bit of motor oil or a specialized tapping fluid) is essential for reducing friction and heat. As you drill, periodically withdraw the bit slightly and reapply lubricant. This also helps to flush out metal shavings. You can learn more about effective cutting fluids from resources like Machinist’s Hobbyist.

- Clear Swarf Regularly: As you drill, metal shavings (called swarf) will build up. Periodically pull the drill bit out of the hole while it’s still spinning slowly to clear the swarf. This prevents the shavings from packing in the flutes, which can cause the bit to bind or overheat.

- Cool the Bit: If you’re drilling a deep hole, you might need to pause a bit to let the bit and the workpiece cool down. Immerse the bit in water or let it air cool if it becomes too hot to touch.

After Drilling:

- Clean Your Bits: After you’re done, clean off any remaining metal shavings and lubricant from your cobalt bits. A stiff brush works well.

- Store Them Properly: Store your bits in a drill bit organizer to protect the sharp edges and prevent them from getting lost or damaged.

Cobalt Drill Bits vs. Other Types: A Quick Comparison

To truly appreciate the value of cobalt bits, let’s see how they stack up against other common drill bit types:

| Drill Bit Type | Material | Hardness | Heat Resistance | Best For | Pros | Cons |

|---|---|---|---|---|---|---|

| High-Speed Steel (HSS) | Molybdenum and Tungsten steel alloy | Good | Moderate | Wood, plastics, soft metals (aluminum, brass), mild steel | Affordable, versatile, good for general use | Dulls quickly in hard metals, prone to overheating |

| TiN Coated HSS (Titanium Nitride) | HSS with a Titanium Nitride coating | Very Good | Good | Same as HSS, but with better performance in mild to medium-hard steel | Cuts faster, lasts longer than plain HSS, good for steel | Coating can wear off, still struggles with extremely hard metals |

| Cobalt (HSS-Co) | HSS with 5-8% Cobalt added | Excellent | Excellent | Hard metals (stainless steel, cast iron, hardened steel), high volume drilling | Drills very hard materials, extreme durability, long life, high heat resistance | More expensive, can be slightly more brittle than regular HSS if abused |

| Carbide (Tungsten Carbide) | Tungsten Carbide particles bonded with metal | Exceptional | Exceptional | Extremely hard materials, concrete, masonry, very hard metals (often used in masonry bits) | Cuts through almost anything, very long life in appropriate applications | Very brittle, prone to chipping or shattering if dropped or subjected to impact, expensive, requires high drill power |

As you can see, cobalt bits fill a crucial gap. They are designed for applications where standard HSS bits simply cannot perform. While carbide bits are even harder, their brittleness and intended use for materials like concrete make cobalt the premier choice for drilling into tough metals within typical workshop or DIY contexts.

The Proven Value of Cobalt Drill Bits

So, are cobalt drill bits good? The evidence overwhelmingly says YES. Their value comes from their ability to tackle difficult drilling jobs effectively and efficiently, saving you time, frustration, and ultimately, money.

Think about the time saved by a bit that doesn’t constantly break or dull. Consider the cost of ruined projects due to off-center holes or damaged materials caused by inadequate tools. Cobalt drill bits mitigate these issues. For the DIY homeowner who occasionally needs to drill through a stainless steel appliance bracket or a cast iron pipe, the investment in a good set of cobalt bits might seem steep initially. However, when that project comes up, having the right tool means the job gets done smoothly and safely, without the need to call a professional or spend hours struggling.

For those who work with metal more regularly, whether as an auto hobbyist, a metalworker, or a serious DIYer, cobalt drill bits aren’t just a good investment – they’re essential. They provide a level of performance and longevity that justifies their cost many times over.

Beyond the tangible benefits, there’s also the value of confidence. Knowing you have the right tool for the job allows you to approach challenging projects with certainty. This can lead to more ambitious projects, better craftsmanship, and a more rewarding DIY experience. The enhanced cutting ability and durability mean less chance of tool failure interrupting your workflow, contributing to a more positive and productive time in your workshop. Resources like Popular Mechanics often highlight the importance of having specialized bits for specific tasks, and cobalt definitively falls into that category for metalworking.

Cobalt Drill Bits: A Cost-Benefit Analysis for the DIYer

Let’s break down the costs and benefits in a more practical sense:

Costs:

- Higher Initial Purchase Price: Cobalt drill bits are more expensive than standard HSS bits. A single cobalt bit can cost several times more than an equivalent HSS bit. A full set can represent a significant upfront investment.

- Potential for Brittleness: While robust, if subjected to extreme impact or improper use, they can be more prone to snapping than softer steel bits.

Benefits:

- Extended Lifespan: They last significantly longer when used for their intended purpose, meaning you buy fewer bits over time.

- Reduced Project Time: Faster drilling means less time spent on each hole, especially in hard materials.

- Fewer Tools Needed: Instead of burning through multiple standard bits, one or two cobalt bits can complete a job.

- Reduced Material Waste: Precise drilling with a sharp, capable bit reduces the chance of mistakes like missed holes or damaged workpieces.

- Safety: A bit that performs predictably and doesn’t bind or break unexpectedly contributes to a safer work environment.

- Job Completion: Most importantly, they enable you to complete jobs that would be impossible or extremely difficult with lesser bits.

For the homeowner or hobbyist who only drills metal occasionally, investing in a small set of the most common sizes (e.g., 1/8″, 3/16″, 1/4″, 5/16″) is a wise move. For professionals, or serious hobbyists who frequently drill hard metals, a comprehensive set is an absolute necessity.

Frequently Asked Questions About Cobalt Drill Bits

To wrap things up and address some common questions:

Q1: Do I need to use a special drill for cobalt drill bits?

No, you can use them with any standard drill (corded or cordless). However, ensure your drill has variable speed control so you can operate at the slower speeds recommended for drilling hard metals.

Q2: How do I know if a drill bit is cobalt?

Cobalt drill bits are often distinguishable by their color, which can range from bronze/gold to a darker, almost blackish hue, compared to the silver or metallic grey of standard HSS bits. Many will also be clearly labeled as “Cobalt” or have “Co” in their part number. Always check the packaging if you’re unsure.

Q3: Can I use cobalt drill bits on wood or plastic?

Yes, you can, but it’s usually not recommended. They will work, but they’re overkill and can sometimes generate more heat, potentially melting softer plastics. Standard HSS bits are usually better suited and more economical for wood and these softer materials.