Decking Screws vs Wood Screws: Essential Guide

Decking screws are specially designed for outdoor projects like decks due to their corrosion resistance and holding power, while standard wood screws are better suited for indoor woodworking. Choosing the right screw ensures a stronger, longer-lasting build.

Hi there, fellow DIYers and future deck builders! Md Meraj here. Have you ever stood in the hardware store, staring at a wall of screws, wondering which ones are right for your project? It can be confusing, especially when you’re building something important, like a deck. You want it to be safe, strong, and last for years. Don’t worry, we’ve all been there! Understanding the difference between decking screws and regular wood screws is a simple step that makes a huge difference. This guide will walk you through it, so you can pick the perfect screw for your next woodworking adventure with confidence. Let’s get to it!

Decking Screws vs Wood Screws: What’s the Big Deal?

When you’re building anything out of wood, screws are your best friends. But not all screws are created equal! Just like you wouldn’t use a hammer to tighten a bolt, you shouldn’t use any old screw for every job. Decking screws and wood screws look similar, but they have unique features that make them ideal for different tasks. Picking the right one means your project will be stronger, last longer, and look better.

What Are Decking Screws?

Decking screws are built tough, specifically for outdoor use. Think about it – decks face rain, sun, snow, and everything in between. These screws need to handle it all without rusting or weakening.

Key features of decking screws include:

Corrosion Resistance: This is the most important feature. Deck boards are exposed to the elements, so decking screws are usually made from stainless steel or have special coatings (like ceramic or epoxy) to prevent rust. Rusting screws can stain your deck and eventually weaken the connection.

Holding Power: Decking screws have sharp points and aggressive threads that bite deep into the wood, creating a strong hold. This is crucial for deck boards, which experience a lot of movement and stress.

Special Heads: Many decking screws have heads designed to sit flush or slightly below the surface of the wood, or they might have features that help prevent “mushrooming” (where the wood splits around the screw head). Some have star drive (Torx) heads, which are much less likely to strip than Phillips heads, especially when driving them into dense material.

Self-Drilling Tips: Some decking screws have specialized tips that can drill their own pilot hole, making installation faster and reducing the risk of splitting the wood, especially important for hardwoods.

What Are Wood Screws?

Standard wood screws are the go-to fasteners for indoor woodworking projects. They are designed for general-purpose use in furniture, cabinetry, framing, and other interior applications where they won’t be exposed to moisture.

Key features of wood screws include:

Variety of Materials: Wood screws come in many materials, including zinc-plated steel, brass, and stainless steel. For indoor use, standard zinc-plated steel is often sufficient.

Different Head Types: You’ll find a wide range of head types, like round, flat, pan, and oval, with drive types including Phillips, slotted, and square (Robertson).

Thread Design: Wood screws generally have coarser threads than machine screws, designed to grip well in wood. However, their threads might not be as aggressive or specialized as those on decking screws.

Pilot Hole Recommended: While they can sometimes be driven without one, drilling a pilot hole is often recommended for wood screws, especially in harder woods, to prevent splitting and make driving easier.

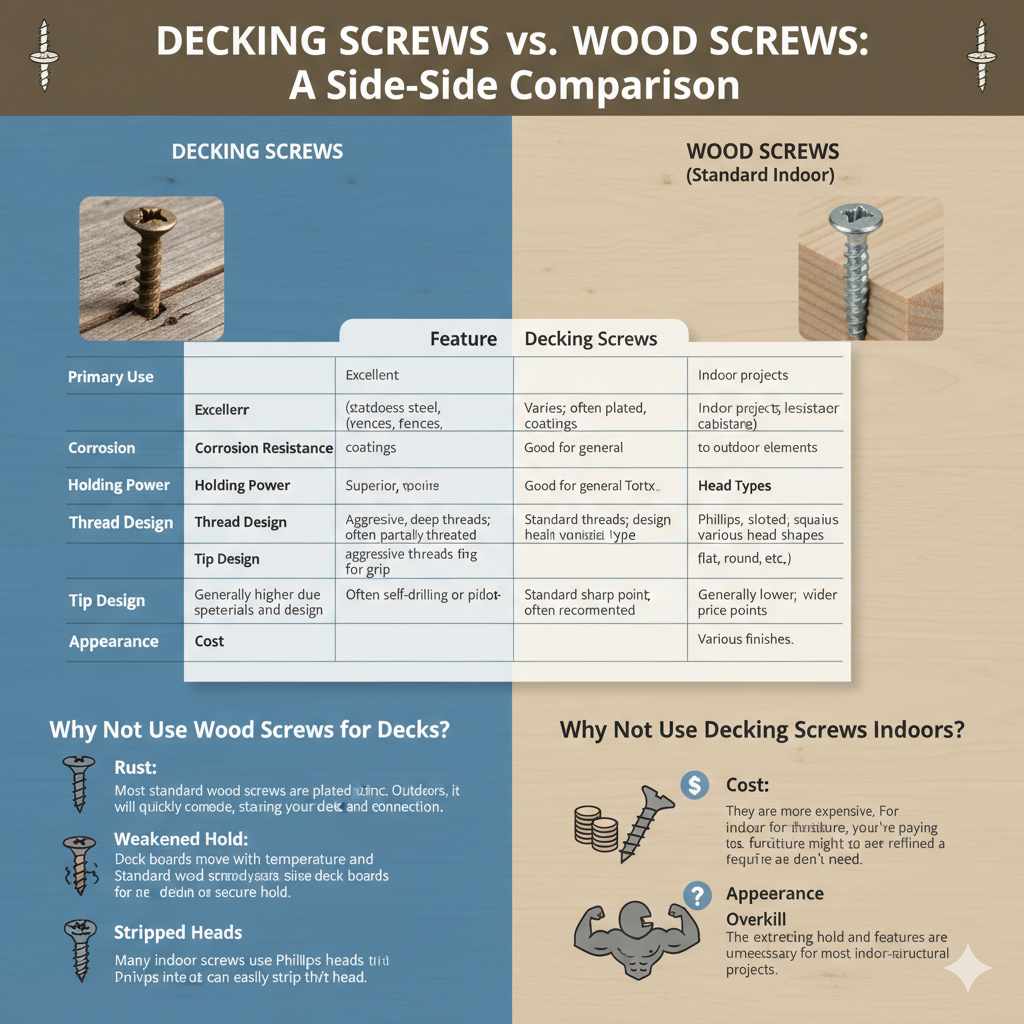

Decking Screws vs. Wood Screws: A Side-by-Side Comparison

To really see the differences, let’s put them head-to-head. This table highlights the key distinctions that matter for your projects.

| Feature | Decking Screws | Wood Screws (Standard Indoor) |

|---|---|---|

| Primary Use | Outdoor projects (decks, fences, pergolas) | Indoor projects (furniture, cabinetry, framing) |

| Corrosion Resistance | Excellent (stainless steel, specialized coatings) | Varies; often plated, less resistant to outdoor elements |

| Holding Power | Superior, especially in decking materials | Good for general woodworking |

| Thread Design | Aggressive, deep threads; often partially threaded for grip | Standard threads; design varies by screw type |

| Head Types | Often star drive (Torx), self-countersinking heads | Phillips, slotted, square; various head shapes (flat, round, etc.) |

| Tip Design | Often self-drilling or self-tapping | Standard sharp point; pilot hole often recommended |

| Cost | Generally higher due to specialized materials and design | Generally lower; wider range of price points |

| Appearance | Functional, designed for outdoor durability. Some have color-matched heads. | Can be decorative (e.g., brass) or functional. Various finishes. |

Why Not Use Wood Screws for Decks?

You might be tempted to grab a box of standard wood screws because they’re cheaper or you already have them. But here’s why that’s a recipe for disappointment:

Rust: Most standard wood screws are plated with zinc. This plating is great for indoors, but outdoors, it will quickly corrode. Rusting screws can stain your beautiful deck boards with ugly orange streaks and eventually weaken the connection, leading to loose boards or even structural failure.

Weakened Hold: Deck boards, especially larger ones, move and expand with temperature and moisture changes. Standard wood screws might not have the aggressive threads needed to keep that hold secure over time.

Stripped Heads: Many indoor wood screws use Phillips heads. When driving them into dense deck boards or at an angle, the driver bit can easily slip and strip the screw head, making them very difficult to remove or tighten.

Why Not Use Decking Screws Indoors?

While decking screws are incredibly robust, using them for indoor projects isn’t usually necessary and can sometimes be less ideal:

Cost: They are more expensive than standard wood screws. For an indoor piece of furniture or a cabinet, you’re paying extra for features you don’t really need.

Appearance: Some decking screws have a very utilitarian look. If you’re building fine furniture, you might want a screw with a more refined head style or finish.

Overkill: The extreme holding power and corrosion resistance are simply not required for most indoor applications.

When to Use Which Screw: Project Breakdown

Let’s break down some common projects and decide which screw is the star performer.

Projects Calling for Decking Screws:

Building a new deck: This is their namesake for a reason! They handle the moisture, movement, and weight.

Repairing an existing deck: When replacing rotten boards or adding supports, use decking screws to ensure a lasting fix.

Outdoor furniture: Benches, picnic tables, Adirondack chairs – anything that lives outside needs the protection decking screws offer.

Fences and gates: Posts, rails, and pickets will all benefit from the secure, weather-resistant hold.

Pergolas and arbors: These structures are exposed to the elements just like decks.

Planter boxes: Even wooden planters that sit outdoors need fasteners that won’t corrode.

Outdoor trim and siding: For wooden elements attached to the exterior of your home.

Projects Calling for Wood Screws:

Indoor furniture: Dining tables, chairs, bookshelves, bed frames.

Cabinetry: Building or installing kitchen cabinets, bathroom vanities.

Shelving units: For inside your home.

Trim and molding: Interior baseboards, door casings, crown molding.

Framing (interior walls): Standard wood screws are common for joining studs.

DIY projects: Birdhouses (if kept under a porch roof), toy boxes, craft projects.

Repairing indoor wooden items: Fixing wobbly table legs, reinforcing drawer boxes.

Key Factors to Consider When Choosing Screws

Beyond just “decking” vs. “wood,” there are a few other things to think about to make sure you get it right:

1. Material and Coating

Stainless Steel: The gold standard for decking screws. It offers the best corrosion resistance. Look for 305 or 316 grades for maximum durability, especially in coastal areas.

Coated Screws: Many decking screws have advanced coatings (ceramic, epoxy, polymer) that offer excellent corrosion resistance. Check the manufacturer’s rating for expected lifespan.

Zinc-Plated: Common for indoor wood screws. Acceptable for dry conditions but will rust outdoors.

Brass: Attractive and corrosion-resistant, often used for decorative or fine woodworking indoors.

For outdoor projects, always prioritize screws rated for the job. A good resource for understanding fastener materials and their resistance properties is the ICC Evaluation Service (ICC-ES), which provides technical evaluations for building products, including fasteners.

2. Screw Head Type

Star Drive (Torx): My personal favorite for both decking and many woodworking screws. The six-pointed star shape makes the driver bit fit snugly, drastically reducing the chance of stripping the head. This is a game-changer when driving lots of screws or working with tough woods.

Phillips: The classic cross shape. Prone to cam-out (slipping) under high torque, which can strip the head or damage the wood.

Square Drive (Robertson): Also excellent at preventing cam-out, popular in Canada.

Flat Head: Designed to countersink flush with the surface.

Washer Head: Creates a larger bearing surface, good for holding thin materials or preventing pull-through.

For decks, I almost always reach for star drive decking screws. For interior work, I use star drive or square drive for strength and ease, but Phillips is perfectly fine for lighter tasks.

3. Screw Length and Diameter (Gauge)

Length: You want the screw to go through your first piece of wood and securely into the second. A common rule of thumb for wood-to-wood connections is that the screw should penetrate the second piece by at least half to two-thirds of its thickness. For deck boards (typically ~1 inch thick), a 2-1/2 inch screw is very common. Always check the best practices for your specific project.

Diameter (Gauge): A larger diameter means a stronger screw. Thicker screws (higher gauge numbers) are better for structural connections, while thinner screws are fine for lighter tasks. For decks, something around a #8 or #10 gauge screw is typical.

4. Thread Type

Coarse Threads: Grip well in softwoods and are common on decking and general wood screws. They drive faster.

Fine Threads: Offer more holding power in hardwoods but drive slower and can strip more easily if a pilot hole isn’t used.

Partial vs. Full Threads: Decking screws often have a smooth shank near the head with threads only on the lower portion. This allows the screw to pull the deck board tightly down to the joist without the threads binding in the top board. Standard wood screws are often fully threaded.

How to Install Screws Like a Pro (Even if You’re a Beginner!)

Regardless of the screw type, proper installation ensures the best results. Here are some tips:

1. Choose the Right Driver Bit

Make sure your driver bit perfectly matches the screw head (e.g., T25 bit for a Torx head screw). A good fit prevents stripping.

2. Use a Pilot Hole (When Needed)

For most indoor wood screws: Especially in hardwoods or near the edge of the wood, a pilot hole slightly smaller than the screw’s core diameter helps prevent splitting.

For decking screws: Many modern decking screws have self-drilling tips, meaning you might not need a pilot hole. However, if you’re working with very dense hardwood or are concerned about splitting, drilling a pilot hole is still a good idea. It also makes driving the screw much easier.

How to drill a pilot hole: Use a drill bit that matches the unthreaded shank of the screw. For the tip, use a bit about 60-70% of the screw’s diameter through the first piece of wood.

3. Control Your Drill/Driver

Set the Clutch: If you’re using a power drill/driver, set the clutch to a low setting initially. This prevents over-driving the screw, which can strip the head or damage the wood. As you get a feel for it, you can adjust.

Drive Straight: Try to keep the drill/driver perfectly perpendicular to the wood surface. This ensures the screw goes in straight and the head sits flush or countersinks properly.

Steady Pressure: Apply consistent, steady pressure as you drive the screw.

4. Countersinking for a Clean Finish

Recessed Head: Most deck boards and many interior projects look best with screw heads slightly below the surface. If your screw head doesn’t naturally sink, you can use a countersink bit after drilling your pilot hole. This creates a cone-shaped recess for the screw head to sit in.

Self-Countersinking Heads: Some decking screws have special heads designed to cut into the wood as they drive, automatically creating a smooth, flush finish.

Safety First!

Working with tools and fasteners always requires care.

Eye Protection: Always wear safety glasses to protect your eyes from flying debris or snapping screws.

Gloves: Consider wearing work gloves to protect your hands from splinters and blisters.

Tool Safety: Understand how your drill/driver works. Never force a tool. Keep cords (if using a corded tool) out of the way to avoid tripping.

* Material Stability: Ensure your wood pieces are stable before drilling or driving. Use clamps if necessary.

Frequently Asked Questions (FAQ)

Q1: Can I use decking screws for indoor furniture?

Yes, you absolutely can, but it’s usually not necessary. Decking screws offer superior strength and corrosion resistance, which are overkill for indoor furniture. They are also typically more expensive than standard wood screws, so you might be spending more than you need to. However, for a very durable piece, they won’t hurt.

Q2: How do I prevent screws from rusting outdoors?

The best way is to use screws specifically designed for outdoor use, like stainless steel decking screws or coated decking screws. These are made with corrosion-resistant materials or have protective coatings that stand up to moisture and the elements. Standard plated screws will rust quickly outdoors.

Q3: What is the difference between a screw “gauge” and screw “length”?

Gauge refers to the screw’s diameter (thickness). A higher gauge number means a thicker screw. Length refers to how long the screw is from the tip to where the head starts to flatten out at the top.

Q4: Do I always need to drill a pilot hole?

Not always. Many modern decking screws and some wood screws have self-drilling or self-tapping tips that create their own pilot holes. However, for harder woods, driving screws near the edge of a board, or if you want to ensure a perfectly straight drive without splitting, drilling a pilot hole is highly recommended. It makes driving easier too!

Q5: What’s the best type of screw head for driving?

Many woodworkers prefer the Star Drive (Torx) head because the driver bit fits very snugly into the recess, making it much harder for the bit to slip and strip the screw head. Square (Robertson) drives are also excellent for this. Phillips heads are common but are more prone to slipping.

Q6: Can I reuse old decking screws?

It’s generally not recommended to reuse old decking screws, especially if they show signs of rust or damage. The threads might be worn, and their holding power could be compromised. For critical structural elements like decks, using new, appropriate screws is always the safest bet.

Conclusion: Build with Confidence!

Navigating the world of fasteners doesn’t have to be complicated. By understanding the unique strengths of decking screws and standard wood screws, you’re already a step ahead. Remember, decking screws are your robust, weather-beaten warriors for outdoor projects, ensuring your decks, fences, and outdoor furniture stand tall against the elements. Standard wood screws are your versatile partners for the indoor realm, holding together the furniture and structures that make your home comfortable.

Choosing the right screw is an investment in the longevity and integrity of your project. It means less worry about rust, fewer repairs down the line, and the satisfaction of a job well done. So next time you’re at the hardware store, armed with this knowledge, you can confidently select the perfect screw. Keep building, keep creating, and most importantly, keep enjoying the rewarding process of bringing your DIY visions to life! Happy building!