10 vs 12 Miter Saw: Choosing the Right Saw for Your Projects

Choosing a miter saw can feel like a big decision, especially when you’re just starting. The question of 10 vs 12 Miter Saw: Which Size Do You Need? often pops up. It’s common to feel a little unsure, as the different sizes and features can seem confusing at first. Don’t worry, though! This post is designed to make it simple. We’ll explore the main differences, so you can pick the saw that’s perfect for your needs. We’ll break down the important things to consider, giving you a clear, step-by-step guide to help you decide. Let’s get started!

What Sets Miter Saws Apart? Size and Function

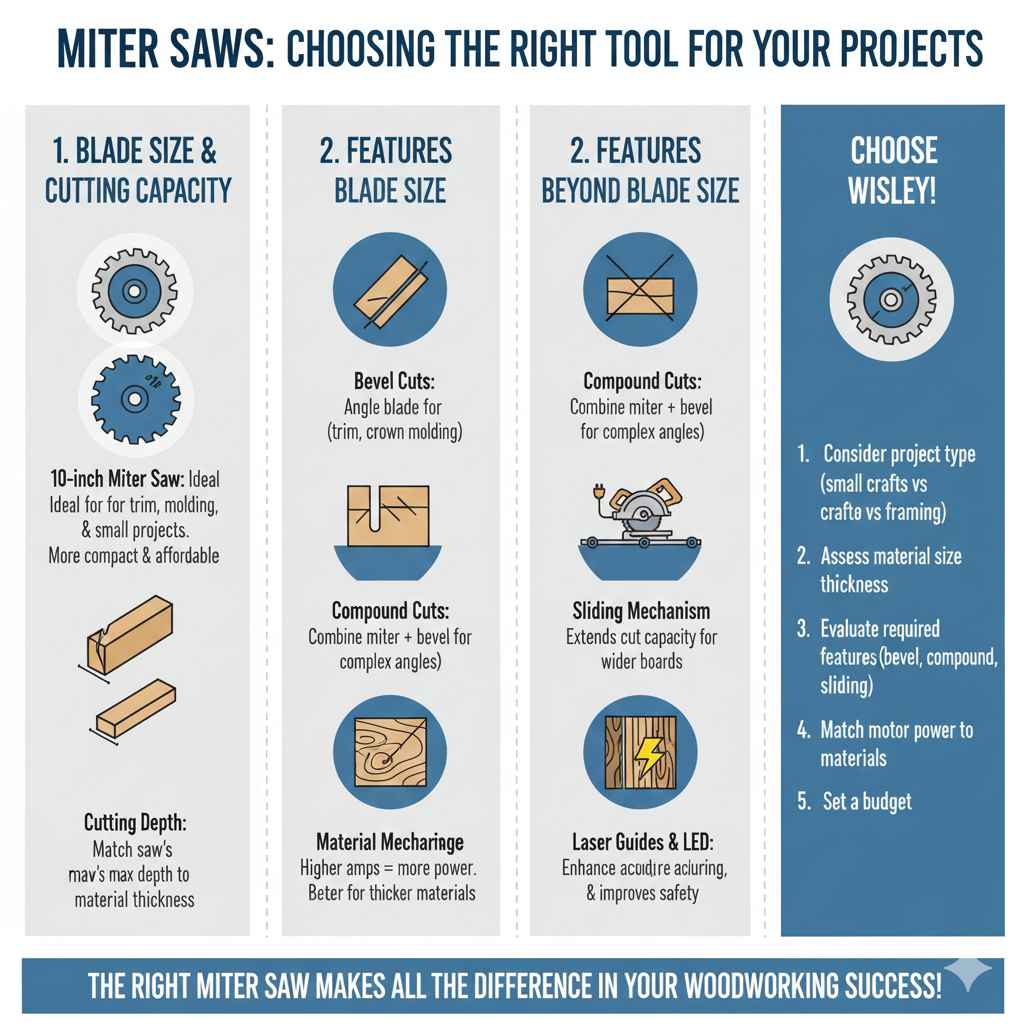

Miter saws are essential tools for anyone working with wood, especially for making precise angle cuts. The main difference between miter saw sizes, like the often-debated 10 vs 12 inch models, lies in their cutting capacity. The blade size dictates the maximum width of the wood you can cut in a single pass. A larger blade typically allows you to handle bigger pieces of material. Besides blade size, various features like bevel and compound capabilities add to a miter saw’s versatility.

Understanding these fundamental aspects is key to choosing the right tool for your specific projects. It’s about matching the saw’s ability to the kind of work you plan to do, from small crafts to larger construction tasks.

Blade Size and Cutting Capacity

The blade size directly impacts the cutting capacity of a miter saw. A 10-inch blade has a smaller maximum cut capacity compared to a 12-inch blade. This means the 12-inch saw can handle wider boards or thicker pieces of material in a single cut. The blade’s size determines how far it can extend across a piece of wood. When choosing, consider the size of the wood you’ll be using most often. For small projects or hobby work, a 10-inch saw might be enough. For larger projects, like framing or cutting wider boards, the 12-inch saw often makes more sense.

- 10-inch Miter Saw: The 10-inch saw generally has a smaller cutting capacity. This makes it ideal for smaller projects like picture frames, molding, or trim work. It is often more compact and can be a good choice if you have limited space. These saws tend to be lighter and more affordable than their larger counterparts. If you primarily work with materials that don’t exceed a certain width, the 10-inch saw is a practical option.

- 12-inch Miter Saw: A 12-inch miter saw has a larger cutting capacity. This allows it to cut wider boards and thicker pieces of material. It is a better choice for bigger projects, such as cutting framing lumber or wider deck boards. These saws are generally more powerful and can handle heavier workloads. Their extended cutting capacity makes them a favorite among professionals and serious DIY enthusiasts.

- Cutting Depth Considerations: The depth of cut also matters. While blade size dictates width, the maximum depth determines the thickness of material you can cut. Both 10-inch and 12-inch saws have different maximum cutting depths. Consider the thickness of your material when choosing a saw. For example, when cutting thicker beams or posts, you’ll need a saw with sufficient depth capacity.

Features Beyond Blade Size

While blade size is important, other features make a big difference in a miter saw’s functionality. Features like bevel adjustments and compound capabilities significantly expand the saw’s usefulness. These features allow you to make more complex cuts, such as angled cuts on both the horizontal and vertical planes. Consider what types of cuts you’ll be making most often. If your projects involve many different angles and complex shapes, these features will become very important to you. Extra features often come with a higher price tag, so it’s a matter of matching features with your specific requirements. Knowing how these features function will help you choose the right tool for your project needs.

- Bevel Cuts: A bevel cut is an angled cut through the thickness of the wood. The ability to make bevel cuts is important for trim work, crown molding, and other projects where you need angled edges. Miter saws with bevel adjustments can tilt the blade to the left or right, allowing you to make these cuts easily. The amount the blade can tilt (the bevel range) is an important consideration.

- Compound Cuts: Compound cuts combine a miter cut (horizontal angle) with a bevel cut (vertical angle). This allows you to cut both angles simultaneously. Compound miter saws are essential for complex joinery, like crown molding, where both angles are needed. This capability can save time and effort.

- Sliding Mechanism: A sliding miter saw has a rail system that allows the blade to slide forward and backward. This extends the cutting capacity, enabling you to cut wider boards than a non-sliding saw. The sliding feature is particularly beneficial for larger projects and cutting wider pieces of wood.

- Laser Guides and LED Lights: Some saws include laser guides or LED lights to help guide the cut. These features project a line onto the material, indicating where the blade will cut. This enhances accuracy, especially when cutting at difficult angles.

The Impact of Motor Power

The motor’s power is another important factor when choosing between 10-inch and 12-inch miter saws. A more powerful motor is better able to cut through thicker or harder materials without bogging down. This becomes especially important when cutting frequently or working with dense wood. While the size of the blade often determines the cutting capacity, the motor’s power ensures a clean, efficient cut. When using a miter saw, a powerful motor reduces the risk of burning the wood or making inaccurate cuts. A motor’s power is often measured in amps. A higher amperage indicates a more powerful motor.

- Motor Amperage: The motor’s power is usually measured in amps. A higher amperage motor means more power. For example, a 15-amp motor is typically more powerful than a 10-amp motor. A more powerful motor makes cleaner, faster cuts, especially through thicker materials.

- Material Considerations: The type of wood you plan to cut can influence your need for motor power. Hardwoods like oak and maple require more power than softwoods like pine. If you plan to work with hardwoods frequently, a more powerful motor is recommended.

- Stall Resistance: A powerful motor is less likely to stall or bog down when cutting. This is especially helpful when making long cuts or cutting through thick pieces of wood. A motor that doesn’t stall will also improve safety, as it reduces the chances of kickback or other accidents.

10 vs 12 Miter Saw: Comparing Practical Uses

To really decide between a 10 and 12-inch miter saw, it’s helpful to see how each performs in real-world scenarios. Thinking about the projects you want to complete helps you make the best choice. This includes a clear idea of the materials you’ll be working with. For instance, if you are planning to focus on smaller projects like furniture or crafts, a 10-inch saw might be enough. If you’re building decks or framing houses, the added capacity of a 12-inch saw is useful. Consider these typical uses to better match your needs.

Typical Tasks Suited for Each Saw

Different tasks are better suited to different sizes of miter saws. Knowing which saw excels at specific jobs can help you make an informed decision. For example, for precise trim work, a 10-inch saw can provide adequate cutting depth and accuracy. For larger construction projects, the extra capacity of a 12-inch saw becomes necessary. Think about your projects and the materials you will be working with most of the time. When planning your work, you will quickly see which saw is ideal for the tasks at hand.

- 10-inch Miter Saw Uses: These saws are great for cutting trim, molding, and smaller boards. They are a good choice for making picture frames, small furniture projects, and general home improvement tasks. Their smaller size also makes them useful in workshops or spaces where space is limited. The compact size of a 10-inch saw allows you to work more easily.

- 12-inch Miter Saw Uses: These are suited to bigger projects like deck building, framing, and cutting wider materials. They can easily handle 2×6, 2×8, or even larger boards. If you need to cut large crown molding in one pass, a 12-inch saw provides the necessary capacity. The extended cutting capability makes it a favorite among professionals.

- Projects for Consideration: For baseboard cuts and door frames, a 10-inch saw can often suffice. For cutting larger beams, wide decking boards, or large sheets of plywood, a 12-inch saw is preferable. Think about what projects you regularly do or plan to do. Then, determine the saw size that matches your most frequent tasks.

Material Size and Types: A Guide

The materials you work with greatly influence your miter saw decision. If you mainly work with thinner materials like trim and molding, a 10-inch saw should be fine. However, if you often cut wider boards or thicker lumber, you may need a 12-inch saw. Consider the materials you use for most of your projects. Make note of their typical dimensions, especially width and thickness. If you often work with hardwoods like oak or maple, consider a more powerful motor. Choosing based on your primary materials ensures that your saw will meet your specific needs.

- Cutting Trim and Molding: Both 10 and 12-inch saws can handle trim and molding. A 10-inch saw is well-suited for smaller pieces. For larger crown molding, the wider cutting capacity of a 12-inch saw is helpful.

- Cutting Framing Lumber: For standard 2x4s and 2x6s, a 10-inch saw may be sufficient. If you often work with larger dimensions like 2x8s or 2x10s, a 12-inch saw is recommended. A 12-inch saw can make these cuts in a single pass.

- Cutting Plywood and Sheet Goods: If you need to cut large sheets of plywood or other sheet goods, the extended cutting capacity of a 12-inch saw may be preferable. A 12-inch sliding miter saw lets you cut across wider sheets. For small craft projects, a 10-inch saw might still be a good choice.

Case Studies and Real-World Examples

- Picture Frame Project: A craft enthusiast decided to build a series of custom picture frames. They chose a 10-inch miter saw because the materials were small. The saw’s compact size and high accuracy met all of their cutting needs. The cuts were precise, and the project went smoothly.

- Deck Building Project: A homeowner planned to build a deck using 2×6 lumber. They chose a 12-inch miter saw to handle the wider boards and make quick work of the cuts. The increased cutting capacity ensured the project could be completed quickly and without problems. The saw’s power made quick work of the necessary cutting tasks.

- Crown Molding Installation: A professional trim carpenter used a 12-inch miter saw. They needed the ability to cut complex angles on crown molding in a single pass. The extended cutting capacity and compound cutting capability were invaluable.

Choosing the Right Saw: Budget, Space, and Needs

Several other factors influence which miter saw is best for you. These factors go beyond blade size and cutting capacity. You will want to think about your budget, the space available in your workshop, and the types of projects you typically do. These elements all contribute to making the right choice. Take a look at all of the considerations to arrive at the best miter saw for you.

Budget Considerations

Price is a key factor when buying a miter saw. Typically, a 10-inch saw is more affordable than a 12-inch saw. This is due to its smaller size and usually lower power requirements. However, the price also depends on added features, such as laser guides, sliding mechanisms, and the overall build quality. Decide how much you can spend, and then compare the features within your budget. Consider what features are important for your projects. Don’t underestimate the ongoing cost of blades, which vary in price depending on the size and type.

- Price Ranges: 10-inch saws can often be found at lower price points. 12-inch saws usually cost more. Prices can vary greatly. The price depends on brand, features, and build quality.

- Value for Money: Consider the features you need. Buying the cheapest saw might not always be the best idea if it lacks essential features. Look for a balance between price and features that meets your needs.

- Cost of Accessories: Remember to factor in the cost of blades, stands, and other accessories. These costs can add up over time. Make sure these extra costs stay within your budget.

Workshop and Storage Space

Your workspace plays a role in your miter saw decision. If you have a small workshop or limited storage, a 10-inch saw might be better because it takes up less space. A 12-inch saw requires more room because it’s generally larger. Consider where you will store the saw when not in use. A smaller saw can be easier to transport and store if you don’t have a permanent workshop. Be sure that your workspace has the space needed for the saw, as well as the space to safely maneuver around it.

- Size and Footprint: 10-inch saws are typically more compact. This means that they have a smaller footprint and take up less room. 12-inch saws have a larger footprint and require more space in your workshop.

- Portability: If you move your saw around often, a lighter and more compact 10-inch saw may be easier to transport. 12-inch saws can be heavy and require more effort to move.

- Storage Requirements: Consider where you’ll store your saw when it’s not in use. A 10-inch saw will be easier to store if you have limited space. You will want to consider how accessible the saw is to your workspace.

Considering Project Scope and Volume

The scope and volume of your projects affect your choice of miter saw. If you’re a casual DIYer or only take on small tasks, a 10-inch saw might be enough. If you’re a professional or take on larger, more frequent projects, a 12-inch saw will probably be a better fit. Consider how often you’ll be using the saw and the size of your projects. If you plan to expand your projects in the future, it might be worth considering a larger saw. This can save money in the long run. If your project volume is low, you might prefer a less expensive model.

- Project Size: For small projects, a 10-inch saw provides enough cutting capacity. For large projects, the extra capacity of a 12-inch saw becomes necessary.

- Project Frequency: If you use the saw regularly, a 12-inch saw can make the work easier. If you use it only occasionally, a 10-inch saw is likely sufficient.

- Future Plans: Think about your projects in the future. If you plan to take on larger projects or work with different materials, choosing the right saw can save money.

10 vs 12 Miter Saw: Key Decision Points

Several main points will help you make a firm decision about which miter saw to buy. This helps you narrow down your choices. You’ll be able to focus your search based on specific requirements, such as the types of materials you’ll cut. This will help you select the saw that best fits your projects.

Reviewing Key Advantages of Each Size

Each size has its strengths. A 10-inch saw is ideal for smaller projects and offers a more compact design. A 12-inch saw provides greater cutting capacity and power for larger tasks. Consider your project needs to see which saw offers the best advantages. Evaluate what types of work you are planning. This review will confirm which miter saw will become your favorite tool.

- 10-inch Saw Advantages: More compact, lighter, and often more affordable. They are suitable for smaller projects like trim and molding. They are easier to store and transport.

- 12-inch Saw Advantages: Larger cutting capacity to handle wider boards and thicker materials. They are suitable for bigger projects such as framing and deck building. They have the power needed to handle demanding tasks.

- Comparing the Benefits: If you need to make precise cuts on trim, a 10-inch saw will work well. If you need to cut large pieces of wood, a 12-inch saw is more suitable. Think about what matters most for your projects.

Assessing Your Cutting Needs

Take a few minutes to consider what types of cuts you’ll be making. Consider the types of materials you’ll be cutting. Do you mainly cut trim, or are you working with framing lumber or wide boards? The answers to these questions will guide your choice. The size and complexity of your projects greatly influence the saw that is best for you. Knowing your project needs is the key to selecting the right tool.

- Material Dimensions: Consider the dimensions of the materials you plan to cut. The width and thickness of the material determine the required cutting capacity. Make sure the saw you choose can handle the dimensions you will be working with.

- Cut Types: Consider what cuts you need to make. Do you need to make miter cuts, bevel cuts, and compound cuts? The saw’s features need to match the complexity of your work.

- Project Complexity: The complexity of your project needs to match the saw’s features. A simple project might require a smaller saw with fewer features. A more complex project might require a larger saw with more features.

Making the Final Choice

Consider all the factors. Think about your budget, workspace, and project needs. Weigh the advantages of both 10 and 12-inch saws to find the best fit. There’s no right or wrong answer. The right choice is the one that best suits your requirements. With a clear picture of your project needs, you can choose the miter saw that will help you achieve success.

- Summarize the Criteria: Review your budget, workspace, and project requirements. Identify the key features you need in a miter saw. Make sure you fully understand your requirements.

- Compare and Contrast: Compare the 10-inch and 12-inch saws based on your criteria. Note the pros and cons of each. This gives you a clear comparison of both saws.

- Making the Decision: Make a decision. Choose the saw that is best suited to your needs. Once you do, you’ll be able to proceed with confidence.

Frequently Asked Questions

Question: What is the main difference between a 10-inch and a 12-inch miter saw?

Answer: The main difference is the cutting capacity, with the 12-inch saw generally able to cut wider boards and thicker material than the 10-inch saw.

Question: Is a 10-inch miter saw good enough for home projects?

Answer: Yes, a 10-inch miter saw is often sufficient for most home projects, especially those involving trim, molding, and smaller pieces of wood.

Question: Which size saw is better for cutting 2x4s?

Answer: Both can cut 2x4s, but a 12-inch saw might be preferable as it can often cut them in a single pass without any adjustments.

Question: Are 12-inch miter saws more powerful?

Answer: Yes, 12-inch miter saws often have more powerful motors, making them better for cutting through thicker or harder materials.

Question: What are the benefits of a sliding miter saw?

Answer: A sliding miter saw extends the cutting capacity, allowing you to cut wider boards than a non-sliding saw.

Final Thoughts

Choosing between a 10-inch and 12-inch miter saw means looking closely at your needs. You’ve explored the differences in size, cutting capacity, and motor power. You’ve also seen how each saw performs in different situations, from trim work to framing. You know the importance of matching the saw to your projects. You’ve considered your budget, space, and how often you will be using the saw. With all this information, you can now make a choice that fits you perfectly. Do some more research on specific models that meet your criteria. Be sure to check user reviews and compare features. By taking this step, you’ll choose a saw that provides reliable performance for years to come. Then, enjoy the satisfaction of creating projects with precision and ease!