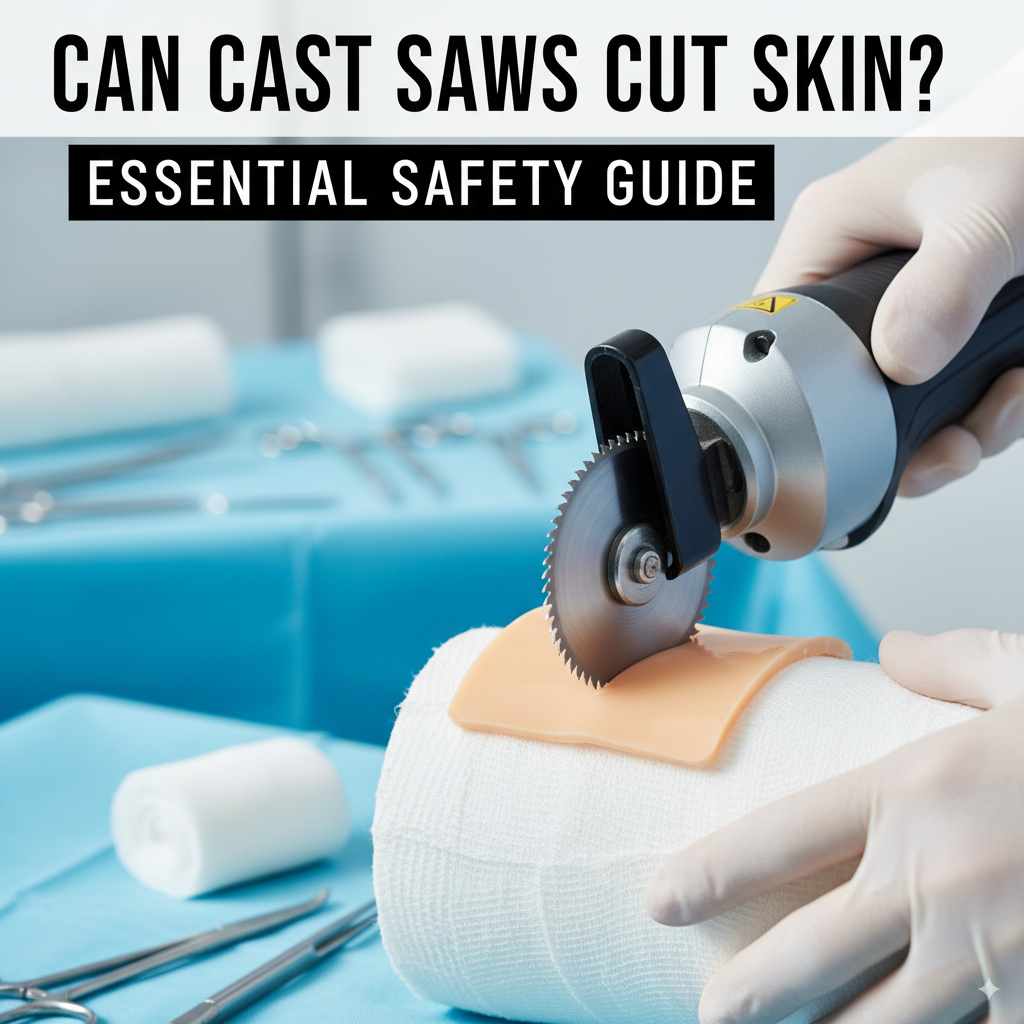

Can Cast Saws Cut Skin? Essential Safety

Yes, cast saws can cut skin, but they are designed to cut plaster and fiberglass casts, not flesh. Their specialized oscillating blades move back and forth rapidly, creating friction and heat that breaks down cast material. While a direct, sustained contact with skin can cause abrasions or burns, the saw’s design and safety features significantly minimize this risk when used properly. Always prioritize safety and understand the tool’s limitations.

Hey there, fellow DIYers and woodworking enthusiasts! I’m Md Meraj, your guide to making your projects shine. Today, we’re tackling a question that might seem a little unexpected in a woodworking context, but it’s crucial for anyone who’s ever needed to remove a medical cast or has seen one removed: “Can cast saws cut skin?” It’s a common worry, and for good reason. These tools look intimidating, and the thought of them near skin can be nerve-wracking.

But don’t you worry! We’re going to break down exactly how these saws work, why they’re surprisingly safe when handled correctly, and what you absolutely need to know to keep everyone safe. We’ll cover the science behind them, the safety gear involved, and how they’re designed to be a game-changer for patients and medical staff alike. Ready to demystify these tools and boost your confidence? Let’s get started!

Understanding the Cast Saw: How It Works

It’s easy to see a cast saw and think it’s a high-speed rotary blade, like a miniature circular saw. That’s where the misconception often begins! The truth is, cast saws operate on a completely different principle, one that’s specifically engineered for safety around the human body.

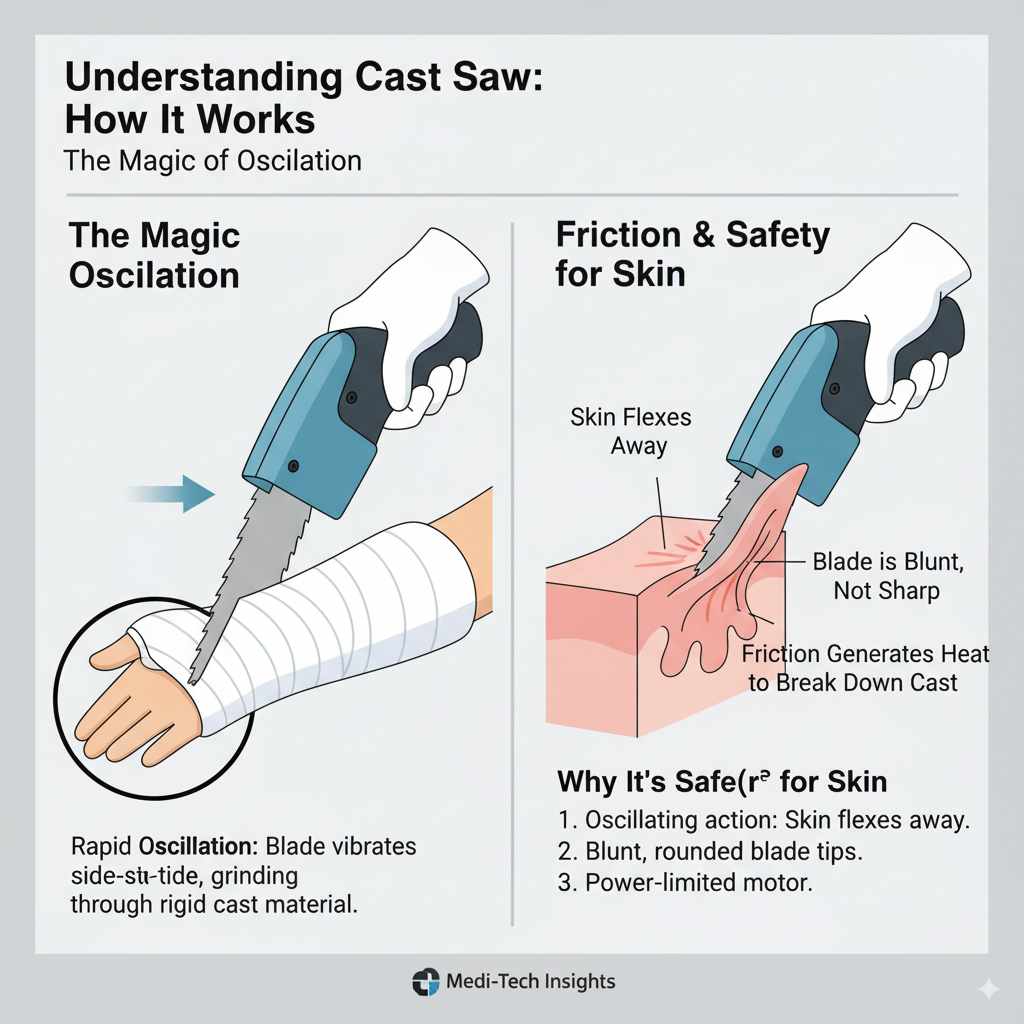

The Magic of Oscillation

Instead of spinning, a cast saw’s blade moves side-to-side in a rapid, oscillating motion. Think of it like a tiny, super-fast reciprocating saw. The blade vibrates back and forth very quickly, typically with a small range of motion (usually just a few millimeters). This back-and-forth action is key to its function and safety.

This rapid oscillation doesn’t have the brute force rotational power to slice through flesh. Instead, it grinds and shreds the hard material of the cast. The blades are often made with serrated edges, designed to catch and break down the fibers in plaster or fiberglass.

Friction, Not Force

The primary way a cast saw cuts is through friction and abrasion. As the blade vibrates against the cast material, it generates heat. It’s this heat and the mechanical action of the teeth against the cast that break down the material, allowing it to be cut. This is why, even though they run at high speeds, they are much less likely to cut skin.

Why It’s Safe(r) for Skin

The key to cast saw safety lies in this design. Skin is soft and pliable. When the oscillating blade encounters skin (which is rare when used correctly), the skin simply flexes away or slides along the vibration Instead of being caught and cut like the rigid cast material, the skin moves out of the way.

Furthermore, the blades are typically short and have rounded tips. This further reduces the chance of accidentally piercing the skin. The motor also has built-in limits to prevent excessive speed and power that could be dangerous.

The Anatomy of a Cast Saw Blade

The blade is the most critical part of the cast saw when it comes to understanding its function and safety. They aren’t just generic blades; they are precision tools designed for a specific purpose.

Blade Material and Design

Cast saw blades are usually made from hardened steel. They can vary in:

- Shape: Most are rectangular or slightly curved.

- Teeth: The teeth are designed to be aggressive on cast material but less so on soft tissue. They are often finely serrated.

- Size: Blades come in different widths and lengths to accommodate various cast types and sizes.

Different Blade Types for Different Casts

You’ll often find different blades designed for specific cast materials:

- Plaster Blades: Typically more aggressive, designed to cut through the dense material of traditional plaster casts.

- Fiberglass Blades: These are often finer-toothed and sometimes coated with materials like diamond or carbide, as fiberglass can be tougher and more abrasive than plaster.

The choice of blade impacts how quickly the cast is removed and the feeling the patient experiences. A well-matched blade leads to a smoother, faster removal. For more information on the specific applications and materials used in medical casting, the American Academy of Orthopaedic Surgeons provides excellent resources on orthopaedic devices.

Can Cast Saws Cut Skin? The Safety Factor

This is the million-dollar question, and the answer is nuanced. Yes, in a theoretical sense, any sharp or rapidly moving object has the potential to cause harm. However, the design of the cast saw makes accidental skin injury highly unlikely when used by trained professionals.

Engineered for Safety

Cast saws are specifically designed to cut hard cast materials while minimizing the risk to underlying skin and soft tissue. Here’s why:

- Oscillating Motion: As we discussed, the back-and-forth movement is gentler than a spinning blade.

- Limited Blade Depth: The blades are typically not designed to penetrate deeply.

- Rounded Edges: Many blades have rounded tips to prevent piercing.

- Heat Generation: While the blade gets hot, causing minor burns is less common and usually a result of prolonged contact or improper use.

The Science Behind Skin vs. Cast

Skin is elastic. When the oscillating blade touches it, the skin tends to stretch and move away from the direct abrasive action of the teeth. The cast material, being rigid, cannot move and is therefore broken down. It’s a bit like trying to cut through a rubber ball versus a wooden block with the same tool – the rubber deforms.

When Can Skin Be Injured?

Despite the safety features, injuries can occur, though they are rare. These instances are typically due to:

- Prolonged Contact: Holding the blade against the skin for an extended period.

- Unusual Angles: Using the saw at an odd angle that might trap skin.

- Improper Technique: Lack of experience or incorrect handling by the operator.

- Pre-existing Skin Conditions: Very thin, fragile skin might be more susceptible.

The National Institutes of Health (NIH) and other medical bodies often publish information on medical procedures. For detailed insights into orthopaedic procedures and device safety, a look at resources from the National Center for Biotechnology Information (NCBI) can offer a deeper understanding of the medical context.

Essential Safety Precautions for Cast Removal

Even though the risk is low when handled by professionals, understanding and implementing safety measures is paramount. This applies to anyone undergoing cast removal and those observing or assisting.

For the Patient: What to Expect and How to Cooperate

If you are the one whose cast is being removed, communication is key!

- Stay Still: Try your best to remain as still as possible. Any sudden movements can increase the risk.

- Communicate Immediately: If you feel any sharp pain, heat, or discomfort, tell the person removing the cast instantly. Don’t wait and hope it goes away.

- Don’t Touch the Blade: Resist any urge to touch the blade or the moving parts of the saw.

- Understand the Noise: The saw is noisy! This is normal and shouldn’t alarm you.

- Watch Out for Dust: A fine powder will be generated. It’s usually harmless plaster or fiberglass, but it’s good to be aware of it.

For the Operator: Professional Use Considerations

If you are a healthcare professional or a highly supervised and trained individual removing a cast, these are critical:

- Proper Training: Always ensure you have received comprehensive training on cast saw operation from a qualified instructor.

- Correct Blade Selection: Use the appropriate blade for the cast material (plaster vs. fiberglass).

- Maintain Distance: Ensure the blade is only in contact with the cast material. Keep the saw perpendicular to the cast surface as much as possible.

- Guard Use: Utilize any safety guards provided with the saw.

- Check for Loose Objects: Ensure there are no loose bandages or clothing that could get caught.

- Monitor Heat: Periodically check if the blade is getting excessively hot. If so, allow it to cool or use a different blade.

- Gentle Pressure: Apply only enough pressure to cut the cast. Forcing the saw can lead to accidents.

- Post-Removal Inspection: After removal, carefully inspect the skin for any signs of abrasion or burns.

Personal Protective Equipment (PPE)

While the operator uses PPE, the patient also benefits from some protection.

Operator PPE typically includes:

- Safety Glasses or Goggles: Essential to protect eyes from cast dust.

- Gloves: To protect hands and improve grip.

- Mask: A dust mask (e.g., N95) is highly recommended to prevent inhalation of cast particles.

Patient Considerations:

- A thin sock or sleeve might be placed over the limb before casting begins, providing an extra layer.

- During removal, the operator will be careful to ensure the skin is not directly exposed to the blade’s path for extended periods.

When to Seek Professional Help

It’s vital to remember that cast removal is a medical procedure. While DIY solutions might seem tempting for broken items (not medical casts!), when it comes to anything involving a medical cast, leave it to the experts.

Why You Shouldn’t Remove Your Own Cast

Medical professionals have the training, the right equipment, and the knowledge to remove casts safely and effectively. Attempting to remove a medical cast yourself, or having an untrained friend or family member do it, can lead to serious injury. This includes:

- Cuts and lacerations to the skin.

- Burns from blade friction or overheating.

- Damage to the underlying healing bone or tissues.

- Infection if the skin is broken.

Who Performs Cast Removal?

Typically, cast removal is performed by:

- Doctors (Orthopedic Surgeons, General Practitioners)

- Nurses

- Physician Assistants

- Physical Therapists (often under supervision or specific protocol)

- Certified Orthopedic Technicians

Always go back to your healthcare provider or clinic for cast removal. They can also assess your healing progress and ensure your limb is ready for life without the cast.

Cast Saw Technology: Innovation with Comfort in Mind

The technology behind cast saws has evolved significantly, with manufacturers constantly looking for ways to improve both efficiency and patient comfort. This innovation is what makes the risk so low today.

Quieter, Smoother Operation

Modern cast saws are designed to be quieter and vibrate less than older models. This not only makes the experience less intimidating for the patient but also reduces the overall stress on the limb and body.

Variable Speed and Power Settings

Many advanced cast saws feature variable speed controls. This allows the operator to:

- Start at a lower speed for initial contact and delicate areas.

- Increase speed for more efficient cutting through tougher cast sections.

- Adjust power based on the type of cast material.

This precise control is crucial for a safe and effective removal process.

Safety Features in Modern Saws

Beyond the oscillating blade, manufacturers incorporate other safety elements:

- Ergonomic Design: Easier for operators to handle, reducing strain and improving control.

- Integrated Dust Collection: Some newer models have systems to reduce the amount of dust released into the air.

- Durable Construction: Built to last and function reliably, which is essential for medical equipment.

The focus on patient comfort and safety is a testament to how far medical device technology has come. Resources from reputable medical technology associations or journals often highlight these advancements. For instance, looking at industry publications or professional organizations like the U.S. Food & Drug Administration (FDA) database related to medical devices can reveal the regulatory standards and innovations in this field.

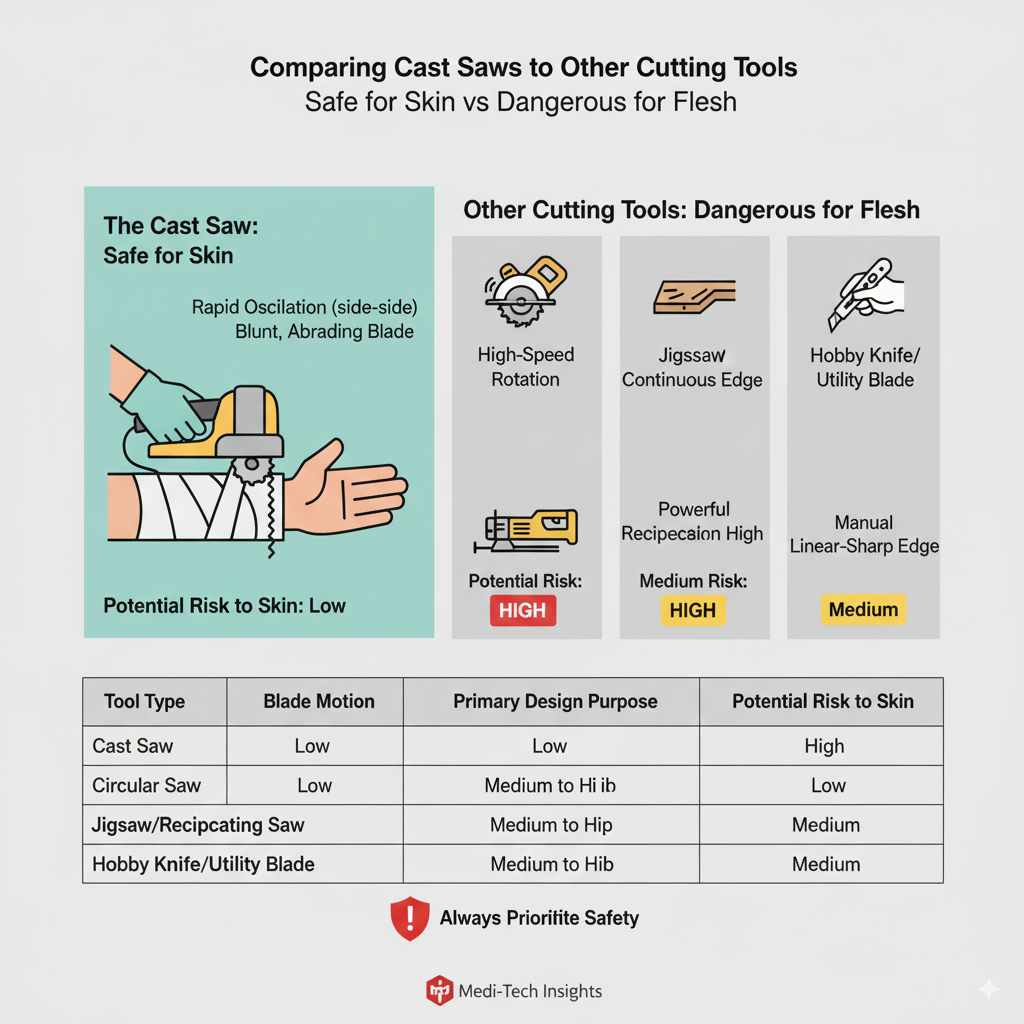

Comparing Cast Saws to Other Cutting Tools

To truly appreciate why cast saws are considered safe for skin, let’s briefly compare them to other common cutting tools you might find in a workshop or around the house.

Cast Saw vs. Circular Saw

A circular saw has a rapidly spinning blade designed for cutting wood, metal, or plastic. The circular motion generates significant torque and a continuous cutting edge. If this blade contacts skin, it will slice through it with high efficiency and cause severe injury. The speed and rotational force are many magnitudes greater than a cast saw’s oscillation.

Cast Saw vs. Jigsaw/Reciprocating Saw

A jigsaw or reciprocating saw also uses an oscillating or back-and-forth motion. However, these tools are typically more powerful, have longer blades, and are designed for cutting much thicker and harder materials like wood beams, metal pipes, or drywall. While potentially less dangerous than a circular saw, their blades are often sharper, longer, and have more stroke length, increasing the risk to skin if used without extreme care.

Cast Saw vs. Hobby Knife/Blade

Even a simple hobby knife or utility blade, while manually operated, has a sharp edge designed to cut. Applying steady pressure with such a blade can easily cut skin. The danger of a cast saw is reduced because it relies on rapid vibration to abrade, not a sharp edge slicing.

The Cast Saw’s Unique Niche

The cast saw occupies a unique place because its design is a careful balance: aggressive enough to cut hard cast materials but gentle enough to minimize risk to the soft, pliable skin beneath. This balance is achieved through the specific oscillating action, blade design, and integrated power limits.

Table: Tool Comparison for Cutting Potential

Here’s a simplified comparison to illustrate the differences in their potential impact on skin:

| Tool Type | Blade Motion | Primary Design Purpose | Potential Risk to Skin (High/Medium/Low) |

|---|---|---|---|

| Cast Saw | Rapid Oscillation (side-to-side) | Cutting plaster/fiberglass casts | Low (when used correctly) |

| Circular Saw | High-Speed Rotation | Cutting wood, metal, plastic (construction) | High |

| Jigsaw/Reciprocating Saw | Oscillation or Reciprocation (back-and-forth) | Cutting wood, metal, plastic (demolition, construction) | Medium to High |

| Hobby Knife/Utility Blade | Manual Linear Cutting | Precision cutting, crafting, utility tasks | Medium |

This table highlights that while other tools are designed for more robust material removal, the cast saw is specialized for a precise medical application where safety is paramount.

Frequently Asked Questions (FAQ) About Cast Saws and Skin Safety

Q1: Will a cast saw hurt me if it touches my skin?

A1: While cast saws are designed to be safe, direct and sustained contact can cause abrasions or minor burns. However, the oscillating blade usually flexes skin away rather than cutting it, making serious injury rare when used properly by professionals.

Q2: Why don’t cast saws use spinning blades like regular saws?

A2: Spinning blades have a sharp, continuous edge that can easily slice skin. Cast saws use a rapid side-to-side oscillation to grind and break down the hard cast material. This motion is much less capable of slicing soft tissue.

Q3: Is it normal for the cast saw blade to get hot?

A3: Yes, the friction generated by the oscillating blade against the cast material causes it to heat up. This is normal. The operator is trained to manage this heat and avoid prolonged contact with skin.