Engineered Hardwood vs LVP: Essential Guide

Engineered hardwood offers the classic beauty of real wood with better stability, while LVP (Luxury Vinyl Plank) provides exceptional durability and water resistance. Both are excellent flooring choices, but the best option depends on your budget, lifestyle, and room conditions.

Hello there! Picking the right flooring can feel like a big decision for your home. You want something that looks great, lasts a long time, and fits your budget. Two popular choices that often get compared are engineered hardwood and LVP, or Luxury Vinyl Plank. It’s easy to get a bit confused between them because they can look so similar! But understanding their differences will help you choose the perfect floor for your space. I’m here to walk you through it, step by step, so you can feel confident in your choice.

Engineered Hardwood vs LVP: What’s the Real Difference?

When you’re setting up your workshop or thinking about home improvements, clarity is key. Let’s break down what engineered hardwood and LVP actually are.

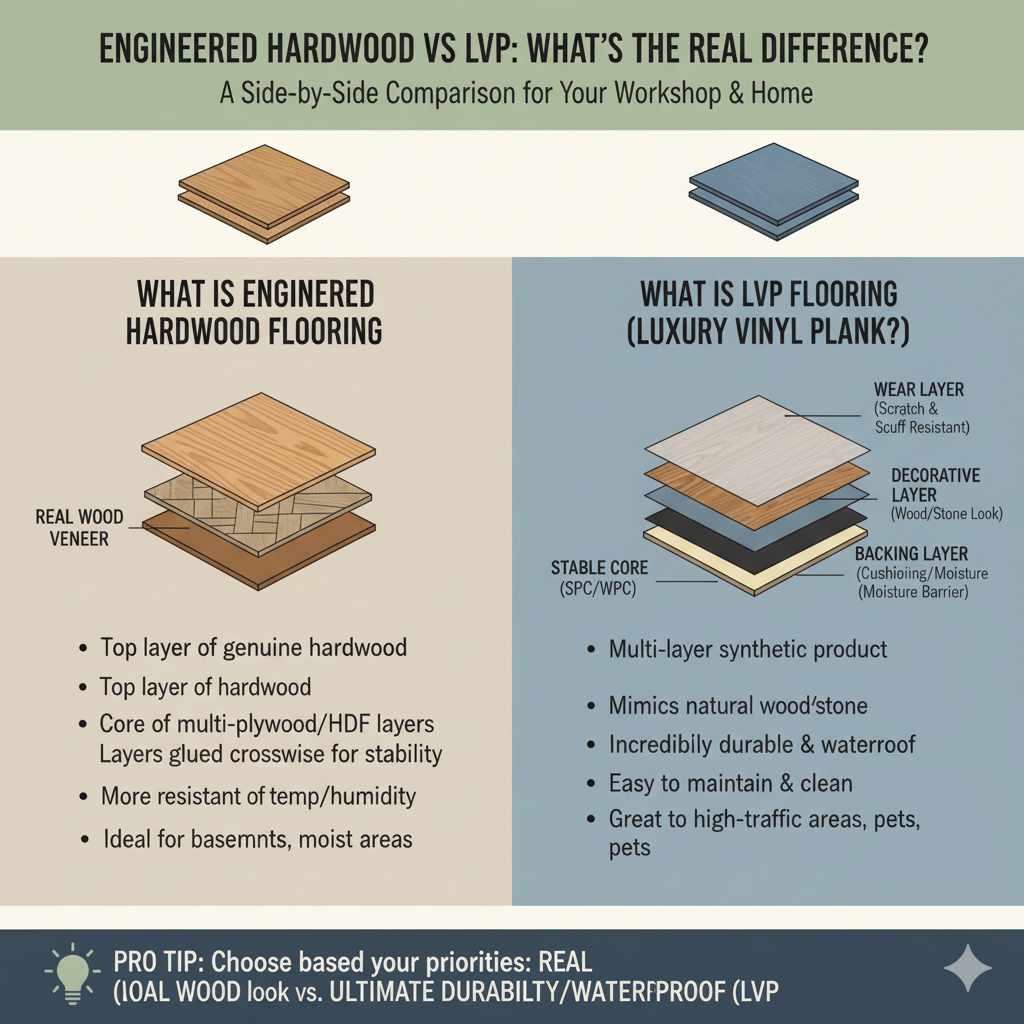

What is Engineered Hardwood Flooring?

Engineered hardwood flooring is a clever type of real wood floor. It’s made with layers. The top layer is a veneer of genuine hardwood – this is the part you see and feel, giving it that authentic wood look. Beneath this visible layer are several other plies, usually made of high-density fiberboard (HDF) or plywood. These layers are glued together crosswise, which makes the whole plank much more stable than solid hardwood.

This construction helps engineered hardwood stand up better to changes in temperature and humidity. It’s a fantastic option for areas where solid wood might struggle, like basements or rooms with occasional moisture.

What is LVP Flooring (Luxury Vinyl Plank)?

LVP, or Luxury Vinyl Plank, is a flooring material made from synthetic materials. It’s engineered to mimic the look and feel of natural materials like wood or stone, but it’s completely man-made. It typically consists of four layers: a wear layer on top to protect against scratches and scuffs, a decorative layer (which is printed with the wood or stone design), a core layer for stability and comfort, and often a backing layer for extra cushioning and moisture resistance.

LVP is known for being incredibly durable, waterproof, and easy to maintain. It’s a practical choice for busy households with kids and pets, and for areas prone to spills and heavy foot traffic.

Key Differences at a Glance

To help you visualize, let’s put the main distinctions side-by-side. Think of this as your quick reference guide.

| Feature | Engineered Hardwood | LVP (Luxury Vinyl Plank) |

|---|---|---|

| Material | Real wood veneer on top, multi-layer core (plywood/HDF) | Synthetic material (PVC), photographic layer |

| Appearance | Authentic wood grain, unique patterns, natural feel | Realistic imitation of wood or stone, consistent patterns |

| Durability | Good, but can scratch and dent; refinishing possible | Excellent, highly resistant to scratches, dents, and stains |

| Water Resistance | Moderate; susceptible to moisture damage if heavily exposed | Excellent; typically waterproof |

| Installation | Glue-down, staple-down, or floating | Click-lock (floating), glue-down, or peel-and-stick |

| Maintenance | Regular sweeping/vacuuming, damp mop | Easy; sweep/vacuum, damp mop, can use mild cleaners |

| Cost | Mid to high | Low to mid |

| Feel/Sound | Warmer, more natural sound, can creak | Can feel slightly softer, quieter underfoot, less resonant |

| Repair | Can be sanded and refinished (limited times) | Dampened by moisture, but individual planks can be replaced |

Pros and Cons: Weighing Your Options

Every material has its strengths and weaknesses. Understanding these will help you pick the best fit for your home.

Engineered Hardwood: The Good and the Not-So-Good

Pros of Engineered Hardwood:

- Authentic Beauty: You get the real wood look and feel that many homeowners love. Each plank has its own unique grain pattern.

- Increased Stability: The layered construction makes it more stable than solid hardwood, so it’s less likely to warp or swell with humidity changes. This makes it suitable for more areas than solid wood.

- Resale Value: Real wood flooring is often seen as a premium feature that can increase a home’s value.

- Refinishable: Depending on the thickness of the top wood veneer, many engineered hardwood floors can be sanded and refinished one or more times to repair damage or refresh the look.

- Versatile Installation: It can be installed in various ways, including floating over a subfloor, which is great for DIYers.

Cons of Engineered Hardwood:

- Moisture Sensitivity: While more stable than solid wood, it’s not waterproof. Prolonged exposure to water can cause damage, making it less ideal for bathrooms or flood-prone basements.

- Scratching and Denting: Like all real wood, it can be scratched or dented by sharp objects or heavy furniture. The wear layer thickness is crucial here.

- Cost: Generally more expensive than LVP, both in material cost and installation.

- Repair Limitations: If the veneer is very thin, it limits how many times it can be refinished. Deep gouges might require plank replacement.

LVP: The Good and the Not-So-Good

Pros of LVP:

- 100% Waterproof: This is LVP’s superpower. It’s perfect for kitchens, bathrooms, laundry rooms, mudrooms, and basements where moisture is a concern. Spills are no problem!

- Extreme Durability: LVP is highly resistant to scratches, dents, stains, and general wear and tear. This makes it excellent for homes with pets and active families.

- Affordability: LVP is typically much more budget-friendly than engineered hardwood, offering a cost-effective way to achieve a premium look.

- Easy Maintenance: Cleaning is a breeze. Regular sweeping and occasional damp mopping are usually all that’s needed.

- Simple Installation: Many LVP products use a click-lock system, making them ideal for DIY installation. It can often be laid directly over existing flooring.

- Comfort: Some LVP has a cushioned core, making it feel softer and quieter underfoot than harder flooring options.

Cons of LVP:

- Not a Natural Material: While designs are realistic, it doesn’t have the genuine warmth or unique variations of real wood. Some people can tell it’s not real wood upon close inspection.

- Potential Fading: Very old or low-quality LVP could potentially fade over time with prolonged, direct sun exposure. Manufacturers often test for UV resistance.

- Subfloor Imperfections: While durable, LVP can telegraph subfloor imperfections if not installed on a flat surface, especially thinner options.

- Not Refinishable: LVP cannot be sanded and refinished like wood. If heavily damaged, individual planks usually need to be replaced.

- Environmentally Conscious Considerations: Being a PVC product, some consumers have concerns about its environmental impact during production and disposal. However, many manufacturers are improving their processes. Check out resources from the Environmental Protection Agency (EPA) for more on flooring materials and indoor air quality.

Where to Install Each Type of Flooring

Knowing where each flooring type shines can make your decision much easier. Let’s look at common areas in the home.

Best Rooms for Engineered Hardwood

Engineered hardwood brings a touch of natural elegance to many rooms. It’s a great choice for:

- Living Rooms and Dining Rooms: These are often high-traffic areas where the visual appeal of real wood makes a big statement.

- Bedrooms: Provides a warm, inviting feel for relaxation.

- Hallways: Offers durability for daily foot traffic while maintaining a classic look.

- Home Offices: Creates a sophisticated and comfortable workspace.

- Family Rooms: Can work well here if moisture is not a significant concern and spill cleanup is prompt.

It’s important to protect engineered hardwood from excessive moisture and very heavy impacts. This means you might want to reconsider it for bathrooms or basements prone to flooding.

Best Rooms for LVP

LVP is the champion of durability and water resistance, making it ideal for areas where life happens! Consider LVP for:

- Kitchens: Spills, dropped utensils, and constant activity are no match for LVP.

- Bathrooms: Its waterproof nature is perfect for steamy, splash-prone environments.

- Laundry Rooms: Protects against water spills from appliances.

- Mudrooms and Entryways: Stands up to wet shoes, dirt, and pet paws.

- Basements: Excellent alternative to carpet or other materials that can be ruined by moisture.

- Playrooms: A durable, easy-to-clean surface for kids’ activities.

- High-Traffic Hallways and Living Areas: If you have pets or a very active household, LVP’s resilience is a huge advantage.

LVP’s versatility means you can use it throughout your entire home for a cohesive, low-maintenance look, or just in specific rooms where its benefits are most needed.

Installation Considerations

How the flooring goes down is a big part of the project, especially if you’re planning a DIY installation.

Installing Engineered Hardwood

Engineered hardwood offers a few installation methods:

- Floating Floor: This is the most common DIY-friendly method for engineered hardwood. Planks interlock with each other. You install an underlayment on your subfloor, then lay the planks on top without gluing or nailing them to the subfloor. The weight of the floor and its interlocking nature keep it in place.

- Glue-Down: The planks are adhered directly to the subfloor using a special flooring adhesive. This creates a very stable and solid feel but is more permanent and can be messy for DIYers.

- Nail-Down/Staple-Down: Similar to solid hardwood, planks are secured to a wooden subfloor using nails or staples. This method is typically used for thicker engineered wood and is often best left to professionals.

You’ll need tools like a miter saw, a tapping block, a rubber mallet, and a measuring tape. Always ensure your subfloor is clean, dry, and level before starting. For detailed instructions, consult the manufacturer’s guide, as methods can vary.

Installing LVP

LVP is generally considered one of the easiest flooring types to install, especially the click-lock varieties:

- Click-Lock (Floating): This is the most popular LVP installation method. Planks have a tongue-and-groove system that snaps together. You lay an underlayment (sometimes built into the LVP itself) and then click the planks into place. This method is very forgiving and ideal for DIYers.

- Glue-Down: Planks are secured to the subfloor with adhesive. This is a durable option, especially in commercial settings or areas with extreme temperature fluctuations, but it’s less common for DIY home projects.

- Peel-and-Stick: These planks have an adhesive backing. You peel off the protective film and stick them down. This is the simplest method but can be less durable and prone to shifting over time if not installed perfectly on a very clean and smooth subfloor.

For click-lock LVP, you’ll need similar tools to engineered hardwood, plus a utility knife or jigsaw for cutting. A good quality underlayment is often recommended for sound dampening and added comfort. For optimal subfloor preparation guidance, you can refer to resources like those from the National Wood Flooring Association (NWFA).

Maintenance and Care

Keeping your new floor looking great is surprisingly simple for both options.

Caring for Engineered Hardwood

Maintaining engineered hardwood is much like caring for solid wood, but with a bit more caution around excessive moisture.

- Daily Cleaning: Sweep or vacuum (with a hard floor attachment, not a beater bar) regularly to remove dirt and grit that can scratch the surface.

- Damp Mopping: Use a damp (not wet!) mop. For this, you’ll want a wood floor cleaner specifically recommended by the manufacturer, or a solution of mild dish soap and water. Wring out your mop thoroughly.

- Spills: Wipe up spills immediately with a soft cloth.

- Furniture Protection: Use felt pads on the legs of all furniture to prevent scratches. For heavy furniture like sofas, consider using furniture coasters or lifting furniture to move it rather than dragging.

- Entry Mats: Place mats both inside and outside entry doors to trap dirt and moisture.

- Avoid Harsh Cleaners: Never use ammonia-based cleaners, abrasive pads, steam mops, or excessive water, as these can damage the wood veneer and the core layers.

Caring for LVP

Clean LVP is a breeze; it’s designed for easy living!

- Daily Cleaning: Sweep or vacuum regularly, using the same hard floor attachment as you would for wood.

- Damp Mopping: A damp mop is all you need. You can use plain water or a pH-neutral cleaner specifically approved by the LVP manufacturer. Avoid abrasive cleaners or excessive water.

- Spills: LVP is waterproof, so spills are easy to handle. Wipe them up promptly with a cloth or paper towel.

- Stain Removal: For tougher spots, a mixture of mild detergent and water or a commercial LVP cleaner usually does the trick.

- Furniture Protection: Use felt pads on furniture legs to prevent scuffs and scratches, just like with engineered hardwood.

- Avoid Wax or Polish: LVP has a protective wear layer and does not need waxing or polishing. These products can make the floor slippery and dull the finish.

Cost Comparison: Budgeting for Your Project

Let’s talk about the wallet. Flooring costs can vary widely, but here’s a general idea.

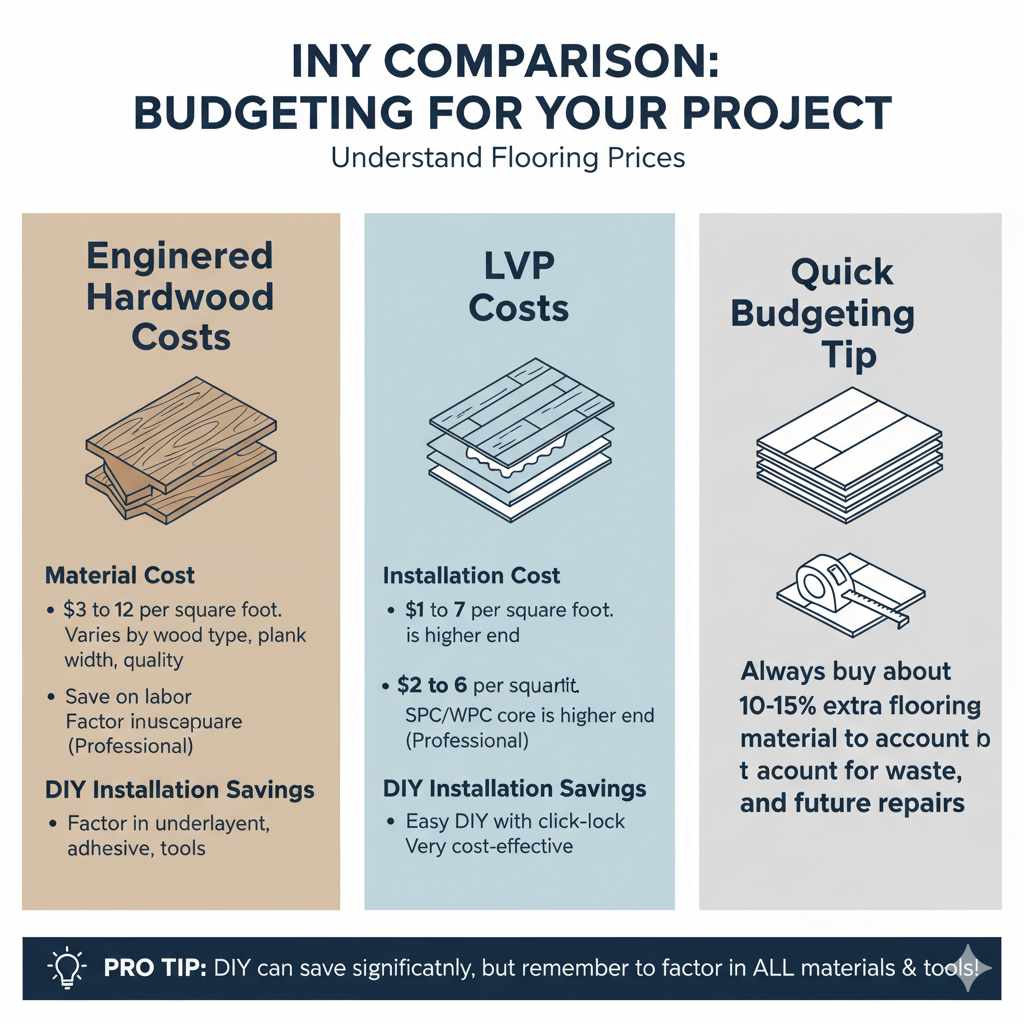

Engineered Hardwood Costs

The price of engineered hardwood depends heavily on the type of wood veneer, the plank width, the quality of the core, and the brand.

- Material Cost: You can expect to pay anywhere from $3 to $12 per square foot for engineered hardwood. High-end exotic woods or wider planks will be at the higher end of this range.

- Installation Cost: Professional installation can add another $3 to $7 per square foot, depending on your location and the complexity of the job.

DIY Installation Savings: If you successfully install it yourself, you save on labor costs, making it a more affordable option. However, be sure to factor in the cost of underlayment, adhesive (if needed), and any necessary tools.

LVP Costs

LVP offers a wide range of price points, making it accessible for almost any budget.

- Material Cost: LVP can range from $1 to $6 per square foot. Basic peel-and-stick options might be at the lower end, while high-end, thick, waterproof SPC (Stone Plastic Composite) or WPC (Wood Plastic Composite) core LVP will be closer to the higher end but still often cheaper than basic engineered hardwood.

- Installation Cost: DIY installation is very common with LVP, especially click-lock systems. Professional installation typically costs $2 to $5 per square foot.

DIY Installation Savings: The ease of installation for many LVP products makes DIY a very cost-effective choice.

Quick Budgeting Tip: Always buy about 10-15% extra flooring material to account for cuts, waste, and future repairs. This is true for both engineered hardwood and LVP.

Frequently Asked Questions (FAQ)

These are common questions beginners often ask:

Q1: Can I install engineered hardwood in a bathroom?

While some engineered hardwoods have better moisture resistance than others, it’s generally not recommended for bathrooms. Bathrooms experience high humidity and potential water splashes that engineered wood cannot withstand long-term without damage. LVP is a much safer choice for bathrooms.

Q2: Is LVP bad for the environment?

LVP is a synthetic product, primarily made from PVC. Its production and disposal can have environmental impacts. However, many manufacturers are working to create more sustainably made LVP, using recycled materials or reducing VOCs (Volatile Organic Compounds). It’s always a good idea to research brands and look for certifications like FloorScore® for better indoor air quality.

Q3: Can I refinish LVP?

No, LVP cannot be refinished. It has a protective wear layer and a decorative print layer. Sanding would remove these layers and ruin the flooring. If LVP gets severely damaged, individual planks need to be replaced.