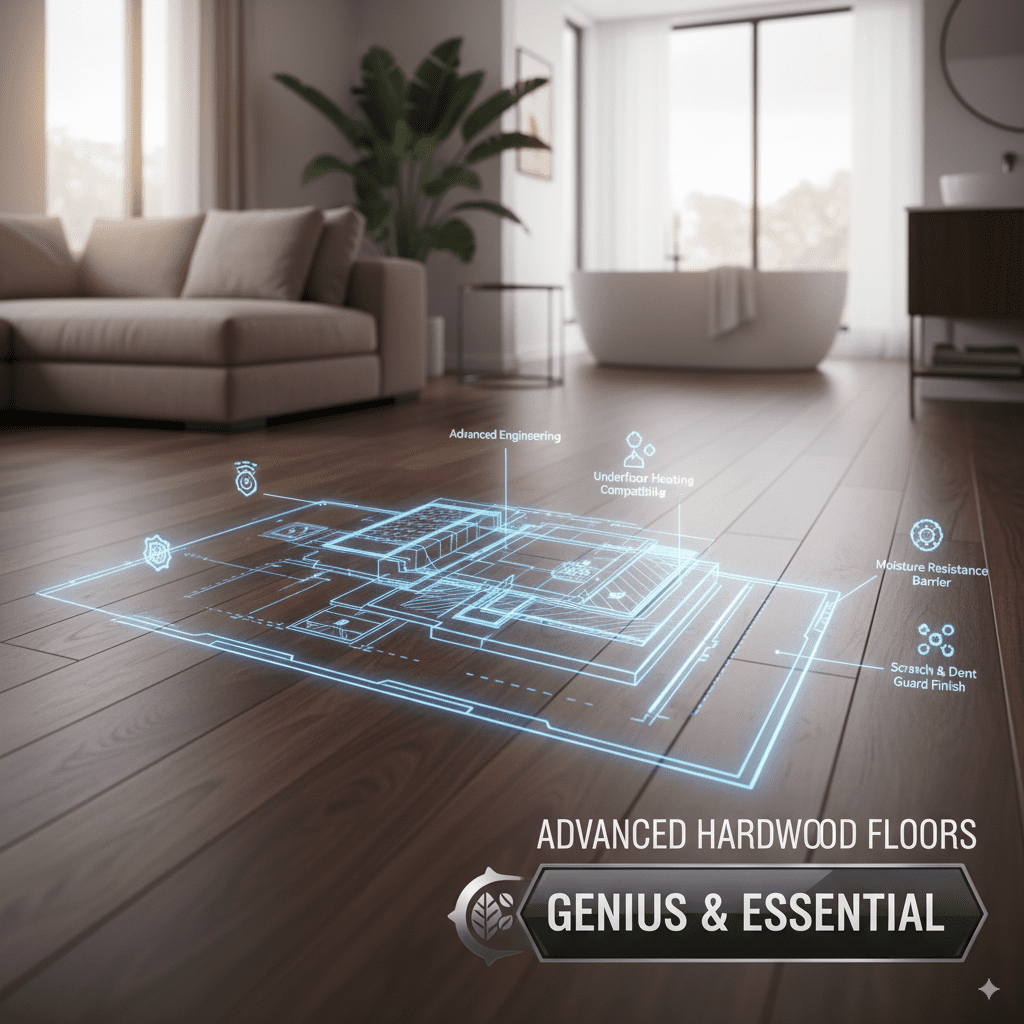

Advanced Hardwood Floors: Genius & Essential

Creating advanced hardwood floors involves thoughtful planning, selecting the right materials, and precise installation for lasting beauty and function. Even beginners can achieve stunning results by understanding the basics of preparation, layout, and finishing. This guide will walk you through essential steps to elevate your flooring project.

Welcome to the World of Advanced Hardwood Floors

Have you ever looked at a stunning hardwood floor and wondered how it was made? Maybe you’re thinking about upgrading your home and want something that truly stands out. Sometimes, choosing the right hardwood can feel a little overwhelming, especially when you hear terms like “advanced.” But don’t you worry! With a little guidance, you can absolutely create beautiful, durable, and impressive hardwood floors. It’s all about taking smart steps and understanding what makes a difference.

We’ll cover everything from picking the perfect wood to making sure it looks amazing for years to come. Get ready to learn some genius ideas that are also essential for any homeowner or DIYer. Let’s dive in and unlock the secrets to beautiful hardwood floors together!

What Makes Hardwood Floors “Advanced”?

When we talk about “advanced hardwood floors,” we’re not necessarily referring to complex, professional-only techniques. Instead, it’s about making informed choices and implementing best practices that lead to superior results in both look and longevity. Think of it as going beyond the basic click-and-lay laminate. Advanced hardwood floors often involve:

- Careful consideration of wood species and their properties.

- Understanding different installation methods and their suitability.

- Mastering the art of preparation for a flawless finish.

- Choosing the right finishes and maintenance plans.

- Incorporating design elements that enhance the space.

These elements combine to create a floor that isn’t just a covering, but a central feature of your home’s design.

Choosing Your Wood: The Foundation of Genius

The type of hardwood you choose is the first big decision. Different woods have unique characteristics that affect durability, appearance, and cost. Here are some popular options and what makes them a “genius” choice for different needs:

The Tough Guys: Durable Hardwoods

These woods are great for busy homes with kids and pets because they resist dents and scratches better.

- Oak (Red & White): A classic for a reason. Oak is incredibly durable, readily available, and takes stains beautifully. Its prominent grain pattern adds character. White Oak is known for its slightly more muted, greyish tones and exceptional resistance to moisture.

- Maple: This wood is very hard and has a smooth, subtle grain. It’s perfect for a clean, modern look and takes light stains or finishes exceptionally well, offering a bright feel.

- Hickory: One of the hardest domestic woods available. Hickory floors are extremely resistant to wear and tear, making them a fantastic choice for high-traffic areas. It often features a lot of natural color variation and knots, adding rustic charm.

- Brazilian Cherry (Jatoba): If you’re looking for intense color and hardness, this is it. It darkens beautifully with age and is incredibly dense, resisting dents and scratches very well.

The Beauties: Character & Style

These woods might be a bit softer but offer stunning visual appeal.

- Walnut: Known for its rich, deep brown color and beautiful grain patterns. Walnut is a softer hardwood, so it might not be the best for extremely high-traffic areas without careful consideration, but its elegance is unmatched.

- Mahogany: Offers a warm, reddish-brown hue and a fine, straight grain. It’s moderately hard and offers a luxurious look, though it can be more expensive.

- Birch: While some varieties are quite hard, others are softer. Birch offers a light, creamy color and a fine grain. It’s a more budget-friendly option that can achieve a sophisticated look.

Consider Engineered vs. Solid Hardwood

Both have their place in advanced flooring projects:

- Solid Hardwood: Each plank is milled from a single piece of lumber. It can be sanded and refinished many times, offering a lifetime of beauty if cared for.

- Engineered Hardwood: This is made of multiple layers of wood or composite material with a hardwood veneer on top. It’s more stable than solid wood, less affected by changes in humidity, and can often be installed in basements or over concrete. This stability makes it a “genius” choice for challenging environments.

A great resource for understanding wood properties is the Woodworking Network’s guide to wood species.

Preparation: The Unsung Hero of Advanced Floors

You’ve chosen your wood – fantastic! Now comes the part that many people overlook, but it’s absolutely crucial for a professional, advanced finish: preparation. This applies whether you’re installing new floors or refinishing existing ones.

For New Installations: What to Prepare

Before a single plank is laid, the subfloor needs to be perfect. This is where you prevent future problems like squeaks, unevenness, and buckling.

- Check Subfloor Condition: Ensure your subfloor (usually plywood or OSB) is clean, dry, and free of damage. Remove any old flooring, nails, or staples.

- Level & Flat: A level subfloor is essential. Use a long, straight board or a laser level to check for dips or high spots. You can fix minor imperfections with floor leveling compound. Major issues might require more extensive work.

- Moisture Test: Excess moisture is the enemy of hardwood. Conduct a moisture test to ensure the subfloor is within the acceptable range for your flooring type. This is especially important over concrete slabs or in basements. For concrete, a calcium chloride or relative humidity test is recommended.

- Acclimate the Flooring: This is a “genius” step often skipped! Hardwood needs time to adjust to the temperature and humidity of the room where it will be installed. Typically, this means letting the unopened boxes sit in the room for 48-72 hours. Check the manufacturer’s specific recommendations.

For Refinishing Existing Floors: Deep Cleaning & Repair

If you’re breathing new life into old floors, preparation is about revealing the beauty hidden beneath.

- Thorough Cleaning: Sweep and vacuum meticulously. Then, wash the floors with a pH-neutral hardwood floor cleaner. Ensure they are completely dry before proceeding.

- Inspect and Repair: Look for any loose boards, squeaks, or damaged areas. Secure loose boards by screwing them down through the subfloor if possible. Replace any planks that are cracked or beyond repair.

- Filling Gaps: Small gaps between boards can be filled with a wood filler mixed with sawdust from the sanding process. For larger gaps, you might need to insert wood slivers.

Installation Techniques: The Art of the Lay

How your hardwood is installed makes a world of difference. The “advanced” approach often means choosing the most suitable method for your subfloor and desired aesthetic.

Nail-Down Installation

This is a traditional and very secure method, often preferred for solid hardwood planks.

- How it Works: A specialized flooring nailer (cleat nailer) is used to drive nails through the tongue of the hardwood plank into the subfloor.

- Best For: Plywood or OSB subfloors in rooms above ground level.

- Pros: Provides a very secure, long-lasting installation. Allows for multiple refinishes over time.

- Cons: Requires specific tools and a compatible subfloor.

Glue-Down Installation

Using adhesive creates a strong, solid bond.

- How it Works: A special wood flooring adhesive is spread onto the subfloor using a trowel, and the planks are laid directly into the glue.

- Best For: Engineered hardwood, sometimes solid hardwood, and often used over concrete subfloors or in basements where nailing isn’t feasible.

- Pros: Excellent for sound dampening, can be used in more locations (like basements), and creates a very stable floor.

- Cons: Messy if not done carefully, difficult to remove later, and requires specific adhesives and trowels.

Floating Floor Installation

This method is common for engineered hardwood and laminate, where planks lock together.

- How it Works: Planks are not attached to the subfloor. Instead, they are joined to each other, creating a single “floating” floor that lies on top. An underlayment is typically used for cushioning and moisture protection.

- Best For: Engineered hardwood, especially designed for this method. Can be installed over various subfloors.

- Pros: Relatively easy for DIYers, quick installation, can accommodate minor subfloor imperfections.

- Cons: Can feel slightly less solid underfoot than nailed or glued floors, less suitable for very large areas without expansion breaks.

Laying Out Your Floor: The Genius Design Touch

Beyond just laying planks, think about the layout. This is where you can add that “advanced” visual appeal:

- Running Bond: The most common pattern, where planks are staggered. Ensure the end joints of adjacent rows are offset by at least 6 inches (15 cm) for a professional look and structural integrity.

- Herringbone/Chevron: These intricate patterns involve cutting planks at angles to create a beautiful, classic woven look. This requires more skill, precise cuts, and often more material, but the result is stunningly advanced.

- Inlays and Borders: Adding decorative borders around the perimeter of a room or creating intricate inlay patterns using contrasting wood species can elevate your floor from ordinary to extraordinary.

A helpful guide on installation methods can be found on the The News-Press.

Finishing Touches: Protecting Your Investment

The finish is what protects your hardwood floors from daily wear and tear, spills, and UV damage, while also dictating their final look – matte, satin, or high gloss.

Types of Finishes

The finish is applied after installation (for unfinished solid wood) or comes pre-applied (factory finish on engineered wood).

- Polyurethane (Oil-Based): Durable and provides a warm amber tone over time, enhancing the wood’s natural color. It has a strong odor and requires good ventilation during application.

- Polyurethane (Water-Based): Dries faster, has low odor, and stays clear, avoiding the ambering effect of oil-based poly. It may require more coats than oil-based for equivalent durability.

- Hardwax Oils: These penetrate the wood and create a matte or satin finish that feels very natural. They are easy to repair in localized areas and offer a sophisticated look, but might require more frequent maintenance than polyurethanes.

- Lacquer: Less common for residential floors today due to durability and VOC concerns, but offers a very hard, fast-drying finish.

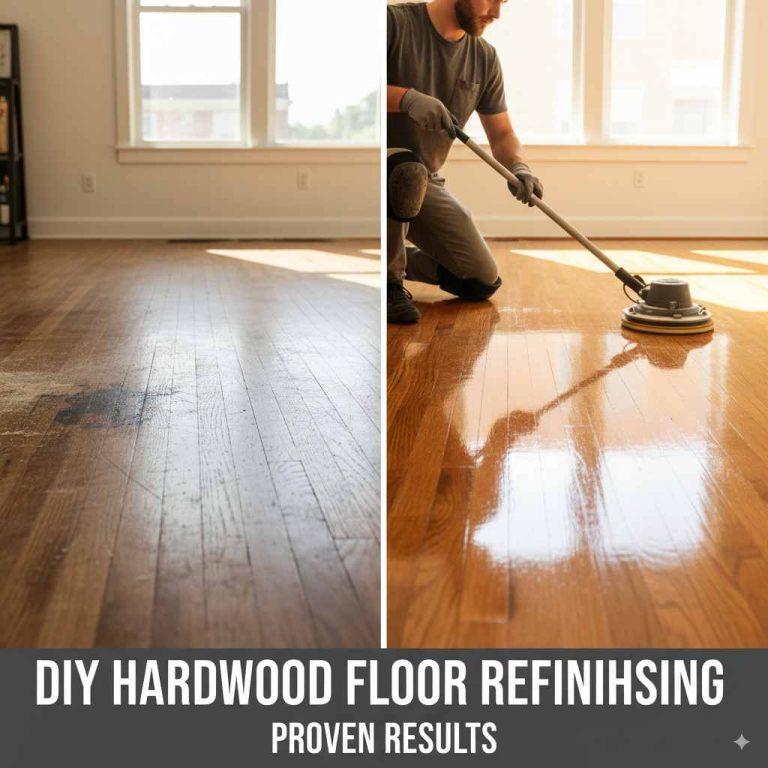

Sanding for a Seamless Finish

If you’re installing unfinished solid hardwood, or refinishing, sanding is the key to a smooth, beautiful surface.

- Progressive Grits: Start with a coarse grit sandpaper (e.g., 36-40 grit) to remove old finishes and level the floor. Gradually move to finer grits (e.g., 60, 80, 100, 120-150 grit) to smooth the surface.

- Edge Sanding: Use an edge sander for areas the drum sander can’t reach.

- Detail Sanding: A small hand sander or detail sander is used for corners and tight spots.

- Vacuum Thoroughly: After each sanding grit, vacuum all dust. A shop vac with a fine dust filter is essential. A tack cloth wipe-down before applying finish is a genius move to catch final dust particles.

For detailed information on refinishing, consider resources from the U.S. Environmental Protection Agency (EPA) on indoor air quality, as proper dust control is vital during sanding.

Applying the Finish

This is the final step to protect and beautify your floor. Always follow the manufacturer’s instructions!

- Cleanliness is Key: Ensure the room is as dust-free as possible. Turn off HVAC systems to minimize air circulation and stirring up dust.

- Apply Thin, Even Coats: Use a high-quality applicator (like a lamb’s wool pad or roller specifically designed for finishes). Apply the finish evenly, avoiding puddles.

- Allow Proper Drying Time: Each coat needs to dry completely before the next is applied. Lightly scuff sand with a very fine grit (e.g., 220) between coats if recommended by the manufacturer, then vacuum and tack cloth again.

- Multiple Coats: Most floors require at least three coats of finish for optimal durability.

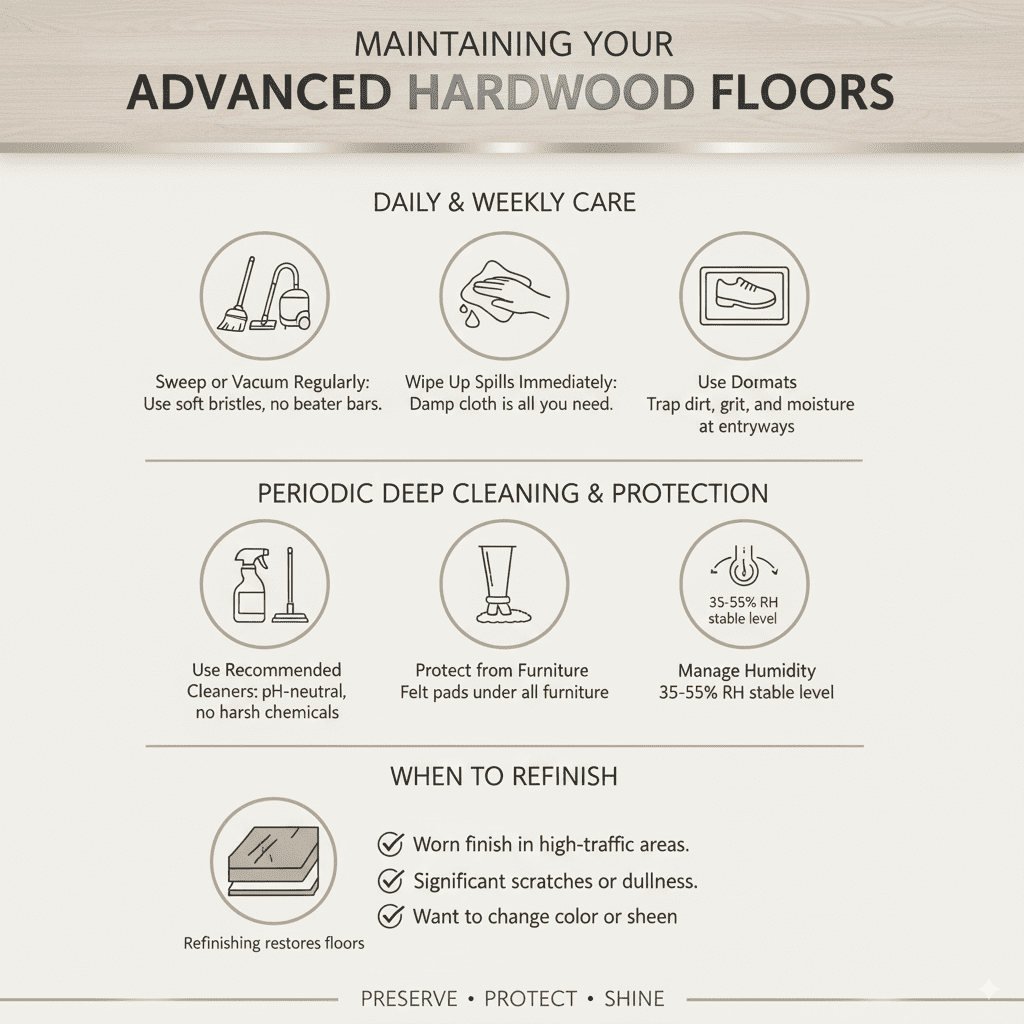

Maintaining Your Advanced Hardwood Floors

Once your beautiful floors are installed and finished, proper maintenance is essential to keep them looking advanced for years to come.

Daily & Weekly Care

- Sweep or Vacuum Regularly: Use a soft-bristle broom or a vacuum cleaner with a hardwood floor attachment. Avoid vacuums with beater bars, as they can scratch the finish.

- Wipe Up Spills Immediately: Damp cloth or paper towel is all you need. Don’t let liquids sit on the floor.

- Use Doormats: Place mats both inside and outside entryways to trap dirt, grit, and moisture that can scratch and dull the finish.

Periodic Deep Cleaning & Protection

- Use Recommended Cleaners: Stick to pH-neutral hardwood floor cleaners. Never use harsh chemicals, ammonia, or excessive water, as they can damage the finish and the wood.

- Protect from Furniture: Use felt pads under the legs of all furniture. For very heavy items like pianos or large sofas, consider furniture coasters.

- Avoid High Heels and Cleats: These can cause dents and scratches.

- Manage Humidity: Hardwood expands and contracts with humidity. Aim for a stable relative humidity level between 35% and 55% year-round. A humidifier or dehumidifier can help.

When to Refinish

Even with the best care, hardwood floors will show wear over time. You’ll know it’s time to refinish when:

- The finish is worn through in high-traffic areas.

- The wood shows significant scratches or dullness.

- You want to change the color or sheen of the floor.

Refinishing (sanding and reapplying finish) can bring your floors back to their original glory, extending their lifespan significantly.

FAQs About Advanced Hardwood Floors

Q1: How long does it take to install hardwood floors?

The time can vary greatly depending on the size of the room, the installation method (nail-down, glue-down, floating), and whether it’s a new install or refinishing. A typical room might take 1-3 days for installation, plus acclimation time. Refinishing a whole house can take a week or more.

Q2: Can I install hardwood floors myself?

Yes, with careful planning and the right tools! Floating floors are generally the most DIY-friendly. Nail-down and glue-down methods require more specialized tools and practice. It’s always wise to start with a smaller room if you’re a beginner.

Q3: Is engineered hardwood as good as solid hardwood?

Both have pros and cons. Engineered hardwood is more stable in changing humidity and can be installed in more places (like basements). Solid hardwood can be sanded more times. For many modern homes, engineered hardwood offers “genius” stability and versatility.

Q4: What’s the most durable hardwood species for a busy family?

Hickory, Maple, and Oak (especially White Oak) are excellent, very durable choices. They are hard and resistant to dents and scratches, making them ideal for homes with pets and children.

Q5: How do I protect my hardwood floors from scratches?

Use felt pads under all furniture legs, doormats at entrances, and avoid wearing high heels or shoes with hard soles on the floors. Regular sweeping and vacuuming also prevent grit from scratching the surface.

Q6: Can I install hardwood over existing tile?

It depends on the condition of the tile and subfloor. Tile needs to be well-adhered and level. Floating floors are sometimes an option, but it’s crucial to ensure there’s no moisture risk and the tile won’t crack under the weight of the new floor. A glue-down installation might also be possible, but often removing old flooring is the best way to ensure a stable subfloor.