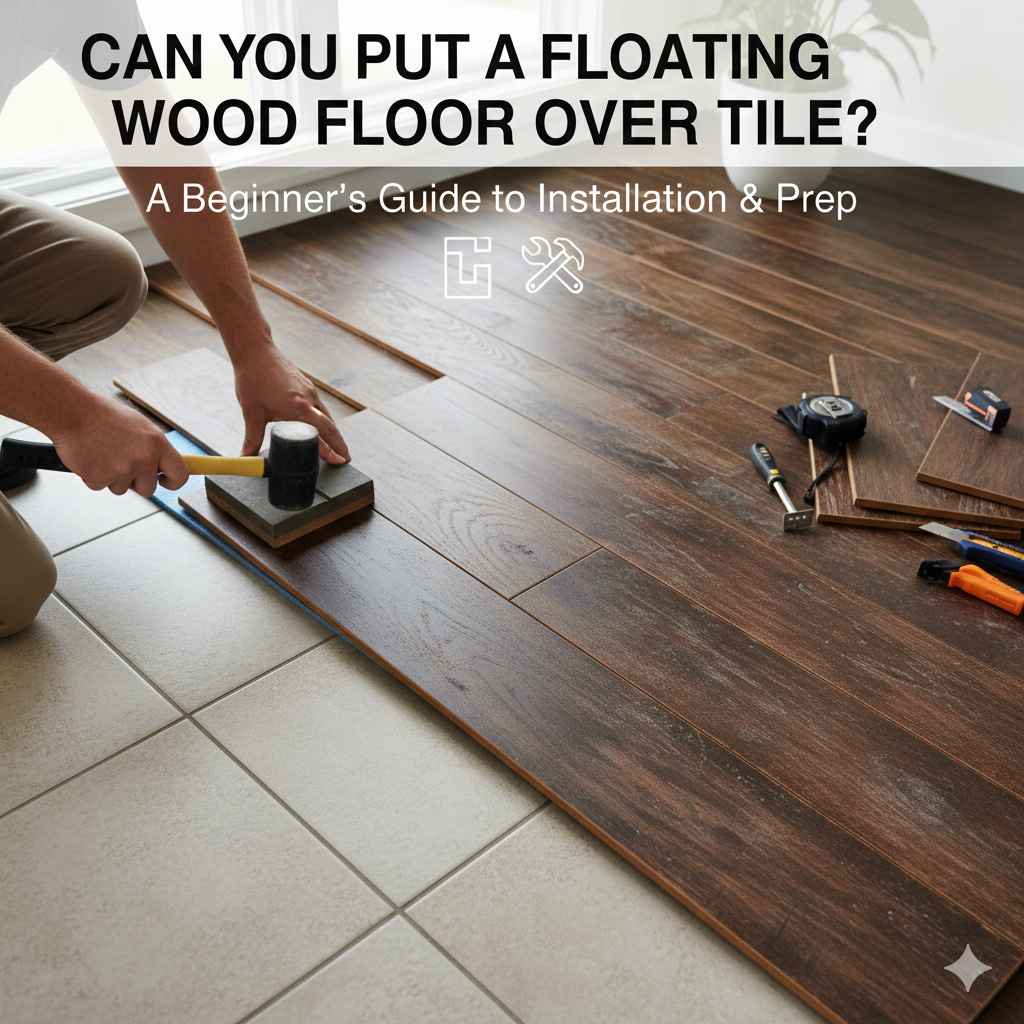

Can You Put a Floating Wood Floor Over Tile? A Beginner’s Guide

Thinking about a new floor? Many people wonder, Can You Put a Floating Wood Floor Over Tile? It seems easy, but it can be a bit tricky if you’re just starting. Don’t worry, though! It’s a common question, especially for those wanting a quick and easy home update. The process has its challenges, but it’s totally manageable. We’re here to help you through the process, step by step, making it simple to grasp. We’ll explore everything you need to know to see if this project is right for your home, starting with what you’ll need to know about preparing your subfloor.

What You Need to Know Before Laying Flooring

Before you even think about laying a floating wood floor, there are important points to remember. It’s like building a house – you need a solid foundation first. This section lays out the groundwork, ensuring you’re prepared before starting. Many issues can arise during the installation process, so it is necessary to consider the existing conditions of your tile subfloor. If the subfloor is not properly prepared, your flooring project may be a waste of time and money.

This includes checking for moisture, assessing the tile condition, and gathering your tools. By focusing on these initial factors, you will avoid future headaches. Let’s explore each point in more detail.

Checking for Moisture and Leveling

One of the most important things to check is moisture. Moisture can be the enemy of wood flooring, as it can cause it to swell, warp, or even develop mold. To test for moisture, you can use a moisture meter, which is a simple tool available at most hardware stores. There are various types, including pin-type and pinless meters. Pin-type meters are great for quick, pinpoint readings, whereas pinless are useful for checking areas on the surface without causing any damage. The moisture level in your existing tile should be within acceptable limits, usually under 3%.

Any excess moisture will quickly damage your new flooring. You can also look for signs of moisture, like discoloration or a musty smell. Additionally, the existing tile subfloor needs to be level. Uneven surfaces can prevent the flooring from clicking together correctly and cause squeaks or other problems down the road. You can use a long level to identify any low or high spots.

- Moisture Meter Basics: Understanding how a moisture meter works is vital. It’s like having a sensor for dampness, providing a reading to indicate whether or not the area is moist. Different types exist, and it’s important to select the one that suits your needs. For tile, non-invasive meters are often best.

- Leveling Compounds: If you find any unevenness, you might have to use a leveling compound. These compounds are designed to create a flat, smooth surface. They come in different forms. Some are self-leveling, which means they spread out on their own to fill gaps, while others must be spread manually.

- Moisture Mitigation: If the moisture levels are too high, you might need to take additional steps. This could involve using a moisture barrier, which is a thin layer that stops moisture from penetrating the flooring. It is similar to waterproofing your floors.

Assessing Your Existing Tile Condition

Next up is assessing your existing tile condition. This step is about seeing whether your tile is up to the task of becoming the base for your new floor. Check for cracks, loose tiles, or any other damage. Cracked tiles may cause unevenness and can affect the stability of the wood floor. Loose tiles can become a major problem since they may cause movement, which may lead to your floating wood floor shifting. Also, evaluate the grout lines; are they intact?

Worn or missing grout can let moisture seep in, which you want to avoid. If you notice any of these issues, you might have to repair the tiles. It is always better to address any problems at this stage rather than find out later when the new floor is installed.

- Cracked Tiles: Cracked tiles are a sign of trouble. They can indicate that the subfloor beneath is unstable or that the tile has been damaged from impact. Replacing cracked tiles is a necessary step.

- Loose Tiles: Loose tiles are just as bad, as they can shift and move. When the floating wood floor is installed, they will cause problems, such as squeaking. Refasten or replace any loose tiles.

- Grout Inspection: Examine the grout lines carefully. Look for any cracks, gaps, or signs of wear. Grout prevents moisture from penetrating to your subfloor. Repair or replace any damaged grout before proceeding.

Gathering Your Tools and Materials

With the subfloor evaluation complete, the next thing you will want to do is gather your tools and materials. Having the correct tools makes the process much simpler and less time-consuming. You will need a variety of tools, including a measuring tape, a saw for cutting the flooring (circular or miter saw), a tapping block or pull bar, and safety equipment.

The type of flooring you select will determine the tools required, so be sure you have the right equipment for your installation. Moreover, you’ll need the right materials, such as underlayment (if needed), the wood flooring itself, and any transition strips for doorways or other areas. Purchasing the right materials guarantees that your new floor looks great and is properly installed.

- Essential Tools: The basic tools include a measuring tape, a saw (circular or miter saw), a tapping block or pull bar, a utility knife, and safety glasses. These are all useful to get the job done properly and efficiently.

- Underlayment Selection: If you’re placing a floating wood floor over tile, underlayment is an important consideration. It cushions the floor, reduces noise, and can serve as a moisture barrier.

- Transition Strips: These strips cover the edges of your flooring where it meets other surfaces, like doorways or the edges of rooms. They also help hide expansion gaps that are needed for the flooring to move as it expands and contracts.

Preparing the Tile Subfloor for Floating Wood Floors

Once you’ve done your homework and assessed your tile subfloor, it’s time to move on to the prep work. The process of preparing your subfloor helps ensure a successful installation. You will need to address any unevenness, clean the surface thoroughly, and, in some instances, apply an underlayment. Let’s explore each point in detail.

Leveling Uneven Areas

The goal is a completely flat surface. If your tile floor has high or low spots, now is the time to resolve them. Slight imperfections can be managed with underlayment, but more noticeable issues require leveling compounds. These compounds are a type of cement that can fill in dips and create a smooth finish. You’ll apply the compound, spreading it with a trowel, and let it cure. The self-leveling varieties do all the work for you, creating a flat surface as they spread. Properly leveling ensures your floating wood floor clicks together nicely, and it also prevents the boards from flexing or cracking under foot traffic. For larger discrepancies, a different solution might be required.

- Identifying Low Spots: Use a long level to find low areas. You can use a straight edge and a measuring tape to find the depths of the areas.

- Using Leveling Compounds: Leveling compounds come in various types, including self-leveling and patch compounds. Self-leveling compounds are easy to use. Patch compounds are better for small areas.

- Curing Time: Leveling compounds require time to cure completely. Follow the instructions on the packaging for cure times before proceeding.

Cleaning the Tile Surface

Your existing tile floor needs a thorough cleaning. Any dirt, dust, or debris can get in the way of a good installation. This includes everything from everyday grime to older adhesive residue. A thorough cleaning guarantees the new flooring has a nice, clean surface to bond to. Begin by sweeping and vacuuming the tile to remove loose particles. Next, mop the tiles with a solution that’s designed to remove grease and grime. Consider using a degreasing cleaner.

If there are old adhesive residues, you might need a scraper or a special adhesive remover. Removing any contaminants ensures the underlayment (if you choose to use it) or your flooring will bond to the tile properly.

- Sweeping and Vacuuming: Begin by sweeping or vacuuming the tile floor to remove all loose debris. Make sure to get into the corners.

- Mopping the Surface: Use a mop with a suitable cleaning solution that’s designed for cleaning tile. Avoid excessive water.

- Adhesive Removal: Scrape away any residue from old adhesive. For tough spots, use an adhesive remover.

Considering and Applying Underlayment

The use of underlayment is an important consideration. Underlayment adds a layer of padding between the tile and the wood floor. It serves multiple purposes, including providing a moisture barrier, reducing sound, and adding comfort. You’ll have different options. Some underlayments come with moisture barriers built-in, which protects your floating wood floor from moisture that might come from the subfloor. Acoustic underlayment is designed to absorb sound.

Consider your needs and the type of flooring to select the right underlayment. Laying underlayment is easy. You’ll usually roll it out over the clean, leveled tile. Some have adhesive to keep them in place, while others need to be taped to the floor.

- Benefits of Underlayment: Underlayment offers many benefits, including cushioning, noise reduction, and moisture protection. It can also help smooth out any small imperfections in the tile subfloor.

- Types of Underlayment: There are various types of underlayment, including foam, rubber, and cork. Some have a built-in moisture barrier.

- Underlayment Installation: Underlayment is usually rolled out and taped. Make sure to follow the manufacturer’s instructions for the best results.

Installing Your Floating Wood Floor

Now comes the exciting part: installing the floating wood floor. This is where you get to see your vision come to life. A floating wood floor is called “floating” because it isn’t attached to the subfloor. Instead, the planks click or snap together, creating a unified surface. The process involves precise measurements, careful cutting, and following the manufacturer’s instructions to ensure a perfect fit. Here are the steps involved, from planning your layout to the finishing touches.

Planning Your Layout and Measurement

Before you start laying planks, plan your layout. This is like creating a blueprint. It’s important to figure out how the boards will be positioned to minimize waste and to make the floor look good. Start by measuring the room and calculating how much flooring you’ll need, adding about 10% for waste and mistakes. Then, think about the direction the planks will run; often, the planks run parallel to the longest wall.

This makes the room appear longer. You’ll need to measure and cut the boards to fit around walls, door frames, and other obstacles. To achieve the best results, use a straight edge, a measuring tape, and a pencil. Careful planning guarantees a smooth, efficient installation and a professional finish.

- Room Measurement: Determine the area by measuring the length and width of the room. Always add extra flooring to account for cuts and waste.

- Plank Direction: The orientation of the planks is another consideration. In most cases, you’ll want to lay the planks in the direction of the longest wall.

- Cutting and Fitting: You will have to cut the planks around obstacles such as pipes or doorway openings. Measuring and marking these locations accurately is crucial.

Laying the First Rows

The first rows lay the foundation for the entire floor. The success of the rest of the installation hinges on this. Start with a straight, level line along one wall. This might involve using a chalk line to ensure everything is aligned. Position the first row of planks, making sure they are parallel to the wall, and leave an expansion gap. This gap is necessary to allow the wood to expand and contract without pressing against the wall.

The expansion gap is usually about ¼ to ½ inch, depending on the manufacturer’s directions. Next, click the planks together, following the manufacturer’s locking system. Ensure that the first rows are straight and securely connected. This step lays the groundwork for the rest of your flooring project.

- Starting the First Row: The first row is the most important, so take your time. Be sure it’s straight, level, and that you have an expansion gap.

- Using Spacers: Use spacers to maintain the expansion gap along the walls. These spacers guarantee consistent spacing.

- Clicking the Planks: Follow the manufacturer’s guidelines to join the planks. You might need to use a tapping block and hammer to help the planks lock together.

Cutting and Fitting the Remaining Planks

Once the first rows are in place, the rest is repetition and cutting. As you move across the room, you will need to cut the planks to fit around walls, door frames, and other obstacles. Be sure to use the right tools. Careful measurements are critical to prevent wasting materials. Mark the boards precisely before cutting. Use a saw to get clean, accurate cuts. A miter saw can make the angled cuts you need. If you’re working near a wall, you’ll need to cut the planks to fit the shape of the wall.

This is usually done by tracing the wall onto the plank and then cutting along the line. Remember to keep the expansion gap around the perimeter of the room. If it is done correctly, the result should be a neat and professionally installed floor.

- Precise Measurement: Accurate measurements are essential. Measure twice, and cut once.

- Using a Miter Saw: A miter saw is great for making the angled cuts you need. It helps to make precise cuts.

- Wall Fitting: When fitting planks against a wall, use a piece of cardboard or a wall tracing tool to get the shape just right.

Finishing Touches and Transition Strips

The final step is the finishing touches. This stage includes installing transition strips, baseboards, and cleaning. The transition strips connect the new floor to other floor surfaces. This could be doorways or where the flooring meets a carpeted area. These strips cover the expansion gaps and create a smooth transition between different floor levels. Baseboards are the decorative trim along the bottom of the walls. These cover the expansion gap and make the room look finished. After installing the baseboards, clean the floor.

This eliminates dust, dirt, and any construction debris that might be left. These details complete the installation and give your new floor a polished look.

- Installing Transition Strips: Install transition strips in doorways. These strips create a smooth transition from one floor to the other.

- Adding Baseboards: Baseboards will hide the expansion gap, making your floor look more finished.

- Final Cleaning: Sweep, vacuum, and mop the floor. Be sure to remove any dirt or debris before you begin using your new floor.

According to the National Wood Flooring Association, wood flooring can add value to your home. On average, a wood floor adds about 2.5% to the value of your home. It’s a great way to add value to your home. The average cost to install wood flooring is between $6 and $14 per square foot, so it can be a significant investment. Wood flooring is a good choice for many rooms, particularly bedrooms and living rooms.

| Factor | Description | Impact on Installation |

|---|---|---|

| Moisture Content | Wood expands and contracts with changes in humidity. | High moisture can cause warping or buckling; too dry leads to gaps. |

| Subfloor Levelness | A subfloor that is not even. | Causes an uneven look. |

| Expansion Gaps | Necessary gap around the perimeter. | Not providing an expansion gap can result in the wood pushing against the walls, causing damage and buckling. |

Common Challenges and Solutions

While the process of laying a floating wood floor is usually straightforward, there can be challenges. Some difficulties are related to leveling the subfloor, dealing with moisture, or cutting and fitting planks around tricky areas. Being aware of these issues helps prepare you for any problems. Having a solution in mind will help avoid setbacks. We’ll look at the common issues and the steps you can take to fix them, so you can overcome any hurdle.

Uneven Tile and Subfloor

Uneven tile is a frequent challenge when placing a floating wood floor. Tiles that are not level can cause problems. It’s hard to make a stable and even floor surface. This will result in squeaking, flexing, or unevenness in your new wood floor. Small imperfections may be resolved using underlayment. For bigger issues, use a leveling compound or self-leveling material. Leveling compounds smooth out the surface, ensuring a flat base for your new floor.

If the tile subfloor is significantly damaged or uneven, you might need to remove and replace the damaged areas or the entire tile floor. Addressing any unevenness before installing the floating wood floor is the best approach.

- Minor Imperfections: Use underlayment to smooth out slight differences.

- Major Imperfections: Level the subfloor with compounds.

- Tile Repair or Replacement: Fix or replace any loose or damaged tiles.

Dealing With Moisture Issues

Moisture is a significant concern when placing wood flooring over any surface. Moisture can cause the wood to warp, buckle, or experience mold. To address moisture issues, it is necessary to begin by testing the moisture levels in the tile subfloor before starting the project. Use a moisture meter to ensure the levels are within acceptable limits. If the levels are too high, think about a moisture barrier underlayment.

This will help protect the flooring from moisture from below. When you install your new flooring, consider the room’s environment. Consider the effects of humidity. Keeping the room’s humidity under control is important to maintain the integrity of the wood floor. These proactive steps will help avoid problems.

- Moisture Testing: Always test the tile subfloor.

- Using Moisture Barriers: Use underlayment with moisture-proof materials.

- Managing Room Humidity: Regulate humidity levels to protect the floor.

Cutting Around Irregular Shapes

Cutting and fitting planks around irregular shapes, such as door frames, pipes, and odd-shaped walls, is another common challenge. Getting these cuts right requires accuracy. When facing these challenges, use precise measurements and consider some tips and strategies. One popular method is to use templates to get the shape of the wall or object. You can create a template by placing a piece of cardboard against the obstacle and tracing its outline.

Then, transfer the outline to the wood plank. When measuring, measure twice and cut once. Consider using a jigsaw for intricate curves. It is better to cut carefully. By taking your time and using the right techniques, you can make perfect cuts. This guarantees a professional look.

- Template Creation: Make templates of hard-to-cut shapes.

- Accurate Measurements: Measure everything precisely.

- Using a Jigsaw: Use a jigsaw to make complex curves.

According to the Consumer Product Safety Commission, falls are the leading cause of injuries. Slips and falls can be reduced by ensuring that the floor is clean, dry, and in good condition. Improperly installed flooring can be a safety hazard. If you’re concerned about safety, consider using non-slip rugs. For busy households, it’s necessary to select flooring materials that can withstand wear and tear.

Can You Put a Floating Wood Floor Over Tile? The Pros and Cons

The question, Can You Put a Floating Wood Floor Over Tile?, requires an examination of the advantages and disadvantages. There are many benefits. Floating wood floors are easier to install than traditional flooring methods. They are a good choice for people wanting to update their homes quickly and without significant remodeling work. The result is a warmer and more comfortable feel than tile. Yet, there are some downsides, such as the need to prepare the subfloor and the risk of moisture problems. By considering the benefits and challenges, you can make the best choice for your project.

Advantages of Floating Wood Floors Over Tile

There are many advantages of placing a floating wood floor over tile. One of the greatest advantages is the ease of installation. Floating wood floors don’t require adhesive or nails. They click or lock together, which saves time and effort. This is great for DIY projects. The floors are a cost-effective option for home updates. It reduces the costs of a new floor. Additionally, the wood provides a warmer, more comfortable feel underfoot than tile.

Finally, installing a wood floor over tile has a great aesthetic appeal. It transforms a room. It adds a touch of beauty and can add value to your home. These advantages are important for homeowners.

- Easy Installation: The floating wood floor is easy to install, which is helpful for DIY projects.

- Cost-Effective: It reduces the cost.

- Warm Underfoot: Wood flooring is more comfortable than tile.

Disadvantages to Consider

There are some downsides to keep in mind. One of the main challenges is the need to prepare your tile subfloor. You will need to check the level, clean it well, and manage any existing moisture issues. Without proper preparation, you may face problems later on. There is also the potential for moisture damage. If moisture penetrates the wood floor, it can cause warping or mold. Selecting a wood floor over tile can limit your choice of flooring materials.

Most floating wood floors must be properly installed to ensure they look good. The floor’s long-term performance will depend on the installation and how you treat it. This requires the homeowner to think about the work before they start the project.

- Subfloor Preparation: You need to prepare your existing subfloor.

- Moisture Concerns: Moisture can cause damage to the wood floor.

- Limited Material Choices: Some flooring materials are not suitable for floating installation.

Comparing Floating Wood Floors to Alternatives

When you’re deciding on flooring, it’s a good idea to compare floating wood floors to other choices. For example, if you compare floating wood to other flooring materials like engineered wood, you will see a similar appearance, but the installation might be different. Engineered wood has a real wood veneer over a core of wood. With traditional hardwood, the pieces are installed by nails. Another choice is laminate flooring, which is known for being durable.

It is more resistant to moisture. Vinyl flooring is also a practical option. Each choice has its own set of benefits. Comparing these flooring materials will help you find the best option for your home. Compare features like ease of installation, appearance, and maintenance requirements.

| Flooring Type | Installation | Pros | Cons |

|---|---|---|---|

| Floating Wood | Easy, clicks together. | Easy installation, warm feel, appealing look. | Subfloor preparation, moisture issues. |

| Engineered Wood | Nail or glue, or click-lock. | Real wood appearance, more stable than solid wood. | Can be expensive, needs careful installation. |

| Laminate | Click-lock, floating. | Durable, resistant to moisture, budget-friendly. | Can feel less warm underfoot, can be difficult to repair. |

| Vinyl | Glue-down or click-lock. | Waterproof, easy to maintain, many styles. | Can feel less premium, prone to damage. |

Frequently Asked Questions

Question: Do I need to remove the existing tile before installing a floating wood floor?

Answer: In most cases, you don’t need to remove the existing tile. You can install the floating wood floor right over it if the tile is in good condition, is level, and is cleaned. Always check for moisture before you proceed.

Question: What’s the best underlayment to use when putting a floating wood floor over tile?

Answer: The best underlayment is one with moisture protection. This layer serves as a barrier and reduces sound. Make sure the underlayment is suitable for the type of flooring you are using. Read the flooring manufacturer’s instructions for what they recommend.

Question: What do I do if my tile floor isn’t level?

Answer: If the tile floor isn’t level, you’ll need to level it. Use a leveling compound. These materials fill in low spots. Apply the compound according to the directions. Make sure that it’s completely dry before you put your wood floor down.

Question: Can I use any type of floating wood floor over tile?

Answer: Not all types of floating wood floors are suitable for installation over tile. Solid hardwood flooring should not be installed using the floating method. Engineered wood and laminate are good options, but you’ll need to check the manufacturer’s recommendations. Make sure to check the instructions for the specific product.

Question: How do I handle transitions to other rooms or flooring types?

Answer: You can use transition strips to handle transitions. These strips cover the expansion gaps at doorways and at the edges where the wood floor meets other surfaces. There are many different types of transition strips available, so you can select one that fits your needs.

Final Thoughts

So, Can You Put a Floating Wood Floor Over Tile? The short answer is yes, with the proper planning and preparation. Think of it as a DIY project that can transform your home. The key is to start with a solid foundation. Make sure the tile is level, clean, and free of moisture. You will need to prepare your existing subfloor. Use underlayment for added comfort and moisture protection. Carefully plan your layout, measure accurately, and make precise cuts. Remember to leave an expansion gap to allow for movement.

The finishing touches, such as installing transition strips and baseboards, will give your new floor a polished look. By addressing the challenges, you can create a floor that is both beautiful and functional. So, prepare your tools, follow the steps, and enjoy the process. You’ll soon have a great-looking wood floor.