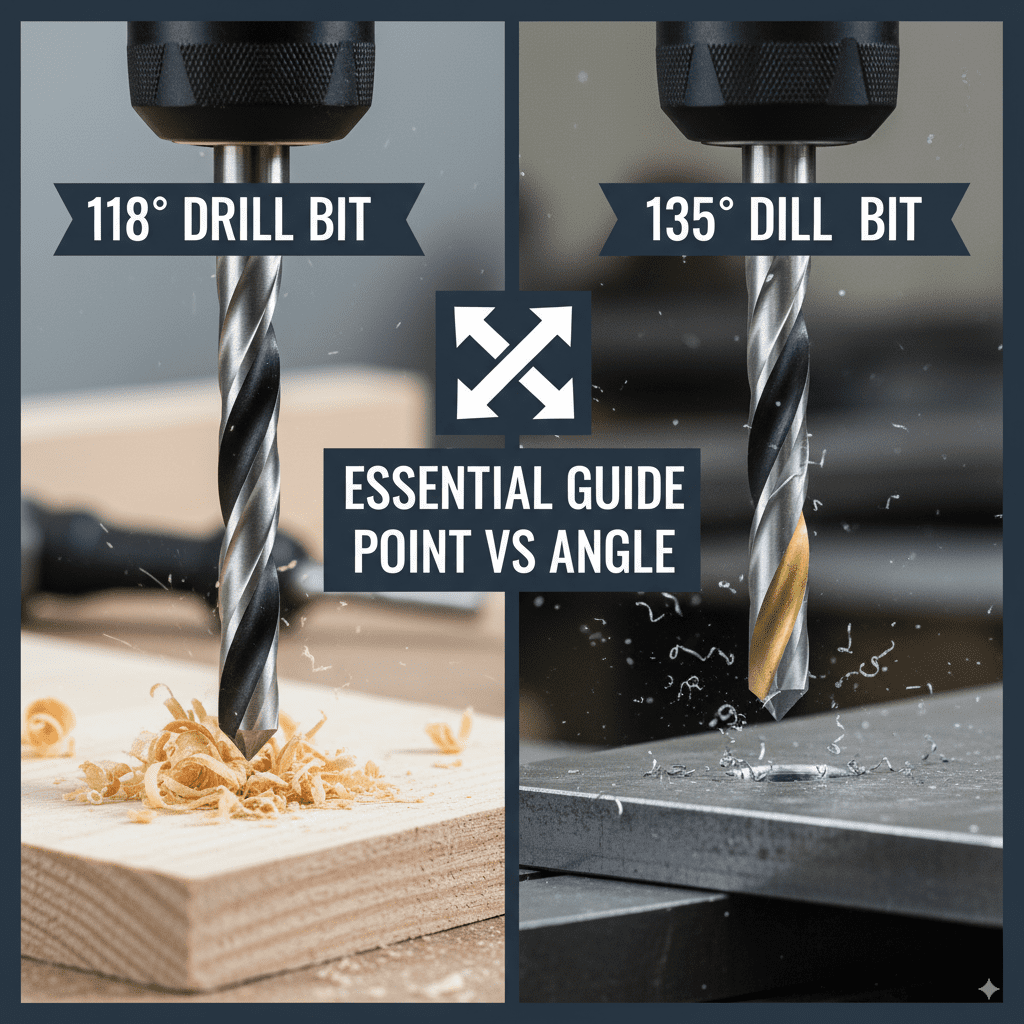

118 vs 135 Drill Bit: Essential Guide

Choosing between a 118° and 135° drill bit depends on the material. 118° is best for softer materials like wood and plastic, while 135° excels with harder metals, offering better bite and less slippage. Understanding this difference prevents tool damage and ensures cleaner holes.

Hey there, fellow DIY adventurers! Md Meraj here, your go-to guy for all things workshop and home improvement. Ever stood in front of the drill bit aisle, feeling a bit lost? You’re not alone! Among the sea of shiny metal, you’ll often see drill bits with tips labeled 118° and 135°. It might seem like a tiny detail, but knowing which one to grab can make a world of difference in your projects. Using the wrong one can lead to frustration, broken bits, and holes that just aren’t right. But don’t worry! In this guide, we’ll break down the 118° vs 135° drill bit mystery. Get ready to drill with confidence!

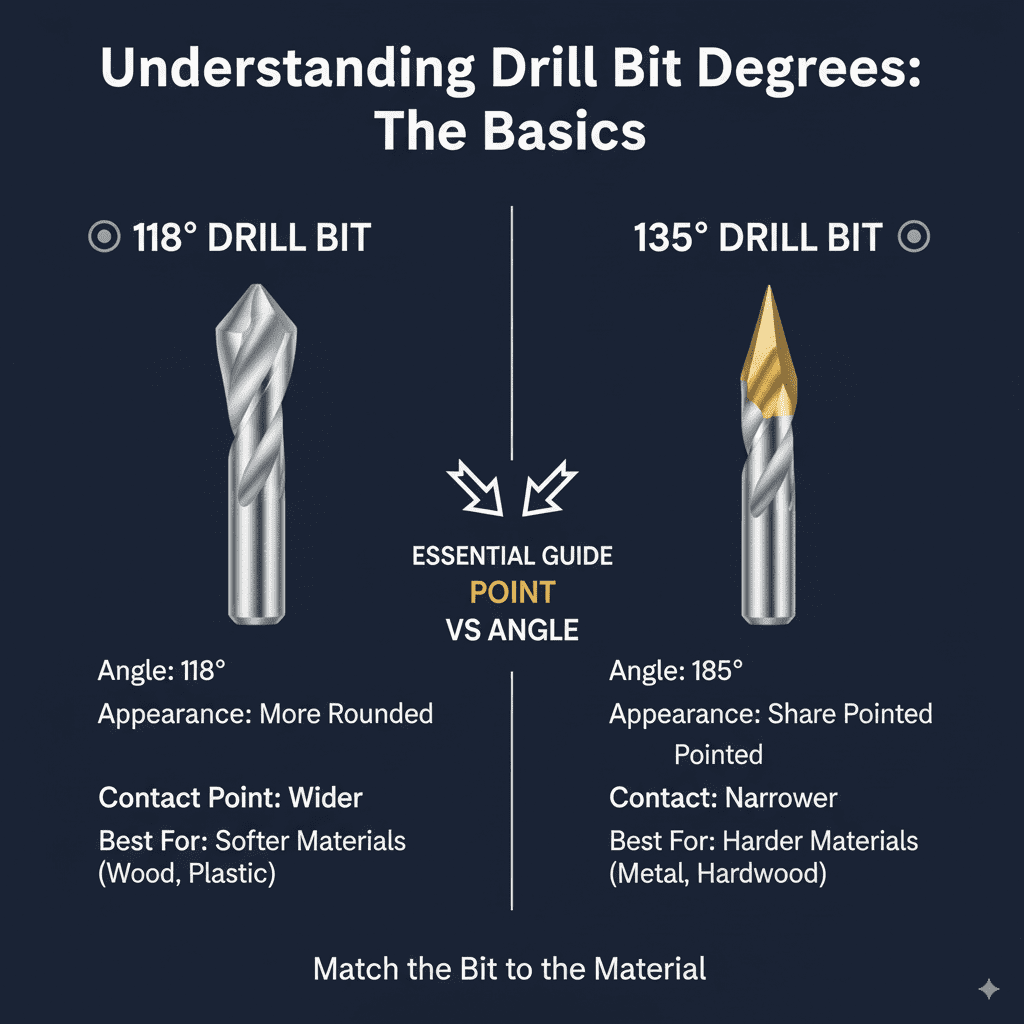

Understanding Drill Bit Degrees: The Basics

Drill bits are designed to cut through various materials, and the angle of their tip plays a crucial role in how effectively they do that. Think of it like a knife: a sharper angle cuts through soft things easily, while a more obtuse angle is better for tougher jobs. The degree you see on a drill bit refers to the included cutting angle at the very tip of the bit. This angle directly influences how the bit engages with the material, how much pressure you need, and how it clears away the debris, or ‘swarf’.

What is the 118° Drill Bit Angle?

The 118° drill bit is the most common type you’ll find. It has a sort of rounded-out, conical tip. Because the angle is less acute, it has a broader contact point with the material. This makes it more forgiving and less prone to wandering when you start drilling. It’s the everyday workhorse for most general-purpose drilling tasks.

Key Characteristics of 118° Drill Bits:

- Angle: 118 degrees (inclusive angle).

- Appearance: Tip looks more rounded or conical.

- Contact Point: Wider.

- Best For: Softer materials.

What is the 135° Drill Bit Angle?

The 135° drill bit has a sharper, more pointed tip. This steeper angle allows the bit to penetrate harder materials more easily and with less effort. Because it bites into the material more aggressively, it tends to create less heat and reduces the risk of “walking” or sliding across the surface, especially when starting a hole in metal. This is why you’ll often see 135° bits specifically recommended for metalworking.

Key Characteristics of 135° Drill Bits:

- Angle: 135 degrees (inclusive angle).

- Appearance: Tip looks sharper and more pointed.

- Contact Point: Narrower.

- Best For: Harder materials, especially metals.

118° vs 135° Drill Bit: The Material Matchup

The biggest deciding factor in choosing between an 118° and 135° drill bit is the material you’re drilling into. Using the right bit ensures efficiency, prolongs the life of your drill bit, and gives you a cleaner hole. Let’s dive into which bit is best suited for different substances.

Drilling in Wood and Softer Materials (118° Ideal)

Wood, plastics, and some composite materials are generally considered softer. For these, the 118° drill bit is your go-to. Here’s why:

- Easier Start: The broader angle distributes pressure, making it easier to start a hole without the bit skittering across the surface.

- Efficient Chip Evacuation: While not as aggressive as metal bits, 118° bits still do a decent job of clearing wood chips when paired with a standard drill’s speed.

- Less Heat: Softer materials don’t generate as much friction and heat, so the less aggressive cutting action of a 118° bit is perfectly adequate.

- Cost-Effective: Standard 118° bits are generally less expensive and widely available.

When you’re building that awesome bookshelf, crafting a birdhouse, or putting up shelves, your standard twist drill bits are almost certainly 118°. They are the everyday heroes for the vast majority of home DIY projects involving wood and plastics.

Drilling in Metal and Harder Materials (135° Recommended)

When you move to harder materials like steel, aluminum, cast iron, or even tough plastics, the 118° bit starts to struggle. This is where the 135° bit shines:

- Superior Penetration: The sharper point of a 135° bit bites into hard surfaces much more effectively.

- Reduced Slippage: The steeper angle helps “center” the bit, significantly reducing the tendency for the bit to wander and causing a clean start.

- Less Heat Build-up: The faster penetration means less friction and heat generated at the point of contact. This is critical for metal, as excessive heat can quickly dull and destroy a drill bit.

- Overall Efficiency: You’ll find that drilling through metal is quicker and requires less force with the correct 135° bit.

For tasks like attaching metal brackets, working on car repairs, or drilling into pipe, a 135° bit will make your life much easier and deliver cleaner results. It’s worth noting that many 135° bits are also made with specific coatings (like titanium or black oxide) to further enhance their durability and performance in metal.

When Can a 135° Bit Be Used in Wood?

While 118° bits are standard for wood, a 135° bit isn’t entirely unusable in softer materials. In fact, some woodworkers prefer them, especially for specific tasks:

- Starting Holes: The self-centering nature of a 135° point can be helpful when you need to start a hole precisely without a center punch, particularly on smooth surfaces.

- Drilling Through-Dense Woods: For exotics or very hard hardwoods, the more aggressive bite of a 135° bit might offer a slight advantage.

- Specialty Bits: Some specialized wood bits, like certain Forstner bits or step bits, might incorporate steeper angles for specific cutting actions.

However, for general-purpose wood drilling, the 118° remains the more forgiving and common choice. Using a 135° bit in wood might require a bit more control to prevent it from digging in too aggressively.

When Can an 118° Bit Be Used in Metal?

Using an 118° drill bit in metal is generally discouraged, especially for harder metals like steel. However, there are a few exceptions and nuances:

- Very Soft Metals: For extremely soft metals like thin aluminum sheeting or copper, an 118° bit might suffice. The material is so pliable that the angle difference is less critical.

- Lubrication is Key: If you must use an 118° bit in metal, using a cutting fluid or lubricant is absolutely essential. This will help reduce friction, keep the bit cool, and prolong its life.

- Low Speeds: Drilling at very low speeds will also help manage heat and prevent the bit from overheating and dulling too quickly.

- Not for Heavy-Duty: For any structural metalwork or thicker gauge steel, an 118° bit is simply not the right tool for the job and will likely fail or produce a poor hole.

Think of it this way: while you can hammer a nail with the wrong end of a screwdriver, it’s incredibly inefficient and likely to damage both the screwdriver and the nail head. Similarly, using an 118° bit on metal is a compromise that often leads to poor results.

Drill Bit Coatings and Materials: Beyond the Angle

While the 118° vs 135° angle is a primary differentiator, other factors significantly impact drill bit performance, especially when drilling metal. For harder jobs, these are just as important:

HSS (High-Speed Steel)

This is the most common material for drill bits. HSS bits can withstand higher temperatures than standard carbon steel bits, making them suitable for a wider range of materials. Most general-purpose twist drill bits are made from HSS.

Cobalt

Cobalt drill bits are made from HSS with a percentage of cobalt added. This alloy significantly increases the hardness and heat resistance of the bit. Cobalt bits are excellent for drilling into hard, abrasive metals like stainless steel and cast iron. They are best paired with a 135° point angle.

Titanium Nitride (TiN) Coating

This is a thin, gold-colored coating applied to the surface of a drill bit. Titanium nitride is extremely hard and slippery. It reduces friction, which helps the bit cut cooler and faster, and extends its life. TiN-coated bits are great for metal and hardwoods. They work well with both 118° and 135° angles, but are particularly beneficial on 135° bits for metal.

Black Oxide Coating

This is a chemical treatment that gives drill bits a black, non-reflective finish. Black oxide provides some corrosion resistance and improves lubricity, reducing friction and heat. While not as hard as titanium nitride, black oxide bits are effective for general-purpose drilling in metal and wood, and they are generally more affordable.

Carbide Tipped

These bits have a solid carbide tip brazed onto a steel shank. Carbide is exceptionally hard and can drill through very tough materials, including brick, tile, concrete, and extremely hard metals. They are often used for masonry drilling but can also be found for metal applications. Their effectiveness is less about the 118° vs 135° angle and more about the carbide’s inherent hardness.

Comparing 118° and 135° Drill Bits: A Quick Table

To help you quickly decide, here’s a comparison table:

| Feature | 118° Drill Bit | 135° Drill Bit |

|---|---|---|

| Angle | 118 degrees (less acute) | 135 degrees (more acute) |

| Tip Appearance | More rounded, conical | Sharper, more pointed |

| Best For | Wood, plastic, composites, soft metals | Hard metals (steel, iron, brass), tough plastics, hardwoods |

| Drilling Action | Less aggressive, wider contact | More aggressive, bites deeply |

| Heat Generation | Moderate | Lower (in hard materials) |

| Risk of Slippage | Higher (in hard materials) | Lower |

| Common Use | General home DIY, woodworking | Metalworking, demanding materials |

| Availability | Very common, widely available | Common, especially in hardware stores for metalworking |

| Cost | Generally more affordable for standard bits | Slightly more expensive for specialty bits, but worth it for metal |

How to Choose the Right Drill Bit for Your Project

Making the correct choice is simpler than it seems. Follow these steps:

- Identify Your Material: This is the most critical step. Are you drilling wood, plastic, drywall, aluminum, steel, or something else?

- Consider the Hardness: Softer porous materials (like wood or drywall) generally do well with 118° bits. Dense, hard materials (like steel or cast iron) require the 135° bit.

- Think About Precision: If you need to start a hole precisely on a smooth surface (especially metal), the 135° bit’s self-centering point is a big advantage.

- Evaluate Bit Type: Is it a standard twist bit? A spade bit? A masonry bit? For standard twist bits, the 118°/135° rule applies most directly. For specialized bits, consult the manufacturer’s recommendations.

- Check for Coatings: If you’re drilling metal regularly, consider HSS Cobalt or a TiN/Black Oxide coated bit, regardless of the angle, as these enhance performance and longevity.

- When in Doubt, Go 135° for Metal: If you’re unsure and it’s metal, it’s almost always safer and more effective to use a 135° bit.

For example, if you’re assembling IKEA furniture (wood and particle board), your standard 118° bits are perfect. If you’re drilling a pilot hole in a metal frame for a TV mount, a 135° bit (preferably HSS or coated) is the better choice.

Essential Accessories for Drilling

Having the right drill bit is only part of the equation. To ensure successful and safe drilling, consider these tools and accessories:

Drill Bit Sharpeners

Even the best drill bits can become dull with use. A dedicated drill bit sharpener can save you money and ensure your bits perform at their best. They are especially useful for maintaining the cutting edge on metal-drilling bits.

Cutting Fluid or Lubricant

When drilling into metal, a cutting fluid or lubricant is essential. It reduces friction and heat, which helps prevent the drill bit from overheating, dulling, and breaking. It also helps to clear away metal shavings more effectively.

Center Punch

For precise hole placement, especially in metal and hard plastics, a center punch is invaluable. You strike it with a hammer to create a small indentation, which acts as a guide for the drill bit’s tip, preventing it from “walking” or skittering across the surface. The steeper angle of a 135° bit reduces the need for a center punch compared to a 118°, but it’s still good practice for critical locations.

Drill Press Vice

If you’re drilling multiple holes in metal parts or need extreme accuracy and stability, a drill press vice is a must. It securely holds your workpiece, preventing it from spinning, which is crucial for safety and getting perfectly straight holes.

Safety Glasses!

This is non-negotiable. Always wear safety glasses when drilling. Metal shavings, wood chips, or broken bit fragments can fly at high speed. Protecting your eyes is paramount for all DIY tasks, especially drilling. According to the Occupational Safety and Health Administration (OSHA), proper eye protection is required in environments where there is a hazard from flying particles.

Work Gloves

While you want good grip on your tools, heavy-duty work gloves can protect your hands from sharp edges and debris, especially when handling metal workpieces.

Common Pitfalls to Avoid

Even with the right bit, beginners can fall into a few traps. Here are common mistakes to steer clear of:

- Using the Wrong Bit: This is the most obvious. Forcing a 118° bit into hard steel will likely result in a broken bit, a damaged workpiece, and a lot of frustration.

- Drilling Too Fast: Excess speed generates heat, which dulls drill bits quickly and can even melt plastics. Always match your drill speed to the material and bit size. Generally, slower speeds for larger bits and harder materials.

- Not Using Lubrication (for Metal): Skipping cutting fluid when drilling metal is a surefire way to overheat and ruin your bits.

- Applying Too Much Pressure: Let the drill bit do the work. Forcing the drill can cause the bit to break, the workpiece to slip, or create an oversized, ragged hole.

- Not Securing the Workpiece: A workpiece that spins or moves while drilling is dangerous and will produce inaccurate results. Always clamp it down.

- Ignoring Drill Bit Angle Differences: This guide is all about that! Understand when the 118° vs 135° angle truly matters for your material.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between a 118° and 135° drill bit?

The main difference is the angle of the tip. A 118° bit has a more rounded tip!