What Are Portable Band Saws Used For: Genius Solutions

Portable band saws are incredibly versatile tools perfect for cutting various materials like metal, wood, and pipe with precision and ease. They’re ideal for DIYers, contractors, and hobbyists needing a compact, powerful saw for on-site or workshop use, offering cleaner cuts and greater control than many alternatives for specific tasks.

Struggling to make clean, precise cuts on different materials? You’re not alone! Many DIY enthusiasts and even seasoned pros find that traditional saws can be bulky, messy, or just not the right tool for the job. This is where a portable band saw shines. Don’t let the thought of a new tool intimidate you. We’re going to break down exactly what these handy saws are used for and how they can make your projects simpler, safer, and much more satisfying.

Think of a portable band saw as your go-to solution for tackling challenging cuts without a fuss. Whether you’re working in tight spaces, need to bring the saw to the material, or simply want a cleaner finish, a portable band saw has your back. We’ll explore its many uses with clear, easy-to-understand examples, so you’ll be ready to tackle your next project with confidence.

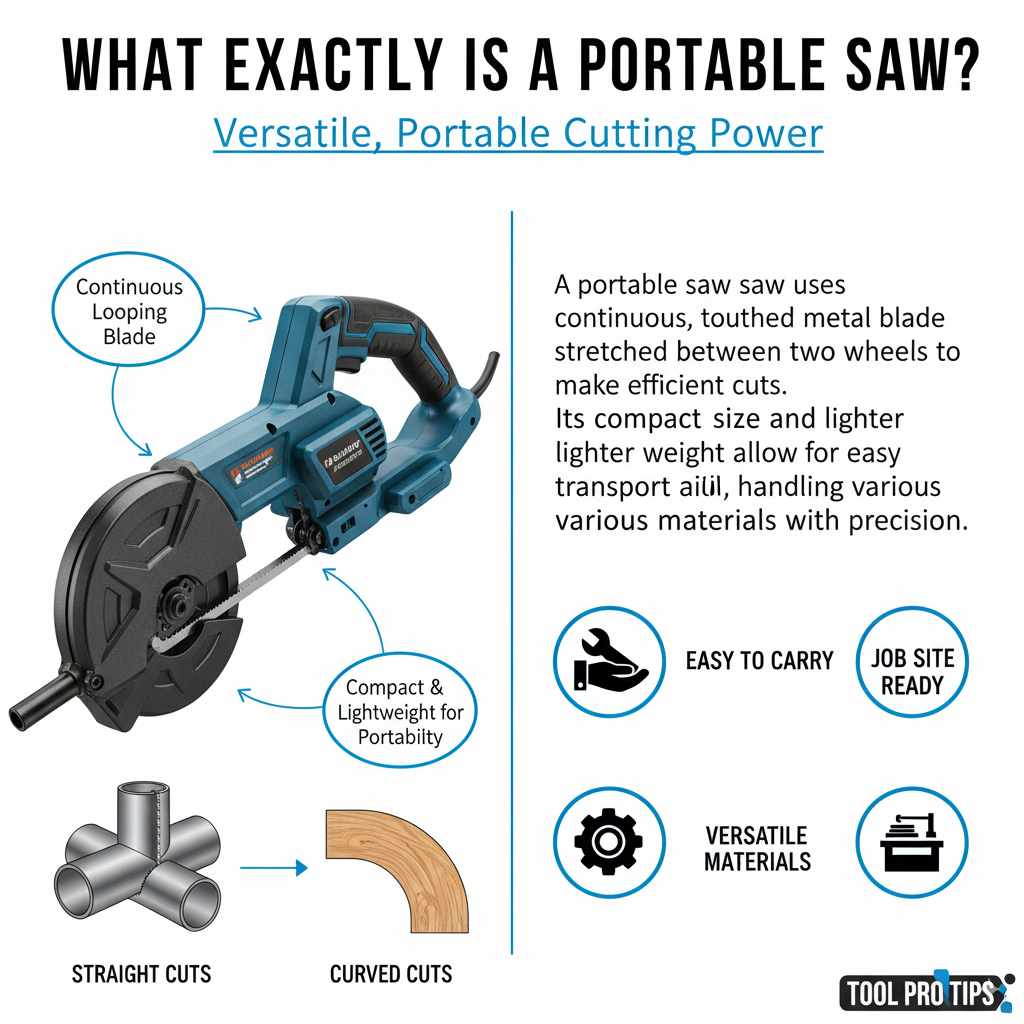

What Exactly is a Portable Band Saw?

At its heart, a portable band saw is a power tool that uses a continuous, looping blade stretched between two wheels to make cuts. What makes it “portable” is its relatively compact size and lighter weight compared to its stationary counterparts. This design allows you to easily carry it to a job site, maneuver it around your workshop, or even use it overhead. The blade, which is a thin band of metal with teeth along one edge, moves at a consistent speed, creating a smooth and efficient cutting action.

This type of saw is known for its versatility. Unlike some saws that are designed for very specific tasks, a portable band saw can handle a surprising range of materials and applications. Its ability to make both straight and curved cuts, coupled with its portability, makes it an invaluable tool for many different types of work.

The Genius Uses of Portable Band Saws

Now for the exciting part! What can you actually do with a portable band saw? Prepare to be impressed by its versatility. These saws aren’t just for one or two specific jobs; they can be game-changers across many different scenarios.

Cutting Metal with Precision

This is perhaps one of the most common and celebrated uses for portable band saws. Metal fabrication, plumbing, and even automotive repair often require cutting various metal stock. Portable band saws excel here for several key reasons:

- Clean Cuts: They produce significantly cleaner cuts on metal compared to abrasive saws or even angle grinders. This means less secondary finishing work is needed, saving you time and effort.

- Minimal Sparks: Unlike abrasive cutting methods that generate a lot of heat and sparks, band saws create fewer sparks, making them a safer option in environments where flammable materials might be present. This is a huge advantage for safety-conscious individuals.

- Versatility in Metal: You can cut through steel pipes, rebar, conduit, angle iron, threaded rods, and even some aluminum stock with the right blade.

- Controlled Operation: The continuous blade action offers more control, allowing for more accurate cuts on metal workpieces.

For example, a plumber might use a portable band saw to quickly and cleanly cut copper or steel pipes on a job site, avoiding the mess and heat associated with other cutting methods. A metalworker could use it to size aluminum extrusions for a project, getting a perfect fit every time.

Woodworking Wonders

While often associated with metal, portable band saws are also highly capable woodworking tools, especially for specific types of cuts or when working with larger stock.

- Resawing Lumber: For those looking to split thick lumber into thinner boards, a portable band saw can perform resawing. This is a technique where you cut a board lengthwise along its grain. While larger stationary band saws are typically preferred for this, a powerful portable unit can handle smaller stock or occasional resawing needs, offering a more accessible option for DIYers.

- Rough Shaping and Sculpting: For projects requiring curved or irregular shapes, a band saw is fantastic. You can cut out intricate patterns or rough out the basic shape of a piece before moving to finer tools.

- Cutting Large Stock: If you have a particularly thick or wide piece of wood that won’t fit on a miter saw or table saw, a portable band saw can often manage it.

- Trimming and Notching: Quickly trim excess material or cut notches for joinery.

Imagine needing to cut a large, curved wooden leg for a custom piece of furniture. A portable band saw makes these kinds of organic shapes much more manageable than trying to do them with a jigsaw in tight spaces.

Plumbing and Electrical Work

The portability and clean-cutting nature of portable band saws make them ideal for tradespeople. In plumbing, cutting through copper, PVC, PEX, or steel pipes becomes quick and easy. For electricians, cutting through metal conduit or even some types of plastic pipes is no match for a portable band saw.

Consider a contractor working on a renovation. They might need to cut multiple lengths of PVC pipe for a new plumbing run or trim metal studs on-site. A portable band saw allows them to do this efficiently without needing to transport large stationary equipment or deal with the mess of other cutting methods.

Demolition and Renovation

When it comes to tearing down or modifying existing structures, a portable band saw can be surprisingly useful. It can efficiently cut through metal pipes, conduits, or even light structural metal that might be in the way during a renovation project. Its controlled cutting action can sometimes be more precise than a reciprocating saw, allowing for selective removal of materials.

For instance, if you need to remove an old metal heating duct in a wall, a portable band saw can cut through it with less mess and dust than other demolition tools might create.

DIY Projects and Hobbyists

For the dedicated DIYer or hobbyist, a portable band saw opens up a world of possibilities. It’s a tool that bridges the gap between basic hand tools and more complex stationary machinery.

- Custom Shelving and Furniture: Cutting metal brackets for shelves or intricately shaped wooden components for small furniture pieces.

- Crafting Metal Art: For those who enjoy creating metal sculptures or decorative items, a portable band saw is essential for shaping and cutting pieces.

- Small-Scale Construction: Building dog houses, backyard sheds, or other home projects that involve cutting various stock materials.

- Repair Work: Quickly cutting replacement parts or modifying existing items.

A hobbyist building a custom workbench might use the band saw to cut metal legs to precise lengths or trim wooden tops. The ability to make these cuts accurately and cleanly ensures a professional-looking result.

Key Features to Look For

When choosing a portable band saw, several features can enhance its usability and performance for beginners. Understanding these will help you pick the right tool for your needs.

Blade Speed and Control

Variable speed control is a significant advantage. Different materials benefit from different blade speeds. Metal typically requires slower speeds to prevent overheating and blade damage, while wood can be cut effectively at higher speeds.

Cutting Capacity

Pay attention to the saw’s cutting capacity. This is usually expressed as a maximum depth or throat capacity (e.g., 3.5 inches deep, 4×4-inch capacity). Ensure it’s sufficient for the types of materials and sizes you plan to cut.

Blade Type and Tension

Different blades are designed for different materials (metal, wood, general purpose). Look for a saw that accepts a good variety of blade types and makes blade tensioning straightforward. Proper tension is crucial for accurate cuts and blade longevity.

Weight and Ergonomics

Since it’s a portable tool, weight is important. A lighter saw is easier to maneuver, especially when working overhead or in tight spaces. Good ergonomics, including comfortable grip design and well-placed controls, also contribute to safer and more efficient operation.

Power Source

Portable band saws are typically corded or cordless (battery-powered). Cordless models offer maximum portability but can be limited by battery life. Corded models provide consistent power but require a nearby outlet.

Safety First: Using Your Portable Band Saw Responsibly

Safety is paramount with any power tool, and portable band saws are no exception. Always follow these guidelines to ensure a safe working environment:

- Read the Manual: Before even plugging it in, thoroughly read your tool’s owner’s manual. It contains specific safety instructions and operating procedures for your model.

- Wear Safety Gear: Always wear safety glasses or a full face shield to protect your eyes from flying debris. Hearing protection is also recommended.

- Use the Right Blade: Ensure you have the correct blade installed for the material you are cutting. A blade designed for metal will perform poorly and potentially unsafely on wood, and vice versa. For more on blade selection and safety, the Occupational Safety and Health Administration (OSHA) offers guidance on machine guarding and safe tool operation.

- Secure Your Workpiece: Always clamp down the material you are cutting. This prevents it from shifting during the cut, which could lead to injury or a bad cut.

- Proper Grip: Maintain a firm grip on the saw, using both hands if possible. Keep your body balanced and avoid overreaching.

- Keep Hands Clear: Never place your hands or fingers in the path of the blade.

- Check the Saw: Before each use, inspect the blade for damage, ensure it’s properly tensioned, and check that the guard is in place and functioning correctly.

- Be Aware of Your Surroundings: Ensure the area is clear of obstructions and that you have adequate lighting.

Remember, a little caution goes a long way in preventing accidents and ensuring your projects are completed successfully and safely.

Portable Band Saw vs. Other Saws

It’s helpful to understand where a portable band saw fits in your toolkit compared to other common saws:

| Saw Type | Best For | Portable Band Saw Advantages | Portable Band Saw Disadvantages |

|---|---|---|---|

| Reciprocating Saw (Sawzall) | Demolition, quick rough cuts on various materials. | Cleaner cuts, more controlled, less vibration. | Slower for demolition, can be less aggressive. |

| Circular Saw | Making straight cuts in sheet goods (plywood, OSB) and lumber. | Cuts thicker materials, better for metal, can cut curves. | Less portable for some applications, can be dustier. |

| Angle Grinder with Cutting Disc | Cutting metal, masonry, quick stock removal. | Significantly fewer sparks, cleaner cuts, more control. | Not ideal for wood, very dusty/sparky for metal. |

| Jigsaw | Intricate curves, cutting sheet goods, wood. | Better for thicker materials, handles metal more easily. | Not as good for very fine curves, can’t cut thick metal. |

As you can see, the portable band saw fills a unique niche. It’s not necessarily a replacement for every saw you own, but it excels in areas where other saws might struggle, particularly with its blend of portability, precision, and material versatility.

Pros and Cons of Portable Band Saws

To give you a clear picture, here’s a breakdown of the benefits and drawbacks:

Pros:

- Versatility: Cuts through a wide range of materials (metal, wood, pipe, etc.).

- Clean Cuts: Produces smooth, precise cuts with minimal burrs or tear-out.

- Portability: Lightweight and compact for easy transport and use on-site or in tight spaces.

- Safety: Generates fewer sparks and dust compared to abrasive saws, especially when cutting metal.

- Controlled Operation: Offers more control and accuracy for detailed cuts.

- Reduced Noise: Often quieter than reciprocating saws or abrasive chop saws.

Cons:

- Cutting Capacity Limitations: Smaller than stationary band saws, limiting the thickness or width of material that can be cut.

- Blade Wear: Blades can wear out, especially when cutting harder metals, requiring replacement.

- Speed: May not be as fast as a reciprocating saw for pure demolition tasks.

- Cost: Can be a significant investment, especially for higher-end models.

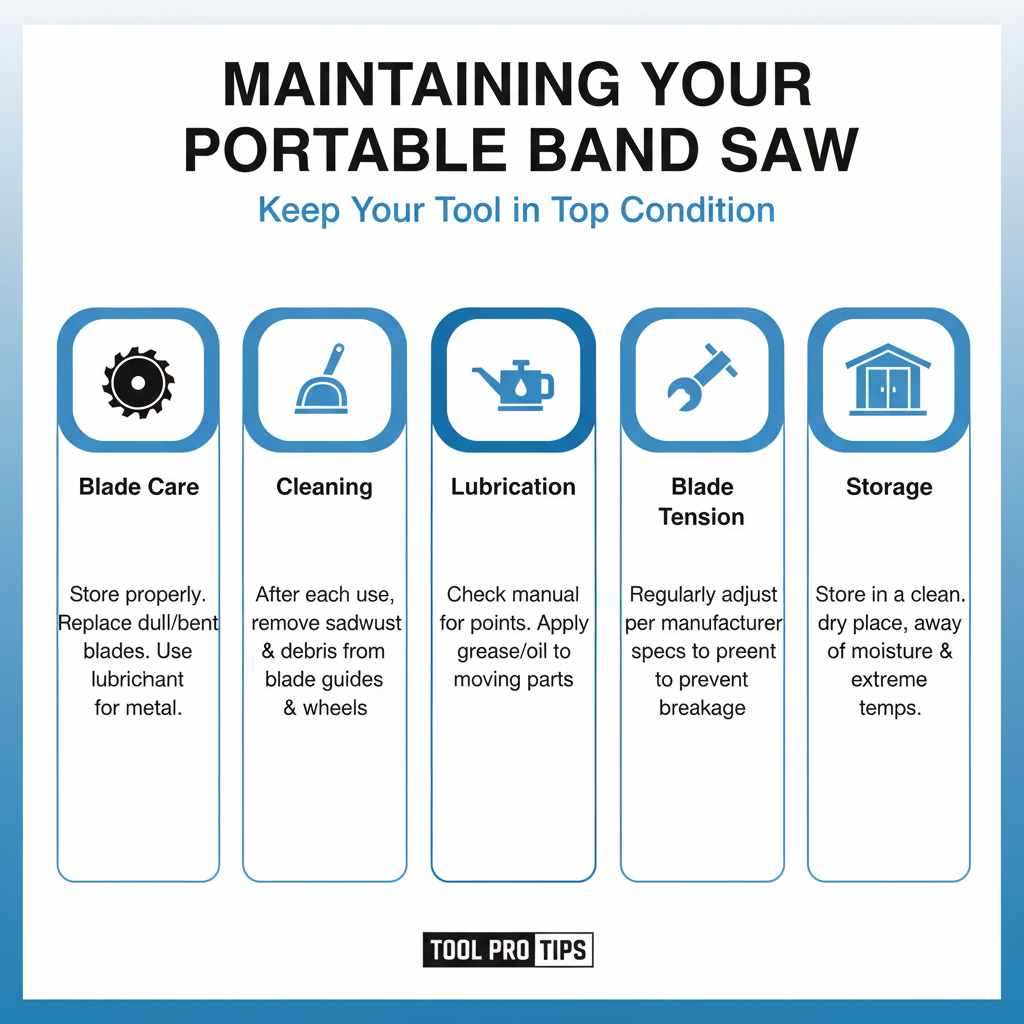

Maintaining Your Portable Band Saw

To ensure your portable band saw lasts and performs at its best, a little maintenance goes a long way. Regular care will save you frustration and money in the long run.

- Blade Care: Always store blades properly to prevent damage. If a blade gets dull or bent, replace it immediately. A dull blade requires more force, increases the risk of kickback, and produces poor cuts. For optimal cutting, especially on metal, consider using a lubricant. Using a cutting fluid can significantly extend blade life and improve the cut quality.

- Cleaning: After each use, clean the saw of sawdust, metal shavings, or other debris. Pay attention to the blade guides and wheels. A clean tool operates more smoothly and efficiently.

- Lubrication: Check your owner’s manual for any lubrication points. Some models may require occasional application of grease or oil to moving parts.

- Blade Tension: Regularly check and adjust blade tension according to the manufacturer’s recommendations. Improper tension can lead to blade breakage or poor cutting performance.

- Storage: Store your portable band saw in a clean, dry place, protected from moisture and extreme temperatures.

Proper maintenance ensures your tool is ready when you are and helps achieve professional results every time.

Conclusion

So, what are portable band saws used for? In a word: everything! From the professional contractor on a demanding job site to the weekend warrior tackling a home improvement project, these tools offer a uniquely effective solution for clean, precise cuts across a wide array of materials. They provide a balance of power, portability, and precision that makes them indispensable for many tasks that other saws simply can’t handle as well.

By understanding their capabilities, choosing the right one for your needs, prioritizing safety, and keeping them well-maintained, you’ll find that a portable band saw becomes one of the most valuable tools in your arsenal. It’s an investment that pays dividends in time saved, quality achieved, and the sheer satisfaction of completing your projects with confidence and skill. Happy cutting!

Frequently Asked Questions (FAQ)

Q1: Can I use a portable band saw to cut wood as effectively as metal?

A: Yes, you can! However, you’ll need to use a blade specifically designed for wood and potentially adjust the saw’s speed if it has variable settings. Wood blades have different tooth pitches than metal blades. Using the right blade ensures cleaner cuts and prolongs the life of both the blade and the saw’s motor.

Q2: Are portable band saws safe for beginners?

A: With proper safety precautions, yes. Like any power tool, they require respect and careful operation. Always read the manual, wear safety glasses, secure your workpiece.