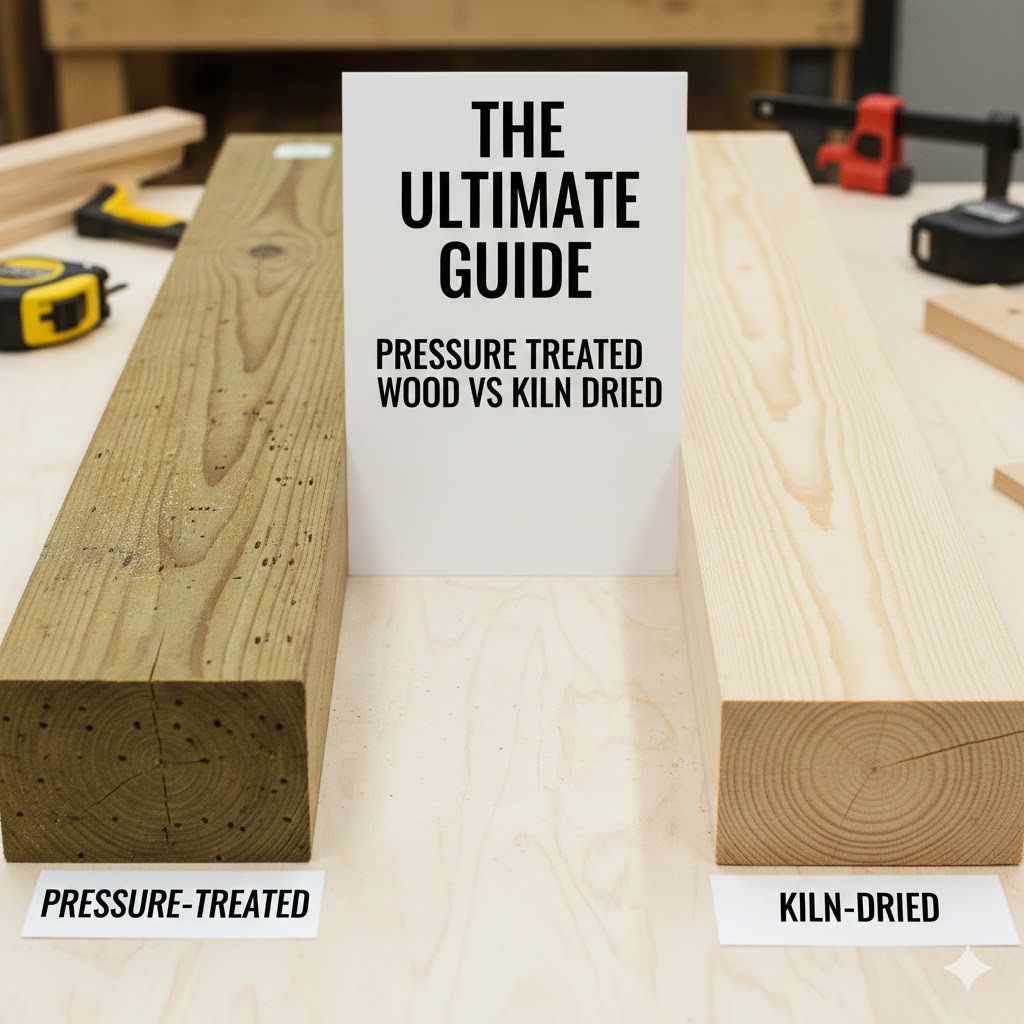

Pressure Treated Wood Vs Kiln Dried: The Ultimate Guide

Pressure-treated wood is best for outdoor projects like decks and fences because it resists rot, decay, and insects. Kiln-dried wood is ideal for indoor projects like furniture and cabinets because it is stable, straight, and ready to paint or stain. Choose pressure-treated for durability outside and kiln-dried for craftsmanship inside.

Hi there, I’m Md Meraj. Walking into a lumberyard can feel overwhelming. You see stacks of wood, and two common labels pop up: “Pressure-Treated” and “Kiln-Dried.” They look similar, but choosing the wrong one can ruin your project. It’s a common mistake many beginners make, but don’t you worry. I’m here to clear up the confusion and help you make the right choice with confidence. Picking the right wood is simple once you know what each one is for. In this guide, I’ll walk you through everything, making your next project a success right from the very start.

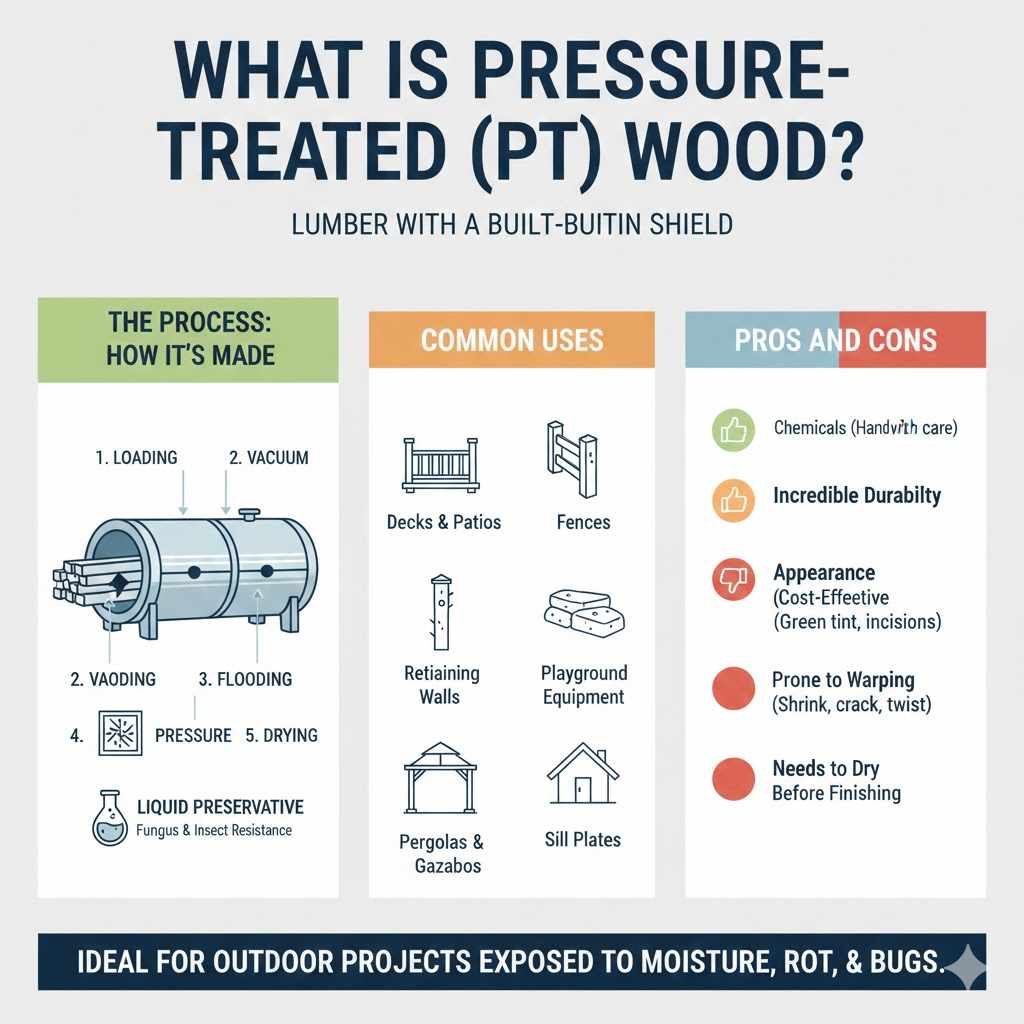

What Is Pressure-Treated (PT) Wood?

Let’s start with the workhorse of outdoor projects: pressure-treated wood. Think of it as lumber with a built-in shield.

The Process: How It’s Made

Pressure-treated wood starts as regular lumber, usually a softwood like Southern Yellow Pine. The magic happens inside a large, sealed tank called a retort. Here’s a simple breakdown of the process:

- Loading: The lumber is stacked and loaded into the retort.

- Vacuum: All the air is sucked out of the tank, which also pulls air out from the wood’s cellular structure.

- Flooding: The tank is filled with a liquid preservative solution. These are water-based solutions containing chemicals that fight off fungus and insects.

- Pressure: The tank is pressurized, which forces the preservative deep into the wood fibers. It’s like using a sponge—the vacuum opens it up, and the pressure pushes the liquid all the way in.

- Drying: After the treatment, the wood is removed. It is often very wet and heavy and needs time to dry before it’s ready to be used in a project.

This process is what gives the wood its incredible resistance to the elements that would destroy untreated wood in just a few years.

Common Uses for Pressure-Treated Wood

Because it stands up so well to moisture, rot, and bugs, you’ll find pressure-treated wood used almost exclusively for outdoor projects. If the wood will touch the ground or be exposed to rain and snow, this is your go-to choice.

Popular projects include:

- Decks and patios

- Fences and fence posts

- Retaining walls

- Playground equipment and swing sets

- Pergolas and gazebos

- Sill plates (the bottom-most piece of wood in a house frame that sits on the foundation)

Pros and Cons of Pressure-Treated Wood

Like any material, it has its strengths and weaknesses. Here’s a quick look:

Pros:

- Incredible Durability: It is highly resistant to rot, fungal decay, and termites. This is its number one benefit.

- Cost-Effective: It is much cheaper than naturally rot-resistant woods like cedar, redwood, or tropical hardwoods.

- Widely Available: You can find it at any home improvement store or lumberyard.

- Long Lifespan: A properly maintained pressure-treated structure can last for decades.

Cons:

- Chemicals: The preservatives can be a concern for some people. Modern treatments are safer than older versions (like CCA), but you still need to handle them with care.

- Appearance: It often has a greenish or brownish tint and can have small incisions on the surface from the treatment process. It’s not typically considered a “finish-grade” wood for fine furniture.

- Prone to Warping: Because it’s saturated with liquid during treatment, it can shrink, crack, warp, or twist as it dries if not handled properly.

- Needs to Dry Before Finishing: You can’t paint or stain it right away. You have to wait for the wood to dry out, which can take weeks or even months.

What Is Kiln-Dried (KD) Wood?

Now, let’s head indoors and talk about kiln-dried wood. If pressure-treated wood is about brute strength and survival, kiln-dried wood is all about stability and precision.

The Process: How It’s Made

All wood contains water. Freshly cut “green” wood is very heavy and unstable. If you built something with it, it would shrink and warp dramatically as it dried. Kiln-drying is a process to speed up and control the drying process.

- Stacking: Lumber is carefully stacked in a large oven, or “kiln,” with spacers between the boards to allow for even airflow.

- Controlled Heating and Humidity: The temperature and humidity inside the kiln are precisely controlled. This process gently removes moisture from the wood at a consistent rate, from the inside out.

- Final Moisture Content: The goal is to bring the wood’s moisture content down to a specific level, typically between 6% and 12%, which is ideal for interior environments. This makes the wood far more stable than air-dried lumber.

This careful process prevents common drying defects like cracking and twisting, resulting in straight, stable, and reliable boards.

Common Uses for Kiln-Dried Wood

Because of its stability and clean appearance, kiln-dried wood is the standard for almost all indoor applications.

Typical projects include:

- Furniture making (tables, chairs, bookcases)

- Cabinetry and vanities

- Indoor framing (studs for walls are typically kiln-dried)

- Hardwood flooring

- Interior trim, molding, and millwork

- Shelving

Pros and Cons of Kiln-Dried Wood

Let’s weigh the benefits and drawbacks of this versatile material.

Pros:

- Exceptional Stability: It is far less likely to warp, shrink, or twist than air-dried or green lumber. This is crucial for projects that require tight joints, like furniture.

- Ready to Use: You can work with it and apply finishes like paint, stain, or clear coats immediately.

- Beautiful Appearance: It’s clean, free of chemical tints, and brings out the natural grain and color of the wood.

- Stronger and Lighter: Removing water makes the wood lighter and increases its strength-to-weight ratio.

- Kills Insects and Fungi: The high heat of the kiln kills any insects, eggs, or fungal spores that might be in the wood.

Cons:

- Not for Outdoor Use (Without Protection): Kiln-dried wood has no natural or chemical resistance to rot or insects. It will decay quickly if exposed to moisture.

- Higher Cost: The kiln-drying process adds to the cost of the lumber, making it more expensive than untreated “green” lumber of the same species.

- Can Be Brittle: Over-drying can sometimes make the wood a bit more brittle than air-dried wood, but this is rarely an issue for most projects.

Pressure Treated Wood Vs Kiln Dried: A Head-to-Head Comparison

Feeling clearer already? Great! Let’s put them side-by-side to make the differences crystal clear. This table is your ultimate cheat sheet for choosing the right wood.

| Feature | Pressure-Treated Wood | Kiln-Dried Wood |

|---|---|---|

| Best Use | Outdoors, ground contact, high-moisture areas (decks, fences, retaining walls). | Indoors, controlled environments (furniture, cabinets, flooring, trim). |

| Durability | Extremely resistant to rot, fungus, and insects. Built for harsh weather. | Not naturally durable against weather or pests. Susceptible to rot if it gets wet. |

| Stability | Less stable. Prone to shrinking, warping, and cracking as it dries. | Very stable. Minimal movement once acclimated to its environment. |

| Cost | Generally less expensive than kiln-dried hardwoods or naturally rot-resistant woods like cedar. | Cost varies by species. Softwoods (pine, fir) are affordable. Hardwoods (oak, maple) are more expensive. |

| Appearance | Often has a green or brown tint. May have small incision marks. Utilitarian look. | Clean, natural wood appearance. Highlights the grain and true color of the species. |

| Finishing (Painting/Staining) | Must be completely dry before finishing, which can take weeks or months. | Ready to be finished immediately. Accepts paint and stain very well. |

| Safety & Handling | Requires gloves and dust mask when cutting. Sawdust and scraps should not be burned. | Standard woodworking safety (dust mask) applies. Sawdust is non-toxic. |

When You Absolutely Should Choose Pressure-Treated Wood

The golden rule is simple: If your project lives outside, use pressure-treated wood. It’s not just a suggestion; it’s essential for the safety and longevity of your work.

Here are scenarios where pressure-treated wood is the only right answer:

- Deck Framing: The entire support structure of a deck—the posts, beams, and joists—must be pressure-treated. These parts are close to the ground and constantly exposed to moisture.

- Fence Posts: Any part of a fence that goes into the ground will rot in a year or two if it’s not pressure-treated.

- Retaining Walls: These structures are in constant contact with damp soil, creating the perfect environment for decay.

- Garden Bed Frames: For raised garden beds, pressure-treated lumber provides a long-lasting frame. (More on safety in the FAQ below!)

- Sill Plates in Construction: The first piece of lumber that connects a house frame to its concrete foundation must be pressure-treated to create a barrier against moisture wicking up from the concrete.

A Quick Word on Safety

Working with pressure-treated wood is perfectly safe if you follow a few simple rules. The chemicals used today are much safer than older formulations, but it’s always best to be cautious.

- Wear Gloves: Avoid splinters, which can get chemicals into your skin.

- Wear a Dust Mask: Always wear a mask when cutting or sanding to avoid inhaling the treated sawdust.

- Wash Up: Wash your hands thoroughly after handling the wood, especially before eating.

- Never Burn It: Never, ever burn pressure-treated wood scraps. Burning releases the chemicals into the air in a toxic smoke. Dispose of scraps with your regular construction trash.

For more detailed information, the U.S. Environmental Protection Agency (EPA) provides comprehensive guidelines on handling treated wood safely.

When Kiln-Dried Wood is Your Best Friend

If your project is for the inside of your home, then kiln-dried wood is your champion. Its stability is non-negotiable for creating beautiful, long-lasting indoor pieces.

Choose kiln-dried wood for:

- Fine Furniture: A dining table made from wood that isn’t properly dried will warp and crack as it adjusts to your home’s humidity, ruining all your hard work. Kiln-dried wood prevents this.

- Kitchen Cabinets: Cabinet doors need to stay flat and square to open and close correctly. Only stable, kiln-dried wood can guarantee this.

- Built-in Bookcases and Shelving: These projects require precise measurements and straight boards that won’t sag or twist over time.

- Hardwood Flooring: Flooring is milled to tight tolerances. Kiln-dried wood ensures the boards fit together perfectly and stay flat on your floor.

- Any Project Requiring a Flawless Finish: Because it’s ready to accept paint or stain right away, kiln-dried wood gives you a smoother, more professional-looking result without the long wait.

Can You Use Pressure-Treated Wood Indoors?

This is a common question, and my answer is almost always a firm no. It’s not designed for indoor use. The preservatives can off-gas, and there is no benefit to using it inside where there are no threats of rot or termites. Stick to clean, safe, kiln-dried wood for anything inside your living space.

Can You Use Kiln-Dried Wood Outdoors?

Technically, yes, but you must be prepared to protect it fanatically. If you want to use a beautiful piece of kiln-dried oak for an outdoor table, you must coat it with multiple layers of a high-quality exterior varnish or sealant. You’ll need to cover all surfaces—top, bottom, and all edges—to completely encapsulate it from moisture. Even then, it will require regular maintenance to re-seal it every year or two. For beginners, it’s much safer and easier to just use pressure-treated wood for outdoor projects.

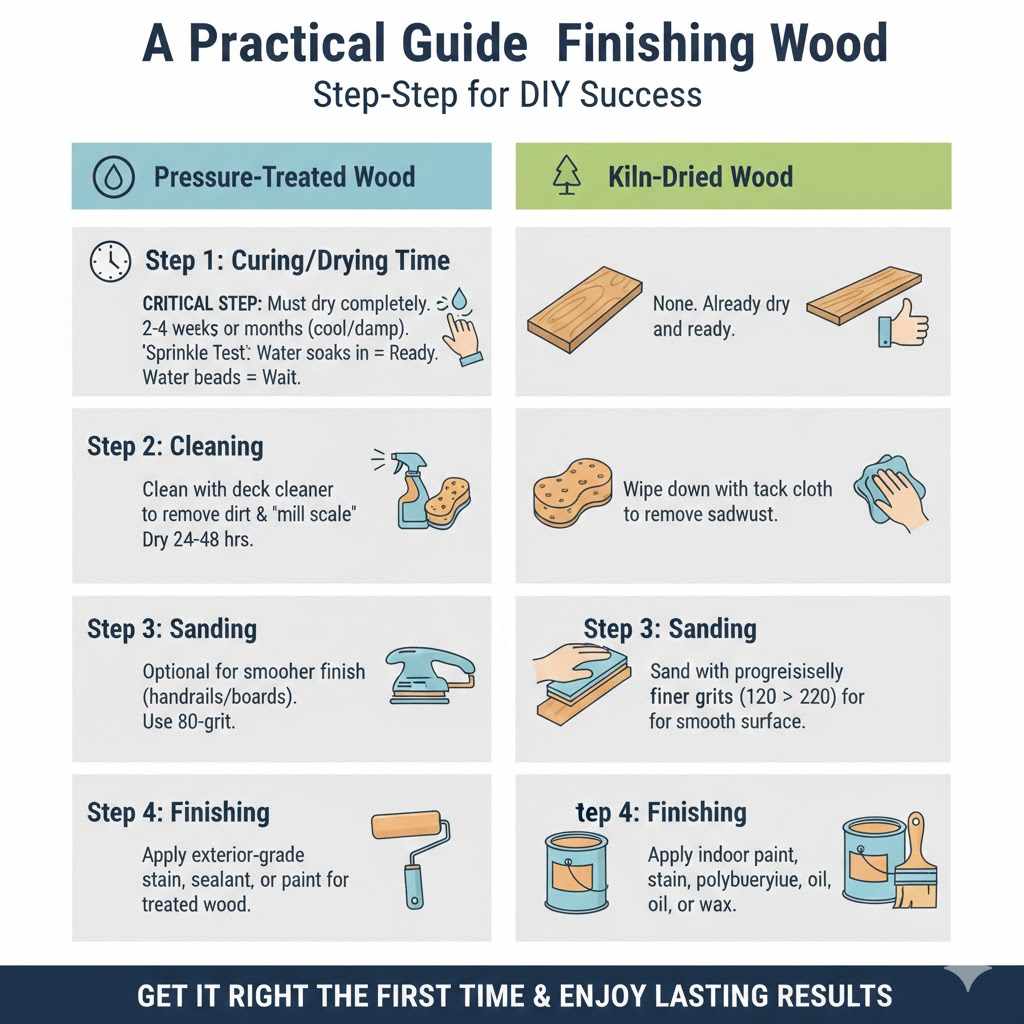

A Practical Guide to Painting and Staining

Finishing is where many DIYers get tripped up, especially with pressure-treated wood. The preparation is totally different for each type. Here’s a simple guide to get it right.

| Step | Pressure-Treated Wood | Kiln-Dried Wood |

|---|---|---|

| 1. Curing/Drying Time | CRITICAL STEP: Must dry completely. Can take 2-4 weeks in hot, dry weather or several months in cooler, damp weather. Use the “sprinkle test”: sprinkle water on it. If it soaks in, it’s ready. If it beads up, wait longer. | None. It’s already dry and ready for the next step. |

| 2. Cleaning | Clean with a deck cleaner to remove dirt and “mill scale,” a glossy film from the planing process. Let it dry again for 24-48 hours. | Wipe down with a tack cloth or a clean rag to remove any sawdust or dust. |

| 3. Sanding | Optional but recommended for a smoother finish, especially on handrails or deck boards. Use 80-grit sandpaper. | Sand with progressively finer grits (e.g., 120-grit then 220-grit) for a glass-smooth surface. |

| 4. Finishing | Apply an exterior-grade stain, sealant, or paint designed for treated wood. Follow the product’s instructions. | Apply your choice of indoor paint, stain, polyurethane, oil, or wax. The wood will absorb it evenly for a beautiful finish. |

Frequently Asked Questions (FAQ)

1. How can I tell if wood is pressure-treated?

There are a few easy ways to tell. First, look for a greenish or brownish tint, although some newer treatments are more subtle. Second, check the surface for small, evenly spaced slits—these are incision marks to help the preservatives penetrate deeper. Finally, look at the end of the board for a staple or tag that provides information about the chemical used and the retention level (e.g., “Ground Contact”).

2. Is pressure-treated wood safe for vegetable garden beds?

This is a hot topic! Modern pressure-treated wood no longer uses arsenic (CCA) and is considered safe by the U.S. Forest Service for agricultural use. The chemicals used today bind very tightly to the wood fibers. However, if you are still concerned, you can line the inside of the garden bed with a thick plastic sheeting to create a barrier between the wood and the soil. Alternatively, naturally rot-resistant woods like cedar or redwood are great chemical-free options.

3. Why does my new pressure-treated wood feel wet and heavy?

That’s completely normal! It’s heavy because it is still saturated with the water-based preservative solution from the treatment process. This is why it’s so important to let the wood dry out thoroughly before you use it for things like deck boards or try to paint or stain it. Stacking it with spacers in a dry, well-ventilated area will help it dry faster.

4. How long does pressure-treated wood need to dry before I can stain it?

There is no exact answer because it depends on your climate, humidity, and sun exposure. It can range from a few weeks to a few months. The best method is the “sprinkle test.” Sprinkle a few drops of water onto the wood. If the water beads up on the surface, the wood is still too wet. If it soaks in quickly, it’s dry enough to absorb the stain or sealer properly.

5. Can I cut pressure-treated wood?

Yes, absolutely. Just remember to wear your safety gear—gloves, eye protection, and a dust mask. After you make a cut, the exposed end is untreated wood. You must apply a wood preservative (available in a can at hardware stores) to the cut ends to protect them from rot and insects. This is a crucial step that many people forget!

6. Which is stronger: pressure-treated or kiln-dried wood?

This is a great question that often confuses people. The strength of a piece of wood comes from the species (e.g., pine vs. oak) and its grade, not the treatment. The pressure-treating process does not add structural strength; it adds durability against rot and insects. A kiln-dried Douglas Fir board is structurally stronger than a pressure-treated Southern Yellow Pine board of the same size, but the pine will last much longer outdoors.

Your Next Project Starts with the Right Choice

And there you have it! The mystery is solved. The choice between pressure-treated and kiln-dried wood isn’t complicated once you understand their purpose.

Think of it this way:

- Building something for the great outdoors that needs to battle rain, soil, and bugs? Grab pressure-treated wood.

- Crafting a beautiful piece of furniture or anything for the cozy indoors that needs to be stable and look great? Kiln-dried wood is your answer.

By making the right choice at the lumberyard, you’re setting your project up for success before you even make the first cut. You’re ensuring that your outdoor deck won’t rot away and your indoor table won’t warp into a pretzel. Now you have the knowledge and confidence to walk into any home center and select the perfect boards for the job. Go ahead and start planning that next project—you’ve got this!