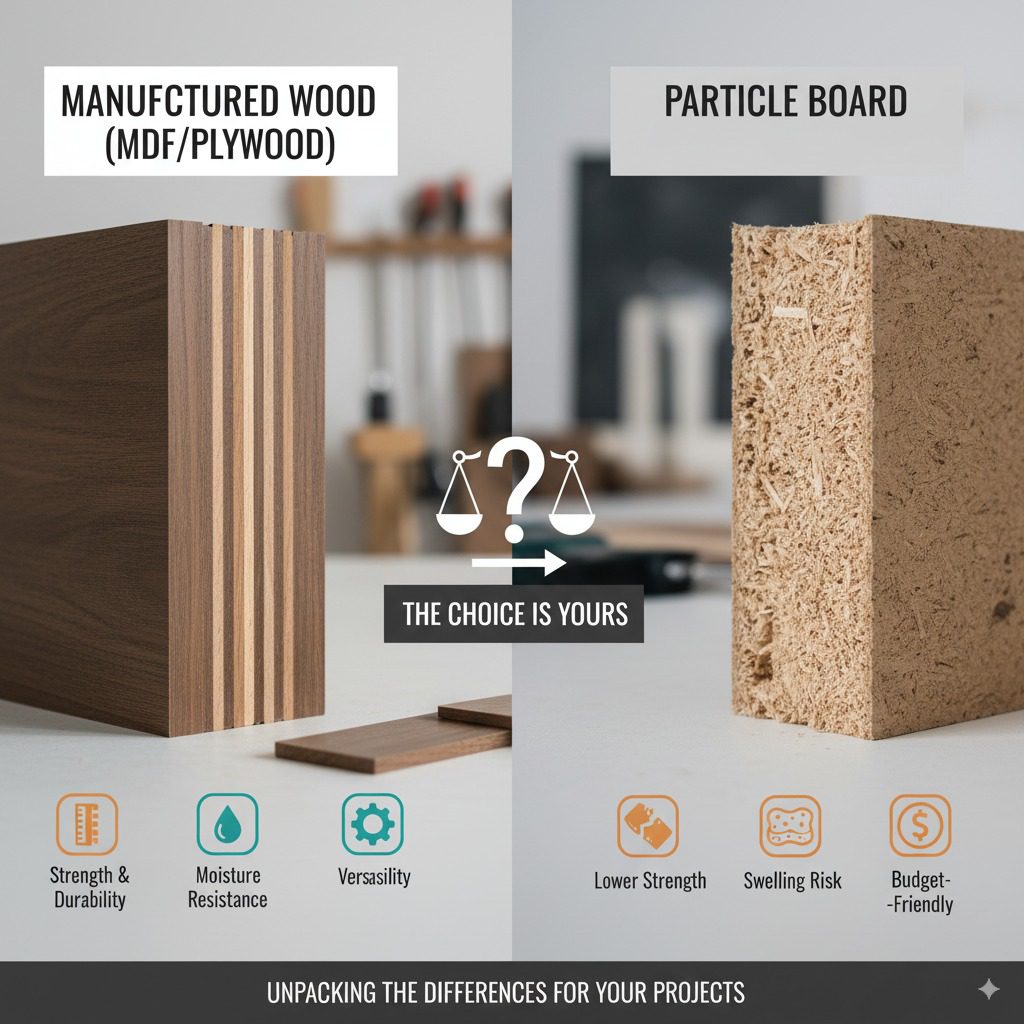

Manufactured Wood vs. Particle Board: Unpacking the Differences

Manufactured wood is a broad term for engineered wood products like particle board, MDF, and plywood, made from wood fibers or veneers. Particle board is a specific type of manufactured wood, made from compressed wood chips and resin. While similar, they differ in quality, strength, and uses, impacting your DIY project choices.

Hey there, DIY friend! If you’re diving into woodworking or tackling a home project, you’ve likely come across terms like “manufactured wood” and “particle board.” These can be confusing, and picking the wrong material might lead to wobbly furniture or wasted effort. I’m Md Meraj, your woodworking guide, here to simplify things with clear, beginner-friendly advice. With the right know-how, you’ll choose materials confidently and build projects that last. Let’s break down the differences, uses, and steps to work with these materials!

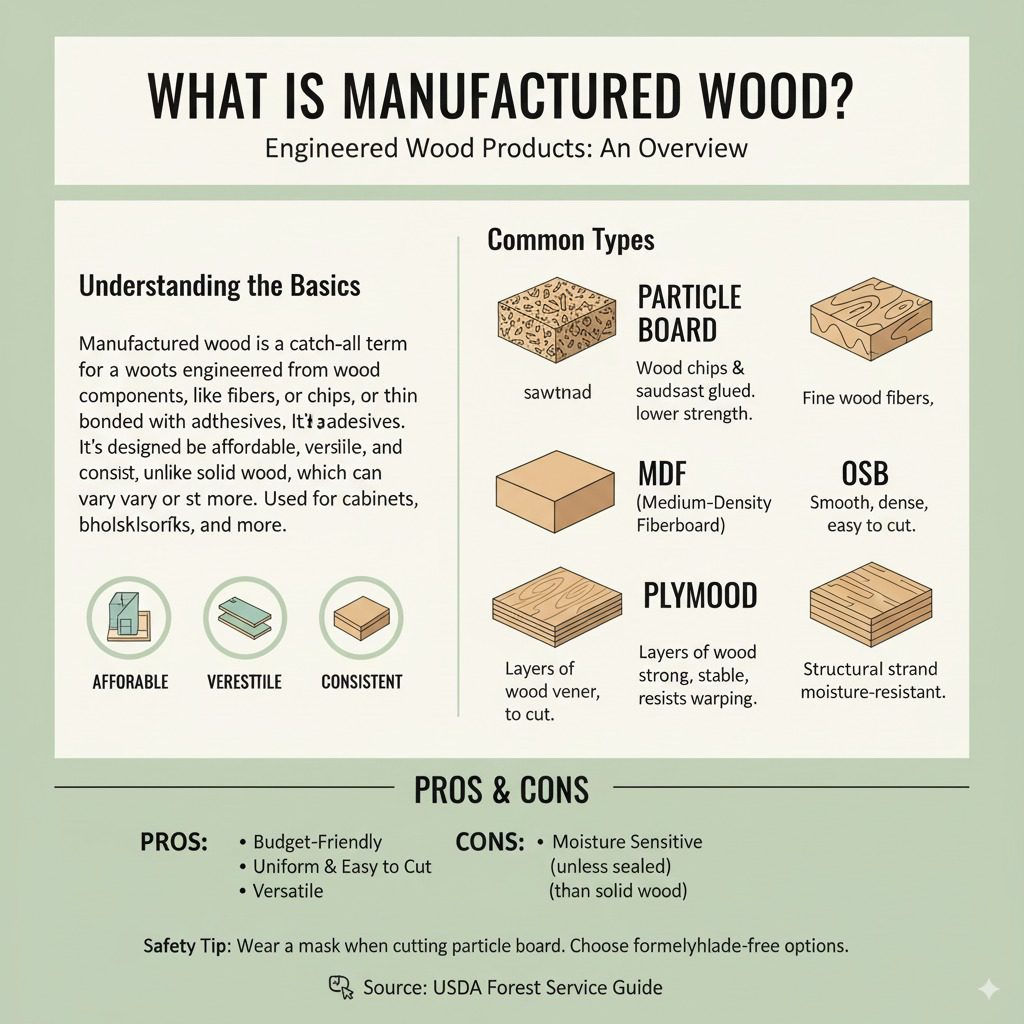

What Is Manufactured Wood?

Manufactured wood is a catch-all term for wood products engineered from real wood components, like fibers, chips, or thin layers, bonded with adhesives. It’s designed to be affordable, versatile, and consistent, unlike solid wood, which can vary in grain or strength. In my years of guiding homeowners, I’ve seen manufactured wood used for everything from cabinets to bookshelves.

Common types include:

- Particle Board: Made from wood chips and sawdust glued together.

- MDF (Medium-Density Fiberboard): Smoother, denser, from fine wood fibers.

- Plywood: Layers of wood veneer glued in alternating directions for strength.

- OSB (Oriented Strand Board): Large wood strands pressed together.

Each has unique traits, but all are budget-friendly compared to solid wood. They’re great for DIY because they’re uniform and easy to cut. However, they can be sensitive to moisture unless sealed properly. For more on engineered woods, check this USDA Forest Service guide.

What Is Particle Board?

Particle board is one type of manufactured wood, made by compressing wood chips, sawdust, and resin into flat panels. It’s the budget champ—often the cheapest option at hardware stores. I’ve used it for simple shelves or as a base for laminates, but it’s not the strongest kid on the block.

It comes in different densities grades, from low to high, but even the best particle board isn’t as sturdy as plywood or MDF. It’s great for flat surfaces like tabletops when covered with veneer, but it doesn’t hold screws well and can sag under weight. Always seal edges to prevent swelling in humid areas, like kitchens.

Safety tip: Wear a mask when cutting particle board, as the dust can irritate. Also, check for formaldehyde-free options to avoid harmful fumes, especially for indoor projects.

Key Differences Between Manufactured Wood and Particle Board

Think of manufactured wood as the big family, and particle board as one of the siblings. Here’s a clear comparison to help you decide what’s best for your project.

| Aspect | Manufactured Wood (General) | Particle Board |

|---|---|---|

| Definition | Engineered products like plywood, MDF, OSB, particle board | Compressed wood chips and resin |

| Strength | Varies (plywood is strong, MDF is moderate) | Low to moderate, prone to sagging |

| Cost | $10-$100 per sheet, depending on type | $10-$30 per sheet, very affordable |

| Weight | Light to heavy (MDF is heavier) | Light but brittle |

| Moisture Resistance | Poor unless sealed (plywood better) | Very poor, swells easily |

| Uses | Furniture, flooring, construction | Shelves, laminated furniture |

| Screw Holding | Good (plywood), fair (MDF) | Poor, needs special fasteners |

Particle board is great for low-cost projects, but other manufactured woods like plywood shine for structural needs. For deeper insights, see Popular Woodworking’s guide.

When to Use Manufactured Wood vs. Particle Board

Your project’s needs dictate the material. Particle board works for light-duty tasks, like temporary shelving or furniture with a veneer finish. It’s a go-to for flat-pack furniture because it’s cheap and easy to mass-produce.

Other manufactured woods, like plywood, are better for heavy-duty projects—think cabinets, subflooring, or outdoor structures (with proper sealing). MDF is ideal for painted furniture or intricate cuts due to its smooth surface. OSB suits construction, like wall sheathing, for its strength and low cost.

If you’re on a tight budget, particle board can save you money, but don’t expect it to last decades. For humid areas, avoid particle board unless you seal it well—plywood or treated MDF is safer. Test your choice with a small piece if you’re unsure how it’ll hold up.

Tools and Materials Needed for Working with Manufactured Wood and Particle Board

Having the right tools makes cutting and assembling these materials a breeze. Here’s what you’ll need, based on my workshop experience.

| Category | For Manufactured Wood | For Particle Board |

|---|---|---|

| Basic Tools | Circular saw, jigsaw, drill, 80-120 grit sandpaper | Table saw, fine-tooth blade, drill |

| Materials | Wood glue, screws, edge banding, sealant | Laminate sheets, contact cement, anchors |

| Safety Gear | Dust mask, safety glasses, gloves | Respirator, ear protection |

| Optional Extras | Router for edges, clamps | Veneer tape, painter’s tape |

Keep costs low—basic tools are under $100 total. For tool tips, visit Fine Woodworking’s guide. Clean tools after use to avoid resin buildup.

How to Work with Particle Board: Step-by-Step Guide

Particle board is tricky due to its fragility, but these steps ensure a clean result. Take it slow to avoid chipping.

- Measure and mark: Use a straightedge and pencil to mark cuts. Double-check measurements.

- Choose the right blade: Use a fine-tooth saw blade (60-80 teeth) to minimize splintering.

- Cut carefully: Score the cut line with a utility knife, then use a circular saw. Support the board to prevent sagging.

- Sand edges: Smooth rough edges with 120-grit sandpaper.

- Seal edges: Apply edge banding or sealant to protect from moisture.

- Fasten securely: Use coarse-thread screws with anchors for better grip. Pre-drill holes to avoid splitting.

- Finish: Paint or laminate for a polished look. Seal all surfaces for durability.

This takes a few hours but saves headaches. If chips occur, fill with wood putty and sand smooth.

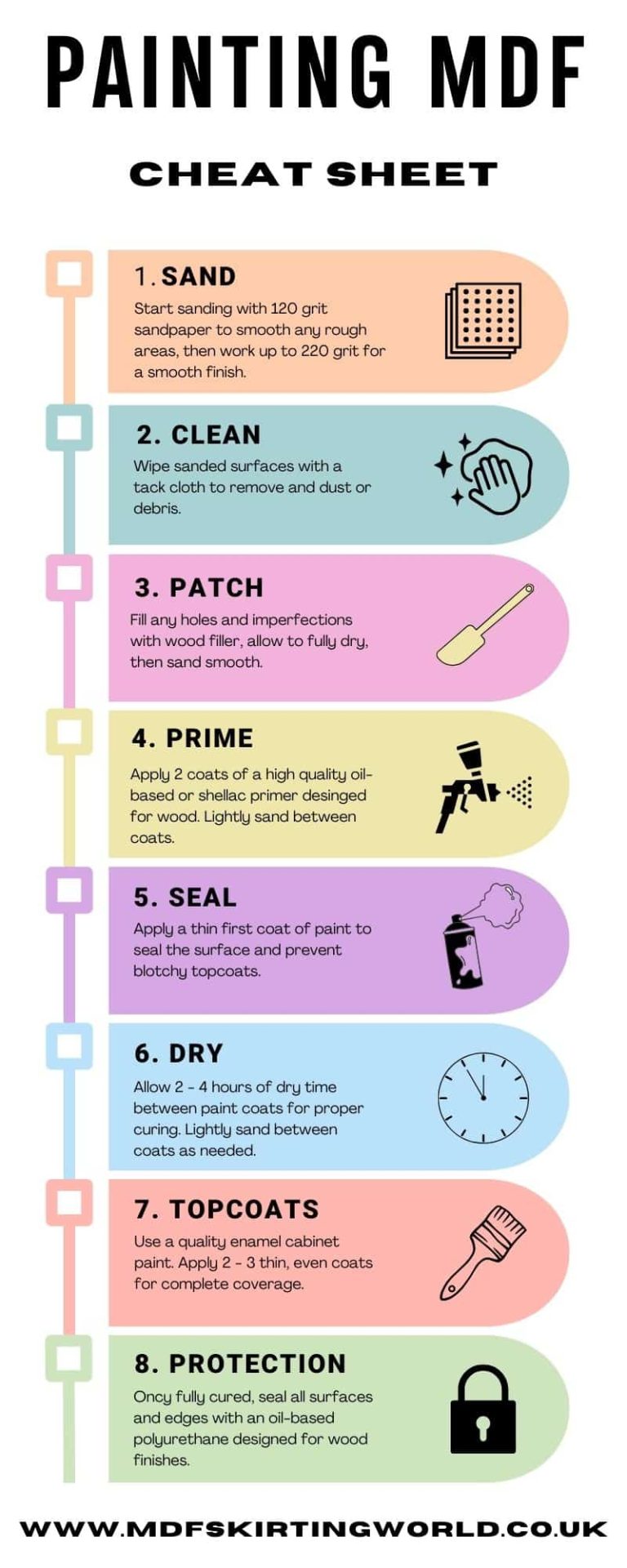

How to Work with Other Manufactured Woods: Step-by-Step Guide

Plywood and MDF are more forgiving but need care for best results. Follow these steps for sturdy builds.

- Select the grade: Choose cabinet-grade plywood or high-density MDF for furniture. Check for voids.

- Measure and cut: Use a circular saw with a plywood blade. Tape cut lines with painter’s tape to reduce splintering.

- Sand surfaces: Start with 80-grit, finish with 150-grit for smoothness.

- Join pieces: Use wood glue and screws. Clamp joints for tight bonds.

- Seal or finish: Apply primer and paint for MDF, or stain and varnish for plywood. Seal edges well.

- Check alignment: Use a level to ensure pieces are square before setting.

Plywood projects can last decades if sealed properly. MDF needs extra moisture protection indoors.

Common Mistakes to Avoid

Even beginners can nail these materials with caution. Here are pitfalls to skip.

- Ignoring moisture: Particle board swells fast—always seal it. Plywood needs exterior-grade for outdoor use.

- Using wrong blades: Coarse blades chip edges. Get fine-tooth blades for clean cuts.

- Overloading particle board: It sags under heavy weight. Reinforce with supports.

- Skipping pre-drilling: Particle board splits without pilot holes. Drill first.

- Poor ventilation: Dust and fumes are hazards. Work in open spaces with a mask.

- Ignoring formaldehyde: Choose low-VOC products for safety, per EPA guidelines.

Tips for Professional Results

Want your project to shine? These tips from my workshop will help.

- Test cuts on scraps to perfect your technique.

- Use painter’s tape on cut lines to reduce tear-out.

- Reinforce particle board shelves with metal brackets.

- Apply two thin coats of sealant for better protection.

- Store boards flat to prevent warping.

- Label pieces before assembly for easier builds.

Frequently Asked Questions

Is particle board as strong as other manufactured woods?

No, particle board is weaker than plywood or MDF. It’s fine for light shelves but not for heavy loads or structural use.

Can I paint particle board?

Yes! Sand lightly, prime with a sealing primer, then paint. Seal edges to prevent swelling.

Is manufactured wood eco-friendly?

It can be! Many use recycled wood. Look for FSC-certified or low-formaldehyde options for sustainability.

Can particle board be used outdoors?

Not recommended—it swells with moisture. Use exterior-grade plywood or treated MDF instead.

How do I fix chipped particle board?

Fill chips with wood putty, sand smooth, and paint or veneer over it for a seamless look.

Which is better for furniture: particle board or plywood?

Plywood is stronger and holds screws better, ideal for lasting furniture. Particle board suits budget, temporary pieces.

Does manufactured wood need special tools?

No, standard woodworking tools work. Use fine-tooth blades and pre-drill to avoid damage.

Conclusion

Now you’re armed with the know-how to choose between manufactured wood and particle board for your DIY projects. Particle board is a budget-friendly option for simple, low-stress builds, while other manufactured woods like plywood or MDF offer strength for more demanding tasks. With the right tools and steps, you can create sturdy, beautiful pieces that make your home shine. Start small, stay safe, and enjoy the process—your next project is going to be a hit!