3 4 Sanded Plywood Lowes: Essential Guide

For projects needing a smooth, flat surface and solid support, 3/4 sanded plywood from Lowe’s is an excellent, affordable choice. It offers durability and a finished look, making it ideal for shelves, cabinets, and creative DIY builds. This guide simplifies choosing and using it.

Ever stared at a woodworking project idea, only to get stuck before you even start? Choosing the right materials can feel like deciphering a secret code. That’s especially true for plywood. You might think, “What’s the big deal? It’s just wood!” But the type of plywood you pick makes a huge difference in how your project turns out. If you’ve been a bit confused about what exactly “3/4 sanded plywood” means and why Lowe’s is a go-to spot for it, you’re in the right place! We’re going to break it all down, making it super simple so you can get building with confidence. Let’s unlock the secrets of this versatile sheet good and get your projects looking fantastic!

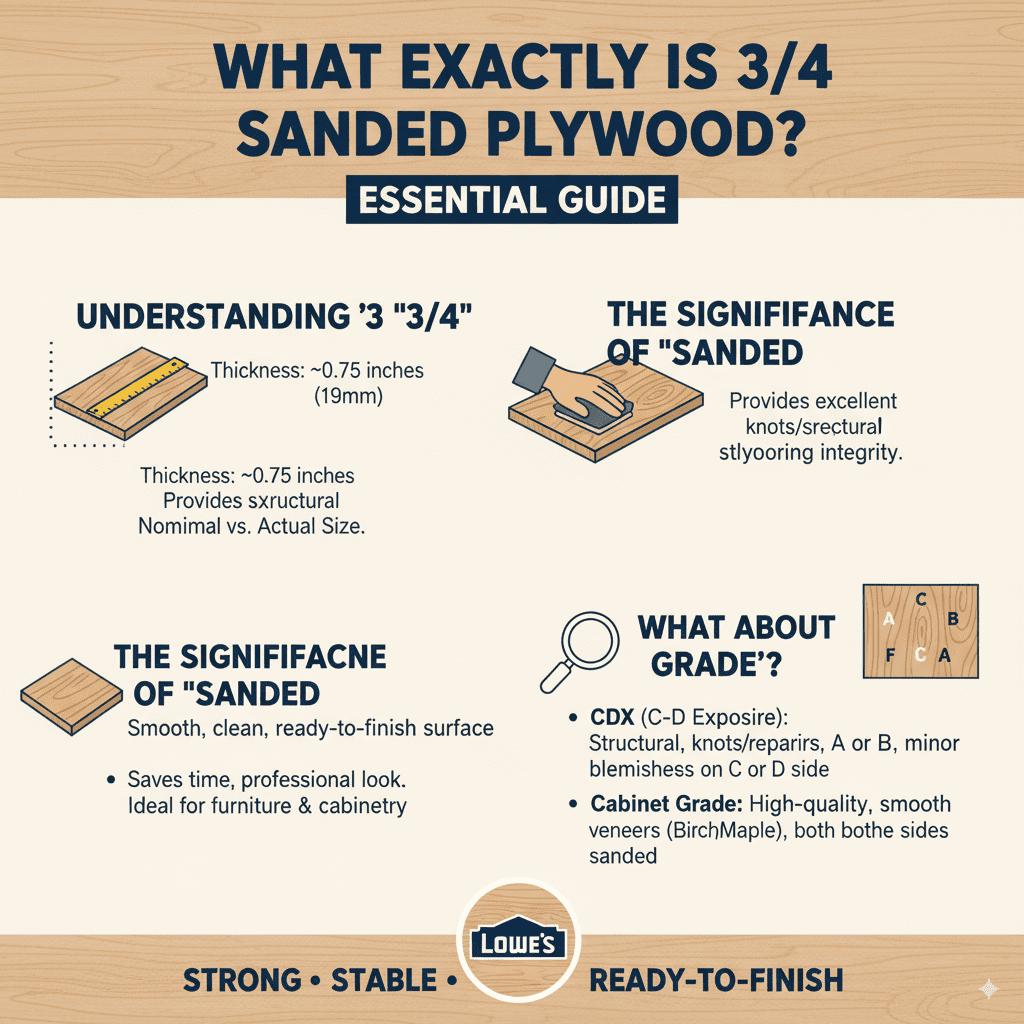

What Exactly is 3/4 Sanded Plywood?

Think of plywood as layers, or “plies,” of wood glued together. These thin sheets are stacked on top of each other with their grain running in different directions. This crisscross pattern is what makes plywood so strong and stable, preventing it from warping or cracking easily. When we talk about “3/4 sanded plywood,” we’re referring to a specific type of this engineered wood product:

Understanding the “3/4”

The “3/4” in “3/4 sanded plywood” tells you the thickness of the sheet. Standard plywood sheets are sold in nominal thicknesses, meaning the actual size might be slightly less. For a 3/4-inch sheet, the actual thickness is usually very close to 0.75 inches (about 19mm). This thickness provides excellent structural integrity for a wide range of applications.

The Significance of “Sanded”

The “sanded” part is key for DIYers and homeowners! It means that at least one side (and often both sides) of the plywood sheet has been smoothed down with sandpaper. This creates a clean, ready-to-finish surface. You won’t have to spend hours sanding rough patches yourself, which is a huge time-saver and makes your project look much more professional. This makes it perfect for projects where aesthetics matter, like furniture, cabinetry, or decorative shelving.

What About the “Grade”?

Plywood also comes in different grades, which tell you about the quality of the wood veneer on the surface. For sanded plywood, common grades at Lowe’s might include:

- CDX Plywood: The “C” side typically has some knots and repairs, while the “D” side is more fully featured with open defects. This is still a solid structural panel, often used for subflooring or sheathing on less visible parts of projects. It’s sanded, but might not be as pristine as higher grades.

- AC or BC Plywood: These grades indicate that one side (A or B) is much smoother and freer of blemishes than the other (C or D). If you need a nice finish on one side, look for AC or BC. The “A” side is the smoothest and most attractive, often clear of knots and ready for paint or stain. The “B” side is still good but might have minor imperfections.

- Cabinet Grade Plywood: This is usually a higher-grade plywood, often with birch or maple veneers, specifically made for visible cabinetry where a beautiful, smooth finish is paramount. It’s usually sanded very well on both sides.

For most DIY projects where you want a smooth surface without a premium price tag, a good quality sanded plywood grade like AC or a higher-end CDX will likely be sufficient. Always check the panel itself or ask an associate if you’re unsure about the grade.

Why Choose 3/4 Sanded Plywood from Lowe’s?

Lowe’s is a popular destination for DIYers, and for good reason, especially when it comes to sheet goods like plywood. Here’s why their 3/4 sanded plywood is a go-to choice for many:

- Availability and Convenience: Most Lowe’s stores carry a decent selection of 3/4 sanded plywood, including various grades and wood species. This makes it easy to pick up what you need for your project without a special trip.

- Consistency: While there can be variations between batches, Lowe’s generally stocks products that offer predictable quality. You can usually count on their sanded plywood to be relatively flat and free of major defects.

- Affordability: Compared to solid wood boards of equivalent size, plywood is often more cost-effective, especially for larger surfaces. 3/4 sanded plywood offers a good balance of strength, finish quality, and price.

- Pre-Sanded Surface: As we’ve discussed, the “sanded” finish is a massive benefit. It saves you time and effort, allowing you to move directly to painting, staining, or sealing, which significantly speeds up project completion.

- Structural Integrity: The 3/4-inch thickness provides a robust and stable material suitable for many weight-bearing applications.

Common Projects for 3/4 Sanded Plywood

The versatility of 3/4 sanded plywood makes it a staple for a vast array of home improvement and DIY projects. Its strength, smooth surface, and affordability are a winning combination. Here are some of the most popular ways people use it:

Shelving Solutions

This is perhaps the most common use! Whether you’re building sturdy garage shelving, elegant book nooks, or simple closet organizers, 3/4 sanded plywood is an excellent choice. The 3/4-inch thickness provides enough rigidity to span decent distances without sagging, especially when supported properly. The sanded surface means you can easily paint or stain it to match your decor.

Cabinetry and Furniture

For DIY cabinet boxes, drawer bottoms, or even tabletops, 3/4 sanded plywood is a workhorse. Higher grades of sanded plywood (like birch or maple) are particularly beautiful when finished and can rival hardwoods in appearance for furniture projects. It’s much more stable than solid wood, which is crucial for keeping cabinets and furniture from warping over time.

Workshop and Garage Builds

When building workbenches, tool storage solutions, or jigs in your workshop, durability and a flat surface are paramount. 3/4 sanded plywood is often the material of choice. It can withstand the rigors of a workshop environment and provides a reliable base for tools and projects.

Subflooring and Underlayment

While CDX plywood is more common for this, thicker sanded plywood can also be used as a subfloor or underlayment, especially in areas where a smoother surface is desired before laying down tile or vinyl. Always check local building codes for specific requirements, but generally, 3/4-inch thickness offers good stability.

For more information on construction standards, you can refer to resources like the Building Science Corporation, which offers in-depth technical guidance on building materials and assemblies.

DIY Projects Galore

From pet enclosures and playhouses to custom closet systems and decorative wall panels, the possibilities are nearly endless. The ease of cutting and finishing this material makes it ideal for bringing unique ideas to life around the house.

Choosing the Right 3/4 Sanded Plywood at Lowe’s

Navigating the plywood aisle at Lowe’s can sometimes feel overwhelming. To make it easier, let’s break down what to look for:

Consider Your Project’s Needs

Before you grab the first sheet you see, ask yourself:

- Will the surface be visible? If yes, opt for a higher grade like AC or BC, or cabinet grade.

- Will it bear significant weight? 3/4 inch is generally good, but ensure the span between supports is appropriate for the load.

- Will it be painted or stained? If staining, a knot-free or finely sanded surface is best. If painting, you have more flexibility with grades.

- Will it be exposed to moisture? Standard plywood can be sensitive. For potentially damp areas, consider exterior-grade plywood or apply a waterproof sealant.

Understanding Different Core Materials

While Lowe’s might primarily stock softwood (like fir or pine) plywood, some higher-end options are available. The core material (the inner plies) affects strength and weight. Softwood is common, durable, and readily available. Hardwood plywood (like oak or birch) is generally stronger, heavier, and more expensive, often used for furniture.

Inspect for Defects

Even with sanded plywood, it’s wise to give the sheets a quick inspection:

- Flatness: Lay the sheet flat and check for significant bowing or twisting. A little warp can often be managed, but severe issues can make projects difficult.

- Surface Imperfections: Look for large cracks, open knots, or delamination (layers separating). While some minor imperfections are normal for sanded plywood, you want a good surface to work with.

- Edge Quality: Check that the edges are reasonably intact, as you may need to edge-band or trim them.

Know Your Panel Size

Standard plywood sheets are typically 4 feet by 8 feet. Keep this in mind for transportation and planning your cuts.

Working with 3/4 Sanded Plywood: Tips for Beginners

Once you’ve got your 3/4 sanded plywood, it’s time to get to work! Woodworking is all about understanding how materials behave and using the right techniques. Here are some essential tips to make your experience smooth and successful.

Safety First!

Woodworking involves tools that can cause injury. Always prioritize safety:

- Safety Glasses: Protect your eyes from dust and flying debris. Always wear them when cutting, sanding, or drilling.

- Hearing Protection: Power tools can be loud. Use earplugs or earmuffs to prevent hearing damage.

- Dust Mask/Respirator: Plywood dust can be irritating and harmful. Wear a mask, especially when sanding.

- Secure Your Work: Use clamps to hold the plywood firmly in place while you cut or drill. This prevents the piece from moving unexpectedly.

- Read Tool Manuals: Familiarize yourself with your tools’ operation and safety features.

For more on general workshop safety, the Occupational Safety and Health Administration (OSHA) provides valuable guidelines for workspace safety.

Cutting Techniques

Making clean cuts is crucial for a professional-looking project. Here are some tips:

- Mark Your Cut Line Clearly: Use a sharp pencil and a straight edge or speed square.

- Use the Right Blade: A blade with a higher tooth count (e.g., 60T or 80T) will generally give you a smoother cut on plywood.

- Support the Plywood: If cutting a large sheet, ensure the offcut piece is well-supported to prevent tearing as the cut finishes. You can use sawhorses or a cutting table.

- Cut with the Grain Direction (when possible): For rip cuts (cutting with the length of the sheet), try to cut with the grain to minimize tear-out.

- Support the Cut Edge: To prevent tear-out on the bottom side of the cut, you can use painter’s tape along your cut line before you start. Alternatively, a zero-clearance insert on a table saw can greatly improve cut quality.

Joining Methods

How you connect pieces of plywood is vital for the project’s strength:

- Wood Glue and Screws (or Nails): This is the most common and effective method. Apply a generous amount of wood glue to the joint surfaces and then secure with screws or nails. Pre-drilling pilot holes for screws is highly recommended to prevent the plywood from splitting, especially near edges. For a cleaner look, countersink screw heads and fill the holes with wood filler or plugs.

- Pocket Holes: Using a pocket hole jig (like those from Kreg Tool) creates angled holes that allow you to drive screws from one piece into another discreetly. This is a very strong and relatively easy joining method for DIYers.

- Dadoes and Rabbets: For more advanced joinery, cutting dadoes (grooves) or rabbets (rebates) allows pieces to interlock for greater strength. These can be cut with a table saw or router.

Finishing Your Project

The sanded surface is ready for a beautiful finish. Here are some options:

- Painting: Apply a good quality primer, followed by two coats of your chosen paint. Semi-gloss or satin finishes are popular for durability and ease of cleaning.

- Staining: Apply a pre-stain wood conditioner first to ensure an even stain absorption, especially on softer woods. Then, apply your stain and seal it with a polyurethane or varnish for protection.

- Sealing: Even if you don’t paint or stain, a clear sealant (like polyurethane or lacquer) will protect the plywood from moisture and wear, and enhance its natural appearance.

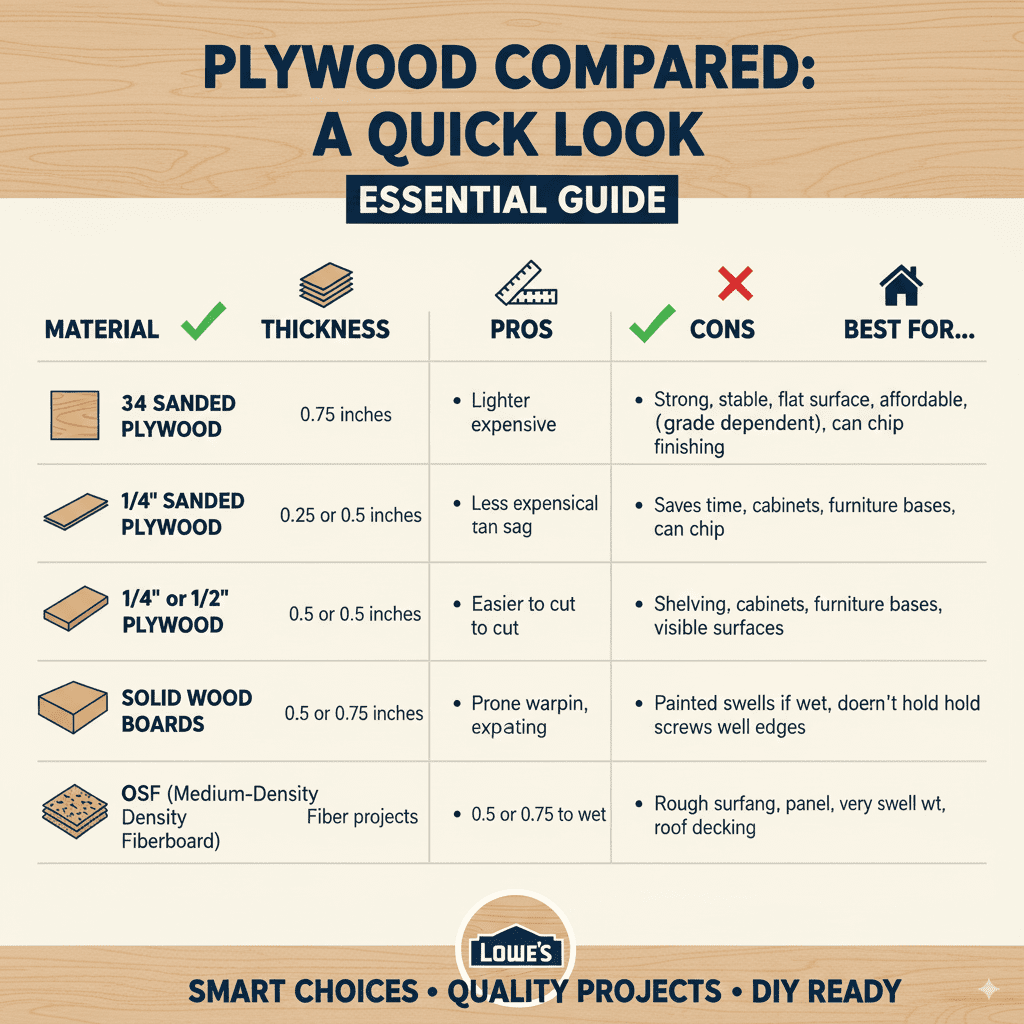

Plywood Compared: A Quick Look

To help you better understand where 3/4 sanded plywood fits into the larger picture of wood materials, here’s a comparison with other common options. This isn’t exhaustive, but it highlights key differences for DIY projects.

| Material | Typical Thickness | Pros | Cons | Best For… |

|---|---|---|---|---|

| 3/4 Sanded Plywood (Lowe’s) | ~0.75 inches | Strong, stable, flat surface, affordable, good for finishing, widely available. | Can have veneer imperfections (grade dependent), can chip if not cut carefully. | Shelving, cabinets, furniture bases, workshop projects, visible surfaces. |

| 1/4″ or 1/2″ Plywood | ~0.25 or 0.5 inches | Lighter, less expensive, easier to cut for certain applications. | Less structural strength, can sag more easily, may not be suitable for load-bearing shelves. | Drawer bottoms, cabinet backs, smaller craft projects, jigs. |

| Solid Wood Boards (e.g., Pine, Oak) | Varies (e.g., 1×4 is ~0.75×3.5) | Authentic wood grain, can be planed, can be edge-glued for wider panels, classic appearance. | Prone to warping/cupping, can be more expensive, requires more careful joining, end grain is less durable than plywood face. | Fine furniture, decorative trim, tabletops where natural wood is desired. |

| MDF (Medium-Density Fiberboard) | ~0.5 or 0.75 inches | Very flat, smooth, consistent, great for painting, no grain to worry about. | Heavy, weak across spans without support, swells badly if exposed to moisture, doesn’t hold screws as well at edges, dust is finer and more hazardous. | Painted cabinet doors, modern furniture panels, speaker enclosures. |

| OSB (Oriented Strand Board) | ~0.5 or 0.75 inches | Strong structural panel, very rigid, less expensive than plywood. | Rough surface (not suitable for finishing), can swell if wet, can be directional in strength, difficult to get perfectly smooth when cut. | Subflooring, wall sheathing, roof decking, structural framing elements. |

As you can see, 3/4 sanded plywood offers a sweet spot for many DIY projects, balancing cost, performance, and a good finish.

Frequently Asked Questions (FAQ)

Q1: Is 3/4 sanded plywood smooth enough to stain directly?

Yes, generally. A good quality sanded plywood, especially grades like AC or BC, will have a surface smooth enough for staining. For the best results, always use a pre-stain wood conditioner, as plywood can sometimes absorb stain unevenly due to its layered construction and the different types of wood used in the plies.

Q2: Can I use 3/4 sanded plywood for an outdoor project?

Standard sanded plywood is not designed for prolonged exposure to the elements. While you can use it for outdoor projects if you meticulously seal and paint every surface with a high-quality exterior finish, it’s better to use exterior-grade plywood (often marked with a “W” for waterproof glue) or treated lumber for durability in outdoor applications like garden beds or outdoor furniture.