1 2 Drill vs 3 8: Proven Essential Bits

Choosing between a 1/2-inch and 3/8-inch drill isn’t about which is “better,” but which is right for your woodworking tasks. The 3/8-inch drill is lighter and more versatile for smaller jobs, while the 1/2-inch drill offers more power for tougher drilling and driving. Understanding their key differences ensures you pick the perfect drill for your projects, saving you effort and frustration.

Hey there! Md Meraj here, your woodworking buddy. Ever stood in the tool aisle, staring at drills, wondering, “which one is for me?” It’s a common spot for beginners, and honestly, it can feel a bit overwhelming. You want to nail that bookshelf, fix that wobbly chair, or start that cool DIY craft, but the tool choice seems to be the first hurdle. The big question often boils down to drill size, specifically the chuck size: 1/2 inch versus 3/8 inch. It’s not as complicated as it sounds! Today, we’ll break down the differences in a way that makes perfect sense, so you can pick the drill that’ll be your best companion in the workshop. We’ll look at power, size, and what each drill is best suited for. Stick around; we’ll get you drilling with confidence in no time!

Understanding Drill Chucks: The Heart of the Matter

The chuck is the part of the drill where you insert the drill bit. Think of it as the drill’s handshake – it grips the bit tightly so it can spin and do its job. The size of the chuck, measured in inches, tells you the maximum diameter of a drill bit shank it can securely hold. So, when we talk about a “1/2 drill vs 3/8,” we’re really talking about the chuck size and what that allows the drill to do.

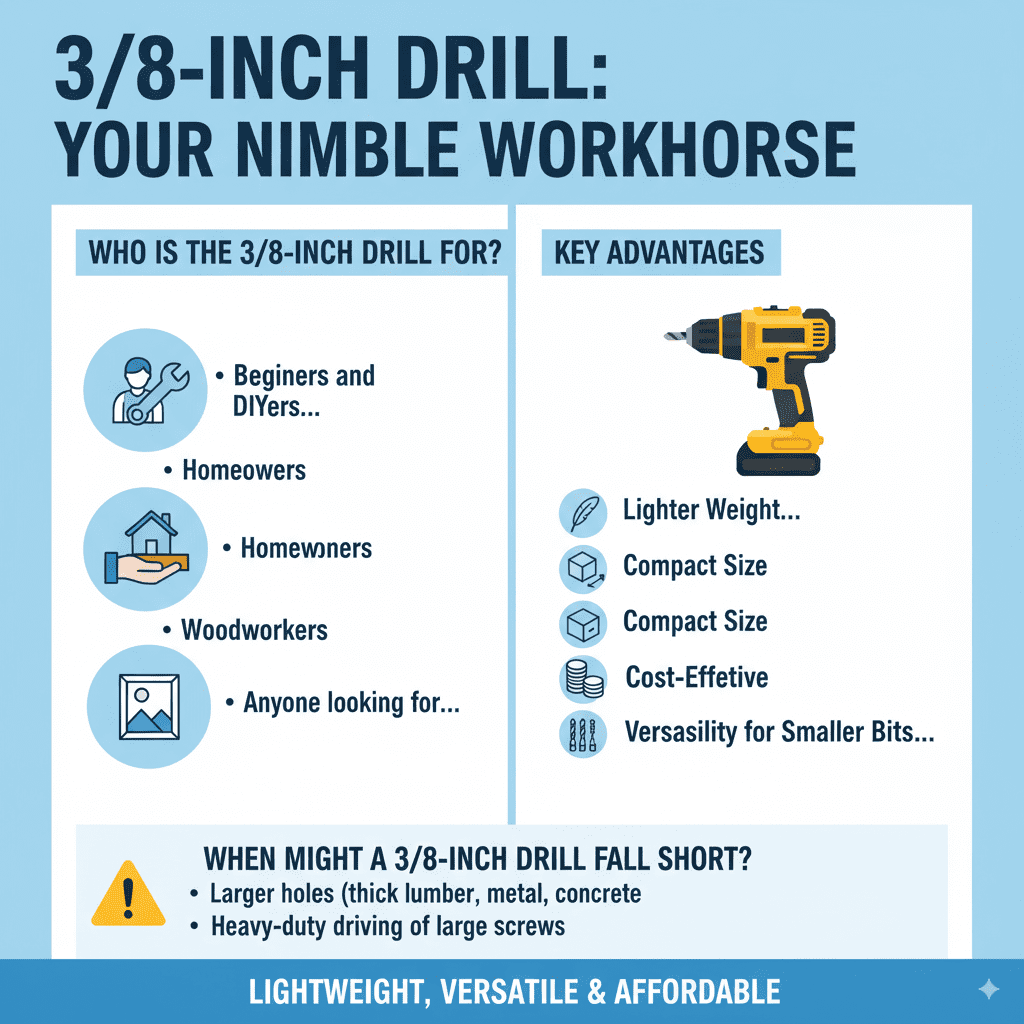

The 3/8-Inch Drill: Your Nimble Workhorse

The 3/8-inch drill is often the first drill many DIYers and hobbyists encounter, and for good reason. Its smaller chuck size typically means the drill itself is lighter and more compact. This makes it incredibly comfortable to handle for extended periods, especially in tighter spaces or when you need precision.

Who is the 3/8-inch drill for?

- Beginners and DIYers who primarily work on smaller projects.

- Homeowners needing a versatile tool for repairs and light DIY tasks.

- Woodworkers who value maneuverability and a comfortable grip.

- Anyone looking for a go-to drill for everyday tasks like hanging pictures, assembling furniture, or drilling pilot holes in softer woods.

Key Advantages of a 3/8-inch Drill:

- Lighter Weight: Easier to control and less fatiguing to use.

- Compact Size: Great for working in confined areas.

- Cost-Effective: Generally more affordable than their 1/2-inch counterparts.

- Versatility for Smaller Bits: Perfect for smaller drill bits, ideal for pilot holes and most common tasks. Many 3/8-inch drills come with a wide range of accessory bits suitable for various materials.

When Might a 3/8-inch Drill Fall Short?

While fantastic for many jobs, a 3/8-inch drill has its limits. When you need to drill larger holes, especially in hard materials like thick lumber, metal, or concrete, the smaller chuck and generally less powerful motor of a 3/8-inch drill might struggle. It might also not have enough torque (twisting power) for heavy-duty driving of large screws.

The 1/2-Inch Drill: The Powerhouse for Tougher Jobs

The 1/2-inch drill is the bigger sibling, built for more demanding work. Its larger chuck can accommodate thicker drill bits, and these drills typically feature more powerful motors and beefier gearboxes. This translates to more torque and the ability to handle tasks that would push a 3/8-inch drill to its limit.

Who is the 1/2-inch drill for?

- Woodworkers tackling larger projects and requiring larger bit sizes.

- DIYers who need to drill through dense hardwoods, metal, or masonry.

- Anyone frequently using large-diameter bits like hole saws or spade bits.

- Professionals or serious hobbyists who need a robust, high-performance tool.

Key Advantages of a 1/2-inch Drill:

- Greater Power and Torque: Ideal for drilling larger holes and driving larger fasteners.

- Larger Bit Capacity: Can accept a wider range of bit sizes, including those needed for significant material removal.

- Durability: Often built with more robust components for heavy-duty use.

- Better for Driving: The increased torque makes them excellent for driving large screws and lag bolts.

When Might a 1/2-inch Drill Be Overkill?

For simple tasks like assembling flat-pack furniture or drilling pilot holes in soft woods, a 1/2-inch drill can feel like using a sledgehammer to crack a nut. Its larger size and weight can make it less comfortable for delicate work or for long periods of overhead use. They are also typically more expensive.

1/2 Drill vs 3/8: A Direct Comparison

To make the choice clearer, let’s look at them side-by-side. This table highlights the main differences you’ll notice when choosing between these two essential drill sizes.

| Feature | 3/8-Inch Drill | 1/2-Inch Drill |

|---|---|---|

| Chuck Size | Up to 3/8 inch (9.5mm) shank diameter | Up to 1/2 inch (13mm) shank diameter |

| Motor Power & Torque | Generally lower, suitable for lighter tasks | Generally higher, designed for tougher jobs |

| Size & Weight | Lighter, more compact, easier to maneuver | Heavier, bulkier, offers more stability for powerhouse tasks |

| Ideal For | Pilot holes, small to medium fasteners, general household repairs, lighter woodworking, working in tight spaces. | Large diameter bits (spade, hole saw), drilling dense materials, driving large screws/lag bolts, heavy-duty construction. |

| Portability & Comfort | High – excellent for prolonged or delicate use. | Moderate – can be tiring for extended periods or in awkward positions. |

| Cost | Typically more affordable. | Typically more expensive. |

Choosing the Right Drill Bit Size: What Does it Mean for You?

The chuck size dictates the largest drill bit shank you can use. Most standard drill bits have round shanks, but some larger bits, especially for wood, might have hex shanks or specialized shanks. A 3/8-inch chuck can generally accommodate most common drill bit sizes needed for household projects. A 1/2-inch chuck, however, opens the door to using much larger bits with thicker shanks, which are essential for tasks like drilling clearance holes for large bolts or using large-diameter hole saws for cutting big openings.

Beyond Chuck Size: Other Factors to Consider

While chuck size is critical, it’s not the only thing that matters when picking a drill. Here are a few more points to keep in mind:

1. Corded vs. Cordless

- Cordless Drills: Offer unparalleled freedom of movement. They run on rechargeable batteries, making them perfect for working anywhere without worrying about power outlets. Battery life and charging time are key considerations here. Brands offer various battery voltages (e.g., 12V, 18V, 20V MAX) which generally correlate to power. For more power-hungry tasks, higher voltage is usually better. You can find excellent cordless options in both 3/8″ and 1/2″ chuck sizes.

- Corded Drills: Provide continuous, unlimited power as long as they’re plugged in. They are often more affordable and can offer more consistent power for very demanding, lengthy jobs. However, you’re tethered by the cord, which can be inconvenient or even dangerous if not managed carefully.

2. Motor Type (Brushed vs. Brushless)

Modern drills increasingly use brushless motors. These are more efficient, run cooler, and typically last longer than traditional brushed motors. While often found in higher-end models, if your budget allows, a brushless motor is a great upgrade for longevity and performance.

3. Weight and Ergonomics

As we discussed, weight is a big factor. How does the drill feel in your hand? Is the grip comfortable? Can you easily reach the trigger and controls? For long projects, a well-balanced and comfortable drill makes a world of difference.

4. Speed Settings and Clutch

- Speed Settings: Most drills have at least two speed settings. A lower speed is better for high-torque applications like driving screws, while a higher speed is ideal for drilling through materials quickly.

- Clutch: This feature lets you set a maximum torque level. When that torque is reached, the clutch disengages to prevent overtightening screws or damaging the material. This is essential for preventing stripped screw heads or cracked wood.

When to Use Which Drill: Practical Scenarios

Let’s put this into practice with some everyday scenarios:

Scenario 1: Assembling a Flat-Pack Bookshelf

Recommendation: 3/8-inch Drill (cordless, 12V or 18V)

You’ll be driving many screws, but they are typically not excessively large, and wood is usually particleboard or MDF, which is relatively soft. A 3/8-inch drill offers enough power, excellent control, and the lightweight design makes it comfortable to work with for an hour or two. The clutch function on most 3/8-inch drills is perfect for avoiding overtightening.

Scenario 2: Building a Deck or Fence

Recommendation: 1/2-inch Drill (cordless, 18V or higher, or a powerful corded drill)

This project involves drilling into tougher lumber, potentially denser hardwoods, and driving large lag screws or deck screws. The higher torque of a 1/2-inch drill is crucial for this. You might also use larger bits like a spade bit to pre-drill clearance holes for substantial structural fasteners. The power and capacity of a 1/2-inch drill will make these tasks much easier and faster.

Scenario 3: Hanging Pictures and Light Fixtures

Recommendation: 3/8-inch Drill (cordless, 12V)

For drilling into drywall or plaster, or perhaps into a wooden stud, a small, lightweight 3/8-inch drill is ideal. You’ll be using small drill bits, and the drill’s low weight makes it easy to hold steady for precise placement. A 12V cordless model is often perfect for this kind of light, versatile work around the house.

Scenario 4: Drilling Large Holes for Plumbing or Electrical

Recommendation: 1/2-inch Drill (cordless or corded, with ample power)

If you need to cut a 3-inch hole through a thick piece of wood using a hole saw for a pipe, or a 2-inch hole for ventilation, you absolutely need the power and the bit capacity of a 1/2-inch drill. These bits require significant torque and consistent power to cut through material effectively. Always ensure you have a sturdy grip and consider where the drill bit is heading! According to the Occupational Safety and Health Administration (OSHA), proper tool selection is a key component of workplace safety, and this applies just as much to your home workshop.

Pro Tips for Choosing Your First Drill

If you’re just starting out and budget is a concern, a good quality 3/8-inch cordless drill is likely your best first investment. It can handle a vast majority of common household and beginner woodworking tasks. As you grow as a woodworker and take on more ambitious projects, you can then consider adding a more powerful 1/2-inch drill to your arsenal.

When buying, look for reputable brands known for durability and good customer support. Reading reviews from other DIYers can also be incredibly helpful. Consider buying a kit that includes a couple of batteries and a charger, as running out of power mid-project is always frustrating.

FAQ: Your Drilling Questions Answered

Q1: Can a 3/8-inch drill be used for driving screws?

Yes, absolutely! 3/8-inch drills are great for driving screws, especially smaller to medium-sized ones. The key is to use the clutch setting on your drill to prevent overtightening and damaging the screw head or the material.

Q2: Do I need both a 3/8-inch and a 1/2-inch drill?

Not necessarily when you’re starting out. A good 3/8-inch drill can handle most homeowner and beginner woodworking tasks. A 1/2-inch drill is more specialized for heavier-duty applications. Many seasoned DIYers eventually own both, but start with the one that best suits your current needs.

Q3: What is the largest drill bit a 3/8-inch drill can hold?

A 3/8-inch drill can hold drill bits with shanks up to 3/8 of an inch in diameter. This covers most standard drill bits for wood, metal, and plastic used in home projects.

Q4: Is a 1/2-inch drill too heavy for a beginner?

It can be, depending on the model. 1/2-inch drills are generally heavier and bulkier due to their more powerful motors and robust construction. If you’re a beginner, it’s worth holding one in a store to see how it feels, but a lighter 3/8-inch drill might be more comfortable for your first tool.

Q5: What are “cordless” and “corded” drills?

Cordless drills run on rechargeable batteries, giving you freedom of movement around your workspace. Corded drills must be plugged into an electrical outlet for continuous power but are typically more affordable and can offer more sustained power for very demanding tasks.

Q6: Which type of drill is better for metal drilling?

For drilling into tougher metals, a 1/2-inch drill generally offers more power and torque, which is beneficial. For thinner metals or smaller holes, a 3/8-inch drill can also work effectively, especially with the right drill bit. Always use a lubricant when drilling metal to keep the bit cool and extend its life.

Q7: Does the brand of drill matter significantly?

Yes, brand reputation often correlates with build quality, durability, motor efficiency, and customer support. While you can find good tools from less common brands, sticking with well-known, reputable manufacturers in the industry, such as DeWalt, Makita, Milwaukee, Bosch, or Ryobi, is generally a safe bet for both performance and longevity. For more information on tool safety and selection, the National Electrical Manufacturers Association (NEMA) also provides valuable insights into power tool standards and innovations.

Conclusion: Empower Your Projects

Choosing between a 1/2-inch and a 3/8-inch drill isn’t about picking a “winner.” It’s about understanding what each tool is designed to do best. The 3/8-inch drill is your agile, everyday tool, perfect for a wide range of common tasks, offering comfort and control. The 1/2-inch drill is your heavy-duty ally, stepping up when more power and a larger bit capacity are required for more demanding projects. By considering your typical projects, the materials you work with, and your comfort level, you can confidently select the drill that will serve you well. Remember, the right tool makes all the difference, turning daunting tasks into rewarding experiences. Happy drilling, and happy crafting!