What is 19/32 Plywood: Essential Guide for DIY Projects

19/32 plywood refers to plywood that is approximately 19/32 inch thick. This type of plywood is commonly used in construction and woodworking projects, offering a good balance of strength and flexibility.

Plywood is a versatile building material that is commonly used in construction, furniture making, and various woodworking projects. The term “19/32 plywood” refers to the thickness of the plywood, which is approximately 19/32 inch. This particular thickness is often used in applications where a balance of strength and flexibility is required, making it suitable for a wide range of projects.

Whether you’re working on a DIY home improvement project or a professional construction job, 19/32 plywood can be a valuable material due to its durability and versatility.

Introduction To 19/32 Plywood

Discover the versatile 19/32 plywood, a sturdy wood panel commonly used in construction projects for its durability and strength. Ideal for various applications, this plywood comes in a specific thickness, making it a popular choice among builders and DIY enthusiasts alike.

Key Characteristics

19/32 plywood, also known as 5/8 inch plywood, is a versatile building material that’s known for its strength and durability. It is commonly used in construction and woodworking due to its specific properties.

Common Uses

Given its robust nature, 19/32 plywood is frequently utilized in various applications such as roofing, sheathing, subflooring, and as a base for siding. It’s also commonly used in cabinet and furniture making, as well as in DIY projects where a sturdy and reliable material is required.

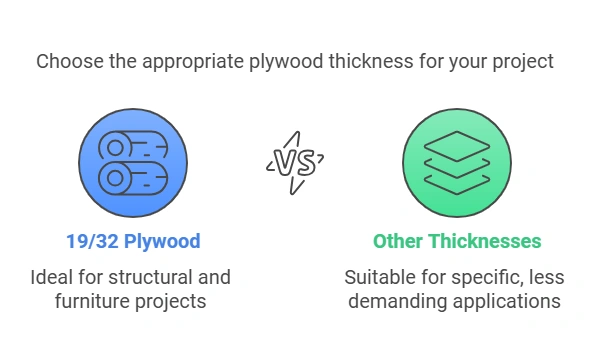

Comparing Plywood Sizes

19/32 plywood is a type of plywood that measures 19/32 of an inch in thickness. It is commonly used for roof sheathing and other structural applications due to its strength and stiffness. When comparing plywood sizes, it’s important to consider the actual thickness and size rather than just the nominal size.

When it comes to selecting the right plywood for your project, size matters. Plywood is available in various sizes, but the most common sizes are 4×8 feet and 5×5 feet. However, one of the most popular sizes is 19/32 plywood. In this section, we will compare plywood sizes, specifically focusing on nominal versus actual thickness and standard dimensions.

Nominal vs Actual Thickness

Plywood thickness is often referred to as nominal thickness, which is the thickness stated on the label. However, the actual thickness of the plywood may differ slightly due to manufacturing tolerances. For instance, 19/32 plywood has a nominal thickness of 19/32 inches, but its actual thickness may range between 17/32 inches to 19/32 inches.

Standard Plywood Dimensions

Plywood is available in various dimensions, including length, width, and thickness. The most common plywood size is 4×8 feet, which is widely used for construction and woodworking projects. Another standard size is 5×5 feet, which is commonly used for furniture and cabinet making. However, 19/32 plywood is a popular size for subflooring, roofing, and wall sheathing.

The table below summarizes the standard dimensions of plywood:

| Plywood Size | Length | Width | Thickness |

| — | — | — | — |

| 4×8 feet | 8 feet | 4 feet | Various |

| 5×5 feet | 5 feet | 5 feet | Various |

| 19/32 plywood | 8 feet | 4 feet | 19/32 inches |

In conclusion, plywood comes in various sizes, and the most popular size is 19/32 plywood. When selecting plywood, it’s essential to consider the nominal versus actual thickness and standard dimensions to ensure you select the right size for your project.

Material Composition

When it comes to understanding plywood, it’s important to dive into its material composition. Plywood is a versatile building material that is widely used in various construction and woodworking projects. One popular type of plywood is 19/32 plywood, which refers to its thickness. But what exactly does the material composition of 19/32 plywood entail?

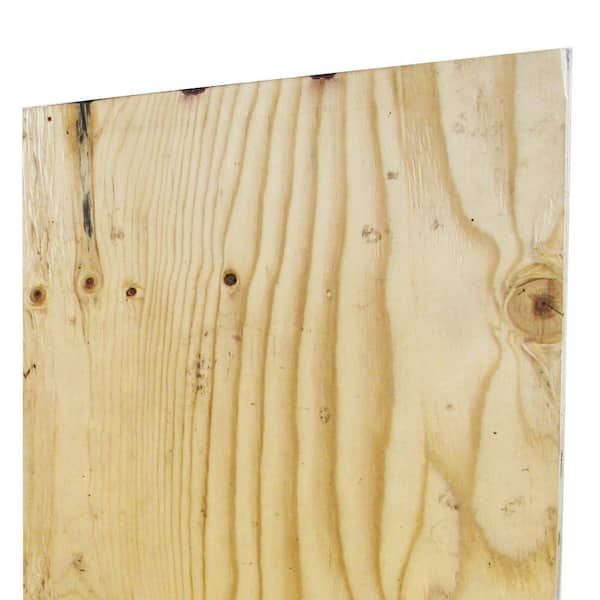

Layers And Core Types

19/32 plywood is made up of multiple layers, also known as plies, that are glued together to form a strong and durable sheet. These layers are typically made of thin wood veneers, which are sliced from logs and then stacked together with alternating grain directions. This cross-grain construction provides added strength and stability to the plywood sheet.

The core of 19/32 plywood can vary depending on its intended use. Common core types include:

- Structural Plywood Core: This type of core is made from solid wood strips or veneer sheets, providing excellent strength and stability. It is commonly used in applications that require load-bearing capabilities, such as flooring and roofing.

- Particleboard Core: Particleboard is an engineered wood product made from wood particles and adhesive. Plywood with a particleboard core is more affordable and suitable for non-structural applications like cabinets and furniture.

- MDF Core: Medium Density Fiberboard (MDF) core is made from compressed wood fibers and resin. It offers a smooth and uniform surface, making it ideal for projects that require a painted finish.

Veneer Quality

The quality of the veneer used in 19/32 plywood can greatly affect its appearance and performance. Veneer quality is graded based on factors such as wood species, thickness, and surface imperfections. Here are the common veneer grades:

| Grade | Description |

|---|---|

| A | High-quality veneer with a smooth and consistent surface. Suitable for visible applications and staining. |

| B | Good-quality veneer with minor surface imperfections. Generally used for non-visible areas or projects that will be painted. |

| C | Lower-quality veneer with more noticeable surface imperfections. Typically used for structural purposes where appearance is not a primary concern. |

By understanding the layers, core types, and veneer quality of 19/32 plywood, you can make informed decisions when choosing the right plywood for your specific project. Whether you need a strong structural plywood or a cost-effective option for interior applications, 19/32 plywood offers versatility and reliability.

Strength And Durability

When it comes to choosing the right plywood for your project, strength and durability are crucial factors to consider. One type of plywood that offers excellent strength and durability is 19/32 plywood. In this section, we will explore the structural properties of 19/32 plywood and its resistance to swelling and telegraphing.

Structural Properties

19/32 plywood is a powerful structural product that is used in various construction applications where strength and stiffness are essential. With its solid composition and high-quality construction, this plywood provides exceptional stability and load-bearing capacity. It is commonly used in flooring, roofing, and sheathing projects where structural integrity is paramount.

Resistance To Swelling And Telegraphing

One of the notable features of 19/32 plywood is its resistance to swelling and telegraphing. This plywood is manufactured to reduce edge swell, which means it is less prone to expanding or warping when exposed to moisture or changes in temperature. This characteristic makes 19/32 plywood ideal for applications where weather protection is required, such as in roof and wall sheathing.

Additionally, 19/32 plywood has a smooth surface that minimizes telegraphing. Telegraphing refers to the visibility of imperfections or patterns from the underlying structure through the plywood surface. With its strong and stiff composition, 19/32 plywood effectively minimizes telegraphing, resulting in a clean and uniform appearance for your project.

In conclusion, 19/32 plywood offers exceptional strength and durability. Its structural properties and resistance to swelling and telegraphing make it a reliable choice for various construction applications. Whether you’re working on a flooring, roofing, or sheathing project, 19/32 plywood provides the stability and performance you need.

Selecting The Right Plywood

Plywood is a versatile material that can be used in a variety of construction projects. It is made by gluing together thin layers of wood veneers, and each layer is oriented in a perpendicular direction to the layer above and below it. This construction method gives plywood its strength and stability, making it a popular choice for flooring, walls, roofs, and more. However, with so many different types of plywood available, it can be challenging to select the right one for your project. In this post, we’ll focus on 19/32 plywood, and what you need to consider when selecting it.

Grade Considerations

When selecting 19/32 plywood, you need to consider the grade of the plywood. Plywood is graded based on the quality of its surface veneers, with higher grades having fewer defects. The most common grades of plywood are A, B, C, and D. Grade A is the highest quality, with no knots or defects, while grade D is the lowest quality, with knots and defects that are visible from a distance.

When To Choose 19/32 Plywood

19/32 plywood is a popular choice for construction projects that require a strong and stable material. It has a thickness of approximately 15.5mm, making it suitable for floors, walls, roofs, and more. It is also commonly used in the construction of furniture and cabinets. If your project requires a material that can withstand heavy loads and frequent use, 19/32 plywood may be the right choice for you.

When selecting plywood for your construction project, it’s essential to consider the grade of the plywood and the specific requirements of your project. 19/32 plywood is an excellent choice for projects that require strength and stability, and it’s important to choose the right grade to ensure the quality of the finished product.

Applications In DIY Projects

When it comes to DIY projects, 19/32 plywood is a versatile material that can be used in various applications. Its durability and strength make it ideal for both indoor and outdoor projects.

Furniture And Cabinetry

- AC plywood with a sanded finish is perfect for furniture, cabinetry, and shelving.

- It provides a smooth surface for painting or staining, enhancing the overall look of the project.

- The knot-free finish ensures a clean and professional appearance.

Roofing And Sheathing

- 19/32 plywood is a popular choice for roofing and sheathing applications.

- Its stiffness and strength make it suitable for weather-protected roof and wall installations.

- Manufactured to reduce edge swell and telegraphing, ensuring a smooth and uniform finish.

Installation Tips

When it comes to 19/32 plywood, it refers to the actual thickness of the plywood sheet, which is 19/32 of an inch. This type of plywood is commonly used in construction projects for its strength and durability.

Cutting And Fastening Techniques

When working with 19/32 plywood, use a sharp saw for clean cuts.

- Ensure to measure and mark accurately before cutting.

- For straight cuts, use a circular saw with a fine-tooth blade.

- For curved cuts, a jigsaw with a smooth blade is recommended.

Finishing And Sealing

Proper finishing and sealing enhance the durability of 19/32 plywood.

- Before applying any finish, sand the surface smoothly.

- Apply a coat of primer suitable for plywood to improve paint adhesion.

- Use a high-quality paint or sealant for long-lasting protection.

Maintenance And Care

19/32 Plywood refers to the thickness of the plywood sheet, which is approximately 19/32 of an inch. It is commonly used for various applications such as cabinetry, furniture, paneling, and shelving where a knot-free and sturdy product is required. With its sanded surface, it provides a smooth finish for a polished look.

Cleaning Practices

Regularly clean 19/32 plywood with a mild detergent and water solution.

Avoid using harsh chemicals or abrasive cleaners that can damage the surface.

Dry the plywood thoroughly after cleaning to prevent moisture damage.

Longevity And Replacement

Inspect 19/32 plywood for signs of wear and damage periodically.

Consider replacing plywood that shows significant wear or structural issues.

Proper maintenance can extend the lifespan of 19/32 plywood.

Frequently Asked Questions

What Is 19/32 Plywood Equivalent?

19/32 plywood is equivalent to a thickness of approximately 15. 08mm or 0. 59375 inches. This is a common thickness used in construction and woodworking projects.

How Thick Is 3/4 Inch Plywood?

3/4 inch plywood is actually 23/32 inches thick.

Is 23/32 The Same As Three Quarter Inch Plywood?

Yes, 23/32 is the same as three-quarter inch plywood.

Can I Use 19/32 For Roof Sheathing?

Yes, you can use 19/32 for roof sheathing. It is a suitable thickness for providing structural support.

Conclusion

Understanding 19/32 plywood is crucial for any woodworking or construction project. Knowing its actual thickness and size helps in making accurate measurements and ensuring structural integrity. Whether you’re a professional or a DIY enthusiast, having this knowledge will contribute to the success of your endeavors.