MDF vs Plywood Price: Essential Comparison

For DIYers and homeowners, understanding the cost difference between MDF and plywood is crucial for smart project budgeting. While plywood often offers superior strength and water resistance, MDF can be a more budget-friendly option for many indoor applications. This guide breaks down the price factors and helps you choose wisely.

Welcome to the workshop! Choosing the right building material for your next DIY project can feel a bit overwhelming, especially when you’re staring at two popular but different options: MDF and plywood. You’ve probably heard of both, and you might even know they’re used for similar things, like shelves and cabinets. But what about the most important question for any budget-conscious crafter – the price? It’s a common sticking point, and that’s perfectly okay! My goal is to make this easy to understand, so you can feel confident in your choices. We’ll explore what influences their costs and how they stack up against each other, making your next project a success without breaking the bank. Let’s dive in and figure out which is the better buy for your needs.

Understanding MDF and Plywood: A Quick Look

Before we get deep into the numbers, let’s quickly recap what MDF and plywood are. Knowing their basic makeup helps explain why their prices differ.

What is MDF?

MDF stands for Medium-Density Fiberboard. It’s made from wood fibers (tiny wood dust and particles) that are mixed with wax and resin binders. These are then pressed together under high heat and pressure. Think of it like a super-compressed wood particle board. Because it’s so uniform, it has a smooth surface, which is fantastic for painting and applying veneers.

What is Plywood?

Plywood, on the other hand, is made by peeling thin layers, or “veneers,” of wood from a log. These thin sheets are then glued together with their grain running in different directions. This cross-graining is what gives plywood its amazing strength and stability. It’s layered like a cake, with each layer adding structural integrity.

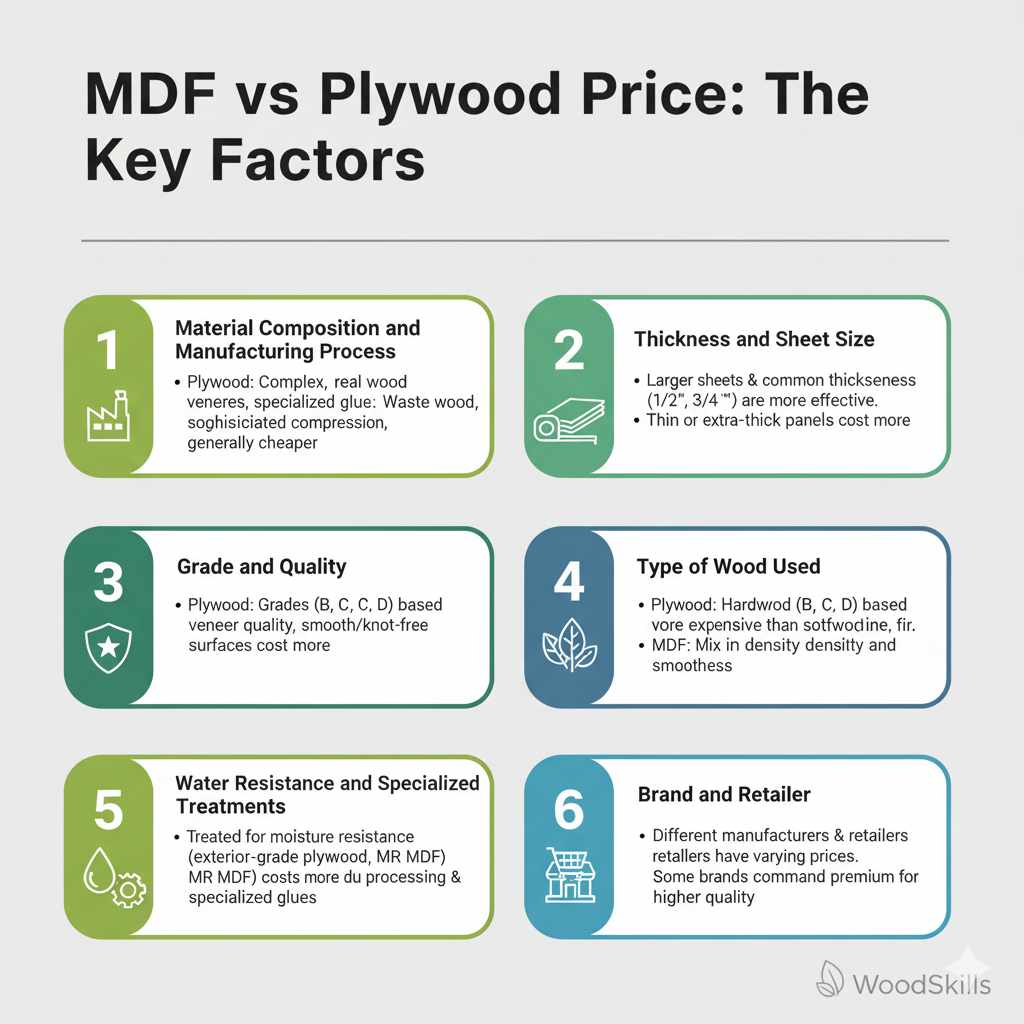

MDF vs Plywood Price: The Key Factors

The price of both MDF and plywood isn’t set in stone. Several things can make one sheet cost more or less than another. Let’s look at what influences these costs:

1. Material Composition and Manufacturing Process

This is the biggest driver of price. Plywood involves more complex manufacturing with real wood veneers and specialized glues, requiring more labor and raw material harvesting. MDF, while requiring sophisticated machinery for compression, often uses waste wood products and fewer types of adhesives, which can make it cheaper to produce.

2. Thickness and Sheet Size

Just like buying anything in bulk, larger sheets and common thicknesses (like 1/2 inch or 3/4 inch) are usually more cost-effective per square foot. If you need very thin MDF for a decorative insert or extra-thick, high-grade plywood for structural use, expect to pay more.

3. Grade and Quality

This is especially true for plywood. Plywood has different grades (like A, B, C, D) that refer to the quality of the wood veneers on its surfaces and core. Higher grades, with smooth, knot-free surfaces, cost significantly more. MDF quality also varies, with some being denser and smoother than others.

4. Type of Wood Used

For plywood, the type of wood veneer can drastically change the price. Hardwood plywood (like birch, oak, or maple) is generally more expensive than softwood plywood (like pine or fir). MDF is usually made from a mix of hardwoods and softwoods.

5. Water Resistance and Specialized Treatments

If a panel has been treated for moisture resistance (like exterior-grade plywood or certain types of MDF designed for humid environments), it will cost more due to the additional processing or the use of specialized waterproof glues.

6. Brand and Retailer

Different manufacturers have different pricing structures. Shopping around at various lumber yards, home improvement stores, and specialty wood suppliers can yield different prices for the exact same product. Plus, some brands might be known for higher quality, commanding a premium price.

MDF vs Plywood Price Comparison Table

To give you a clearer picture, here’s a general price comparison. Keep in mind that these are estimated averages and can change based on the factors we just discussed. Prices are typically for a standard 4’x8′ sheet in common thicknesses (e.g., 1/2″ or 3/4″).

| Material | Typical Price Range (per 4’x8′ sheet) | Key Price Influencers |

|---|---|---|

| MDF (Standard) | $20 – $40 | Thickness, density, brand |

| Plywood (Standard Construction Grade) | $25 – $60 | Wood species, grade (e.g., CDX, AC), thickness |

| Plywood (Hardware Grade, e.g., Birch/Oak) | $40 – $100+ | Wood species, grade (e.g., A/B, AC), thickness, veneer quality |

| Moisture-Resistant MDF | $30 – $60 | Thickness, specific formulation |

| Exterior-Grade Plywood (e.g., for subflooring) | $35 – $70 | Wood species, grade, thickness, glue type |

As you can see, standard MDF is often the most affordable option, especially when compared to higher-grade plywood. However, basic construction-grade plywood can sometimes be priced similarly to MDF, making the choice depend more on the project’s needs.

When is MDF the Cheaper Choice?

There are definitely scenarios where opting for MDF will save you money and still give you great results.

1. Projects Requiring a Smooth, Paintable Surface

If your project involves intricate details or you want a flawless painted finish (like decorative trim, cabinet doors, or custom shelving for a living room), MDF is often cheaper than a high-grade plywood with a smooth veneer. You avoid the cost of a premium plywood surface and get a surface that takes paint beautifully.

2. Simple, Non-Structural Indoor Applications

For projects that don’t need to bear heavy loads or be exposed to moisture, MDF is a budget-friendly workhorse. Think about:

- Internal cabinet boxes

- Drawer construction (sides and bottoms)

- Decorative paneling

- Jigs and shop fixtures

- Enclosures for speakers

3. When You Need a Uniform Finish

Unlike plywood, MDF doesn’t have a visible wood grain. This can be a huge advantage if you want a consistent, modern look without the natural variations that come with real wood. For applications where appearance is key but budget is tight, MDF can be the smart, cost-effective answer.

When is Plywood a Better Value (Even if Slightly More Expensive)?

Sometimes, paying a little more upfront for plywood is actually a better value in the long run. This is because plywood offers advantages that MDF can’t match, especially for certain types of projects.

1. Structural Integrity and Strength

Plywood’s layered construction makes it significantly stronger and more stable than MDF. It resists warping, cracking, and delaminating much better. For projects that need to hold substantial weight or endure stress, plywood is usually the better investment.

- Shelving that needs to support heavy items (e.g., in a garage or pantry)

- Workbench tops

- Structural components in furniture

- Projects where durability is paramount

2. Moisture Resistance

Standard plywood is more resistant to moisture than MDF, which can swell and disintegrate if it gets wet. For projects that might encounter occasional spills or are intended for environments with higher humidity, even basic construction-grade plywood is a safer bet. For truly wet conditions, specific exterior-grade plywood or marine-grade plywood is available, though at a higher cost.

For instance, if you’re building outdoor furniture or a garden planter box, exterior-grade plywood is essential. You can learn more about the different types of plywood and their uses from the Forest Products Laboratory at the USDA Forest Service, a highly reputable source for wood science.

3. Screw Holding Power and Durability

Plywood generally holds screws better than MDF, especially along the edges. While MDF can sometimes crumble, the wood fibers in plywood offer a more reliable grip for fasteners, which is important for the longevity of your project. This means your furniture is less likely to fall apart over time.

4. Projects Where a Natural Wood Look is Desired

If you plan to stain or clear-coat your project to showcase a beautiful wood grain, then plywood is your only option. MDF can be veneered, but the base material itself lacks that natural wood aesthetic. For fine furniture making, or projects where the natural beauty of wood is a key feature, plywood is indispensable.

Comparing Costs for Specific Projects

Let’s imagine a couple of common DIY projects and see how MDF and plywood might compare in price and suitability.

Project Example 1: A Basic Bookshelf for a Bedroom

For a bookshelf in a dry, climate-controlled bedroom, you have options:

- MDF: You could build a beautiful, easily paintable bookshelf using 3/4″ MDF. It will be budget-friendly, smooth, and take paint perfectly. However, it won’t hold extreme weight without sagging over longer spans, and water spills would be a disaster. Price: Estimate $70-$120 for materials (for a medium-sized bookshelf).

- Plywood: Opting for a decent-grade construction plywood (like pine or fir) would be stronger and more durable. If you want a clean surface to paint, you might choose an AC-grade plywood. If you want to stain it, you’d look at a nicer grade like good-quality birch or oak plywood. Price: Estimate $90-$180+ for materials, depending on the grade.

Verdict: For most bedroom bookshelves, MDF is the cheaper and perfectly adequate choice, especially if you’re painting. If you plan to store very heavy books or want a stained wood look, plywood becomes a better value.

Project Example 2: Garage Shelving

Garage shelving needs to be strong and potentially handle moisture:

- MDF: Not ideal. MDF is too susceptible to moisture if there’s any chance of dampness from cars or a leaky roof. Its strength might also be a concern for heavy-duty storage without extensive support.

- Plywood: This is where plywood shines. A sturdy construction-grade plywood (like CDX) or even a finer grade if you want it to look nicer is ideal. It’s strong, more resistant to moisture, and will hold fasteners well for long-term durability. Price: Estimate $100-$200+ for materials, depending on size and grade.

Verdict: Plywood is the clear, more cost-effective choice in the long run for garage shelving due to its durability and resistance to the elements, even if the initial cost is slightly higher than MDF.

Cost-Saving Tips for Both Materials

Whether you choose MDF or plywood, here are some ways to keep your project costs down:

1. Buy Full Sheets When Possible

Most panels come in standard 4’x8′ sheets. Lumber yards and home centers often charge a cutting fee for custom sizes. If your project can utilize full or half sheets, you’ll save money and reduce waste. Many places will make a few basic cuts for free if you ask nicely or are buying a significant amount.

2. Shop Around

Prices can vary significantly between different retailers. Check local lumber suppliers, big-box home improvement stores, and even online options. Don’t be afraid to call around for quotes or compare prices online.

3. Consider Scraps and Remnants

Sometimes, lumber yards have a scrap section with discounted pieces of MDF and plywood. These are perfect for smaller projects, test pieces, or components where a full sheet isn’t needed. You might find some hidden gems!

4. Optimize Your Cuts

When planning your cuts, use a cutting diagram. This helps you arrange your pieces on the 4’x8′ sheet to minimize waste. Software like “CutList Optimizer” or even just sketching it out on graph paper can save you from buying an extra sheet.

5. Look for Sales and Promotions

Keep an eye out for seasonal sales or special promotions at your favorite hardware stores. You might be able to snag materials at a discount.

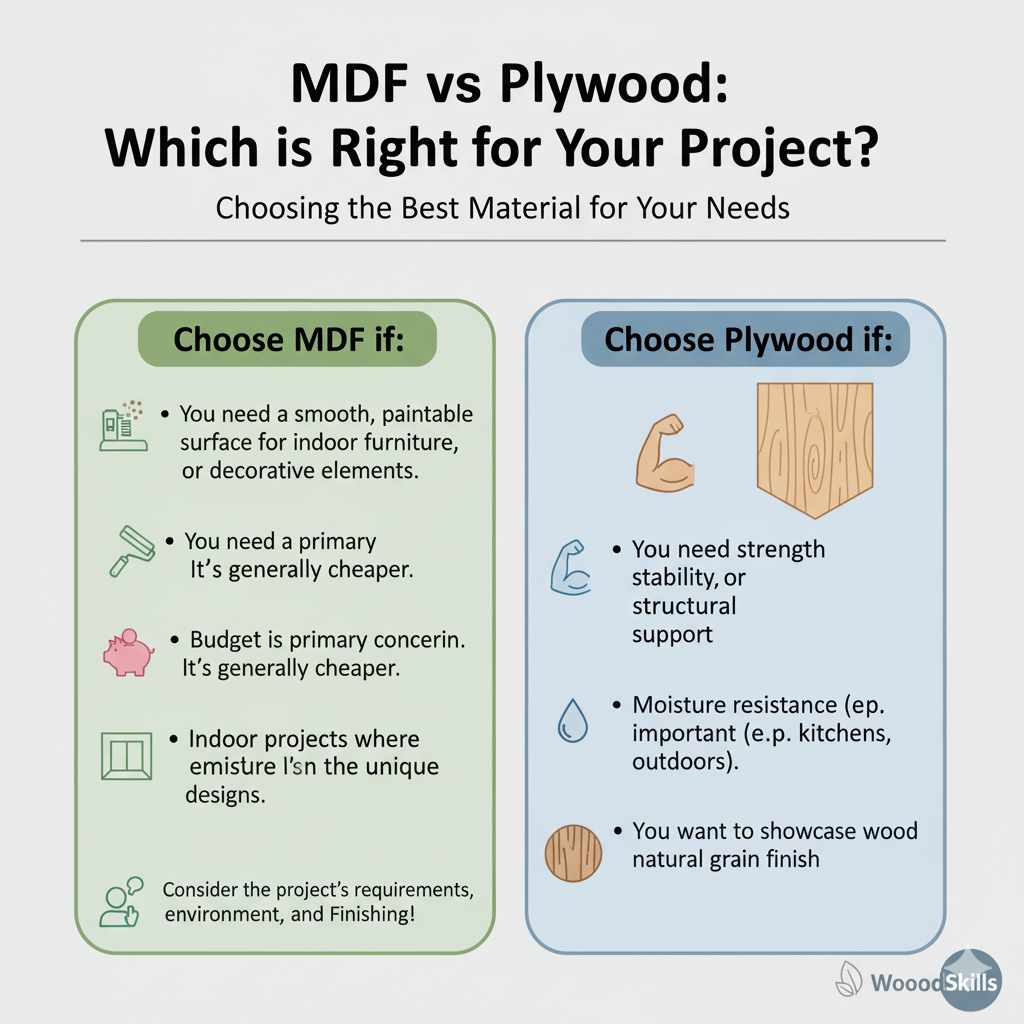

MDF vs Plywood: Which is Right for Your Project?

The “cheaper” material isn’t always the best value. It really depends on what you’re trying to build.

Choose MDF if: You need a smooth, paintable surface for indoor furniture, cabinet boxes, or decorative elements, and budget is a primary concern. It’s fantastic for projects where you’ll be painting or covering the surface and don’t anticipate moisture.

Choose Plywood if: You need strength, stability, moisture resistance, or if you want to showcase a natural wood grain. It’s the go-to for structural applications, furniture that needs to last, and anything that might encounter dampness.

FAQ Section

Q1: Is MDF or plywood cheaper per square foot?

Generally, standard MDF is cheaper per square foot than most types of plywood. However, the price can vary significantly based on the grade, thickness, and type of wood used.

Q2: Can MDF be used for cabinets?

Yes, MDF is commonly used for cabinet doors and sometimes for cabinet boxes, especially for painted finishes. It provides a very smooth surface for paint. However, for cabinet boxes in high-moisture areas, or if you need maximum strength for heavy items, plywood might be a better choice.

Q3: Will MDF swell if it gets wet?

Yes, standard MDF is highly susceptible to swelling and damage when exposed to moisture. It will absorb water rapidly and can become warped or disintegrate. Moisture-resistant MDF is available but is more expensive.

Q4: Is plywood stronger than MDF?

Yes, in most practical applications, plywood is stronger and more stable than MDF due to its layered construction. It has better structural integrity and resists warping and breaking under stress more effectively.

Q5: Can I paint MDF or plywood?

Both can be painted! MDF provides an exceptionally smooth surface for a flawless paint finish. Plywood can also be painted, but you may need to fill any voids or imperfections on the surface and sand it well for the best results. For a stained finish, only plywood (or veneered plywood) will show a natural wood grain.

Q6: Which is better for shelves – MDF or plywood?

For shelves that need to hold a lot of weight or span longer distances without sagging, plywood is generally the better choice. For lighter-duty shelves in a dry environment, or if you plan to paint them, MDF can be a more affordable option, but you’ll need to consider support methods to prevent sagging.

Q7: Is it better to buy MDF or plywood for a workbench top?

Plywood is typically recommended for workbench tops. Its superior strength, stability, and resistance to impacts and wear make it more durable than MDF for a high-use surface like a workbench.

Conclusion

Making the right choice between MDF and plywood, especially when considering their price, is all about understanding your project’s specific demands. MDF often wins the budget battle for projects requiring a smooth, paintable surface for indoor use, offering exceptional value where its limitations aren’t a concern. Plywood, while sometimes carrying a higher initial cost, often proves to be the more economical and reliable choice for structural applications, areas exposed to moisture, or when the natural beauty of wood grain is desired.

By weighing the factors like strength, moisture resistance, finish requirements, and, of course, price, you can confidently select the material that will lead to a successful, durable, and budget-friendly outcome for your next woodworking adventure. Remember, the cheapest option isn’t always the best value; it’s the material that best fits your project’s needs and your long-term goals. Happy building!