How Much to Rip Up Carpet and Put Down Hardwood: Genius Way

To rip up carpet and put down hardwood, expect costs from $5 to $15 per square foot for materials and labor when doing it yourself, or $10 to $25+ per square foot with professional installation. This includes removing old carpet, preparing the subfloor, the hardwood itself, and installation. Prepare for significant time and effort if taking a DIY route.

Transforming a room from soft carpet to elegant hardwood can seem like a big project, but it’s a dream many homeowners share! The thought of endless carpet cleaning meetings, pet stains, and dust bunnies underfoot often leads to looking for brighter, and cleaner, flooring solutions. Many want that timeless beauty and easy maintenance that hardwood floors consistently offer. If you’ve been wondering about the costs and actual steps involved, you are in the right place. I understand that taking on a renovation task can feel overwhelming, especially with so many details to consider regarding ripping out old flooring and installing new. Relax, because by breaking it down, you’ll see just how achievable those beautiful hardwood floors are. We’ll go through everything you need to know, whether you’re keen on tackling it solo or seeking out the best professionals. Let’s get your home looking even more stunning!

How Much to Rip Up Carpet and Put Down Hardwood: The Smart Way to Estimate

Thinking about pulling out that old carpet, but you’re not sure how deep your wallet needs to be? It’s a common question, and understanding the costs gives you the power to plan your budget like a pro DIYer. The “how much” has a few key pieces to it: the removal of the old, preparing the place for the new, the beauty that is hardwood itself, and fitting it all seamlessly.

Let’s break down the price tag so you can estimate with confidence. The final number depends on several factors, but with a good understand of each dollar you fork out, you and your wallet will be ready.

Understanding the Breaktdown: What Goes into Replacing Carpet with Hardwood?

When we talk about “ripping up carpet and putting down hardwood,” we’re really talking about a multi-step renovation. Each phase has its own cost, and bundling them together gives us the full picture. Over at Building America, a leader in home construction insights, they highlight how foundational steps significantly impact the overall quality and cost of any flooring project.

Here are the typical cost contributors:

1. Carpet Removal and Disposal

First things first: you’ve got to get that old carpet out! This means pulling up the carpet, the padding underneath, and often, nails or staples that hold everything in place. Disposal also comes into play; in many areas, you can’t just toss old carpet with your regular trash, meaning you might need a dedicated disposal service or to haul it to a facility, which adds to cost for both DIY and hired jobs. For a professional, this part alone can range from $100 to $300 or more, depending on the size of the room and local disposal fees. If you’re grabbing your utility knife and doing it yourself, your cost is mainly your effort, plus waste disposal fees.

A Tip from Meraj:

Don’t underestimate the grunt work in carpet removal. If the carpet is old and really well-stapled right into your subfloor, it can be a tougher job than you might think. Wear gloves and safety glasses!

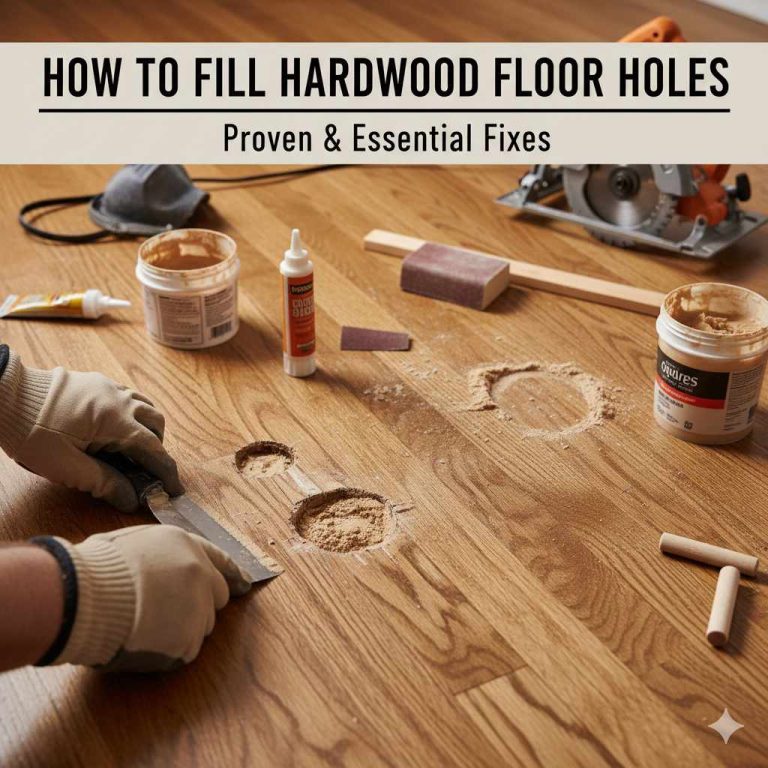

2. Subfloor Preparation

This is a critical step that many beginners overlook but pros know is essential for a beautiful, long-lasting hardwood floor. The carpet might mask underlying issues. Your uncovered subfloor needs to be clean, level, and securely fastened. If you have any dips, humps, or loose subflooring (happens often with older homes or water damage), it needs fixing before hardwood goes down. Expect for:

Cleaning: Removing all remaining carpet tack strips, staples, glue, and dirt. This needs to be spotless!

Repairing: Patching minor damage or replacing warped boards.

Leveling: Using a smoothing compound if floors aren’t perfectly flat.

Condition: Addressing new or problematic subfloors. Plywood or OSB are generally fine, but concrete needs a decent moisture barrier plus a leveling compound. Particle board, if present, usually has to go.

Subfloor issues can inflate your budget. Minor prep might add $50-$100. Major repairs, especially on older wood subfloors or after water damage detected by resources like the Environmental Protection Agency’s guidance on healthy indoor air for avoiding harmful embedded materials, might lead to costs of several hundreds of dollars. It’s better to fix it right now rather than regret it when your new wood floor creaks or swells later!

• Consider New Subflooring? (Especially For Cement Floors)

If we are working over concrete or a significantly damaged or unsuitable subfloor (like particle board), often the most durable solution is adding a new underlayment or even repairing/reframing sections of your subfloor. For concrete, this usually means installing sleepers and then laying plywood on top. This adds complexity plus material costs but gives the hardwood proper nailing surface and a necessary buffer against moisture.

3. Material Costs: Hardwood Flooring itself

This is where much of your budget will go day-to-day. The style and wood type dictate costs. Here’s what you’ll find:

Types of Hardwood: You can choose from solid hardwood or engineered hardwood. Solid hardwood is milled directly from a single piece of wood. Engineered hardwood has a real wood veneer on top of layers of wood or fiberboard.

Wood Species: Oak and maple are popular, durable, and economically sound domestic options. Exotic woods or those needing complex milling processes can cost significantly more.

Pre-finished vs. Unfinished: Pre-finished planks (done at the factory) are usually $1-$2 more per square foot but save immense on-site time and hassle while offering much cleaner finishes usually. Unfinished requires sanding, staking, blocking etc. after install.

Plank Width and Length: Wider or longer planks are often more expensive.

Construction: Solid wood is a premium. Engineered wood can come ready to nail, glue, or float–all affecting installation practices and costs.

Here’s a quick average on material pricing. These can shift greatly with sales and region:

|Prefinished Hardwood (solid or engineered) | |$5 – $10 | | More labor savings and often better, consistent finish that needs no extra curing time (no room downtime after install. This is my preferred professional choice typically.

What About the Underlayment? Don’cha ever have one thing lead right to the next like me? Now remember a lot of hardwood floor MUST or VERY STRONGLY NEED to have is a vapor wrap over concrete sublors on that 2 inches worth spacing between joist bays for acoustics. It works via a foam or cork in the way that makes nice and is then normally nailed or stapled in place… The standard practice usually asks for it; so make darn near SURE if your old floors needs its one installed… Many people can NOT use wood over slab, due to no attachment but to GLULING these require some sort of good SUBfloor layer as 2-4 pounds of pressure applied must ALWAYS be a good and sound plan! Hence one needs either Solid or Engineered Wood with the specified use you are thinking so that NO one can make mistake from installation point AND no building professional must EVER use another layer. Most modern flooring has rubberized or felt underlayment attached during its production so we check that one also. Be Careful, read instructions!!! The expense for UNDERLAYMENT can range to between $0.50 $1.00 additional dollars per squar foot. It must BE CONSIDERED for budget plan.

Understanding Plank Dimensions

Is 2-inch wide versus an 8-inch wide plank the only variation? Nope! The wider, generally hand-scraped rustic stuff or longer, straighter plank flooring is almost always more $$$. BUT your wallet is looking at even a very specific, engineered option today or it’s only 3.25 inches for a much smoother run. So, remember this: width can be as big a variate as style. Even within two standard engineered options pricing this makes us sure!

4. Installation Labor

This is where costs add up when hiring pros. While removal costs about $15-;$30 /SQ FT in most areas, hardwood install typically breaks down to $5 – $15+ / Sq Ft, often due to the skill required and the intricacies of ensuring that all those perfectly prepped pieces line up without gaps, and that means cutting and careful angling, especially if they are new flooring.

Let’s look at DIY vs. Pro rates to get a clearer budgeting path:

DIY Install: Your own labor is ‘free’ though it commands tons of care, patience too – plus any tool rentals IF you want to speed up or upgrade quality. BUT, remember, a rookie install job could SET YOU BACK even MORE $$ through mistakes that need rework! This brings us more towards ~$4 $$1;SQ FT for the floor itself+ underpadding.

Professional Install: Professional hands for installation cost more. It can add $5 to $15, or even more per square foot, because they have training AND the knowledge – like knowing how many rooms need special care (e.g., around doorframes, irregular walls) and the specialty nail tools for HARDWOOD.

A pro’s typical charge covering rip-out, prep, actual flooring PLUS PLUS necessary adhesives materials, as well as 5 mil plastic vapor shield underling may hover between these amounts shown:

| Flooring Type | Avg. Material Price (per sq ft) | Notes |

|---|---|---|

| Solid Hardwood (Oak, Maple,domestic) | $4 – $8 | Classic beauty, can be refinished many times. Must be familiar with moisture requirements. |

| Engineered Hardwood (common domestic species) | $3 – $7 | More stable regarding humidity shifts; fewer board warping issues than solid, veneer thickness determines refinishing count. Usually more install variety. |

| Luxury Brand Hardwood | $8-$18 and up (per sqFt) | Premium wood like .; walnut, exotic woods, or special treatments / design |

Total Estimated Cost Per Square Foot $6 – $18This ALL INCLUDES removal till final finished floor, as shown in cost analysis by top diyhomeexpert.net!

| Phase | Typical Cost (per Sq Ft) | Notes |

|---|---|---|

| Carpet Removal & Disposal | $1 – $3 | Drives costs IF room or area is in a high tier city center requiring $ specific licensing or particular waste, e.g. in a large metropolitan market where disposal costs. |

| Subfloor Prep | $2 – $5 | Can jump quickly if the existing subfloor isn’t the optimum quality for WOOD INSTALL. Concrete typically includes a $2-$text3.5 extra for moisture test. |

| Hardwood Material purchase | $3 – $10 | With a quality $8-$10 selection, most homes can have top look – PLUS you can buy from any wholesale or retailer as prices come down. |

How Much Hardwood Material Do I Really Need?

I gotta tell ya, buying enough hardwood is tricky. You never want to order stingy, but you don’t want a house load to waste either. You must purchase additional ALL necessary for waste due to cuts – especially if you’re dealing with patterned laying rooms, or have off-cuts from doors, niches, stairs, this usually ranges at 8% for those working busy homes up near ten percent (of your main flooring total).

So if you’ve just measured a space measuring the exact dimension for its carpet AND it turned out that your room was, say, 10’ by 10’, this implies 100 square feet of perfect hardwood floor FROM THAT point TO the existing floor line, it would be:

100 sq ft</STRONG x M = X

Your SQ Foot Needs 120%) Floor Quantity = TOTAL BOARD FT REQUIRED Since MOST of this ordering requires ALL THE NEEDS plus ALL wastage

More than you might guess, yes!

Wait, what if my room isn’t square?

For rooms measured OUTSIDE of the actual perimeter – be honest if you can!, 5’x’37’ for a walk path, these ARE the dimensions – make sure you get measurements on EXACT perimeter THEN ADD ABOUT ONE INCH ON THE PERIMETER WHICH GIVES MOSTLY ALL of the FINAL flooring calculation. Measure all irregular or long AND EVEN STEEP WALLS in your bedroom: your measure could increase drastically

So say your room is precisely 120sqft, that would be to take from the whole equation. Adding in 10% for WASTE makes one purchase no SHORTER THAN about 132 sq. ft.!

Which is Best for You? That Dependent Selection YOU NEED to Make!

Let’s recap The GREAT HARDWOOD SELECTION:

Installation Cost: Though generally cheaper, installing unfinished solid-wood, plus needing to then sanding/sealing onsite implies MORE LABOR FROM FLOOR INSTALLER. Prefinished engineered boards on other handy installs? WAY LESS! NO WAY, a room needs NO MORE than a FLOOR SAND OF 3 STRIPPED COATS.

DIY Versus Professional Installation

DIY Hardwood Installation: The DIY path can save YOU MONEY ($2 to $’$7 per SQR’ foot on installation IF this IS a well-planed idea; but this needs skills as described BY THE NATIONAL WOOD FLOORING ASSOCIATION(www DOT NWFL “.” OR G DOT COM). Without the skill? The RESULT MAY NOT EVEN BE FAIR; needing FIXING later WILL COST FAR MORE! Your BIG RISK is getting this done NOT PERFECTLY CORRECT, making damage DOWN the path! DIY is VERY welcome if you have skills; BUT THIS is FAR FROM beginner’s work at home!

FAQs: Beginner’s Questions on Carpet to Hardwood Installation

Q1: Is ripping out carpet myself a hard job?

It sounds tough, but ripping carpet is usually one the MORE manageable DIY tasks you COULD tackle. You’ll grab your gloves, utility knife, and pliers. Once you get the hang of it, especially in corner areas, the long rolls and underlying padding, you see NOT ALL THAT scary afterall—just PLENTY of YARD WORK and physical exertion needed for EACH carpeted SPACE.

Q2: Do hardwood floors need special cleaning?

That depends on the kind of wood: Some NEED specialized hardwood soap and it cannot bear WONDER of damp mops or water splashing onto surfaces. While NEW finish techniques or oils means they CAN get ALL MOST water spilled/dropped OFF from OFF TO surface. FOR DIY hardwood install that often REQUIRES no water, EVER. My PRO SECRET is get a spray bottle: NO MORE water needs wetting YOUR hardwood floors ANY OF THE THRIEVERY!

Q3: How can I make sure my subfloor is ready for hardwood?

MOST TIMES, there’s JUST a SMALL layer OF felt ON SOME WOOD SUBFLOOR BOARDS AND THAT’S IT? NOT AT MOST NEW HOUSES! The OLDer home flooring MUST BE DRY, FIRMWELDER and FLAT in order for hardwood installation to stand the VERY LONG REAL test of time. MOST ALL homes’ SUB SUBFLOOR should BE measured FOR how MUCH it could RANDO SE slope/dip (like within oneeighth inch OF OVER A measure OF SIX /7’ FEET MEASURES!). USE A LONG LEVEL, MAKE ME SURE it is FLAT OR THAT YOU must SECURF it and THAT YOU can repair it too

Q4: Are there cheaper ways to get a hardwood look?

When does one DECIDE To put In NEW FLOORS FOR YOUR HOUSE? WHAT CONSIDERATIONS Make IT THE BEST WAY TO A WINNING BID, NOT A FAILURE…? YOUR HOME SIZE TO LOOK BETTER… THAT CAN START WITH REMOVING SO MUCH OLD MATERIAL… OR CHANG<ST)Final Considerations: Bringing Your Hardwood Visions To Life