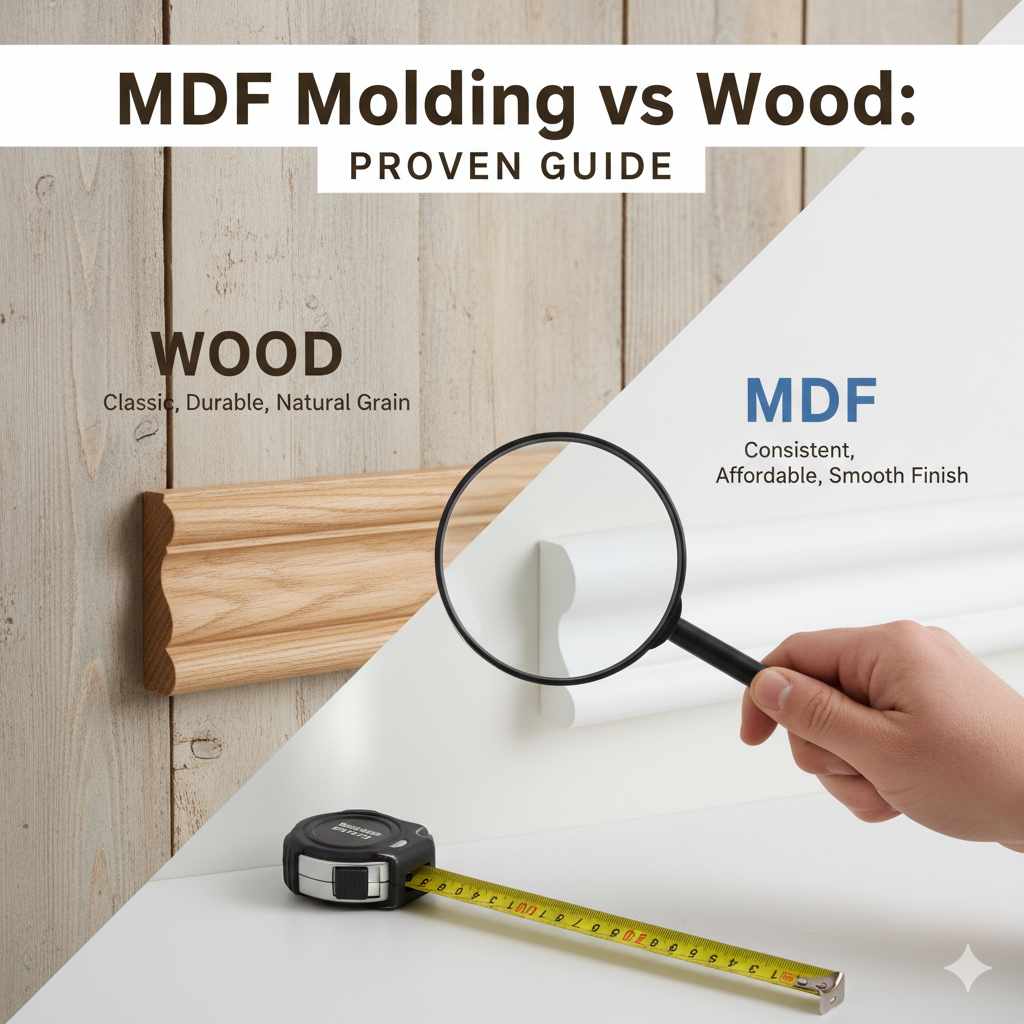

MDF Molding vs Wood: Proven Guide

MDF Molding vs. Wood: The best choice depends on your project’s needs and budget. MDF offers a smooth, paintable surface for budget-friendly interior trim, while solid wood provides superior durability and a natural aesthetic for high-traffic areas or custom finishes. This guide helps you decide.

Choosing the right molding can make a big difference in your home’s appearance and your project’s success. It’s a common question for DIYers and homeowners: should I use MDF molding or solid wood? Both have their strengths, and picking the wrong one can lead to frustration and added costs. Don’t worry, though! We’ll break down everything you need to know. You’ll learn the key differences, understand where each material shines, and feel confident making the best choice for your next DIY adventure. Ready to find the perfect molding? Let’s dive in!

What is MDF Molding?

MDF, which stands for Medium-Density Fiberboard, is an engineered wood product. It’s made by breaking down hardwood and softwood into wood fibers, then combining them with wax and resin binder. This mixture is then heated and pressed into flat sheets. For molding, these sheets are cut and often shaped into various profiles.

MDF molding is known for its incredibly smooth surface, free from the natural knots and grain patterns you’d find in wood. This smoothness makes it an excellent candidate for painting. It’s also generally more affordable than solid wood, which is a big plus for budget-conscious projects. However, because it’s made from wood fibers and adhesives, it’s susceptible to moisture damage and can be more challenging to repair if damaged.

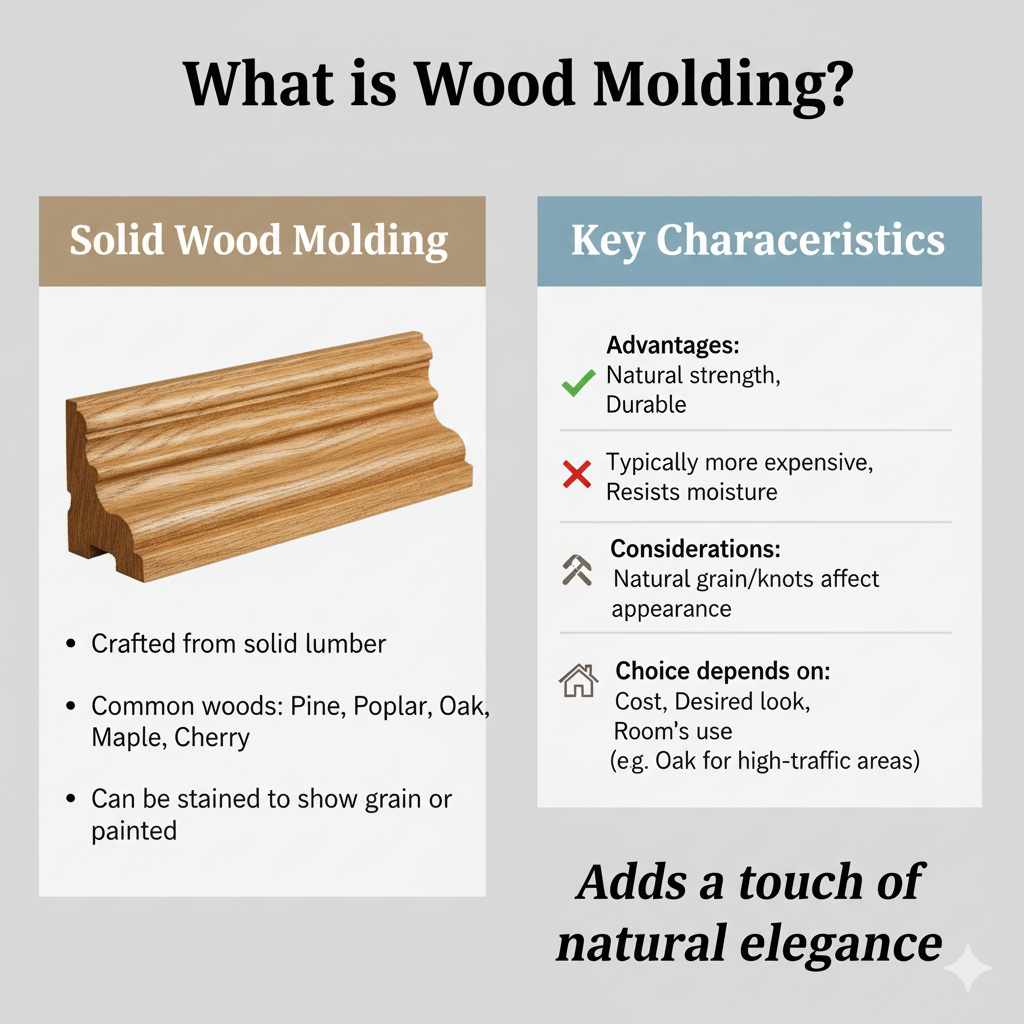

What is Wood Molding?

Wood molding refers to trim crafted from solid lumber. Common woods used for molding include pine, poplar, oak, maple, and cherry, each with its own unique characteristics, grain patterns, and hardness. Solid wood comes in a wide variety of species and can be stained to highlight its natural beauty or painted for a uniform look.

The main advantage of solid wood is its natural strength, durability, and resistance to moisture compared to MDF. It can also be sanded and repaired more easily, and it adds a touch of natural elegance to any space. However, solid wood molding is typically more expensive, and its natural grain and potential for knots can influence its appearance, especially if you’re aiming for a perfectly smooth, painted finish. The choice between specific wood types often comes down to cost, desired look, and the room’s intended use. For instance, harder woods like oak are more durable for high-traffic areas than softer woods like pine.

MDF Molding vs. Wood: Pros and Cons

To help you make a clear decision, let’s look at the advantages and disadvantages of each material side-by-side. This comparison will highlight the key differences that matter for your home projects.

MDF Molding

Pros:

- Cost-Effective: Generally less expensive than solid wood, making it a budget-friendly option for large projects or areas where cost is a primary concern.

- Smooth Surface: Its uniform, knot-free surface is ideal for painting, providing a flawless finish that wood might struggle to achieve without extensive preparation.

- Consistent Profile: MDF is manufactured, ensuring a very consistent shape and size across all pieces, which can simplify installation.

- Easy to Work With: It can be easily cut, shaped, and drilled with standard woodworking tools.

- Environmentally Friendly Options: Some MDF products are made with recycled materials, aligning with sustainable building practices, though emissions from binders can be a concern. For more information on wood product standards, you can refer to resources from the U.S. Environmental Protection Agency (EPA).

Cons:

- Moisture Sensitivity: MDF swells and warps when exposed to moisture, making it unsuitable for bathrooms, kitchens, or basements unless specifically treated or protected.

- Less Durable: It can be more prone to chipping and denting than solid wood, especially on sharp edges.

- Difficult to Repair: Dings and dents are harder to fix seamlessly. Unlike wood, you can’t easily sand out deep damage without potentially compromising the profile.

- Weight: It can be heavier than some types of solid wood, which might affect handling and installation.

- Dust Concerns: Cutting MDF generates fine dust that can be an irritant and requires good ventilation and respiratory protection.

Solid Wood Molding

Pros:

- Durability and Strength: Solid wood is naturally strong and resistant to damage, making it ideal for high-traffic areas.

- Moisture Resistance: While not waterproof, wood holds up better to moderate humidity than MDF. It can also be sealed and finished to improve moisture resistance.

- Repairable: Dents and scratches can often be sanded out and repaired, allowing for a lasting finish.

- Natural Beauty: The natural grain patterns of wood add warmth and character to a room, offering unique aesthetic appeal.

- Stainable and Paintable: Wood can be stained to showcase its natural beauty or painted for a classic look.

- Longevity: A well-maintained wood molding can last for decades, adding value and charm to a home.

Cons:

- Higher Cost: Solid wood molding is generally more expensive than MDF, especially for premium wood species.

- Potential for Imperfections: Natural wood can have knots, variations in grain, and warping, which may require more careful selection and preparation.

- More Difficult to Install: Some hardwoods can be denser, making them harder to cut and requiring sharper tools.

- Expansion and Contraction: Wood can expand and contract with changes in humidity and temperature, which may lead to minor gaps over time if not installed correctly by using proper techniques and fasteners.

- Environmental Impact: Sourcing sustainable wood is important, as deforestation can be an issue. Look for certifications like FSC (Forest Stewardship Council) to ensure responsible sourcing. Detailed information on wood sourcing and sustainability can be found on the Forest Stewardship Council (FSC) website.

Feature Comparison: MDF Molding vs. Wood

To make the choice even clearer, here’s a table that summarizes the key differences:

| Feature | MDF Molding | Solid Wood Molding |

|---|---|---|

| Cost | Lower | Higher |

| Durability | Lower (prone to chipping/denting) | Higher (resistant to damage) |

| Moisture Resistance | Very Poor (swells/warps) | Moderate (can be enhanced with finishes) |

| Surface Finish (Ideal for Paint) | Excellent (smooth, no grain/knots) | Good (may require priming/sanding for perfect smoothness) |

| Surface Finish (Ideal for Stain) | Poor (cannot be stained naturally) | Excellent (reveals natural grain) |

| Ease of Installation | Easy to cut/shape, but can be dense | Varies by wood type; can be dense and harder to cut |

| Repairability | Difficult for significant damage | Easier (sanding, filling) |

| Weight | Can be heavy | Varies by wood type; generally lighter than dense MDF |

| Aesthetic Appeal | Uniform, smooth, modern (when painted) | Natural, warm, classic (grain variations) |

When to Choose MDF Molding

MDF molding is an excellent choice for several scenarios, especially when budget and a smooth, paintable finish are top priorities.

Ideal Applications for MDF Molding:

- Interior Trim for Painting: If you plan to paint your molding a solid color, MDF offers a superior surface. Its smoothness means less sanding and priming are needed compared to wood with visible grain. Think baseboards, door casings, and window trim in bedrooms, living rooms, and hallways where moisture is minimal.

- Budget-Friendly Renovations: When you need to refresh multiple rooms or cover a large area, the cost savings of MDF can be significant. It allows you to achieve a polished look without breaking the bank.

- Crown Molding in Dry Areas: For decorative crown molding in main living areas, MDF can be a great choice. Its ability to hold intricate profiles makes it ideal for adding architectural detail.

- Temporary or Rental Properties: If you’re looking for an attractive, affordable update that doesn’t require long-term investment in premium materials, MDF is a practical option.

- Crafting Projects: MDF sheets can be cut into various shapes and sizes, making them suitable for DIY craft projects, shelving, or decorative panels where a smooth, paintable surface is desired. Websites like Popular Mechanics often showcase creative uses for MDF.

When to Choose Wood Molding

Solid wood molding is the go-to choice when durability, natural beauty, and longevity are paramount.

Ideal Applications for Wood Molding:

- High-Traffic Areas: In entryways, busy hallways, or areas with frequent activity, the durability of solid wood can prevent nicks and damage. Baseboards in these areas are particularly susceptible to bumps from vacuum cleaners or furniture.

- Moisture-Prone Areas: While not waterproof, hardwood molding is a far better choice than MDF for kitchens, bathrooms, laundry rooms, or basements. Proper sealing and finishing will further protect it from humidity.

- Stained Finishes: If you love the natural look of wood grain and want to stain your molding to match existing furniture or floors, solid wood is the only option. This is common for rustic, traditional, or high-end interior design styles.

- Challenging Installs or Repairs: For angled walls, complex corners, or areas that might need future repair, the malleability of wood is a significant advantage. It can be more forgiving during installation and easier to fix if damaged.

- Adding Long-Term Value: Solid wood molding adds a sense of quality and permanence to a home. It’s an investment that can enhance property value.

- Outdoor or Semi-Outdoor Applications: While this guide focuses on interior molding, it’s worth noting that certain types of treated or rot-resistant woods are used for exterior trim and have no comparable MDF counterpart.

Installation Considerations: MDF vs. Wood

The installation process for MDF and wood molding shares many similarities, but there are a few key differences to keep in mind. Knowing these will help ensure a smooth and successful project.

Cutting and Shaping:

- MDF: Cuts cleanly with sharp blades, but produces a fine dust that requires good ventilation and a dust mask. Overheating a blade can cause it to melt and adhere to the blade, so avoid dull blades. For intricate profiles, MDF can hold detail very well.

- Wood: The ease of cutting varies greatly by wood species. Softer woods like pine are easy to cut but can splinter. Hardwoods like oak require sharper blades and more force. Wood dust is also a concern, but it’s generally coarser than MDF dust.

Joining and Fastening:

- MDF: Nails can cause MDF to split or crumble. Using a finer nail or staples, and applying glue generously, is recommended. Pre-drilling pilot holes for screws is often necessary, especially near the edges, to prevent the material from cracking. Specialist adhesives designed for MDF can provide a stronger bond.

- Wood: Generally accepts nails and screws well. For hardwoods, pre-drilling is highly recommended to prevent splitting, especially when working near the ends of the board. Wood glue also forms a strong bond for joints.

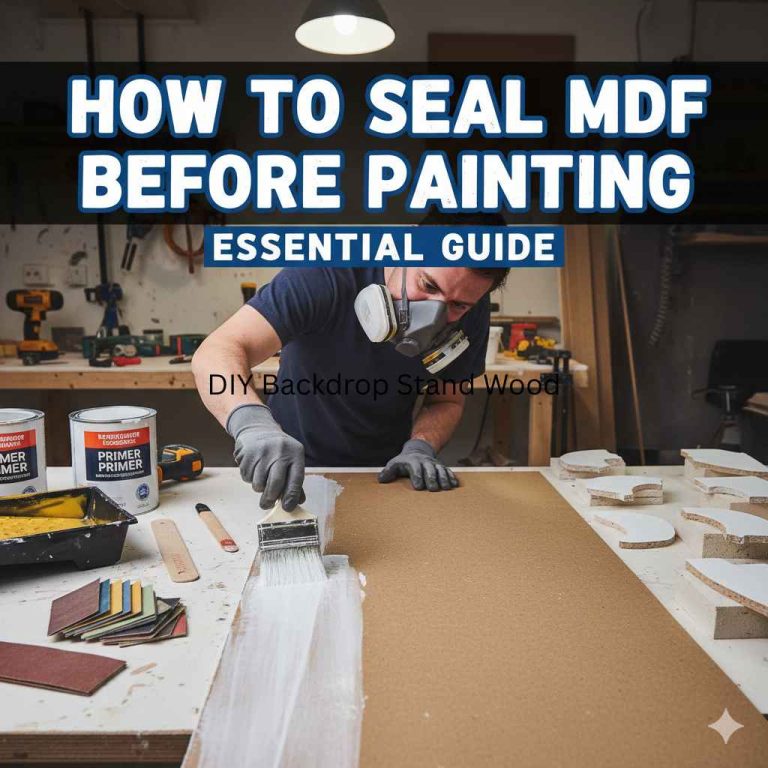

Finishing:

- MDF: Requires a good quality primer, often two coats, to seal the porous surface. Once primed, it takes paint beautifully for a smooth, uniform finish. Any sanding on MDF should be done with a mask to avoid inhaling fine particles.

- Wood: Primer is usually recommended, especially for woods with prominent grain or for achieving a smooth, solid color. Staining requires careful preparation, including sanding with progressively finer grits. You can find excellent guides on wood finishing techniques from organizations like Wood Magazine.

Repairing Damage:

- MDF: Minor dents can be filled with wood filler or spackle and sanded smooth. However, deeper gouges or swelling from moisture are very difficult, if not impossible, to repair seamlessly. Replacement of the damaged section is often the best solution.

- Wood: Dents can often be steamed out. Deeper damage can be filled with wood filler or epoxy, then sanded and refinished to blend in. Knots can sometimes be a point of failure or can be filled for a smooth finish.

Cost Comparison: MDF Molding vs. Wood

The price difference is often the most significant factor for homeowners and DIYers. Let’s look at a typical comparison:

Entry-Level Baseboards (per linear foot):

- MDF:

- Basic profiles: $0.50 – $1.50

- More intricate profiles: $1.00 – $3.00

- Pine (a common, affordable wood):

- Basic profiles: $0.80 – $2.50

- More intricate profiles: $1.50 – $5.00

- Hardwoods (e.g., Oak, Maple):

- Basic profiles: $2.00 – $6.00

- More intricate profiles: $3.00 – $10.00+

This table clearly shows that even basic wood moldings can be more expensive than comparable MDF options. However, the cost of wood can increase significantly with higher-quality species and more complex designs. When calculating costs, remember to factor in primer, paint, stain, fasteners, and the potential for more waste with natural wood due to knots or imperfect boards.

Frequently Asked Questions: MDF Molding vs. Wood

Here are some common questions beginners have about choosing between MDF and wood molding.

Can I use MDF molding in a bathroom?

Generally, no. Standard MDF is highly susceptible to moisture and will swell, warp, and disintegrate if it gets wet. Some manufacturers offer moisture-resistant MDF, but it’s still not ideal for areas with direct or prolonged exposure to water. Solid wood, especially when properly finished and sealed, is a much better choice for bathrooms.

Is wood molding more durable than MDF?

Yes, solid wood molding is generally more durable and resilient than MDF. It’s less prone to chipping and denting, and it can withstand minor impacts better. While MDF can chip, especially on its edges, wood is more forgiving and can often be repaired.

Can I stain MDF molding?

No, you cannot stain MDF molding in the way you stain natural wood. MDF is made from wood fibers and resins, so it lacks the natural grain patterns that absorb stain and create a wood look. MDF is designed to be painted, not stained.

Which is easier to install, MDF or wood?

Both can be easy to install, but there are nuances. MDF is often more uniform and easier to cut precisely with power tools. However, it can be heavier and more prone to chipping if not handled carefully. Wood can be lighter or heavier depending on the species, and its natural variations might require more careful selection and cutting. For beginners, MDF’s smoothness and consistency can make painting simpler.