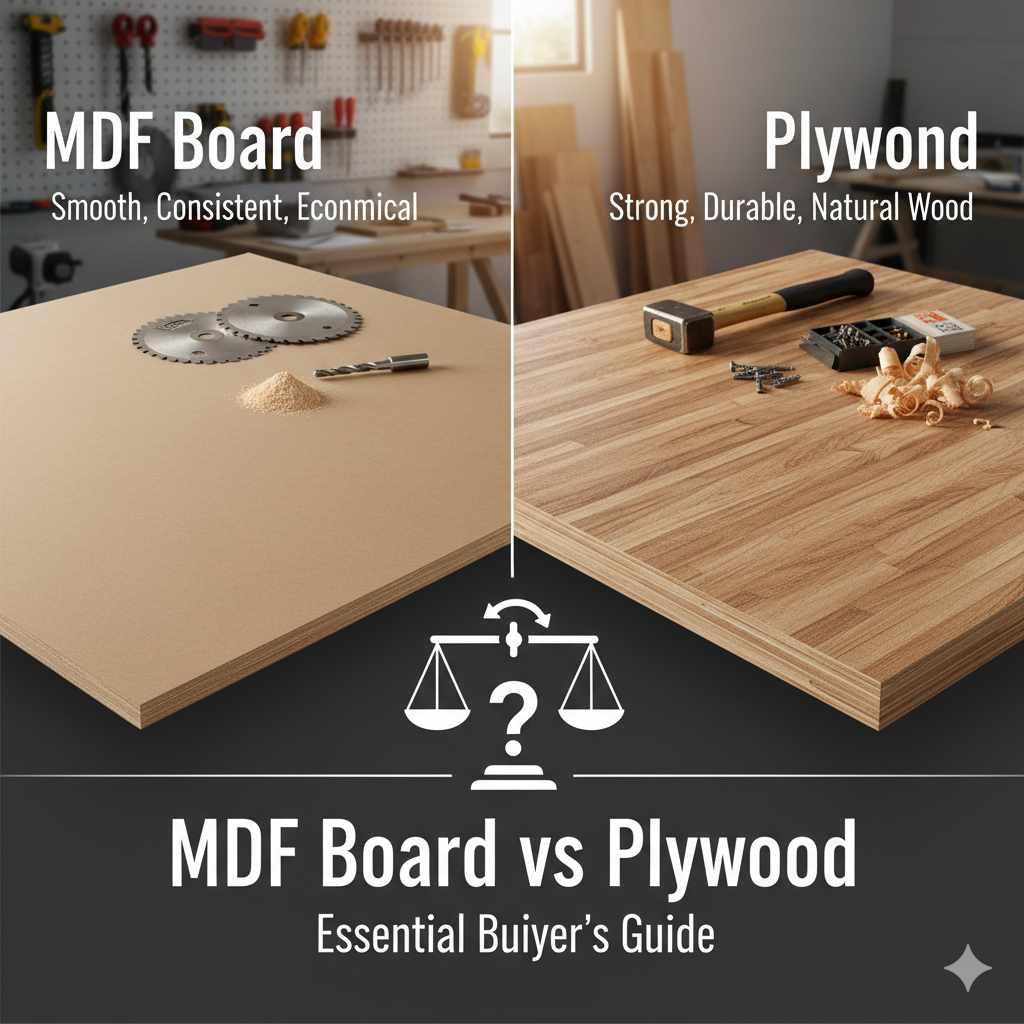

MDF Board vs Plywood: Essential Buyer’s Guide

MDF board vs. plywood: For most beginner DIY projects needing a smooth surface and stability, MDF is great. For projects needing strength, moisture resistance, or screw-holding power, plywood is usually the better choice. This guide helps you pick the right one!

Choosing the right building material can feel like a puzzle, especially when you’re just starting out in the workshop. Two common materials you’ll often see are MDF (Medium-Density Fiberboard) and plywood. They look similar enough, but they behave very differently. Picking the wrong one can lead to wobbly shelves, cracked finishes, or projects that just don’t turn out as planned. Don’t worry, though! I’m here to break down MDF board vs. plywood in a way that makes sense, so you can confidently choose the best material for your next DIY adventure. We’ll explore what makes each unique, their pros and cons, and where they shine. Let’s get building!

MDF vs. Plywood: The Big Picture

Think of MDF and plywood as two different types of engineered wood. They’re both made from wood fibers or pieces, but how they’re put together makes all the difference. Understanding these fundamental differences is your first step to making informed decisions for your projects.

What is MDF?

MDF, or Medium-Density Fiberboard, is made from fine wood fibers that are mixed with wax and resin. These ingredients are then heated and pressed together under high pressure. The result is a very dense, smooth, and stable panel. Because it’s made from such small particles, you can’t see any wood grain in MDF, which gives it a perfectly uniform surface.

What is Plywood?

Plywood, on the other hand, is made from thin sheets of wood veneer that are glued together. These layers, called plies, are arranged so that their wood grain runs in alternating directions. This cross-graining makes plywood incredibly strong and less likely to warp or shrink. It’s like building with layers of strength!

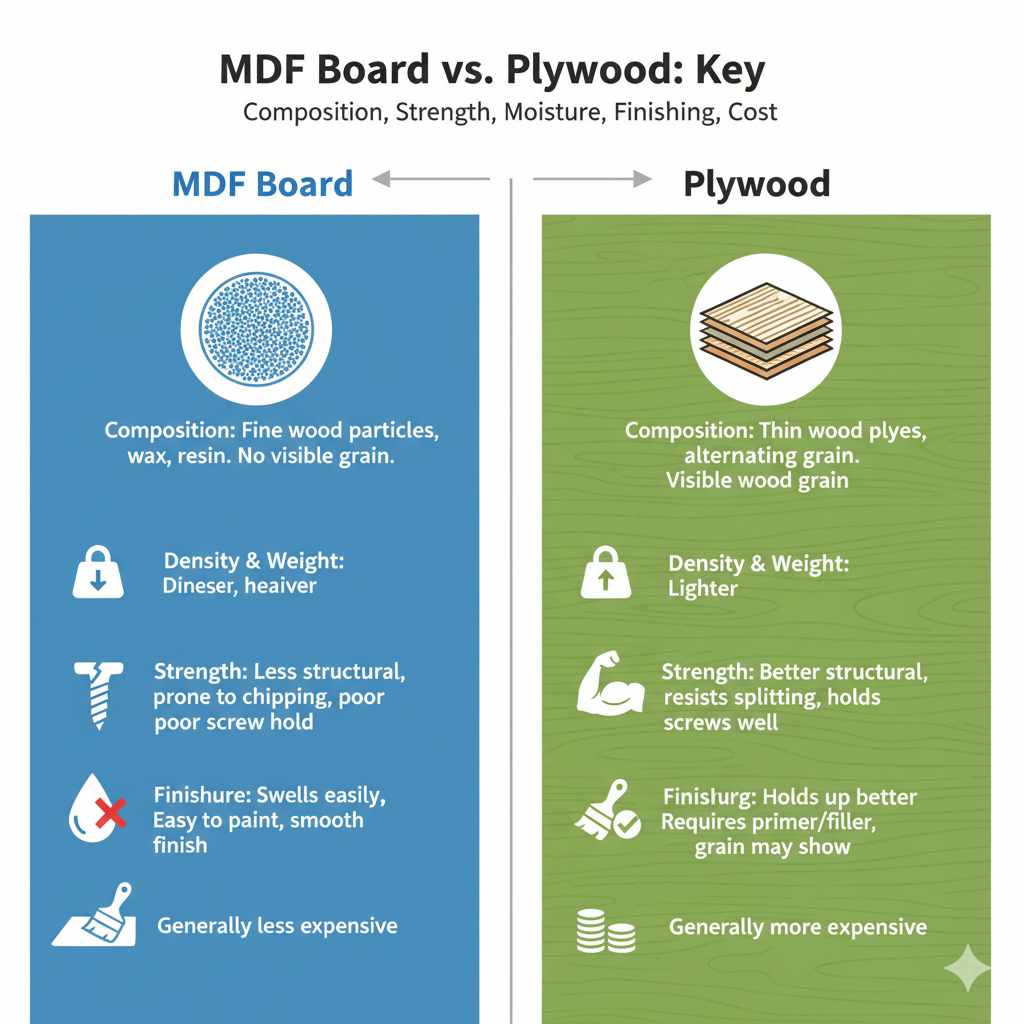

MDF Board vs. Plywood: Key Differences

When you’re deciding between MDF board vs. plywood, consider these core differences. They impact how the material performs, what it costs, and how you’ll work with it.

Composition and Structure

- MDF: Made from fine wood particles, wax, and resin, pressed into a uniform, dense board. No visible wood grain.

- Plywood: Made from thin layers (plies) of wood veneer glued together with grain running in alternating directions. Visible wood grain on the surface.

Density and Weight

MDF is generally denser and heavier than plywood of the same thickness. This density contributes to its smooth finish and stability but can make it harder to handle and hang heavy items on.

Strength and Durability

Plywood typically has better structural strength than MDF. Its cross-grained construction prevents it from easily splitting or breaking, making it ideal for applications where loads or stresses are involved. MDF can be strong, but it’s more prone to chipping and can’t hold screws as well as plywood.

Moisture Resistance

Neither MDF nor standard plywood is great with moisture. However, plywood, especially certain grades like marine plywood, generally holds up better than MDF. MDF can swell and disintegrate if it gets soaked, making it unsuitable for damp environments unless specifically treated or sealed.

Finishing and Painting

This is where MDF often shines for beginners. Its smooth, grain-free surface makes it incredibly easy to paint. You don’t have to worry about wood grain showing through, and it takes paint beautifully, giving a factory-like finish. Plywood can be painted, but you’ll often need to fill the grain or use a primer to get a smooth result, and the grain might still be visible.

Cost

On average, MDF is often slightly cheaper than plywood, especially for standard grades. However, prices can vary based on thickness, grade, and specific types of each material.

Pros and Cons: MDF Board vs. Plywood at a Glance

To make your choice even easier, here’s a quick breakdown of the advantages and disadvantages of each material.

MDF Pros:

- Extremely smooth, uniform surface perfect for painting and laminating.

- No wood grain means no telegraphing of the grain through finishes.

- More stable than many types of plywood; less prone to warping.

- Generally less expensive than comparable plywood.

- Easy to machine and cut with clean edges.

MDF Cons:

- Heavy and can be brittle.

- Poor screw-holding ability; screws can strip out easily.

- Susceptible to damage from moisture (swells and degrades).

- Creates very fine dust when cut, requiring good dust collection and personal protection.

- Edges can be prone to chipping if handled roughly.

Plywood Pros:

- Excellent strength-to-weight ratio.

- Good screw-holding ability, especially in the face and edge grain.

- Less prone to chipping than MDF.

- More resistant to moisture than standard MDF (though not waterproof).

- Available in various grades suitable for different applications.

- Can be stained or painted, showing attractive grain patterns.

Plywood Cons:

- Can have voids or knots within its layers.

- Surface can be uneven or have splinters depending on the grade.

- Wood grain can telegraph through paint if not properly prepared.

- Can sometimes warp or delaminate if subjected to extreme moisture or stress.

- Generally more expensive than MDF for similar sizes.

When to Choose MDF for Your Project

MDF is often the go-to for specific types of projects where its unique properties offer the best results. Here are some scenarios where MDF is your likely winner:

For Painted Furniture and Cabinetry

If you’re building cabinet doors, drawer fronts, or furniture pieces that will be painted, MDF is fantastic. Its perfectly smooth surface provides a flawless base for paint. You’ll get a professional, sleek finish without battling wood grain. For example, building a custom vanity for your bathroom or a painted bookshelf? MDF is a superb choice.

For Decorative Trim and Moulding

MDF is excellent for creating decorative trim, mouldings, or ornate panels. It can be easily routed and shaped, and its smooth surface takes paint beautifully, making custom trim work more accessible for DIYers. You can achieve complex profiles with ease.

Where Stability is Key and Moisture Isn’t an Issue

If you need a material that won’t expand or contract much with minor temperature changes and the project won’t be exposed to water, MDF offers great stability. Think interior shelving, wall panelling, or display pieces that stay dry.

For Projects with Laminates or Veneers

MDF provides an ideal substrate for applying laminates or veneers. Its smooth, dense surface ensures a clean bond and prevents any imperfections from showing through. This is common in store-bought furniture or custom built-ins where a sleek, seamless look is desired.

Easy Machining for Intricate Designs

If your project involves a lot of cutting, especially intricate shapes or CNC routing, MDF is very forgiving and easy to work with. It machines cleanly without splintering, allowing for precise details.

When to Choose Plywood for Your Project

Plywood’s strength and versatility make it the workhorse of many woodworking projects. Consider plywood when these factors are important:

For Structural Components and Shelving Under Load

When a shelf needs to hold a lot of books or a cabinet needs to withstand weight, plywood is the stronger option. Its layered construction gives it superior strength and rigidity. For example, workbench tops, heavy-duty shelving in a garage, or structural cabinet carcasses benefit greatly from plywood’s strength.

For Drawers and Boxes Requiring Durability

The sides and bottoms of drawers, or the construction of sturdy boxes, are excellent applications for plywood. It can withstand the repeated opening and closing of drawers and the general wear and tear of use much better than MDF.

For Projects in Humid or Potentially Damp Areas (with caution)

While not waterproof, plywood generally performs better in environments with fluctuating humidity than MDF. For areas like garages, basements, or sheds, even standard plywood (or better yet, exterior or marine grades) is often preferred. Always seal it well, though!

When Screw-Holding Power is Crucial

If your project involves a lot of screwing or requires components to be frequently assembled and disassembled, plywood offers much better screw-holding ability. The veneers grip screws more effectively, reducing the risk of stripping or pulling out.

For Cabinet Backing and Drawer Bottoms

Thinner grades of plywood are commonly used as backing for cabinets or as the bottom panel for drawers. They provide stability and prevent racking without adding excessive weight.

When You Prefer a Natural Wood Look

If you plan to stain your project or want to showcase the natural wood grain, plywood is the obvious choice. Different species and grades of plywood offer beautiful grain patterns that can enhance the aesthetic of your work.

Understanding Plywood Grades

Plywood isn’t just one thing; it comes in different grades that affect its appearance and suitability for various tasks. Knowing these grades can help you pick the best plywood for your specific needs. Here’s a simplified look:

The American Plywood Association (APA) has a grading system. Common grades you’ll see are:

- A-Grade: Smooth surface, best for painting or staining. May have minor repairs like patches or sanding.

- B-Grade: Better than C, with more solid pieces and fewer defects than C. Still good for many uses; paintable.

- C-Grade: Knots and some repairs are allowed. Not ideal for visible surfaces unless you’re planning a rustic look or painting over it.

- D-Grade: The lowest grade, with open knots and larger defects. Usually used where appearance doesn’t matter, like subflooring or concrete forms.

Plywood is often described with two letters, like “AC” or “BC.” The first letter refers to the face (the front side), and the second refers to the back. So, AC has a good yüzey on the front and a decent one on the back.

You might also see labels like “X” for exterior grade (meaning it can withstand moisture better due to waterproof glue) or specific types like Birch plywood, known for its fine grain and strength.

Understanding MDF Types

While standard MDF is most common, there are variations:

- Moisture Resistant MDF: Often colored green, this type has added resins to help it withstand higher humidity levels. However, it’s still not waterproof and is best for damp areas like kitchens or bathrooms, not for direct water contact.

- Fire Retardant MDF: Treated with chemicals to slow down combustion, used in public buildings where fire codes are stringent.

- Lightweight MDF: Made with a different blown sawdust process, it’s lighter and easier to handle, but often less dense and strong.

- Veneered MDF: MDF with a thin layer of real wood veneer applied to the surface, offering the look of wood with the stability of MDF.

Comparing MDF Board vs. Plywood in a Table

To help you visualize the differences, here’s a direct comparison:

| Feature | MDF (Medium-Density Fiberboard) | Plywood |

|---|---|---|

| Construction | Fine wood fibers, wax, resin; pressed under high heat and pressure. | Thin layers (plies) of wood veneer glued together, with grain alternating direction. |

| Surface Finish | Extremely smooth, uniform, no grain. | Visible wood grain; can be smooth or textured depending on veneer. |

| Strength | Good compressive strength, but brittle. Can chip. | Excellent structural strength, resists splitting and breaking due to cross-graining. |

| Moisture Resistance | Very poor; swells and degrades easily. Not recommended for damp areas. | Better than standard MDF; exterior grades are more resistant. Still not waterproof. |

| Screw Holding | Poor; screws strip out easily. Dowels or complex joinery are better. | Good; grips screws well, especially in face and edge grain. |

| Machining & Cutting | Machines very cleanly for routing and shaping. Creates fine dust. | Can chip and splinter, especially on veneers. Specific blades are best. |

| Painting & Finishing | Excellent; smooth surface requires minimal prep for a flawless painted finish. | Good; requires grain filling or priming for a smooth painted finish. Great for staining. |

| Weight | Generally heavier than plywood of the same thickness. | Lighter than MDF for the same thickness. |

| Cost | Often slightly cheaper than comparable plywood. | Generally more expensive. |

| Best For | Painted furniture, cabinet doors, trim, decorative elements, smooth laminating. | Structural shelves, drawer boxes, cabinet carcasses, workbenches, projects needing strength. |

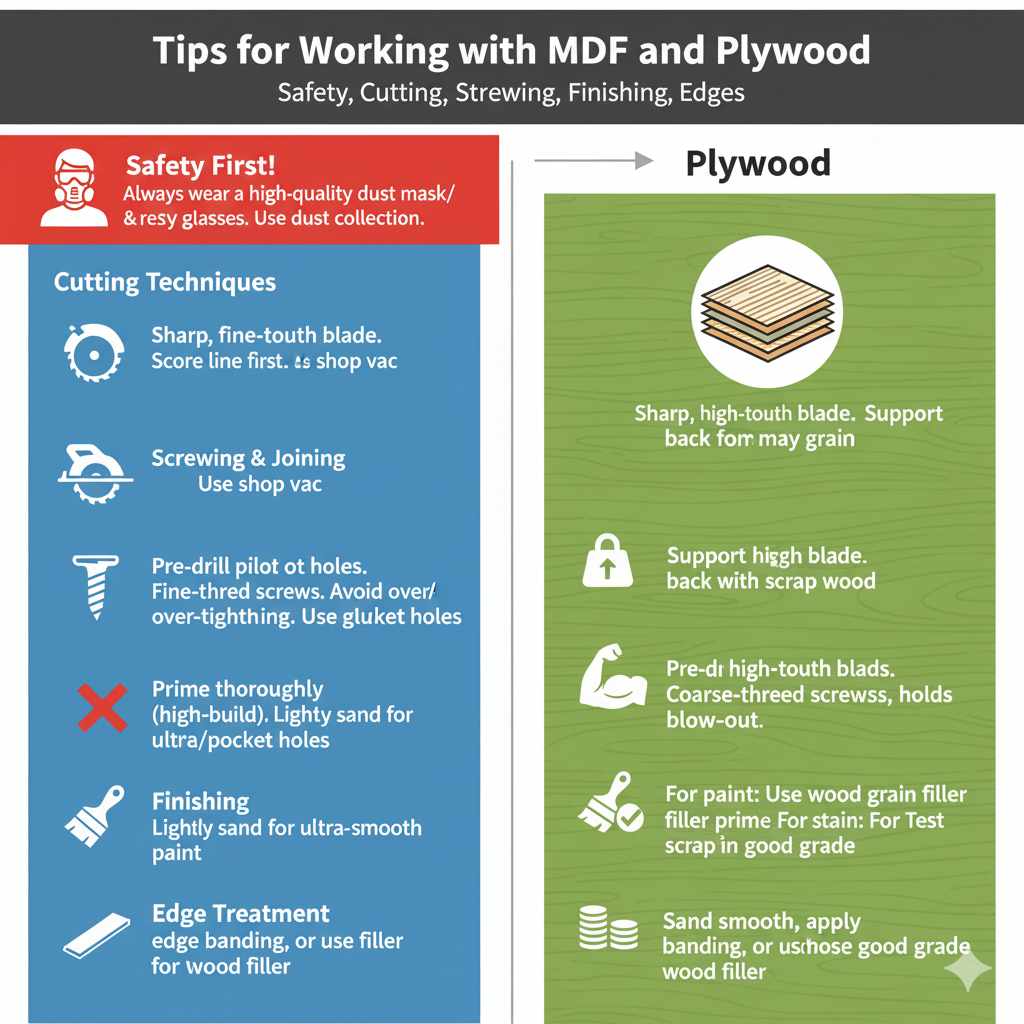

Tips for Working with MDF and Plywood

Whether you choose MDF or plywood, handling them correctly will make your projects smoother and safer. Here are some tips from my workshop:

Safety First!

This is non-negotiable. Both MDF and plywood produce fine dust particles when cut. Inhaling this dust can be harmful to your lungs. Always wear a high-quality dust mask or respirator. Safety glasses are also a must to protect your eyes from flying debris.

For MDF dust specifically, it’s particularly fine and can be an irritant. If you’re doing a lot of cutting, using a shop vac with a dust collection system attached to your saw is highly recommended. You can learn more about proper dust collection from resources like the Occupational Safety and Health Administration (OSHA), which provides guidelines on wood dust hazards.

Cutting Techniques

- For MDF: Use a sharp blade designed for fine cutting (like a triple-chip grind blade). Cutting MDF creates a lot of fine dust, so vacuum collection is ideal. For cleaner cuts, score the line first.

- For Plywood: Use a sharp blade, preferably a plywood-specific blade or one with a high tooth count, to minimize tear-out. Support the back of the plywood near the cut line with a piece of scrap wood to prevent splintering on the exit side.

Screwing and Joining

- MDF: Pre-drilling pilot holes is essential. Use fine-thread screws. Avoid over-tightening, as the material can strip easily. For strong joints, consider pocket hole joinery, glue, or using dedicated MDF connectors.

- Plywood: Pre-drill pilot holes, though it holds screws better than MDF. Coarse-thread screws are good for general use. If you’re screwing near an edge, be mindful of blow-out.

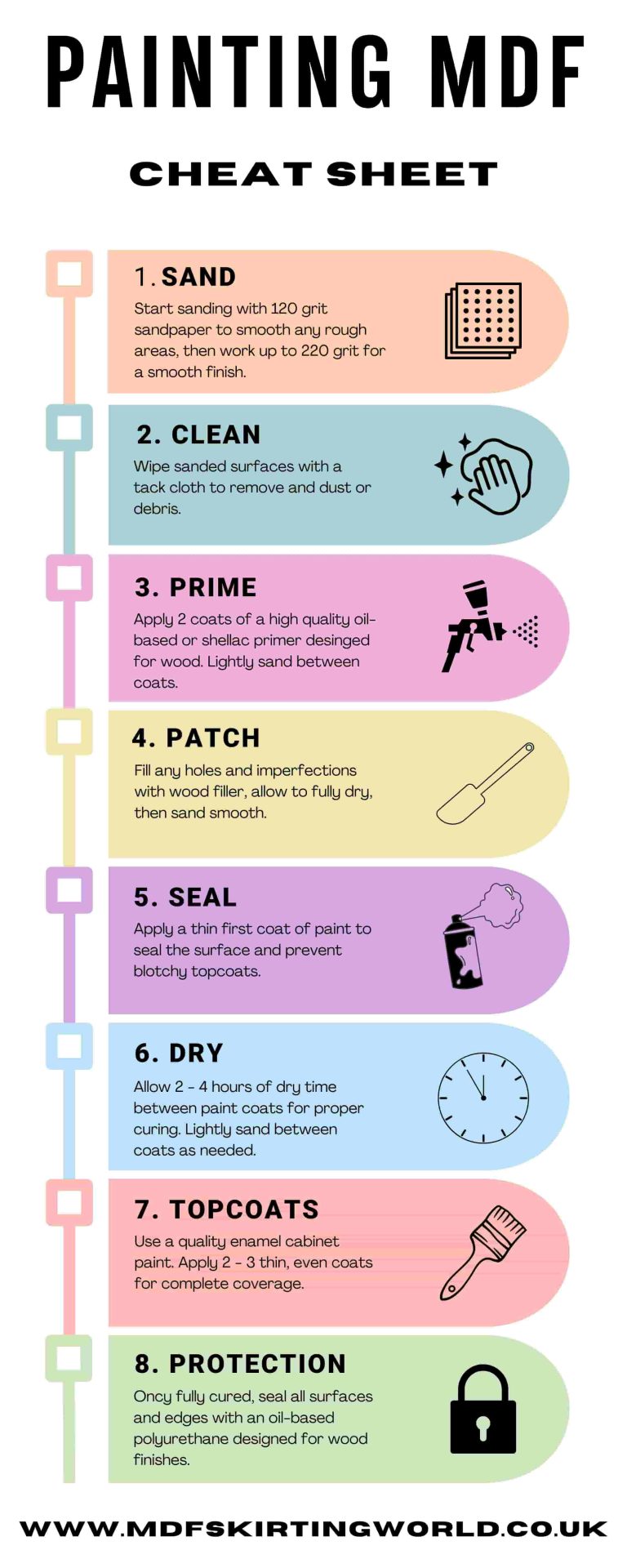

Finishing

- MDF: Prime thoroughly before painting. A good primer will seal the surface and prevent paint from soaking in unevenly. You can use a high-build primer or sand lightly between coats for that ultra-smooth finish.

- Plywood: For a smooth painted finish, you’ll likely need to fill the wood grain with a grain filler product before priming. If you’re staining, choose a plywood grade with attractive grain and test your stain on a scrap piece first.

Edge Treatment

MDF edges are smooth but can be fragile. You can paint them directly, apply edge banding, or use filler for a more finished look. Plywood edges can be left exposed (if it’s a nice veneer), sanded smooth, or covered with edge banding for a cleaner appearance.

MDF Board vs. Plywood: FAQ

Here are some common questions beginners have about MDF and plywood.

Is MDF stronger than plywood?

Plywood is generally stronger in terms of tensile strength and its ability to resist bending or breaking under load, especially across its length. MDF is very dense and strong under compression but can be brittle and chip more easily than plywood.

Can I use MDF outside?

No, standard MDF is not suitable for outdoor use. It absorbs moisture and will swell, warp, and eventually disintegrate. Moisture-resistant MDF offers some protection against humidity but is not waterproof.

Which material is better for DIY furniture?

It depends on the finish! For beautifully painted furniture pieces with clean lines, MDF is often preferred for its smooth surface.