Ash Lumber For Sale: Exclusive & Essential Woods

Looking for ash lumber? You’re in luck! Ash wood offers fantastic durability, beautiful grain, and affordability, making it a top choice for many woodworking projects, from furniture to tool handles. Find out why it’s so popular and where to get it.

Hey there, fellow woodworkers! If you’re on the hunt for a wood that’s strong, looks amazing, and won’t break the bank, then you’ve come to the right place. Ash lumber is one of those fantastic materials in woodworking that just keeps on giving. It’s a go-to for everything from sturdy furniture to those trusty tool handles you depend on. Sometimes finding the right wood can feel a bit overwhelming, especially when you’re just starting out.

But don’t worry, I’m here to guide you through the wonderful world of ash lumber. We’ll explore why it’s such a popular choice and how you can find the best quality ash for your next project. Get ready to discover a wood that’s both exclusive in its quality and essential for your workshop!

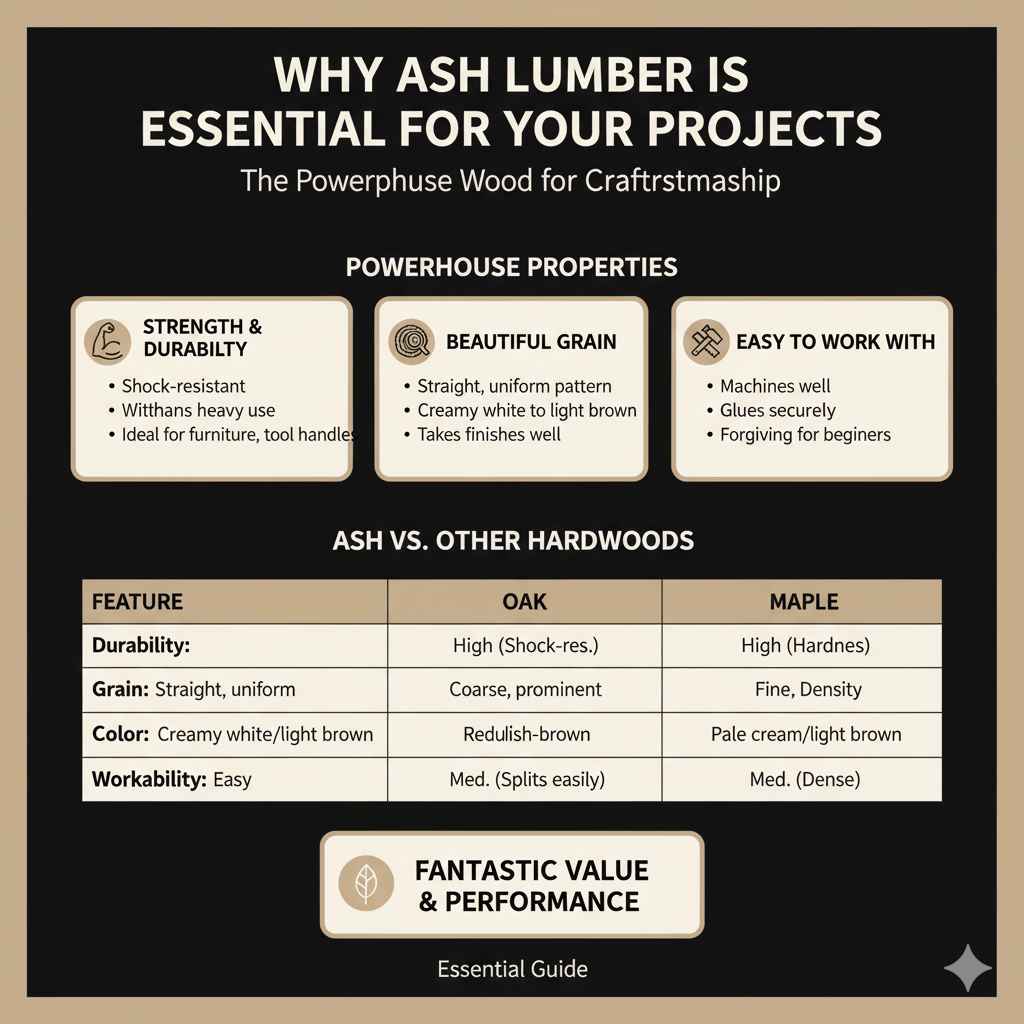

Why Ash Lumber is Essential for Your Projects

What makes ash wood so special?” That’s a question I hear a lot, and it’s a good one! Ash is like the reliable friend in the lumber yard. It’s known for being incredibly strong and shock-resistant. This means it can handle a lot of stress without breaking, which is why it’s perfect for things that need to be tough. Think about baseball bats or tool handles – they need to absorb impact. Ash is also beautiful. It has a straight, attractive grain pattern that can look stunning, especially when finished. It’s a versatile player that works well for so many different things, and for beginners, it’s often easier to work with than some of the harder, more exotic woods. Let’s dive into what makes it such a standout.

The Powerhouse Properties of Ash Wood

Ash lumber boasts a combination of properties that make it highly desirable for a wide range of applications. Its strength and rigidity are among its most celebrated features. This makes it an excellent choice for furniture that needs to withstand daily use, such as chairs, tables, and bed frames. The shock resistance of ash is also exceptional, leading to its historical use in sporting goods and tool manufacturing.

Beyond its physical strength, ash wood offers aesthetic appeal. The grain is typically straight and uniform, with a coarse, open texture. The color can range from creamy white to light brown, often with darker streaks. This natural beauty lends itself well to various finishing techniques, from natural oil finishes that highlight the grain to stains that can dramatically alter its appearance.

For woodworkers, ash is also relatively easy to work with using both hand and power tools. It machines well, takes fasteners effectively, and can be glued securely. While it’s strong, it’s not so dense that it becomes difficult to handle or shape, striking a great balance for hobbyists and professionals alike.

Ash vs. Other Popular Hardwoods

When you’re choosing wood, it’s helpful to see how it stacks up against others. Ash often finds itself compared to oak and maple, two other very popular hardwoods.

- Durability: Ash is generally considered to be as strong or stronger than red oak, especially in terms of shock resistance. It tends to hold up better to heavy impacts.

- Grain Pattern: Ash typically has a more uniform, straighter grain than red oak, which can sometimes have more prominent ray flecks and a coarser texture depending on the cut. Maple has a finer, often denser grain that can appear smoother and sometimes more figured, like flames or curls, if you’re lucky.

- Color: Ash is typically lighter in color than red oak, ranging from creamy white to light brown. Maple is similarly light, often a pale cream to light brown, and is prized for its uniform, pale appearance.

- Workability: Ash is generally easier to machine and shape than some very dense maples. While oak can be prone to splitting, ash is more forgiving. Gluing and finishing are usually straightforward with ash.

- Cost: Ash is often more affordable than maple and can be comparable to or slightly less expensive than red oak, making it a fantastic value for its performance.

You can find more insights into wood properties from resources like The Wood Database, a fantastic online resource for all things wood.

Types of Ash Lumber You’ll Find

While there are many species of ash, when you’re looking for lumber for sale, you’ll most commonly encounter White Ash (Fraxinus americana) and Green Ash (Fraxinus pennsylvanica). These are the workhorses of the ash lumber world. Understanding the slight differences can help you choose the best fit for your project.

White Ash is often considered the premium choice. It’s known for its exceptional strength and shock resistance. The heartwood can range from light to medium brown, while the sapwood is usually a creamy white. It’s highly sought after for furniture, cabinetry, and high-impact applications like tool handles and sports equipment. Its grain is usually straight and attractive.

Green Ash is also very durable and strong, though sometimes considered slightly less so than White Ash. It’s more widespread and often a bit more affordable. Its color is similar, with a light brown heartwood and creamy sapwood. Green Ash is excellent for furniture, general construction, and utility wood where its robust nature is valued.

Occasionally, you might see lumber from other ash species, but these two are the most commercially significant for general woodworking.

Where to Buy Ash Lumber For Sale

Finding quality ash lumber is key to a successful project. Fortunately, there are several reliable avenues to explore. The place you buy from can significantly impact the quality, price, and selection you’ll experience.

Local Sawmills and Lumberyards

This is often the best place to start, especially if you want to see the wood in person. Local sawmills and lumberyards usually sell directly to the public. The benefits here are:

- Inspection: You can physically inspect the boards for defects like warping, knots, or damage from insects.

- Variety: They often carry a good selection of hardwoods, including ash, in various grades and dimensions.

- Expert Advice: Staff can offer valuable advice on wood selection and suitability for your project. They often know exactly where their lumber came from.

- Support Local: You’re supporting businesses in your community.

Searching online for “local lumber mill near me” or “hardwood lumberyard [your city]” is a great way to find these places.

Online Lumber Retailers

The internet opens up a world of options! Many reputable online retailers specialize in hardwoods and ship directly to your door. This is a fantastic option if local choices are limited.

- Convenience: Order from the comfort of your home.

- Wider Selection: You might find species or specific cuts that aren’t available locally.

- Direct Shipping: Lumber is delivered to your workshop or home.

When buying online, always check:

- Shipping Costs: Lumber is heavy, so shipping can add up.

- Return Policies: Understand what you can do if the wood isn’t what you expected.

- Wood Grading: Familiarize yourself with how they grade their lumber (e.g., FAS, Select). You can learn more about hardwood lumber grading from organizations like the National Hardwood Lumber Association (NHLA).

Specialty Wood Suppliers

Some businesses focus specifically on hardwoods for furniture making, turning, or instrument building. These suppliers might have a particularly high quality or specialized selection of ash lumber.

Tips for Buying Ash Lumber:

- Buy a Little Extra: It’s always wise to purchase about 10-15% more lumber than your project requires. This accounts for mistakes, waste from defects, and allow for matching grain patterns.

- Check Moisture Content: Wood should be properly dried (kiln-dried or air-dried) to prevent warping and cracking once it’s in your home. Kiln-dried lumber is generally preferred for indoor projects and furniture.

- Understand Grading: Lumber is graded based on the number and size of defects (knots, splits, etc.). For furniture, FAS (Firsts and Seconds) is a common high-grade. For utility projects, lower grades might suffice.

Working with Ash Lumber: A Beginner’s Guide

So you’ve got your ash lumber! Now what? Don’t be intimidated. Ash is known for being a forgiving wood, making it a great choice for beginners. With a few tips, you’ll be crafting beautiful projects in no time.

Cutting and Shaping Ash

Ash cuts very well for a hardwood. When using power saws like a table saw or miter saw, you’ll find it cuts cleanly. For routers and planers, ash also performs admirably. Just remember to keep your cutting tools sharp; dull blades can lead to tear-out, especially with a coarser-grained wood like ash. Always wear safety glasses and hearing protection when operating power tools.

When routing edges or creating joinery, ash responds well to a sharp bit. You might notice a slight splintering on very fine details due to its open grain, but this is easily managed with careful work or a bit of sanding.

Joining Ash Wood

Ash is a fantastic wood for joinery. It glues up beautifully, so standard wood glues like Titebond work very well. When making glued joints, ensure the surfaces are clean and tightly pressed together during curing. Clamps are your best friend here!

For mechanical fasteners like screws and nails, ash holds them securely. Pre-drilling pilot holes, especially near the ends of boards, is a good practice to prevent splitting, which is common with many hardwoods. This is especially true for ash, which can be prone to checking (small cracks) if not handled properly.

Sanding and Finishing Ash

This is where ash really shines. Its attractive grain pattern can be enhanced with a variety of finishes. For a natural look that highlights its light color and grain, a clear coat of polyurethane or a natural oil finish (like tung oil or Danish oil) is excellent.

Sanding is crucial for a smooth finish. Start with a coarser grit sandpaper (like 80 or 100 grit) to flatten the surface and remove any milling marks. Then, progressively move to finer grits (150, 220, and even 320 grit) for a silky-smooth feel. Because ash has an open grain, you might consider using a grain filler if you’re aiming for an ultra-smooth, pore-filled surface, especially for high-gloss finishes. However, many prefer to leave the grain texture visible.

When you’re ready to apply a finish, test it on a scrap piece of ash first to see how it affects the color and grain. This step alone can save you a lot of potential headaches!

Common Projects Perfect for Ash Lumber

Ash lumber’s versatility means it’s suitable for a vast array of projects, from functional everyday items to beautiful statement pieces.

Furniture Making

This is perhaps where ash truly excels. Its strength and attractive grain make it ideal for:

- Chairs: The durability of ash ensures chairs can withstand constant use.

- Tables: Tabletops and legs made from ash are robust and visually appealing.

- Shelving: Strong enough to hold significant weight, ash makes for sturdy shelves.

- Desks: Its smooth surface and durability are perfect for a workspace.

Tool Handles and Sporting Goods

As mentioned, ash’s shock resistance makes it the material of choice for many tool handles, from hammers and axes to shovels. It’s also traditionally used for things like baseball bats and lacrosse sticks because it can deliver power and absorb impact.

Cabinetry and Millwork

The straight grain and relatively light color of ash make it an excellent choice for kitchen cabinets, built-ins, and decorative millwork. It can be stained to mimic darker woods or finished naturally to maintain a bright, airy feel.

Flooring

While often more expensive than some other options, ash has been used for hardwood flooring due to its durability. Its attractive grain can add warmth and character to a room.

Woodturning and Decorative Items

Ash turns beautifully on a lathe, making it a favorite for craftspeople creating bowls, spindles, and decorative items. Its grain pattern can create stunning visual effects on curved surfaces.

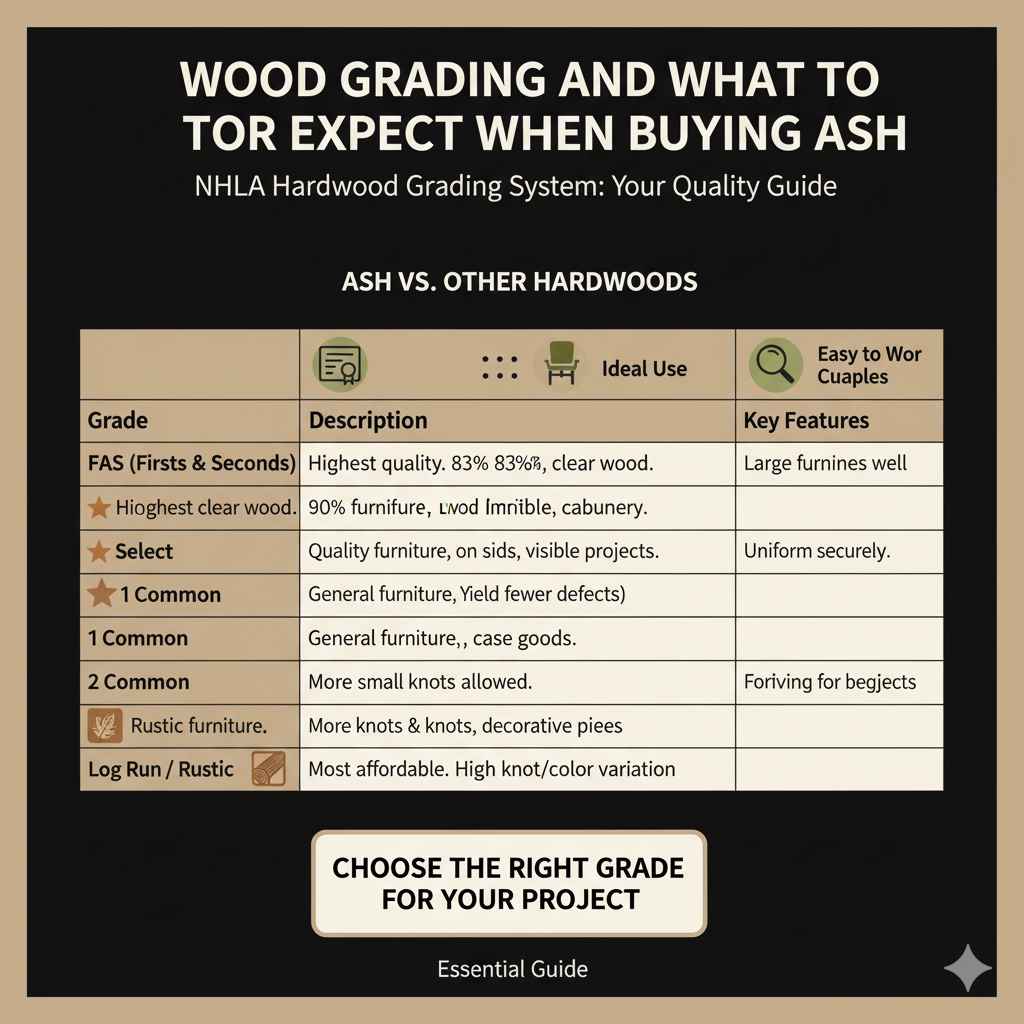

Wood Grading and What to Expect When Buying Ash

Understanding how wood is graded will help you get the best value and quality for your money. The grading system for hardwoods, largely standardized by the National Hardwood Lumber Association (NHLA), primarily focuses on the number and size of defects on the clear cuttings obtained from a board. For beginners, it’s good to know about the common grades:

| Grade | Description | Best For |

|---|---|---|

| FAS (Firsts and Seconds) | The highest grade. Boards are typically at least 6 inches wide and 6 feet long, yielding approximately 83.3% clear wood on the best side. Very few, small defects are allowed. | Fine furniture, cabinetry, high-end projects where appearance is paramount. |

| Select | This grade is common for woods like maple and birch, but can also apply to ash. It typically means the boards are at least 4 inches wide and 6 feet long, with a minimum of 90% clear wood on one side, or 92% on the best combination of sides. It aims for a more uniform appearance. | Furniture, cabinetry, good quality visible projects. |

| 1 Common | Boards are usually at least 4 inches wide and 4 feet long, yielding approximately 66.7% clear wood. More defects are allowed than in FAS, but they are generally smaller or fewer. Yields can be achieved from both sides. | Case goods, less critical furniture parts, general use where some imperfections are acceptable. |

| 2 Common | Boards are at least 3 inches wide and 4 feet long, yielding at least 50% clear wood. This grade allows for more knots and imperfections. | Utility furniture, less visible parts, projects where appearance is not the primary concern. |

| Log Run / Rustic | This grade essentially takes everything the mill cuts, with minimal sorting. It can contain a lot of knots, color variations, and imperfections. It’s often the most affordable but requires more careful selection and is best for rustic projects. | Rustic furniture, decorative pieces, projects where character and imperfections are desired. |

Always ask your lumber supplier about their grading system if it’s not clearly stated. For beginner projects, 1 Common or Select grades often offer a great balance of quality and affordability.

Frequently Asked Questions About Ash Lumber

Why is ash wood so popular for tool handles?

Ash wood is extremely shock-absorbent and has excellent tensile strength and stiffness. This combination means it can withstand hard impacts without breaking or deforming, making it ideal for tools that get a lot of heavy use.

Is ash harder or softer than oak?

Generally, ash is considered to be similar in hardness to red oak, or slightly harder in some classifications. Both are considered hardwoods and are very durable, but ash often has better shock resistance.

Does ash wood swell or warp easily?

Like all hardwoods, ash can expand and contract with changes in humidity. Properly kiln-dried ash is much more stable. However, storing wood in a climate-controlled environment and allowing it to acclimate to your workshop’s conditions before use is essential to minimize warping.

Can I stain ash wood to look like walnut or cherry?

Yes, ash takes stains very well. Its relatively light and neutral color provides a good base for staining. You can achieve a walnut-like or cherry-like appearance with the right stain and finishing techniques, though the grain pattern will inherently look different.

What’s the main difference between white ash and green ash for woodworking?

White ash is typically considered slightly stronger and more shock-resistant than green ash. Green ash is more abundant and often more affordable. For most woodworking projects, both are excellent choices, and the aesthetic differences are usually minor.